By making a knife from a saw with your own hands, you can get at your disposal a cutting device whose performance characteristics are much better than those of factory analogues. When making a knife with your own hands, it is given exactly the shape that suits the master most. Factory-made knives are beautiful, but not always reliable. There is no guarantee that they will not fail at the most crucial moment.

A homemade knife made from a disk, a hacksaw for wood, or a saw for metal will last for many years, regardless of the conditions of storage and use. Let's look at how to make a knife from factory-made metal parts, what is needed for this and what you should pay special attention to.

Tools and materials

The raw material for making a homemade knife can be any new or old cutting part made of hardened steel. It is better to use metal cutting discs, hand and pendulum saw blades as a workpiece. An old chainsaw is a good option. From its chain you can forge and sharpen a blade that is not inferior in quality and appearance to the famous Damascus steel.

In order to make a knife with your own hands, you will need the following equipment and materials:

- Bulgarian;

- grinder;

- electric drill;

- ruler;

- hammer;

- sandpaper;

- whetstones for sharpening;

- files;

- core;

- epoxy adhesive;

- copper wire;

- marker;

- bucket with water.

Separately, you need to think about the issue with the handle. The finished product should fit comfortably in your hand.

To make a handle it is better to use:

- non-ferrous metal (copper, bronze, brass, silver);

- wood (oak, alder, birch);

- organic glass (plexiglass, polycarbonate).

The raw materials for the handle must be intact, without traces of cracks, rot or other defects.

How to make it yourself

Making a knife from a circular saw blade is not as difficult as it seems at first glance. Its manufacture does not require special technical skills or the use of special equipment. If you wish, you can do all the work yourself.

Deciding what we will do

First of all, you need to decide on the purpose, shape and size of the future product. The size of the saw blade used and the required set of tools for manufacturing will depend on these parameters.

For example, to make a hunting knife, it is best to use a 16-inch long concrete cutting blade. For the kitchen, a 12-inch wood saw blade is suitable.

What is needed for making

In addition to the drawing of the future product, to make a knife you will need the following materials and tools:

- saw blade;

- angle grinder with a set of discs;

- drill press or drill;

- drills for wood and metal;

- wooden block;

- sandpaper of various grain sizes;

- sanding block.

Disk selection

Almost all modern saw blades are made from high-carbon steel 9ХФМ. Products made from such material are practically resistant to corrosion and have a long service life. Therefore, choosing a saw blade for making a knife comes down only to the correct placement of the workpiece layout on the disk.

When choosing a high-quality disc, you can check its quality by ear. A good quality disc rings when you tap it, a dull sound is produced by a disc with internal defects.

Step-by-step manufacturing instructions

Before starting work, it is necessary to cut out a template for the future knife and clean the surface of the saw blade from dirt and traces of possible corrosion. In order to make a homemade knife, you must perform the following steps:

- Place the template on the surface of the saw blade and, securing it with magnets, apply markings.

- Using a grinder, cut out the workpiece. The cut must be made along the outer edge of the marking. To prevent overheating and changes in the properties of the metal, the saw blade should be watered with water during operation.

- Using a grinder with a grinding disc, rough the workpiece.

- Place 36-grit sandpaper on a belt sander and give the workpiece the required shape. Periodically it is necessary to dip the workpiece in a bucket of water to cool.

- Place 80 grit sandpaper on the machine and finish the workpiece.

- Clamp the workpiece between two wooden blocks and secure them with a clamp. One of the ends of the block should be at the beginning of the future butt.

- Without removing the stops, sharpen the knife blade.

- Periodically it is necessary to check the difference between the upper and lower ends of the future knife. If the butt thickness is 2 mm, the difference between them should not exceed 1 mm.

- After removing the wooden blocks, polish the shank of the knife by first moistening it with water.

- By installing a grinding wheel with a grain fraction of 240 on the grinder, polish the blade.

