[Metal Pendulum Saw] is a necessary tool for processing this material.

Since the metal is very durable, not every saw can handle it.

The pendulum saw is popular because it gets the job done efficiently, whether you bought it from a store or homemade it. If the price of a suitable saw does not suit you, then you can make the tool yourself.

Assembling a saw with your own hands is not difficult: in the article you will learn about its main functions and how to make it.

How a pendulum saw works and works

Any pendulum saw, regardless of whether it is made by hand or produced by a well-known manufacturer, has the following components in its design:

- bed;

- powerful electric motor;

- saw blade;

- protective casing;

- return mechanism;

- clamp for clamping the sawn product.

Arrangement of pendulum saw units

The massive, heavy saw frame is made of cast metal to ensure stability of the tool during operation. All other saw components are attached to it. First of all, this is a pendulum arm on which a powerful electric motor is mounted, an elongated shaft with grooves and screw threads for installing a saw blade. This lever has a spring mechanism that returns it to its original position after finishing cutting the product.

A button to turn on the saw is installed on the lever handle. For ease of use of the tool, a latch is added to the button that blocks the tool from turning off when the button is released. The cutting tool is completely covered with a protective casing, protecting a person from injury during operation. On some models, manufacturers install two casings - one fixed, the second sliding, completely covering the cutting zone.

Device with description of nodes

A pendulum saw for metal is used not only when working with metal products. It can work with wood, ceramics, and plastic. But to cut other materials you need to use a different cutting blade. Various cutting attachments can be supplied as a set, but can also be sold at retail.

A clamp consisting of two parts is attached to the frame for clamping the product being cut. The first part is rotating, which can be rotated at an angle of up to 45°. It has a pointer and a scale graduated in degrees. The second part has a screw adjustment of the pressure. The clamping jaw on the second part has a hinged fastening, which allows you to firmly fix the part at any turn to the front of the cut of the product, guaranteeing an accurate cut at the selected angle.

This is interesting: Band sawmill for longitudinal cutting of Taiga logs (video)

Do-it-yourself pendulum saw for wood - All about timber and woodworking

When working with metal or wood, the need often arises to make an even cut at a certain degree. It is almost impossible to do this the first time with an ordinary grinder; for these purposes it is worth using a pendulum saw.

A pendulum saw is a special type of tool that is designed to quickly and accurately cut various materials. Most often wood or metal.

It looks like a small machine with a cutting tool installed on it. The disc is attached to a pendulum-like device.

Thanks to this, the mechanism performs pendulum movements, that is, reciprocating, which allows you to make an even cut.

This saw can be considered a type of circular saw. The difference lies in the design . In a circular saw, the motor and disk are attached to the machine in a stationary state, while in a pendulum saw they move along with the mechanism.

Such a tool is an indispensable device in any production. The saw allows you to make precise cuts in almost any material at the desired angle. The cutting element is represented by an abrasive disc. With its help you can saw various metals, wooden blanks, plastic products, porcelain, earthenware and other materials.

This is a very dangerous tool, so its use is only possible if all safety rules are followed. For protection , such machines are equipped with a protection system. Increased safety is a must for both industrial and home use.

The cost varies across a wide price range, so it is easy to choose a model to suit your own requirements. If necessary, you can assemble such a saw yourself if you have the necessary materials.

Every self-respecting owner, accustomed to doing everything with his own hands, strives to equip his home workshop as best as possible. And to work normally with wood, you need to have a good saw and preferably more than one. Today there are a lot of similar tools on the market, and it is often difficult for the average person to figure out what exactly he needs.

This article is devoted to the topic of choosing such a tool.

Photo of a manual circular saw.

First of all, it should be understood that all tools intended for cutting and processing wood can be divided into two main areas. These are hand saws or hacksaws and tools powered by an electric or some other drive.

Drive unit

It is most convenient to use a belt drive as a drive mechanism. To do this you will have to find two pulleys of the same diameter. One of them is mounted on the motor shaft, the second - on the drive shaft of the cutting disc. The disk shaft is mounted on two bearings. It is best to use the scheme when the drive mechanism is located on the left of the disk mounting cloud. It’s more convenient to work this way, and safety rules are followed. The disc fastening nut will not be at risk of loosening.

To tension the drive belt, the engine is mounted at the rear of the pendulum with 4 bolts located in longitudinal slots. It can shift in the direction of the central axis of the machine (perpendicular to the axis of rotation of the motor shaft) by 5-7 centimeters. This will maintain the required belt tension and prevent it from slipping. It will also be easier to replace the belt if the previous one becomes unusable.

Cutting and primary processing of the workpiece

The fastest way to saw a workpiece is with a grinder with a thin metal cutting disc. If it is not possible to use a grinder, you can use a hand hacksaw for metal

It is important to correctly install the file into the hacksaw. The saw teeth should be directed forward and the hacksaw should cut while moving away from you

Cutting and preparing the workpiece

First, the approximate shape of the knife is cut out using straight cuts. Then the bends are cut out. The easiest way to cut them is with several oblique cuts converging at one point.

It is important to leave an allowance of 2-3 millimeters to the drawn outline. This is due to the fact that when using a grinder, the metal at the cutting site overheats. By grinding off 2–3 mm using a file and sandpaper, you can remove the overheated edge of the metal

By grinding off 2–3 mm using a file and sandpaper, you can remove the overheated edge of the metal.

Wood cutting tool

Fundamentally: all tools of this kind are divided into carpentry and carpentry. Models created for carpentry work are designed for a clear and clean cut. Carpenter's tools are designed for the roughest work. For example, all garden saws for trees belong only to the carpentry direction.

Tooth pitch table.

Common parameters when choosing both an electronic and a hand saw are the configuration and frequency of the cutting tooth. As for the frequency, everything is simple: the more frequent the tooth, the cleaner the cut will be.

In the marking, this feature is designated as TPI, in other words, the number of teeth per 1 inch. So for chipboard, TPI 7 - 9 is often taken, and for gardening TPI 3 - 6 is enough. With the tooth configuration, everything is somewhat more difficult.

Types of cutting tooth

- The dagger tooth resembles an isosceles triangle. Both sides of this triangle are sharpened at an identically acute angle. In self-sharpening disk models, this particular configuration is used. At high speeds, the cone bends in the direction opposite to the rotation, but as soon as you turn the disk over, it will work like a new one. Hand hacksaws with such a tooth are designed for cross cutting.

