TIN (lat. Stannum), Sn, chemical. element of group IV of the short form (group 14 of the long form) periodic. systems; at. n. 50, at. m. 118.710. Natural tin contains 10 isotopes 112Sn (0.97%), 114Sn (0.66%), 115Sn (0.34%), 116Sn (14.54%), 117Sn (7.68%), 118Sn (24.22 %), 119Sn (8.58%), 120Sn (32.59%), 122Sn (4.63%), 124Sn (5.79%; weakly radioactive, β-emitter, T1/2 more than 1017 years). Radioisotopes with mass numbers 100–137 have been artificially obtained.

Story

Tin has been known to people for six thousand years. But as a component of bronze. Pure metal was isolated by the 12th century. Eight centuries later, the history of the discovery was supplemented by the solution to the phenomenon of the “tin plague.”

Tin as a metal is mentioned in the books of the Bible and the early Middle Ages encyclopedist Roger Bacon.

The etymology of the name is interesting. The name stannum comes from Sanskrit and means “strong, steadfast.” This was the name given to alloys, and only since the 4th century has the term been applied to tin.

The term “tin” is found in the Baltic and all Slavic languages. However, among the Slavs it means lead. In the Baltic group, the basis is the name of the metal by color: white or yellow.

origin of name

The Latin name stannum, related to the Sanskrit word meaning "steady, durable", originally referred to an alloy of lead and silver, and later to another alloy imitating it, containing about 67% tin; by the 4th century, this word began to be used to refer to tin itself.

The word tin is common Slavic, having correspondences in the Baltic languages (cf. Lit. alavas, alvas - “tin”, Prussian alwis - “lead”). It is a suffix from the root ol- (cf. Old High German elo - “yellow”, Latin albus - “white”, etc.), so the metal is named by color.

What is

Tin is an element of the periodic table.

It is a light silvery-white shiny metal. Consists of ten isotopes.

Tin cube

Tin belongs to the group of light non-ferrous metals.

The international designation is Sn (Stannum).

The world price of a ton of raw materials on the London Metal Exchange is $21,000.

Being in nature

In terms of prevalence on the planet, tin is in 47th position; in the earth’s crust its mass content is calculated in thousandths of a percent.

The main metal carrier mineral in nature is cassiterite (another name for tin stone) - almost 80% of the composition.

Forms of occurrence in rocks and minerals – dispersed and mineral (oxides, hydroxides, silicates, sulfides, spinels).

There are deposits on all continents, reserves amount to millions of tons.

In Russia, the regions of deposits are Khabarovsk, Primorsky Territories, Yakutia, Chukotka.

Application

O. is a component of alloys: with copper (bronze), copper and zinc (brass), antimony (babbitt), lead (solder), zirconium, titanium, niobium (nuclear reactors, turbines, superconductors), etc. O. is used for application coatings on metals, including tinning of tinplate, production of foil, measuring parts. devices, heat exchangers, art. products, etc. SnO2 oxide is used for the manufacture of heat-resistant enamels and glazes. Tin(II) salts are used in mordant dyeing of fabrics. Crystallic. SnS2 (“gold leaf”) is included in paints that imitate gilding; tin fluoride is an additive in fluoride-containing toothpastes.

Physico-chemical characteristics

Metal is endowed with many advantages: ductile, lightweight, malleable, non-toxic.

Chemical properties do not appear at ordinary temperatures.

| Properties of the atom | |

| Name, symbol, number | Tin / Stannum (Sn), 50 |

| Atomic mass (molar mass) | 118.710(7) a. e.m. (g/mol) |

| Electronic configuration | [Kr] 4d10 5s2 5p2 |

| Atomic radius | 162 pm |

| Chemical properties | |

| Covalent radius | 141 pm |

| Ion radius | (+4e) 71 (+2) 93 pm |

| Electronegativity | 1.96 (Pauling scale) |

| Electrode potential | −0,136 |

| Oxidation states | +4, +2 |

| Ionization energy (first electron) | 708.2 (7.34) kJ/mol (eV) |

| Thermodynamic properties of a simple substance | |

| Density (at normal conditions) | 7.31 g/cm³ |

| Melting temperature | 231.91 °C |

| Boiling temperature | 2893 K, 2620 °C |

| Ud. heat of fusion | 7.19; kJ/mol |

| Ud. heat of vaporization | 296 kJ/mol |

| Molar heat capacity | 27.11 J/(K mol) |

| Molar volume | 16.3 cm³/mol |

| Crystal lattice of a simple substance | |

| Lattice structure | tetragonal |

| Lattice parameters | a=5.831; c=3.181 Å |

| c/a ratio | 0,546 |

| Debye temperature | 170.00 K |

Disadvantages: low melting point, vulnerability to the “tin plague”.