- Secure the workpiece to a wooden board using a clamp.

- After securing 400 and 1000 grit sandpaper to a wooden block, use a back-and-forth motion to finely polish the blade.

- Cut 7 mm thick wooden plates to make handles. Their length should correspond to the length of the knife shank.

- Mark the handles.

- Apply two-component epoxy resin to the inner surface of the wooden plates and attach them to the shank of the knife. After this, press them with a clamp.

- After the glue has dried, drill two through holes in the handle to install aluminum rivets.

- Install the rivets into the mounting holes and rivet them with a hammer.

- On a grinding machine, and then manually shape the handle into the desired shape.

- Cover the handles with stain and let it dry completely.

After this, you can dip the knife blade in a 5% nitric acid solution for several minutes to coat it with a protective oxide film. Then you need to thoroughly rinse the blade with running water and sharpen it.

After watching the video, you can see all the subtleties and nuances of making homemade knives from a saw blade, and also learn some ways to protect blades from corrosion.

Rules for working with metal

In order for the blade to be strong and elastic, during its manufacture it is necessary to follow the rules of working with metal. They are as follows:

- The workpieces must not have visible or hidden damage. Before making a knife, the workpieces must be inspected and tapped. A solid part sounds loud, but a defective part sounds dull.

- When designing the shape of the blade, angles must be avoided. In such places the steel can break. All transitions must be smooth, without kinks. The cuts of the butt, handle and fuse must be ground at right angles.

- When sawing and sharpening, do not overheat the steel. This leads to a decrease in its strength. An overheated blade becomes brittle or soft. During processing, the workpiece must be constantly cooled by completely immersing it in a bucket of cold water.

- When making a knife from a saw blade, you need to remember that this product has already gone through a hardening cycle. Factory saws are designed to work with the hardest alloys. If you do not overheat the canvas during the turning and finishing process, then you will not have to harden it.

The blade shank should not be made too thin. It is this part of the product that will bear the heaviest load.

Pros and cons of homemade products compared to factory production

One of the main advantages of a homemade knife is its cost. It costs an order of magnitude cheaper than a factory-made knife. In addition, a homemade blade can be given almost any shape. Here everything depends only on imagination.

Despite its positive qualities, this knife has some disadvantages. Among them are:

- choice of metal . Factory knives are made of various grades of steel, each of which is designed taking into account the application. In the case of a saw blade, the choice of steel is limited;

- blade hardening . Blade hardening is a very complex technological process that requires strict adherence to all standards, which are very difficult to repeat at home.

We also recommend reading a useful article about the best brands of steel for knives; the article reviews the 12 most popular brands in the whole world, their pros and cons, which you should pay attention to when choosing.

Making a knife from a circular saw blade is the simplest and cheapest way. If there is a desire and enough free time, everyone can do it themselves. We hope that after reading the article, you will understand the process of making it, and you can make it yourself.

Making a knife from canvas

If the blade is large and does not have much wear, then several blades for different purposes can be made from it. The effort and time spent are worth it.

A knife is made from a circular saw with your own hands in the following sequence:

- A pattern is applied to the canvas, and the contours of the blade are outlined. Scratches or dotted lines are applied over the marker with a core. This way, the design will not be erased when cutting out the workpiece and adjusting it to the desired shape.

- Workpieces are cut from a circular saw blade. To do this, it is better to use a grinder with a metal disc. You should leave a margin of 2 mm from the contour. This is necessary in order to remove the material burned by the grinder. If you don’t have a grinder at hand, you can sharpen the workpiece using a vice, a hammer and a chisel or a hacksaw.

- Any excess is ground off on the grinding machine. You will have to spend a lot of time on this process so as not to overheat the steel. To prevent this, the workpiece must be regularly immersed in water until it cools completely.

- The blade is outlined. Here you need to be careful to maintain the contour of the knife, not burn it and maintain an angle of 20?.