Interesting read: Do-it-yourself wood turning

Type of dagger tooth.

- A rip saw for wood is usually equipped with a so-called chisel tooth. It looks like a triangle with a cone shifted towards the cut. The blade is sharpened according to the cutting movement, in other words, from the side perpendicular to the product. Such a tooth cuts through the mass like a chisel, in the end it simply goes along the fibers, but at the same time, creating a transverse cut is quite problematic.

Type of chisel tooth.

- If you are interested in a universally suitable option, so to speak for all occasions, then we can recommend a blade with a universally suitable inclined tooth. This is a middle option between dagger and chisel. This tooth has a sharp tip and double-sided sharpening, which allows you to work both along and across the fibers.

Type of oblique all-purpose tooth.

- A tooth that has a beveled top is also considered universal. In fact, this is a dagger version, improved by an additional cutting edge on the top.

Beveled top of the tooth.

- The canvas with the so-called Japanese tooth has absolutely no layout. The cutting here occurs due to the cone-shaped shape of the blade itself and a special method of sharpening. But such sharpening only works in one direction. In hand hacksaws this is when moving towards you, in discs, respectively, in the direction of rotation.

- Garden saws for trees usually have a wolf tooth or its derivatives. This configuration is characterized by gaps between cells and teeth of different shapes. Such saws are intended for dissolving raw wood.

Wolf figured tooth.

Hand Tool Selection

Working with electronic equipment is certainly comfortable, but not everyone can afford it, because the cost of high-quality models is quite impressive. Plus, if a person is not going to set up a professional workshop, then for a one-time job, an ordinary handsaw is enough.

Advice: a two-handed saw, or “friendship” as it is popularly called, was initially intended for preparing firewood and felling trees. And if you are not going to use it for its intended purpose, then there is no point in focusing on this model.

Hacksaw with hardened edge.

There are 2 types of bow saws for wood. These are the traditional wooden version with a crossbar and a tension cord on top, and modern iron models, where the tension is carried out by adjusting the tension screw. Classic is more suitable for precise carpentry work. If you need a saw for your dacha, then it is better to take an iron model.

Traditional bow saw for wood.

When choosing a hacksaw for wood, in addition to the tooth configuration, you need to pay attention to the alloy of the blade. Typically, HRC45, HRC55 or HRC60 is used; the higher the number, the stronger the alloy. Often the body of the blade is made of HRC45, and the edge itself is made of the highest grade of hardened steel HRC55. But remember, if the edge is black, then it is hardened and cannot be cut or sharpened.

Alloy bow saw.

Tip: you can check the properties of a hand saw blade by bending it at approximately 45º. If at first the straight blade after this procedure bends by more than 2 mm, then you are dealing with a low-quality product.

Marking on the product.

Exploitation

Before use, the machine must be installed on a raised table or workbench, this is necessary for the comfort of its use. It is also necessary to make room for cutting, carrying material and storing workpieces.

The Makita LC1230 saw is compact; its installation requires a small area, but do not forget about moving the material and workpieces; as a result, the working area of the cutting saw is a rectangle of 2x4 meters. With a material length of 2–3 meters.

Cutting with a pendulum saw is not a difficult task, but nevertheless requires attentiveness and accuracy. Thus, sparks and hot metal particles flying from under the saw pose a particular danger. Partially, the collar installed on the saw body saves you from them. But nevertheless, we should not forget about personal protective equipment.

Individual use

For ease of use, it is recommended to install a production table or workbench in advance. It is better for a similar table to be adjustable in height and have sufficient area for storing workpieces and sawn parts.

Even for small-sized home models, the desktop area should be around 8 square meters. m. Approximate size - 2x4 meters. This allows you to cut workpieces up to 3 meters in size.

When using a pendulum saw, it is imperative to ensure safety, close the protective curtains and use personal protective equipment. This is very important, because when cutting wood or alloy, small wood or iron shavings fly out from under the working wheel. When cutting iron blanks, flammable water and materials should be removed from the desktop, because hot alloy particles can cause a fire.

How to make it yourself

It is not necessary to spend significant amounts of money on purchasing an expensive pendulum cutting machine. Every master can make such a tool with his own hands. The basis for a pendulum saw for metal can be a conventional electric drill, grinder or electric motor. Even with minimal knowledge and skills in working with tools, you can easily assemble a homemade unit that will not be inferior in power and performance to factory models.

Before you start making such a power tool with your own hands, it won’t hurt you to first familiarize yourself with the drawings and instructions for assembling the machine. During operation, you must adhere to the following algorithm:

Prepare the engine from the angle grinder. The V-belt from the vehicle should be installed so that torque is transmitted from the engine to the spindle. To securely fasten the pendulum mechanism, you will have to make a metal frame. As a material for it, you can use a metal blank with a square cross-section or an attachment to an electric drill. The spindle body must be secured to one side of the frame by welding, and an electric motor must be installed on the other

Pay special attention to the size of the shaft, which must correspond to that shown in the saw assembly drawing. A groove should be made in the frame so that the rolling axis of the cutting disc can be inserted there. At the same stage, you need to weld the frame, but this must be done in such a way that the spindle, rolling axis and motor are parallel to each other. To make a protective case, you can use a sheet of tin

Additionally, a drive handle must be installed on the belt casing.

If you are interested in purchasing professional tools for long-term use, we advise you to choose from machines from reliable and trusted manufacturers. You should not buy cheap devices made in China. And a hand-held metal chain saw will do an excellent job of performing a small amount of work at home.

It is no coincidence that pendulum cutting saws are popular among professionals and amateurs. After all, this equipment has a lot of advantages, among which the most relevant for consumers are versatility, high accuracy and processing performance, and safety. All this makes such machines one of the most attractive for home craftsmen who need a simple tool to perform a small amount of work.

Of course, it is necessary to select this equipment with special care, paying attention not only to the price, but also to the key performance characteristics, as well as the manufacturer. If necessary, you can even try to make such a machine with your own hands, especially since this will require the most accessible tools and materials, minimal knowledge and experience in working with the tool

The main thing is to choose a suitable drawing and carefully study the order of the work and follow it exactly.

How to make a pendulum machine yourself?

In order not to spend extra money on purchasing an expensive device, you can make such a tool yourself. A do-it-yourself pendulum saw for wood can be made using an electric drill, grinder or electric motor. With certain knowledge and skills, you can design your own model, which is not inferior in power and productivity to factory units.