"Tin Plague"

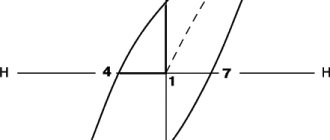

Under normal pressure, the metal takes one of two modifications:

- α-Sn. Temperature less than +13.2°C. Dull gray powder (tin gray).

- β-Sn. Temperature above +13.2°C. Metal, white tin.

Gray and white tin

At air temperatures below +13.2°C, β-tin is reformatted into the α-modification. The structure of the lattice changes, the silver metal becomes a gray powder.

The process proceeds fastest at -33°C. Because of its speed, it was dubbed the “tin plague.” It destroyed Napoleon's army during his campaign in Russia and many museum exhibits when the premises froze.

Physical properties.

Tin is a soft silver-white ductile metal (can be rolled into very thin foil - staniol) with a low melting point (easily smelted from ores), but a high boiling point. Tin has two allotropic modifications: a-Sn (gray tin) with a face-centered cubic crystal lattice and b-Sn (regular white tin) with a body-centered tetragonal crystal lattice. The b ® a phase transition is accelerated at low temperatures (–30° C) and in the presence of gray tin crystal nuclei; There are known cases when tin products in the cold crumbled into gray powder (“tin plague”), but this transformation, even at very low temperatures, is sharply inhibited by the presence of minute impurities and therefore rarely occurs, representing more scientific than practical interest. See also ALLOTROPY; CHEMICAL ELEMENTS; PERIODIC SYSTEM OF ELEMENTS.

Pure tin has low mechanical strength at room temperature (you can bend a tin rod and hear a characteristic cracking sound caused by the friction of individual crystals against each other) and is therefore rarely used. However, it easily forms alloys with most other ferrous and non-ferrous metals. Tin-containing alloys have excellent anti-friction properties in the presence of lubricant, and therefore are widely used as bearing materials.

Receiving technology

The source for obtaining the metal is cassiterite.

Cassiterite crystals - tin ore

The process is simple:

- The ore is crushed to particles no larger than a centimeter.

- The flotation method is used to separate waste rock. The metal content increases to 42-68%.

- Sulfur and arsenic are removed by oxygen roasting of the concentrate.

- The resulting product is loaded into the melting furnace, alternating layers of concentrate with charcoal. The result is reduced tin.

- The second restoration option is aluminum or zinc.

Tin ore

If necessary, the metal is additionally purified by zone smelting or electrochemical refining.

Tin brands

Metallurgists smelt several grades of metal:

| Brand | Amount of impurities (%) |

| OVCh-000 | 0,001 |

| O1pch | 0,085 |

| O1 | 0,010 |

| O2 | 0,435 |

| O3 | 1,51 |

| O4 | 3,51 |

The first four grades of tin are produced in the form of ingots, wire, and rods. Pigs are smelted from O3 and O4. This is the source code for tin products.

Historical reference

O. is known from prehistoric times. times, mentioned in the Old Testament. According to Homer, O. ores were mined on the Cassiterides - the British Islands. Alloys of gold with copper (bronze) have been known since the 3rd millennium BC. e., pure metal from the 2nd millennium BC. e. In ancient times, jewelry, dishes, and utensils were made from ointment. In Ancient Egypt, jewelry was made from O., soldered onto other metals. From the end 13th century in the West In Europe, vessels, church utensils, ceremonial bowls, dishes, and cups with relief images (coats of arms, mythological, genre scenes) were made from O. In Russia, products made from glass (mirror frames, utensils) became widespread in the 17th and 18th centuries.

Lat. the name of the element is probably related to Sanskrit. stha - to hold firm, sthavan - firmly. Origin Russian name "ABOUT." not exactly established.

Where is it used?

Metal is in demand as an independent material, in alloys and compounds.

Its chemical and physical properties make it possible to produce safe, rust-resistant products and coatings.

Tin soldier in mold after casting

Metal

Pure metal is in demand as:

- Containers of food products.

- Packaging foil.

- Anode in chemical current sources.

It is also a coating for copper wires. The metal protects the copper “filling” from the harmful effects of sulfur contained in the insulating material.

Tin cup from Gdansk (Poland)

Tin is the most environmentally friendly of light non-ferrous metals.

Connections

Metal compounds have found application in various segments of the economic complex:

- Aviation and mechanical engineering . Additive in titanium alloys.

- Electrical engineering. Superconducting wire (niobium compound).

- Optics. Abrasive for finishing glass surfaces.

- Light industry . Yellow dye for wool.

- Agriculture . Pesticides.

- Decor. Component of “golden” paints.

Isomers of artificial origin are used in medicine as a source of gamma radiation.

A third of the mined tin is used to make tableware. Another 60% is taken by bearings, packaging foil, and solders. Less than 7% remains for other purposes.

Prospects

The potential of two-dimensional tin layers created using graphene technology is being explored. The name of the material is consonant with its “parent” – stanen.

Connections.