- All straight sections are leveled. This is conveniently done by placing the workpiece on the side of the grinding wheel. The transitions are given a rounded shape.

- The part is cleared of burrs. The blade is ground and polished. To do this, several interchangeable wheels are used on a grinding machine.

Separately, we should dwell on how the handle is made. If wood is used, then a monolithic fragment is taken, in which a longitudinal cut and through holes are made. After this, the blank is placed on the blade, and holes for fastening are marked in it. The handle is fixed to the blade using rivets or bolts with nuts. In the case of a bolted connection, the heads of the hardware are recessed into the wood and filled with epoxy glue.

When the handle is assembled from plastic, 2 overlays are used, which must be symmetrical. To give the knife originality, the plastic linings are painted on the inside. You can make cavities in the overlays that can be filled with jewelry, items made of non-ferrous and precious metals, small compasses and photographs.

After fastening to the blade, the handles are ground until they acquire the required shape and smoothness.

Working tools and materials

The raw material for creating a handicraft knife can be any used or new cutting component made of hardened steel. As a semi-finished product, it is advisable to use saw wheels for metal, concrete, saw wheels for pendulum end saws and hand saws. A decent material would be a used gasoline saw. From its chain it is possible to forge and make a blade, which in its properties and appearance will be no worse than the legendary Damascus blades.

To create a knife from a circular disk with your own hands, you will need the following equipment and materials:

- angle grinder;

- emery machine;

- electric drill;

- ruler;

- hammer;

- sandpaper;

- whetstones for sharpening;

- files;

- center punch;

- epoxy;

- copper wire;

- felt-tip pen;

- container with water.

To create a handle, it is preferable to use:

- non-ferrous alloys (silver, brass, bronze, copper);

- wood (birch, alder, oak);

- plexiglass (polycarbonate, plexiglass).

The material for the handle must be solid, without cracking, rottenness or other defects.

Knife from a chainsaw chain

Saw chains are made of high-quality alloy, which perfectly withstands prolonged friction and high temperature. The blade manufacturing process is long and labor-intensive, but the result is a beautiful, unique and very durable knife. To work you will need a heavy anvil, barbecue and charcoal. To make it easier to handle a hot workpiece, you need to purchase blacksmith tongs.

Making a blade from a chainsaw chain should be carried out in the following sequence:

- Prepare clothes and gloves made of thick fabric and a protective mask. Pour charcoal into the fireplace and light it with a special liquid.

- Fold the workpiece from a single piece of chain. In the place where the handle will be, you can add several pieces of chain. It should be remembered that the result of the work should be a single monolithic product. The handle for the knife is not made separately.

- Place the workpiece on the coals. Provide air flow to raise temperature. Wait until the steel turns dark red. In this state, it becomes forgeable without losing its quality characteristics.

- Remove the hot chain from the fire and place it on the anvil. Flatten it with several strong blows so that the links melt together, turning into a single monolithic part.

- Step by step, by heating the workpiece in the oven and giving it the desired shape with a hammer, forge a knife with a designated handle and blade. After the workpiece has cooled, sharpen and polish it.

- Harden the product. To do this, you need to heat it red-hot again and put it in cold water. After this, you can finish the knife. For this purpose, acid and an engraving machine are used. The finished blade is polished again and washed in a warm soapy solution.

DIY saw knife

The first cutting tools made by man were made of stone. The ancestors of modern knives were very fragile and required a lot of time and labor to manufacture. The metal blade is devoid of these main disadvantages. Steel is relatively easy to process and has good physical characteristics.

A knife made by yourself is the pride of the owner. When manufacturing independently, the characteristics that are necessary are selected. First of all, this is the shape of the blade and handle. The highest quality blades, such as damask steel or Damascus steel, are made by forging. The blade material has the necessary hardness and carbon content.