To make such a saw with your own hands, you will need to study the drawings and instructions for assembling the mechanism. Follow the basic sequence:

- take the electric motor from the grinder;

- install the V-belt from the car in such a way as to transmit rotation from the motor to the spindle;

- to secure the pendulum device, build a metal frame using metal with a square cross-section, or adapt the attachment to an electric drill;

- Weld the spindle housing to one side of the frame, and fasten the electric motor to the other; make the shaft size as indicated in the drawing for assembling a hand-held pendulum saw;

- you need to make a groove in the frame through which the rolling axis of the saw blade will pass; weld the frame so that the motor, rolling axis and spindle are parallel;

- the protective case is best made from an iron sheet; Install the drive handle on the belt guard.

Peculiarities

The device is a design based on a special rotating disk. Using the device you can cut wood, steel, ceramic and other surfaces. Also very often, installers use it during concrete work with the foundation, for cutting reinforcing bars, in the manufacture of porcelain stoneware or when working with solid bricks. Such a tool is popular only on construction sites or in production, since at home there is no need to cut large materials in large quantities. The device should be used very carefully, and before starting work it must be properly configured, otherwise even an experienced operator may be injured.

Cutting machines are used for industrial purposes when it is necessary to quickly and efficiently cut reinforcing bars or boards. The tool for professional work has a large cutter diameter that can cope with cutting a huge number of objects.

Manufacturing companies also present on the market small-sized versions of the device, created specifically for domestic use. There are several stages of protection for operator safety. The main component of the device is the stationary base of the machine - this ensures perfect threading. The frame has a closed body - this guarantees protection of the worker’s hands from cutters and waste flying in all directions.

It is worth noting such important elements of the machine as a durable body and cutting disc. These designs can be divided into subgroups depending on the purpose and direction of rotation of the cutter:

- vertical devices;

- horizontal;

- devices capable of cutting at different angles.

In large companies, electric automated machines are used in production, which are expensive. There are other options - these are small-sized devices that require the constant presence of an operator. Such models are most often found in enterprises. The main feature of the design is high quality and wear resistance. Manufacturers claim that such a device, with constant loads and careful use, will last about 15 years. The unit is capable of processing any surface at high speeds without creating defects or damage.

Constructive personalities

A pendulum saw is a type of miter saw for edging work. It is distinguished by its lightweight design and not always economical cost.

The work table is the base plate. On a pendulum base, the table is equipped with a cutting block that can fix the tool. The electronic engine is installed at the rear of the structure because it has the function of a counterweight. The device is cushioned by additional springs.

A protective case is installed on the blade to protect the cutting operations. When lowering the cutting unit, the case does not interfere with work, because it moves automatically.

- These models do not have the ability to cut the workpiece at an angle.

- In order to improve cutting performance and regulate the cutting depth, limiting devices are used.

- Using a rotating desktop, you can change the position of the workpiece in the horizontal plane.

The simplicity of the design allows you not only to perform quick operations, but also to cut wood, iron, and polymer workpieces.

The size of the structure may vary depending on the model.

Feature of construction parts

The devices are produced on the basis of asynchronous and commutator engines. Asynchronous ones are characterized by a long service life and relatively silent operation. Commutator motors have good power, but the carbon brushes that are placed in it are subject to abrasion and must be replaced repeatedly.

The design features and characteristics of the saw blade influence the properties and width of the cut. In some models, the disk {moves} only in a vertical plane. But there are devices with horizontal guides, in which the cutting blade {moves} forward and backward. The width of the cut, if there are guides, will be a couple of times greater than without them.

The device, equipped with an electrodynamic brake, allows the saw blade to stop instantly.

The presence of a function to support the speed of the cutting unit at a measured value, despite the degree of overload, reduces the time for the operation and increases the efficiency of the saw.

Interesting read: DIY woodworking tools

Some models are equipped with a laser pointer to record the cut strip. If there is vibration in the device, the pointer may become confused and require repeated adjustments.

How to make a start button for a pendulum machine from an angle grinder

The angle grinder works when you press a button. Moreover, the spindle rotation speed depends directly on the pressing force of the button. This means that an adjustment mechanism is built into the button, the operation of which facilitates the operation of the tool. When operating an angle grinder on a stationary machine, it is necessary to consider the starting system so that you do not have to hold the handle with one hand and press the button with the other.

If the tool is equipped with a regular button, which automatically locks when it is turned on, as for example in the first version of the machine, then no difficulties arise here. First, the tool is turned on, and then you can perform work. However, most angle grinders are equipped with self-off buttons that must be held by hand while operating. There are two ways out of this situation:

- Use ties (for example, plastic) or clamps of the appropriate diameter. They fix the button in the pressed position. In this case, it is also necessary to take into account the latch, which is responsible for turning the tool on automatically. Both the latch and the button must be tightened with a clamp, tie or other similar materials. In this case, the principle of operation of the device will be as follows - if you need to start the tool, you need to plug the plug into a socket or make a switch

- It is rational to remake the starting system if the tool is planned to be used more often as a cutting machine than as a stand-alone angle grinder. To do this, it is necessary to route the wires from the angle grinder to a separate switch, which will turn the tool on and off if necessary.

The power button, if it is displayed, is best located on the handle. A homemade machine does not require large expenses for its production, which, in fact, is its main advantage.

Types of equipment

Construction and industry require the highest labor productivity and high-quality cutting operations for various types of materials. An important requirement is equipment mobility. Pendulum saws meet all these indicators.

Alloy pendulum saw

Mechanical cutting allows you to avoid the thermal effect on the alloy. It does not lead to a change in the alloy composition of the alloy and does not worsen its performance properties. The ideal equipment for such cutting is a pendulum saw.

The cutting tool for this type of equipment can be a tipped carbide or an abrasive disc. When the drive with the rotating disk is lowered onto the workpiece, the alloy is cut. These saws are safer than hand cut-off tools. They have the highest cutting properties and low consumption of saw blades.

Depending on the power of the equipment and the type of saw blade, the alloy miter saw is used to work with ferrous and non-ferrous alloys.

In practice, such a saw is used for cutting iron rods, angles and fittings. In window production, it is used to cut duralumin profiles.

Wood sawing tool

This device can be classified as a circular saw. It can be a good assistant when sawing wood. Basically, they do transverse cutting of wood, trimming timber or boards at an angle of 90º. The movements of the saw during operation resemble the swing of a pendulum.