Tin forms a variety of chemical compounds, many of which have important industrial applications. In addition to numerous inorganic compounds, the tin atom is capable of forming a chemical bond with carbon, which allows the production of organometallic compounds known as organotin compounds (see also ORGANOMETALLIC COMPOUNDS). Aqueous solutions of tin chlorides, sulfates and fluoroborates serve as electrolytes for the precipitation of tin and its alloys. Tin oxide is used in ceramic glazes; it gives the glaze opacity and serves as a coloring pigment. Tin oxide can also be deposited from solutions as a thin film on various products, which adds strength to glass products (or reduces the weight of vessels while maintaining their strength). The introduction of zinc stannate and other tin derivatives into plastic and synthetic materials reduces their flammability and prevents the formation of toxic smoke, and this area of application becomes the most important for tin compounds. A huge amount of organotin compounds are used as stabilizers for polyvinyl chloride, a substance used to make containers, pipelines, transparent roofing material, window frames, gutters, etc. Other organotin compounds are used as agricultural chemicals, for making paints and preserving wood.

Alloys

Metallurgy uses tin as a component of alloys. According to the scope of application, they distinguish between bearings, low-melting compounds and solders.

Molten Tin

A classification of alloys by type has been developed:

Babbitts

An alloy based on tin or lead. It is used as a layer created by spraying or filling.

Disadvantages: low strength, quick fatigue. Due to these properties, the alloy is used only in bearings protected by a housing.

Bronze

Copper-tin alloy with a dominance of copper. Pros: hardness, fusibility, resistance to processing, rust, mechanical damage, atmospheric disasters.

Used as a foundry metal in the chemical industry, automotive industry, and exterior decoration of buildings.

Solders

They are easy- and hard-melting. The main component of the alloy is tin.

There are several brands, depending on the ratio of elements. The alloys are used for soldering everything: from cookware, medical equipment, radio components, heating radiators to electronic equipment.

Pewters

Alloy with copper, antimony, bismuth. Decorative, aesthetic option. It is used to make dishes and small objects that decorate life. But application limits toxicity.

In some countries the use of the alloy is prohibited. Such products can only be found in antique dealers.

Coatings made of tin and its alloys.

Tin easily forms alloys with many metals. Tin coatings have good adhesion to the substrate, provide good corrosion protection and a beautiful appearance. Tin and tin-lead coatings can be applied by immersing a specially prepared object in a molten bath, but most tin coatings and tin alloys with lead, copper, nickel, zinc and cobalt are deposited electrolytically from aqueous solutions. The presence of a wide range of compositions for coatings made of tin and its alloys makes it possible to solve a variety of industrial and decorative problems.

Meaning for humans

The microelement is a participant in metabolism and promotes the growth of skeletal tissues.

Diet

Products from several groups are rich in tin:

- Meat – chicken, turkey, beef, pork.

- Dairy products, including hard cheeses.

- Legumes.

- Vegetables – potatoes, beets.

- Sunflower seeds.

Every day a person needs 3-11 mg of the substance. He gets them from food. The excess is disposed of naturally, so poisoning is excluded.

Symptoms of deficiency

A lack of microelement disrupts the mineral balance of the body.

The result is the following symptoms:

- Unmotivated exhaustion.

- Growth inhibition.

- Hearing impairment.

- Dullness, brittleness, hair loss.

Element deficiency is a rare occurrence. Just like oversupply.

Oversupply

Occurs in people who come into contact with the substance (mining in mines, working in a metallurgical plant) or fans of canned foods.

Tin Coated Tin Can

The integrity of the shell of cans is compromised during long-term storage. Some of the tin passes into the contents.

The oversaturation of the body with metal is signaled by:

- Metallic taste in the mouth.

- Lack of appetite, gastrointestinal upset (vomiting, diarrhea).

- Anemia, migraines, dizziness.

- The skin becomes inflamed, pale, becoming grayish. Blueness appears on the gums.

On the emotional level, this is increased aggressiveness and excitability.

Physiological action

Almost nothing is known about the role of tin in living organisms. The human body contains approximately (1-2) 10-4% tin, and its daily intake from food is 0.2-3.5 mg. Tin metal is non-toxic, which allows it to be used in the food industry. Tin poses a danger to humans in the form of vapors and various aerosol particles and dust. When exposed to tin vapors or dust, stannosis can develop - lung damage. Stannan (tin hydrogen) is a powerful poison. Some organotin compounds are also very toxic. The temporary permissible concentration of tin compounds in atmospheric air is 0.05 mg/m3, the maximum permissible concentration of tin in food products is 200 mg/kg, in dairy products and juices - 100 mg/kg. The toxic dose of tin for humans is 2 g.

Harmful impurities contained in tin under normal conditions of storage and use, including in the melt at temperatures up to 600 °C, are not released into the air of the working area in volumes exceeding the maximum permissible concentration in accordance with GOST. Long-term (15-20 years) exposure to tin dust has a fibrogenic effect on the lungs and can cause pneumoconiosis in workers.