DIY circular saw knife

But forging requires certain tools and skills. What should you do if you want to make your own unique blade, but only have a minimal set of tools at hand? In this case, you should pay attention to a circular saw as a blank for the blade. The metal from which the circular saw blade is made lends itself well to hardening and has the necessary elasticity, so the saw will be the optimal workpiece for making a knife with your own hands. A homemade knife made from a circular saw holds an edge well, does not break, and can easily compete with industrial knives.

DIY circular saw knife

How to determine wear?

Checking the saw blade for wear is an important issue that should be given special attention. Deep damage makes it impossible to sharpen the wheel. There are three main signs by which you can understand that the saw needs to be sharpened or replaced:

There are three main signs by which you can understand that the saw needs to be sharpened or replaced:

- The protective casing becomes very hot and produces smoke. The circular saw has a special casing that indicates that the saw has become dull due to heat. In particularly difficult situations, smoke may appear from it.

- Sometimes the saw design involves a mechanical feed (if you need to manually adjust the pressure force). In such a situation, wear can be noticed if the pressure has to be increased.

- If, when sawing wood, carbon deposits and a strong unpleasant odor are formed on the workpiece.

All the situations described above tell the user that it is time to sharpen the device.

Creating a knife layout

The first step is to create a model of the future knife from a saw. At this stage of work, you can decide on the shape of the blade of the future blade and the shape of the handle. The layout is best made from thick cardboard or thin plywood. You can also use thick plastic. A rigid pattern will allow you to understand how a knife from a circular saw will lie in your hand and how convenient it will be to use.

When making a layout, it is important to adhere to the following rules:

- Right angles must be avoided. A right angle is a place of stress concentration. The blade of the knife most often breaks or cracks in this place.

- The shape of the blade must be chosen based on the purpose of the future knife. The most versatile forms are with straight or descending butt. Such a blade can cut and stab equally well.

- The dimensions of the layout must correspond to the size of the circular saw blade.

When making a model, you should also remember that a knife can be classified as a bladed weapon. It all depends on the shape and size. Manufacturing and possession of bladed weapons is criminally punishable. Therefore, in order not to fall under the article of the criminal code, it is necessary to create a layout that complies with the following rules:

- The length of the blade or cutting part should not exceed 9 centimeters. Exceeding this length even by 1 mm will allow you to classify a homemade blade as a bladed weapon.

- A knife with a blade thickness of more than 2.6 mm is also a bladed weapon. This parameter can be neglected, since the thickness of the saw blade is usually 2 mm.

- Hardness should not be more than 42 units. This parameter relates to hardening, so we also skip it at the stage of making the pattern.

- The handle should have a limiter that protrudes beyond its limits by no more than half a centimeter. If there is no limiter, then the sub-finger recess should be less than 4 mm deep.

Once a layout that satisfies the letter of the law and personal preferences has been drawn, you can proceed to transfer the layout to the saw blade. The pattern is applied to the saw blade and outlined with a marker. It's best to use a fine marker. A thin line will allow you to cut the workpiece more accurately and avoid unnecessary filing of the workpiece.

Types of washing machine motors

We all know that the drum in a washing machine is started by the engine. Typically, an ordinary belt drive is used to accelerate the drum. Among the advantages of this method, the softer movement of the drum due to natural shock absorption is most often mentioned. In addition, replacing a belt takes a maximum of 20 minutes and is not expensive.

The belt drive is quite easy to use, if you find such a motor, then making your own homemade product will be much easier.

Each engine type has advantages and disadvantages, as well as strengths and weaknesses. Let's look at the features of the main three types.

Asynchronous

In such a motor there are two working units - a stationary stator and a rotor that causes the drum to rotate. In this case, the motor rotation speed can reach 2800 rpm.

The device of an asynchronous motor.

The weak point of such motors is the reduction in torque. Because of this, the drum begins to literally “walk” and sway.

Advantages of asynchronous motors:

- simplicity of design and maintenance (the main thing is not to forget to lubricate the motor and change the bearings);

- low noise;

- budget cost.