The advantage of such equipment is the ability to monitor the quality of the operation and create a cutting line during operation, this is especially important when there was no preparatory marking of the workpiece.

Another shortcoming of the saw is the limited width of the workpiece being cut. Apart from this, the sawing operation requires physical effort.

In such models, the disk blade has significant diameters - from 500 mm to 650 mm. This makes it possible to saw wide boards. The wider the board, the greater the effort required for sawing. Along with this, the quality of cutting decreases, and the loss of wood species for cutting increases.

Pendulum cutting machine

Cutting machines mean machines that process workpieces for a long time and in huge volumes.

There are 2 types of units:

- With one cutting tool.

- With 2 cutting tools.

Pendulum machines are more common. They are easy to use and better in cost.

Abrasive cutting machines are similar in operating mechanism to pendulum saws. They are used for cutting profiles or iron sheets. In production, they are used to remove excess rolled products and cut long products into small pieces. The machine cuts the alloy at an angle from 0° to 45°.

The machine is massive in size and has additional accessories:

- pumping unit for cooling the cutting area with water;

- adaptation to the vacuum cleaner system;

- deburring equipment.

The choice of model depends on the tasks that the user sets for himself.

Advantages and disadvantages

Assessing the advantages and disadvantages, it is worth noting that there are much more advantages. These include:

- Functionality. By changing the working blade and operating power, such a saw can be used for cutting workpieces made of various materials.

- Quality. Most of these tools are made for professional use. Therefore, the quality and service life of such saws is increased.

- Accuracy. The workpiece is cut very accurately at the required angle of inclination, which cannot be done using another tool.

- Speed of work. Thanks to the design of the machine, you can cut a lot of workpieces in a short period of time. At the same time, changing the angle does not require spending a lot of effort and time.

- Easy to maintain. Changing working tools is quite easy, and the necessary parts can be easily found in almost any hardware store.

The only disadvantages include the high cost of the tool. But when used professionally, it is compensated by properties and characteristics. It should also be noted the low quality of discs made by unscrupulous manufacturers

Therefore, when purchasing consumables, it is recommended to pay attention only to trusted manufacturers.

Cutting tool

Abrasive discs are used as cutting tools. The diameter of such a circle depends on the model, its performance and the operating requirements of the owner.

More often, such saws are equipped with disks 12 in diameter, with 60 teeth. In this case, the manufacturer of the discs does not necessarily have to be the same as the manufacturer of the tool. The main thing is that the dimensions of the circle coincide with the advice indicated in the technical documentation. To increase the strength and performance of the discs, the manufacturer usually applies carbide tipping to the ends of the teeth.

Pros and cons of a pendulum saw

Before adding a pendulum saw to your toolkit, you should study not only the principle of its operation and capabilities, but also all the advantages and disadvantages of this necessary tool. It is necessary to distinguish a professional tool from a household one, because some advantages that suit a home craftsman may turn out to be disadvantages for a professional.

The advantages of a pendulum saw include:

- multifunctionality;

- fairly simple replacement of the saw blade;

- accurate and high-quality cut of the object being cut;

- fairly high cutting speed;

- ease of installation;

- availability;

- easy maintenance.

The disadvantages of the tool include the fact that during operation it is necessary to exert significant force on the lever. In addition, the design of the tool limits the thickness of the workpieces being cut. The productivity of such tools is not very high, so they are used mainly in everyday life. For professional work, other devices are used.

Assembly saws

Assembly saws are a special type, they are used in construction and during repair work. They are distinguished by increased convenience and abundance.

But the construction of the mounting saw is significantly simplified. The pendulum mechanism makes cuts only at right angles, without being able to change the degree. The working disk is made of ordinary metals, without carbide coating.

For ease of use, such tools use a belt drive; it makes the work smoother, without jerking.

Working with such a tool has a number of features:

- Due to the high torque, the saw must be held firmly and launched smoothly to avoid sudden shock.

- The workpiece must be secured before sawing.

- The cutting area should be additionally cleaned, since during the work a burr will form on the workpiece.

What are they?

All electric pendulum saws can be divided into products according to the type of material being processed:

for metal;

cutting (universal).

Electric saws from the first category are capable of working with aluminum and other soft and harder materials. Some models come with a carbide blade and even a rotary table, making the task much easier. You can buy a product for cutting with a large broach. A tool for metal eliminates the thermal effect on this material, thus mechanical cutting does not affect the composition of the alloy, and therefore the characteristics of the metal do not change.

The power of the pendulum saw and the type of disk that sits on it determine what kind of metal the tool can work with. Non-ferrous and ferrous metals can be processed. If we talk about the scope of application, metal saws are used for cutting:

- corners;

- rods;

- fittings.

There are lower power pendulum saws available for sale that are used for cutting wood. Such units are classified as one of the types of circular saws. They are used for trimming timber or cutting wood at right angles. During operation, such a tool swings like a pendulum, hence the name.

During operation, the operator has the opportunity to follow the cutting line, which is very important if no preliminary markings have been made. Disadvantages include limited cutting width and the need for additional effort by the operator

The design uses cutting elements with a diameter of 50 to 65 cm.

This is interesting: The chainsaw will not start - reasons and solutions

Reciprocating saw

In home workshops, grinders, circular saws, pendulum saws, and reciprocating saws are widely used. They all have their own design and technical features.

So that you don’t have any problems finding the differences between a pendulum and a reciprocating saw, let’s clarify some things.

- A home reciprocating saw is great for the job;

- Like a pendulum saw, a reciprocating saw can be equipped with special blades for wood or metal, or with universal cutting tools;

- The reciprocating electric saw is distinguished by its reciprocating movements;

- The device is compact in size and can be conveniently used in a home workshop;

- A reciprocating electric saw is an excellent alternative to a hand saw, which has certain limitations and difficulty in operation;

- The main disadvantage that a reciprocating saw has is vibration during operation. Particularly noticeable vibrations occur when working on thick wood or metal.

How does a pendulum saw work?

Pendulum saws for wood are similar in principle to saws with a circular blade. The only difference between the two types of dust is that in pendulum dust the cutting blade moves during operation using a pendulum device, while in the disk model the blade remains stationary.

With this saw you can make precise and clean cuts at an angle of 90 degrees. Some models can cut at a different angle, with the saw blade in an inclined position.

When cutting metal or hardwood, you can use an abrasive disc. For different types of work, you can use replaceable disks of different configurations. Universal circular blades are also produced to work with any part material.

