Operating principle of a pneumatic spray gun

The pneumatic spray gun is designed for spraying with compressed air various types of paints and varnishes, primers, antiseptics, liquid rubber, etc.

Pneumatic professional tools are combined with compressors, which pump air under pressure (from 1.5-2 to 6-8 bar) through a hose into the paint sprayer and break the paint into small particles, and then push it out of the nozzle.

The average air supply speed in compressors is 100-250 l/min. There are high and low pressure devices.

Small-sized household compressors are piston compressors with an electric drive with a power of about 2 kW. To store compressed air, they have receivers with a capacity of up to 100 liters.

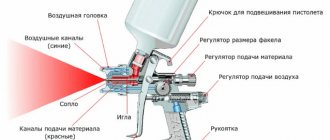

The flow of dyes is controlled using a hand gun. Its structure and operating principle are reminiscent of a household spray bottle, only the container contains paint, not water. To more accurately regulate the flow of paint, the gun nozzle has a guide needle.

This tool is equipped with screws for adjusting the air flow, the amount of material supplied and the width of the ink jet. How the spray gun works is described in the instructions.

The dye tank (with a capacity of 400-600 ml or more) is attached to the gun from the top, side or bottom, depending on the design of the tool. If necessary, the role of a tank can be played by an empty mineral water bottle with an adapter.

Additional items

A compressor spray gun will be easier to use if the kit includes additional parts. Their presence is optional, however, they will help to get the best result.

A compressor spray gun will be easier to use if the kit includes additional parts.

Gearbox for spray gun

A small device that consists of a pressure gauge and a pressure regulator. When working, it is important to know how much pressure is needed for the spray gun to create an even layer. Therefore, the presence of a regulator simplifies adjustment. There are mechanical and digital types of devices.

In the latest professional devices, the gearbox may be built-in.

The pressure gauge that is installed in the compressor can only show the pressure level when spraying. Requires setting the location of the part on the input part.

When working, it is important to know how much pressure is needed for the spray gun to create an even layer.

Water separator

When water-based or other paint must be applied without the slightest defects, it is necessary to exclude moisture in the air, it will leave craters on the surface. To do this, you need a moisture separator, which is placed between the handle and the end of the hose from the compressor.

There are small devices and special stations. The latter, of course, give the best result, completely eliminating moisture and pollution from the air. So it’s easier to get a metallic effect on a car by choosing a similar device.

When water-based or other paint must be applied without the slightest defects, it is necessary to exclude moisture in the air, it will leave craters on the surface.

Paint application technology

The procedure must be carried out at +5...+35°C and relative humidity no more than 80%. Spray guns only work with materials whose ignition temperature is not lower than 210°C.

To protect the respiratory system when painting, you need respirators, and to prevent chemical liquids from getting on your skin and eyes, you need gloves and safety glasses. The work room must be equipped with supply and exhaust ventilation. The surface ready for painting - clean, dry, grease-free, smooth - is additionally treated with sandpaper (P240-P600), after which the dust is removed.

Before use, filter the paint and dilute it according to the instructions, otherwise feeding into the nozzle will be difficult. Work can be carried out indoors or outdoors, under different conditions. It should be taken into account that the viscosity of a substance changes with increasing and decreasing temperature and air humidity. A viscometer is used to measure the viscosity of the paint; if necessary, the material is diluted.

Some technologies, in particular those working with viscous substances in an auto repair shop, require constant inlet pressure. Therefore, even if there is a gearbox, in such cases it is recommended to install an additional device (WESTER 816-004 or 003) that prevents loss of pressure in the air line.

Before painting the main surface, you need to make several test movements. To prevent drips, spraying begins with a small amount of paint. First of all, cover the outer side of the surface to be treated, corners, decorative elements, then the entire remaining area.

Spraying is carried out evenly from the edge to the center of the surface, gradually moving to cross movements. Before applying the second layer, wait until the paint has time to dry.

Uniformity of distribution

In this test, the gun is rotated 90 degrees and paint is added until it begins to run off. Based on the width, location and shape of the drips, one can conclude that the distribution is uniform.

Test to determine the uniformity of paint distribution Source artmalyar.ru

Tool selection criteria

The main indicator of the effectiveness of pneumatic spray guns is the loss of sprayed material. For high pressure (HP) models it is about 55%, for high volume low pressure (HVLP) models - up to 35%, low volume at medium pressure (LVMP) - less than 35%, small volume at low pressure (LVLP) – up to 20%.

How to choose a device: larger or smaller volume, low or high pressure - depends on the type of work planned.

To buy a suitable tool, you need to know the paint viscosity and the throughput of the device. In addition, important factors when choosing may be: cost, weight, reliability and ergonomics of parts, volume of the paint tank, availability of accessories and additional nozzles, adjustment options, etc.

For example, during large-scale painting work, an uninterrupted supply of material is necessary, and the availability of quickly replaceable attachments for various surfaces will be a good help. In an auto repair shop, when working with viscous mother-of-pearl materials, painting equipment requires high throughput of the tool, its ergonomics and soft operation of the gun trigger, accuracy and ease of adjusting the shape of the paint torch.

Problems and their solutions

Any equipment can fail over time, due to wear and tear of parts and others. Some breakdowns can be fixed without any problems. Common problems will be discussed below.

Any equipment can fail over time, due to wear and tear of parts and others.

The gun doesn't paint

There are three options when you can use the spray gun for its intended purpose in case of this error:

- The air is supplied at low pressure; you just need to adjust the compressor;

- The nozzle or needle is dirty; until these parts are removed and cleaned, the paint flow will not open;

- The needle and nozzle are broken and should be replaced with new ones.

The nozzle or needle is dirty; until these parts are removed and cleaned, the paint flow will not open.