Among the main disadvantages:

- bulky motor;

- low efficiency;

- “Clumsy” electrical circuits, inconvenient for re-soldering.

Such engines are most often used in inexpensive models that are not burdened with “smart” electronics.

Brushed motor

Today, commutator motors have almost completely replaced asynchronous motors. Almost 90 percent of all household washing machines are equipped with this type of motor.

And this is not surprising, because such motors are more universal; they can operate on both alternating and direct current.

Such motors consist of three main elements: a stator, a commutator rotor and a tachogenerator or rotation speed generator.

In addition, the design provides special brushes for contacting the rotor with the motor (usually there are two of them). They need to be changed periodically, as they wear off on the collector.

The commutator type engine has a number of advantages:

- compact dimensions;

- high starting torque;

- does not depend on the frequency of the power supply;

- smoother speed control, in this case the rotation is regulated by voltage control.

- versatility;

- simple and accessible control circuit;

Among the disadvantages are:

- short service life;

- the need to periodically replace brushes;

- high noise.

Modern direct drive motors

New generation washing machines use motors that operate without a belt drive. In such motors, the usual pulley is replaced by a special coupling that connects the rotor shaft directly to the drum axis without a belt.

The Direct Drive system was first used in LG washing machines in 2005. In this case, the drive is connected directly to the drum, which eliminates the use of connecting elements - the most vulnerable parts of the motors.

The direct drive design includes an inverter brushless motor, in which the rotation speed is set by electromagnetic waves. It is able to determine the load from the laundry being washed and, depending on this, change the power consumption.

This technology is considered one of the most advanced; drives of this type are used by leading manufacturers of washing machines, such as Haier, Bosch, AEG, Samsung and Whirpool.

Outwardly, such a direct motor somewhat resembles an asynchronous one, however, its operating principle is completely different. In this case, a three-phase inverter type control circuit is used.

Motors of this type have a number of advantages:

- convenient location and absence of unnecessary details;

- wear resistance and ease of replacement of elements;

- compactness;

- low vibration level of the machine;

- High efficiency;

- no belt or brushes that require regular maintenance;

- relative noiselessness.

Such motors significantly increase the overall cost of household appliances. This is due, first of all, to the complex control system of the electrical circuit of such an engine.

Cutting and primary processing of the workpiece

The fastest way to saw a workpiece is with a grinder with a thin metal cutting disc. If it is not possible to use a grinder, you can use a hand hacksaw for metal. It is important to correctly install the file into the hacksaw. The teeth of the saw should be directed forward and the hacksaw should cut while moving away from you.

Cutting and preparing the workpiece

First, the approximate shape of the knife is cut out using straight cuts. Then the bends are cut out. The easiest way to cut them is with several oblique cuts converging at one point. It is important to leave an allowance of 2-3 millimeters to the drawn outline. This is due to the fact that when using a grinder, the metal at the cutting site overheats. By grinding off 2–3 mm using a file and sandpaper, you can remove the overheated edge of the metal.

Giving the workpiece its final shape

The rough workpiece is brought to its final shape using a file or emery. To avoid overheating of the future knife from the saw, when processing it with sandpaper, it is necessary to periodically lower it into a container of water. This will allow the workpiece to cool. When processing a workpiece with a file, no additional cooling is required. The most optimal way would be to roughly process the workpiece on sandpaper, and then fine-tune it with a file.

Processing the knife blank

During finishing, special attention should be paid to the smoothness of the bends. It is important to ensure that the bend is smooth, without depressions or bulges. Miniature depressions can be easily checked with a file. To do this, use a marker to paint over the end of the workpiece being checked. Next, apply a file with light pressure along the workpiece along the entire bend. There are depressions in the places where the marker trace remains.

Processing continues until not a single depression remains.

Next, the workpiece is cleared of burrs and sanded using sandpaper. You can start with 60 grit and finish with 320 grit. The workpiece will still be subject to heat treatment, so finishing the blade will be polished later.