In any dust, protective devices must be installed to reduce the risk of being damaged by a rapidly rotating saw blade.

The main disadvantages of these cutting saws:

- cutting by hand requires a lot of effort, which leads to rapid fatigue;

- the cutting model, like the jigsaw mechanism, can cut a limited thickness of the workpiece;

- The device has low productivity, so it is used as additional equipment or for solving everyday problems.

A wood jigsaw will also help you make patterned cuts with curved lines.

Drawings of a pendulum saw for metal. DIY pendulum saw

Currently, manufacturing companies produce universal and specialized equipment, with the ability to work on plastic, metal, and wood. Metal saws are designed for cutting sheet materials (including profiled ones), pipes, channels, rods, and various profiles.

The main feature of this type of tool is its ability to cut at an angle. Like any other devices for cutting metal workpieces, pendulum saws are equipped with systems to protect the worker from flying sparks (although cutting discs are currently produced that do not produce them at all), and metal particles in the form of a casing.

The casing limits access to the rotating disk blade from the outside, thereby protecting your hands from cuts. The work is carried out on a special emphasis. As a rule, stores that sell equipment, such as, simultaneously supply accessories for it - abrasive wheels and high-speed steel discs.

Design features

The cutting efficiency and wear rate depend on the value of the peripheral rotation speed of the disk and the power of the electric motor.

The higher these indicators, the faster and better the work is done and the lower the wear of tools and equipment.

Currently, manufacturers are paying more and more attention to the issues of simplification - mechanization, acceleration - of auxiliary operations, such as clamping workpieces.

These include systems of a movable jaw, a folding comb, and a screw mechanism. In such equipment, the screw clamping mechanism is used only for final clamping of the part, and the movements of the movable jaw are carried out completely unhindered.

What are the benefits of a pendulum saw for wood?

A pendulum saw is an electric tool used to work on wood or metal. Using this device, you can accurately and quickly cut the workpiece into the required number of pieces. The tool performs cutting due to the reciprocating movements of the saw blade along the wood part.

A DIY pendulum saw for wood looks like a small machine on which the saw blade is mounted in a position perpendicular to the surface on a pendulum. The dimensions of the models vary depending on the power of the unit. With the help of a pendulum, the cutting disc is lowered or raised while cutting wood or iron.

Why are cutting machines needed?

Summer cottages always require minor repairs: replacing a greenhouse post that has worn out over time, making a metal fence for a plot of land, repairing a garden wheelbarrow or cart - cutting metal at right angles or with a bevel is always necessary. Making blanks for any metal products is easier and more efficient using the machine.

Using cutting machines, you can cut any materials: steel, cast iron, copper. Cutting is done at angles of 45º and 90º. You can make products with your own hands from pipes of all diameters. As a rule, cutting mechanisms are used for cutting semi-finished products into measured lengths.

Metal processing equipment can also be used to process other materials, eliminating the work of the cutter. The machine, made with your own hands, is compact; it is possible to install it under a canopy, and in winter, move it to the workroom.

You need a flat and hard surface with lighting. A similar corner can be found on the site of any building. All-welded and dismountable equipment designs are used. In order to reduce manufacturing costs, the device can be periodically given to neighbors for temporary use.

How does a pendulum saw work?

Pendulum saws for wood are similar in principle to saws with a circular blade. The only difference between the two types of saws is that in pendulum saws the cutting blade moves during operation using a pendulum device, while in a circular model the blade remains stationary.

With this saw you can make precise and clean cuts at an angle of 90 degrees. Some models can cut at a different angle, with the saw blade in an inclined position.

When cutting metal or hardwood, you can use an abrasive disc. For different types of work, you can use replaceable disks of different configurations. Universal circular blades are also produced to work with any part material.

Any saw must be equipped with protective devices that reduce the risk of damage from a rapidly rotating saw blade.

The main disadvantages of these cutting saws:

- sawing by hand requires a lot of effort, which leads to rapid fatigue;

- the cutting model, like the jigsaw mechanism, can cut a limited thickness of the workpiece;

- The device has low productivity, so it is used as additional equipment or for solving everyday problems.

A wood jigsaw can also help you make patterned cuts with curved lines.

How do these saw models work?

The device can be classified as a circular model. The cutting disc is installed on a special fixed frame, and the machine itself is powered from the electrical network. The name “cutting” is explained by the fact that the cutting wheel moves down at the moment of cutting, and after completion of sawing it returns to its initial position.

The powerful cutting wheel of the saw is capable of separating not only wood or metal, but also porcelain, glass, plastic or tile. To cut wood, you can use a blade removed from a circular saw.

Advantages and disadvantages

The list of advantages of this model notes what is characteristic of all branded sawing equipment:

- quality of raw materials used;

- application of high-precision metal processing technologies;

- use of new developments in the field of ergonomics and design.

Users positively note the unification of saw blades with products from leading brands, which allows them to use the capabilities of the tool with the highest possible efficiency and productivity.

Owners of electric saws of this brand note the affordable price of spare parts and a wide range of services from service and repair centers.

On the other hand, there are a number of design flaws, in particular:

- forced wear of gearbox gears;

- the ability to install hacksaw blades with a thickness of no more than 1.5 mm;

- lack of soft start systems.

How to make a pendulum machine yourself?

In order not to spend extra money on purchasing an expensive device, you can make such a tool yourself. A do-it-yourself pendulum saw for wood can be made using an electric drill, grinder or electric motor. With certain knowledge and skills, you can design your own model, which is not inferior in power and productivity to factory units.

To make such a saw with your own hands, you will need to study the drawings and instructions for assembling the mechanism. Follow the basic sequence:

- take the electric motor from the grinder;

- install the V-belt from the car in such a way as to transmit rotation from the motor to the spindle;

- to secure the pendulum device, build a metal frame using metal with a square cross-section, or adapt the attachment to an electric drill;

- Weld the spindle housing to one side of the frame, and fasten the electric motor to the other; make the shaft size as indicated in the drawing for assembling a hand-held pendulum saw;

- you need to make a groove in the frame through which the rolling axis of the saw blade will pass; weld the frame so that the motor, rolling axis and spindle are parallel;

- the protective case is best made from an iron sheet; Install the drive handle on the belt guard.

If you need a professional saw for long-term use, choose reliable and trusted manufacturers - avoid purchasing cheap analogue tools made in China. If you need a portable device for sawing wood, a hand-held wood chain saw is suitable for you.