Spray gun spits

This type of failure can be caused by the problems described below:

- The air cap is loose and needs to be tightened;

- The pressure and viscosity of the material are not suitable, the indicators need to be brought back to normal;

- The paint is too thick and it will bleed;

- The breather on the container with the material is clogged and needs to be cleaned;

- The pressure has dropped, you need to bring it to the desired level.

The paint is too thick and it will bleed.

The torch moves to the side

It is possible that the hole on the side of the air cap is dirty and needs to be cleaned thoroughly. Or damage is detected on the holes, then new parts are installed.

It is possible that the hole on the side of the air cap is dirty and needs to be cleaned thoroughly.

A pneumatic spray gun can create a beautiful layer on a variety of surfaces. It is distinguished by the evenness of paint distribution, but it is important to set it up correctly before work. To do this, it is important to study the operating rules that were described above.

Tool parameter settings before use

Before use, you need to make sure that there is no mechanical damage to parts of the tool. To do this, fill the spray gun tank ¾ full and start the compressor. Then connect the gun to the hose of the compressed air source and check the tightness of the bolts and nuts: paint supply adjusting screw, air supply regulator, air receiver nut.

If there are no malfunctions or material leaks, and the adjusting screws operate correctly, then the device is ready for use.

The tool parameters are adjusted using adjustment screws. So, by rotating the screw at the bottom of the gun handle clockwise or counterclockwise, you can increase or decrease the volume of air flow. The same principle applies to adjusting the paint supply using the appropriate screw.

To select the desired torch shape, you need to turn the adjustment screw. When turning to the right, the torch will take the shape of a circle, to the left - an ellipse.

Testing

As a result of the adjustments, the specialist ensured optimal operating parameters for the spray gun. However, for now we are talking about speculative estimates. Additionally, you need to check the serviceability of the device itself. This can be done as follows.

The work methodology in this case requires the following tests:

- Studying the quality of the spray will allow you to check the characteristics of the applied layer.

- You need to make sure that the shape of the torch imprint is the one planned by the master.

- An important characteristic is the uniformity of the applied layer.

The following describes how to check in each case. Successful completion

Spray quality

In this case, the painting process is simulated. If applied evenly, small droplets may form on the surface. The larger their value, the less quality the work is done.

This video is dedicated to how to configure the spray gun:

How to use a spray gun

Before using the spray gun, you need to make several test movements. At the beginning of work, paint consumption should be small. The device should be held parallel to the horizon and perpendicular to the surface to be painted at a distance of about 25-30 cm (when working with ceilings - at a distance of about 40 cm). You need to start and finish painting a little closer to the surface being treated.

Movements should be calm, since sharp and uneven movements can lead to stains and paint sagging. The entire arm should be moved, not just the wrist. The paint paths should intersect each other by about 4-5 cm to avoid gaps.

Video description

How to set up any spray gun.

Instructions for Beginners A common problem with cheap paint guns is that it is very difficult to obtain a uniform spray pattern, since this will require significant pressure, which only powerful compressors can provide. Another problem is that the spray gun will have too much pressure at the outlet, which will not result in an even coat. Therefore, purchasing a tool that is not good enough can sometimes lead to the creation of a poor-quality layer of varnish or paint.

Using a professional paint sprayer Source proautotools.com.ua

Popular manufacturers

The most popular manufacturers - mainly domestic and Chinese - produce affordable spray guns costing up to 2 thousand rubles. These include the following models:

- Kraton HP-01G – for painting fences, walls and gates (Russia);

- STELS AG 810 HVLP 57361 – for finishing work (Russia – China);

- Jonnesway JA-6111 – for extensive painting work (Taiwan);

- HUBERTH R500 RP20500-14 – for painting car parts (China).

Professional construction tools are 10 times more expensive. The best are considered to be the Japanese Anest Iwata, the Italian Walcom, the German SATA and the English DeVILBISS.

Ballpoint pen spray

A small and practical device can be obtained by using a ballpoint pen as a base. Such a home-made device can work with a small cylinder, the volume of which is no more than 1 liter. If you need to carry out small finishing work, then you can create such a spray gun with your own hands quite quickly. Recommendations for performing the work are as follows:

- All you need from the handle is the outer shell, which should not have any defects. To do this, all internal elements are removed. Attention is also paid to the size of the shell; it should not be too large or small.

- The reverse tip is cut off at its widest point.

- You will also need a rod. It is cleaned from the paste using alcohol.

- A hole is created in the central part of the cork that will fit under the rod. It will be drawn to the bottom to connect with the bottle in which the paint is placed.

Spray gun from a pen

You will have to pump the air yourself. That is why this design has not become widespread, since it cannot be used to process a large area.

Selecting a compressor for a spray gun based on performance and receiver volume

And, of course, the capabilities of your compressor should be enough to power the spray gun. Working with a weak compressor will affect the quality of the paint - in the form of drops and smudges.

Let us recall the basic formula for matching a compressor and a pneumatic tool: the compressor output output should be 20 percent greater than the average air consumption of the spray gun.

For a MASTER G 600 spray gun with an air flow rate of 198 l/min, you need a compressor with an output capacity of 198 l/min + 20% = 238 l/min.

Since the manufacturer usually specifies the input capacity, a reduction factor must be applied. For a belt compressor it is 0.75, for a coaxial compressor it is 0.65. That is, we need a coaxial compressor 238/0.65 = 366 l/min or a belt compressor 317 l/min.

In the production of furniture, one of the important stages is the application of paint and varnish coatings, as well as the application of glue in the production of upholstered furniture. It is difficult to imagine that this process will be carried out using an ordinary brush or roller - the speed of such work will be low, and the paint consumption will be colossal. Therefore, for such work in production, the application of paints and varnishes by spraying using a special tool - a spray gun - has long been used.