Shank drilling

The handle on the shank can be secured with rivets or glue. The most reliable option for attaching the handle is to use rivets. To install them, you need to make holes in the shank. The holes are marked on the shank so that they are located approximately in the middle of the future handle. To prevent the drill from slipping at the initial stage of drilling, the holes are cored.

Due to the fact that the circular saw is made of alloy tool steel, drilling it will not be so easy. Ordinary metal drills will not last long here.

Drilling should be done with cobalt drills or a ceramic drill with a pobedite tip.

During the drilling process, it is important to add oil to the drilling area and not allow the drill to overheat.

Drilling through hardened steel is quite a difficult task. Therefore, it is possible to produce holes in the shank using an electrochemical method. To do this, attach a wire to the workpiece, then completely cover the shank with bitumen mastic or plasticine. In areas of future holes, the protective layer is scratched down to bare metal. Next, a saturated solution of table salt is prepared, into which the blade shank with a wire and an unnecessary metal plate, also with a wire, are dipped. Both wires connect to the battery or car charger. A “plus” is applied to the future knife from a circular saw, and a “minus” is applied to the plate. The etching process is accompanied by the release of gas. In 30–50 minutes the holes will be ready.

How to make a knife handle

The easiest way is to glue a handle from two cut and prepared pieces of wood or plexiglass. It is much easier to make than attaching it to the tail of a knife. Naturally, you can choose a simple option and wrap the handle with electrical tape, but why try so hard to end up ruining the aesthetic appearance of the knife?

And now comes the most crucial stage of work. Since you will have to drill in the shank of the knife, the blade can easily burst. Therefore, be vigilant and careful.

Steel is a hard, but at the same time brittle material. If the pressure is evenly distributed when the saw is in operation, it is almost impossible to break it. But with spot drilling, the pressure increases and the metal can easily crack. Therefore, it is better to drill a hole at low machine speeds and do not forget to add oil to the drilling site. In this case, a screwdriver is an ideal tool for accomplishing this goal, since it has fewer revolutions and the possibility of breaking the part is not so high.

After completing the previous step and making holes in the handle, drill the same holes in the halves of the handle. Make a copper or aluminum rivet. For insurance, you can glue the area where the rivet will be located with glue, but it is better if you have epoxy resin.

Forming the cutting edge

Before you begin shaping the cutting edge, it is necessary to carry out preparatory work. It consists of applying markings on the edge of the workpiece. The markings are placed exactly in the center and serve as a guide for making a symmetrical descent.

To do this, paint over the edge that will be cutting with a marker and, using a drill equal in thickness to the workpiece, scratch the markings. The drill has a conical sharpening. Therefore, if you place the drill and the workpiece on the same plane, the tip of the drill will be exactly in the middle.

Edge cutting device

Then, using a coarse file, you can begin shaping the cutting edge. If you do not have the proper skills to create a smooth edge, you can use a simple device. It consists of a base, an angle and a guide with a platform for sandpaper. 180-grit sandpaper is glued onto the platform with the guide. Several holes must be pre-drilled vertically one above the other in the corner. The knife is fixed flat on the base and the guide is inserted into the hole at a height so that the angle between the plane of the base and the platform with sandpaper is the same as that chosen for forming the slopes. A universal angle is from 22 to 30 degrees.

Having made an even descent to the middle of the thickness of the workpiece, turn the knife over, then make the same descent on the reverse side. Using such a simple device, you can easily form an even blade.

Circular saw accessories and their purpose

Today, a carpenter can both make and buy various products that make his work easier. Additional devices to make working with the saw easier are divided into several types. The main ones are:

- Parallel stop.

- Guide rail for sawing sheet blanks.

- Device for perpendicular cutting and facing.

- Installation bars for precise placement of the guide.

- Adjustable guide for cutting workpieces at a fixed angle.