Making a cutting machine from a grinder with your own hands: drawings, technology

The designs of cutting machines made on the basis of an angle grinder are of two types (depending on the placement of the angle grinder).

In the first case, you get a frame on which the angle grinder is very rigidly fixed. Only the disk rises above the working surface, for which there is a special slot in the table. This machine operates on the principle of a circular saw.

Note! When working with such a machine, you have to move the workpiece yourself, which is why the accuracy of the work is lost. In addition, this process can be unsafe, so drawings with a hidden type of placement of an angle grinder are not in high demand.

The second option assumes that the workpiece remains stationary and the cutting element moves. Due to the fact that the grinding machine is located on top of the tabletop, cutting parts does not require much effort.

Working on a homemade cutting machine based on a grinder

Design features of the cutting machine

In order for the machine to serve for many years, it must be made of reliable materials. It is better to make metal structural elements from steel alloys, which are particularly hard. In this case, the operation of the finished equipment will be smooth and stable.

It is better to make the platform from heavy, rigid material - a lot here determines the subsequent position of the machine (whether it will be mobile or stationary).

To ensure reliable fastening of the workpiece, you can mount a more complex structure by including a vice as an element.

The disk may have an abrasive surface if it is intended to process the edges of the metal from burrs formed during cutting. This disc is convenient for processing chamfers.

Classification according to the method of feeding the cutting element

There are a large number of machines on sale; before purchasing, it is important to understand how the cutting element feeding system works. The cutting element can be fed in the following ways:

- front feed of cutting disc;

- a device with the implementation of lower feed of the cutting element;

- a structure whose base works in a pendulum manner.

The metal base of the cutting machine can be floor-standing or table-top when used. In the first case, a larger diameter disk is installed, which allows cutting a larger volume of parts. Desktop equipment is more mobile and has a reduced weight.

Saw selection

To select a unit, you need to decide on the technical features that it must meet. Need to know:

- What is the rated power of the installation?

- Belt or gear drive.

- Is it possible to adjust the number of revolutions and what is the largest number of them?

- What is the size of the external and landing diameter of the disk.

- Dimensions of the structure and its weight.

- The dimensions of the workpieces and the type of material with which you will have to work.

- Is the cutting block movable in relation to the product?

- What are the dimensions of the integrated vice for fastening workpieces?

If you plan to purchase a cutting machine, then you need to know the type of CNC unit. This affects the performance of the machine.

Device Models

The market for modern electronic equipment is varied. To work conveniently with any material, you need to have good equipment. When choosing it, it is better to focus on the ratings of manufacturers and models, as well as user reviews.

Electronic professional tools from the Japanese company Makita Corporation are very popular on the market. Now Makita's assortment includes more than a thousand items of various types of tools, among which there are saws.

Reliable and small-sized model Makita LC 1230. It has a powerful motor, a dust collection filter, and a carbide saw blade with a carbide edging. The blade has an increased service life; the material cut made by this saw element comes out without burrs or burns. By disconnecting the protective case and removing the lock from the spindle, you can simply change the disk. Model specifications:

- engine - 1.75 kW;

- speed - 1300 rpm;

- disc blade - 305 mm;

- depth and width of cut - 115 mm.

There are other models of this company for us with other technical features. For example, Makita 4131 - for cutting steel, Makita 2414 NB - for vertical cutting of ceramics, stone, PVC, alloy.

Highly professional equipment includes Mac model saws, manufactured by a company from England. They are distinguished by good assembly, because they are equipped with elements from European manufacturers. For example, the Mac NEW 350 S model is a professional unit with a huge saw blade, capable of working with large workpieces. The gearbox of this device is contained in an oil bath, which increases its service life. The motor power is 2.2 kW, the width and depth of the cut is up to 120 mm, the revolutions are very high at 3000 per minute, the disc is 350 mm. The motor in such machines is three-phase.

Other saw models can be purchased on the professional electronic tools market.

What is this?

The saw performs reciprocating movements during operation. The saber works exactly the same way.

A cutting pendulum electric saw is a fairly compact machine in size, where the cutting tool is a disk and is mounted vertically on a special pendulum.

The size of the device may vary depending on the model and power. The pendulum provides the ability to raise and lower the cutting blade when working on metal or wood.

The assortment is extensive, which allows the buyer to choose such popular saws as Makita, Zubr, PM 400, etc.

Device Features

Drawing of a typical saw device

- Circular and pendulum saws have approximately the same principle of operation;

- The main difference between the devices is that with a disk cutting tool and the motor are fixed motionless, while with a pendulum device they rise and fall due to the pendulum;

- The cutting pendulum installation provides a high-precision cut at a right angle;

- Additionally, tools such as PM 400, PM 55, Interskol, Zubr, Makita, KD 300, PM 70 and other representatives of the pendulum saw segment are capable of cutting at an angle;

- Often, a cutting system for cutting wood or metal includes an abrasive disc;

- The use of appropriate disks allows you to work efficiently. To process a particular product, you simply need to replace the blade;

- The blade can also be universal, allowing you to cut all kinds of workpieces with one disc;

- A modern cutting pendulum electric saw for cutting workpieces is distinguished by the fact that the cutting blade and disk can be replaced in the shortest possible time. This is what distinguishes the leaders of the segment in the person of PM 70, PM 55, KD 300, Zubr, Makita, Interskol, PM 400, etc.;

- Each cutting tool must be equipped with protection systems. This is because the rotating cutting blade is potentially dangerous;

- By choosing the desired size of the device, you can cut workpieces at home;

- Manufacturers offer both household and industrial models.

Despite its fairly significant advantages, the pendulum cutting saw has several disadvantages.

- For sawing, you have to apply significant force, as when using a grinder.

- A cutting saw has certain restrictions on the width of the material being cut.

- The device is not very productive, so it is often used as an auxiliary equipment in factories or home workshops.

The estimated price of devices for home use is from 12 to 40 thousand rubles.

How it works

To cut materials, you need to know exactly how a pendulum-type electric saw functions.

- A pendulum saw can safely be called a circular saw. Here the circular machine is installed on a special frame;

- The machine operates from the mains;

- Factory models can be equipped with special turntables, due to which the device is used as a miter box. This function cannot be called necessary, but sometimes its relevance is in demand;

- The electric cutting saw received its name due to the fact that the cutting blade is lowered by hand along a pendulum path onto the workpiece, and when the cutting is finished, it rises to its original position;

- Depending on what blade is used, the size and power of the device, a factory-made or home-made electric saw can cut metal, wood, tiles, porcelain, plastic, glass, etc.;

- Cutting discs are used to cut metal. They can be borrowed from an angle grinder;

- If it is wood, a circular blade is used.

Do-it-yourself pendulum saw for wood

When working with metal or wood, the need often arises to make an even cut at a certain degree. It is almost impossible to do this the first time with an ordinary grinder; for these purposes it is worth using a pendulum saw.

A pendulum saw is a special type of tool that is designed to quickly and accurately cut various materials. Most often wood or metal.

It looks like a small machine with a cutting tool installed on it. The disc is attached to a pendulum-like device.

Thanks to this, the mechanism performs pendulum movements, that is, reciprocating, which allows you to make an even cut.

This saw can be considered a type of circular saw. The difference lies in the design . In a circular saw, the motor and disk are attached to the machine in a stationary state, while in a pendulum saw they move along with the mechanism.

Such a tool is an indispensable device in any production. The saw allows you to make precise cuts in almost any material at the desired angle. The cutting element is represented by an abrasive disc. With its help you can saw various metals, wooden blanks, plastic products, porcelain, earthenware and other materials.

This is a very dangerous tool, so its use is only possible if all safety rules are followed. For protection , such machines are equipped with a protection system. Increased safety is a must for both industrial and home use.

The cost varies across a wide price range, so it is easy to choose a model to suit your own requirements. If necessary, you can assemble such a saw yourself if you have the necessary materials.

For industrial production, models with an automatic disk movement mechanism are used. For home needs, a model with a manual mechanism is suitable.

Saw features

A homemade pendulum saw is suitable for processing any metal elements and structures, creating workpieces, etc.

Most often it is used for cutting products, because... This is precisely its key purpose.

The only negative is that the price of pendulum saws is quite high, and therefore not everyone can afford them.

The homemade model has the same principle of operation, which is described below.

A pendulum saw for working on metal is also called a miter saw.

This is a type of circular apparatus, it operates using electric current and is mounted on a frame.

Video:

Factory models are equipped with a special turntable, thanks to which the saw can function not only as a cutter, but also as a miter box.

If you only need a cutting function, then in a homemade model you don’t have to make a circle, so assembling the saw will cost you less and it will be somewhat easier to do.

The name of the saw comes from its functions: during operation, it makes pendulum movements - the cutting mechanism moves alternately up and down, making cutting movements on the metal.

While the machine is operating, the cutting circle is lowered onto the workpiece, and after the work is completed, it must be raised to its original position.

If you buy a ready-made device, then it will be enough to study the main characteristics and brands (Makita, etc.) of the device, as well as read reviews from saw owners.

If you assemble a pendulum saw, you can use it to cut not only metal workpieces, but also glass, porcelain, wood, make tiles of the size you need, etc.

Makita models have a wide functional range, but a homemade model often does not have such parts and is suitable for working mainly with metal.

However, if you often work with other materials, you can make or purchase the necessary equipment to make the cutting saw more functional, especially since this is not at all difficult to do.

Most of the tools needed to work with products will not cost you much: for example, to cut wood you will need a circular saw blade, and for ordinary metal processing a disk that previously belonged to an angle grinder will do.

Therefore, converting a saw is very simple: by replacing the blade from a machine for working with metal, you will get a machine for working with wood, etc.

Changing disks and other elements is very simple. Once you assemble the saw with your own hands, this will not be a problem for you.

The advantages of this type of saw include the ability to create a high-quality and precise cut, which is not always possible when working with other tools. However, you should not compare a saw made by yourself with tools from well-known manufacturers, for example, Makita.

An even cut is obtained due to the fact that the cutting saw has a powerful drive, as well as a cutting wheel that rotates at high speed.

Video:

Another advantage is that these metal saws are safe when working with your own hands: the abrasive wheel of the device is covered with a special housing that protects from sparks and chips that may get in during operation.

Thanks to the high power and rotation speed of the wheel, the work happens faster than when using other tools, which means the energy consumption required for cutting metal will be much lower.

Finally, pendulum saws are more functional - they can process metal products at different angles up to 45 degrees.

If you decide to buy a ready-made tool, the price will depend on several factors: firstly, the size of the product and its power.

Saws designed for processing thick and large parts are very bulky and heavy.

It is very difficult to move such a tool; as a rule, it is placed in a garage or workshop, where there is a three-phase grounded outlet that is necessary for work.

Compact saws are easier to work with: they can be carried around the area or taken with you to the right place. However, they are not suitable for processing massive products. Usually they make this particular version of the tool with their own hands.

How to make a saw?

If you need a saw, but the price quoted by the seller is prohibitive, then it’s time to think about making a tool with your own hands.

A saw designed for metal work will require a more powerful electric motor, such as the Makita models, which will also be useful if you plan to cut thick trees.

In cases where a more powerful tool is required, it is best to make a pendulum frame. Pendulum variations are not only more powerful, but also very effective.

In order for the frame of the device to be stable, it is necessary to use steel rather than wooden corners for its manufacture.

The frame is the base on which all cutting and rotating mechanisms are installed, so make sure that it is strong.

Before you start assembling the saw with your own hands, look at the diagrams with its structure: you can focus, for example, on a machine from Makita, because it is a high-quality and functional device for metal processing.

Each homemade cutting saw must be mounted on some stable surface, usually a table.

It is necessary that it be properly fixed, because if it wobbles, it can not only ruin your workpiece, but also be dangerous for the master.

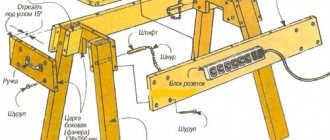

The tool table must be special, and it is also better to make it yourself. For the bed, you can use an old table from the kitchen, or metal or wooden sawhorses.

If you choose trestles, then they need to be connected using a board with a cross-section of 50 mm. The tabletop needs to be installed on top of the resulting base.

The tabletop can be made from metal plates 4 mm wide. You will need two of them to work. Or you can use thick beams that need to be connected with a plywood jumper.

When connecting materials, be sure to leave a gap of at least 10 mm between them.

The most important thing when working is that the edges of the plate are set parallel to each other, otherwise the miter saw will not be able to function correctly.

When attaching the tool to the tabletop, the saw should be in the center of the gap, and sheets should be located on its two sides. You need to make holes in the table into which the saw will be fixed.

After installing it, you need to secure the motor so that the miter saw can operate. If you have made a small saw, the easiest way is to attach it to the motor axle.

Video:

IMPORTANT TO KNOW: Manual plasma cutting: machines, equipment, video

However, the tool is not suitable for cutting thick metal, so if you understand that low power will not be enough for your work, then immediately make a more powerful tool.

You can use a bicycle spindle as a transmission mechanism for a homemade saw. It includes bearings and a shaft, which you will also need in your work.

You can cut the spindle off the bike using a hacksaw. You need to install a sprocket on the bicycle shaft. The best part for this is a part belonging to the D6 or D8 motor.

In order for it to fit tightly to the shaft, you need to make a bushing for the transition.

The circular saw must be attached to the spindle, however, before you do this, you need to decide on the diameter of the device.

The diameter of the bushing must also match the diameter of the other parts so that they all fit tightly together.

A plate with a thickness of at least 5 mm must also be installed on the spindle housing. The sprocket is attached to the shaft, which has a homemade saw.

The sprocket should be 2.5 times the size of the spindle.

The saw chain is put on the body last, after all other parts are correctly installed and secured.

The price of the parts that a cutting saw requires will be much lower than the price of a finished saw, for example, from Makita.

The tools you will need are:

- table;

- several plates;

- several beams and lintels;

- old bicycle spindle;

- bushing for transition;

- star;

- chain;

- shaft.

Some of these tools you probably already have in your garage, while others can be obtained very cheaply.

If you are not confident in your abilities, then it is better to purchase a ready-made tool.

Moreover, the price of some Makita models is quite reasonable, and at the same time they have wide functionality.

Before purchasing a metal cutting saw, research what's on the market and read about the different models of tools.

It is better to choose an already proven device, for example, a Makita saw, which has long proven itself on the market. The price of both circular and pendulum saws is quite affordable for a person with an average income.

How it works

This type of cutting equipment falls under the category of circular cutting machines. In its design, the cutting disc is mounted on a special frame, and the power source for the machine is the electrical network. The presence of the word “cutting” in the name indicates that the cutting disk is lowered during cutting, and after the end of the working cycle it returns to its original position.

The powerful cutting blade allows you to make cuts in a wide range of materials - not only metal and wood, but also tile, plastic, glass and porcelain. To work with wood, you can install a blade used in circular saws on the machine.

Safety rules when working with a homemade machine

Since an angle grinder generates a lot of noise when cutting metal, it is necessary to ensure that there are no flammable materials nearby. The side where the spark will be directed must be protected with resistant sheet metal.

When working on a homemade machine, it is mandatory to install protection, since parts of the disk can fly off in any direction. This protective part also stops circular sparks from the disc.

When making a machine, it is necessary to take into account that sparks should fly from a person, and not towards him, that is, it is necessary to secure the angle grinder with the correct side. But even in this case, it is important to wear protective clothing, glasses, and gloves.

Sharpening two-handed saws yourself or how to simply restore an old long hacksaw

If you have an old two-handed hacksaw Druzhba-2 in the garage, then before using it, it is recommended to restore its integrity

Before using the tool, pay attention to the following points:

- Handles - wooden handles may have dried out over a long period of non-use, so it is possible that they could freely fall out of the holes. You can restore the serviceability of the handles by dipping them in water for several hours so that they swell. You can also machine new handles for the tool, which won’t take a lot of time and effort.

- The presence of corrosion on the canvas - signs of rust should be eliminated, and then treat the device with machine oil

- Sharpening the teeth - after storing the tool for a long time in the garage, there is a high probability that the hacksaw needs to restore the sharpness of the teeth

If there are no difficulties with restoring the handles and removing corrosion, then sharpening the teeth is just the opposite. A large saw requires a lot of time and effort to restore the integrity of the links. However, there is an advantage to this, since large teeth are much more convenient to sharpen. Although the tool differs from an ordinary hand hacksaw, however, the principle of restoring the sharpness of the teeth is similar. A step-by-step description of sharpening teeth on a two-handed saw has the following format:

- First you need to fix the tool. It will not be possible to do this in the jaws of even the largest vice, so we use two corresponding board lengths. We place the boards parallel to the blade, leaving only the teeth visible. If you don’t have a vice, you can use a clamp

- Work should begin with setting the teeth. All teeth must be the same height. You can determine the presence of protruding links by eye, and to align them with the rest, you should work with a flat file

- At the next stage, it is necessary to align the teeth at the same angle of deviation from the plane of the blade. To perform the wiring, you will need a special tool. It is also recommended that you first make a template (layout) to check whether the links are sufficiently spaced (or buy one). The teeth should be spaced 0.5 mm from the plane of the blade or 1 mm from each other. The wiring process is performed one by one. Not many craftsmen know how often to set teeth. According to the rules, it is necessary to carry out setting no more often than 1 time per 5-6 sharpening of teeth

- As soon as the teeth are set apart, you can move on to the final and most important stage - sharpening. For this, a special triangular file is used, the size of which must be no less than the height of the teeth

- Correct sharpening is performed by moving the file away from you with medium pressure against the tooth. In the reverse position, the file should not touch the blade. It is necessary to pass the file confidently, but not quickly

- First you need to go along one side of the teeth, and then along the other. When sharpening, you should also choose the appropriate angle from 35 to 70 degrees.

Finally, all that remains is to treat the tool blade with machine oil and use it for sawing thick logs, trees and even lumber. When carrying out work, it is recommended to follow safety precautions to avoid injury.

This is interesting! If you have mastery of working with a grinder, you can sharpen the teeth with a power tool with an abrasive disc.

The device of a pendulum saw from a grinder

In most cases, a cutting machine from an angle grinder is performed using a pendulum system. Such a tool is popularly called a pendulum saw.

The operating principle of such a device is based on outweighing. Two metal corners are installed on the edge of the vertical support. They must be attached to the hinges strictly in the middle. An assembled device of this type resembles a children's swing. In the place where the parts will be cut, the grinder is attached. At the other edge of the pendulum, a load is installed that will lift the grinder when the cut is completed.

Instead of a load, you can also install a spring that works for compression. The spring stiffness is selected in practice.

How to secure an angle grinder for precise cutting? You need to unscrew the handle on the tool. And using the existing holes in the angle grinder, drill the same ones in the corner. To fasten it you need to screw it with two bolts.

Next, it is recommended to install the angle grinder handle in its place for ease of cutting.

The device of a homemade pendulum machine