Using them will significantly reduce time and reduce labor costs when working with massive and large-sized products.

Circular saw stop

First of all, it is necessary for sawing wood products along the grain to a certain width. However, its design has one significant drawback. To ensure safe operation of the saw, it is designed not to come into contact with the guard when working, so cuts cannot be made beyond a certain width. This parameter varies among different saw models and manufacturers.

Before work you must:

- Lock the stop at the desired cutting width.

- Secure the workpiece.

- Press the edge of the fence against the board and guide the saw along the workpiece.

Guide bars for circular saws

The guide bar is a long strip of plywood on which an aluminum u-shaped profile is screwed, which serves as the actual bar along which the saw itself runs directly. The main task is sawing sheet material. The tire is installed on top of the workpiece, aligned along the cutting line. Then it is secured with clamps. When working, the saw should be guided along the guide.

Circular saw blade

It is an aluminum or wooden board with a cut in it for the disk to operate. Attached to the saw base with screws. Used to prevent chipping when cutting plywood or chipboard.

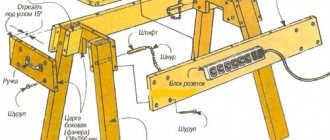

DIY rip fence for a circular saw

It is preferable to make this product from chipboard, since this material is more resistant to wood - in terms of humidity.

The board itself consists of several strips of chipboard or boards, namely four, fastened with self-tapping screws along the entire length along the contour. A semblance of a massive ruler in the form of a box is formed. It is attached to a support board, which ensures its fixation to the tabletop. At the other end there is an eccentric handle. There is a metal runner that ensures smooth sliding of the stop during operation. The stop position is adjusted using bolts that come into direct contact with the table top.

DIY guide bar for a circular saw

It is intended to be used as a stop for the product when cutting. It is a wide board to which a metal corner is attached with screws along its entire length. A saw is placed at the top of this corner of the guide, moving freely along the entire length. Allows smooth cutting of various materials.

DIY ruler for a circular saw

For the ruler you will need several pieces of 12 mm thick plywood, as well as a 20 mm square aluminum profile. A groove is made on the edge of the plywood. The profile along the entire length of the sheet is screwed onto self-tapping screws. The stiffener is screwed to the side using self-tapping screws. Before screwing, the stiffening ribs should be bent slightly to the base of the bending ruler. This is necessary to securely fix the ruler on the part so that it does not “dance.” In addition, a platform is made with a cut-out groove for the guide and for the disk from the same 12 mm thick plywood. It should move freely along the guide.

DIY circular saw carriage

To make a carriage with your own hands, we will need a sheet of chipboard. We bolt two metal corners to it - these are guides. We measure a perpendicular from the saw and place a stop for the carriage. In addition to all this, you can make an additional curved groove in the base of the board at 45 degrees for cutting at an angle.

With the help of these auxiliary tools, any carpenter will make his work easier. At the same time, the speed and productivity of labor will increase.

https://youtube.com/watch?v=Ud5lpoe2ehM

Hardening

Heat treatment will give the knife the necessary hardness; it will not become dull during use.

To harden the knife from the saw, it is necessary to heat it to a temperature of 750–920 degrees. If you do not reach this temperature, the steel will not be hardened, and if it is heated too much, the blade will be too brittle.

At home, it is not possible to determine the exact temperature. However, there is a way out. A simple magnet is suitable for temperature control. As soon as the blade blank stops being magnetic, it is heated to the required temperature.

After the temperature of the workpiece has reached the required limits, it must be kept in this state for approximately 1-1.5 minutes for every 1 mm of thickness. In the case of a homemade knife from a saw, the holding time for hardening is 3–5 minutes. It would be enough. Next, the workpiece is lowered into vegetable or machine oil preheated to 50 degrees. This procedure should be performed carefully. Oil vapors can ignite from a hot workpiece, so you should have a fire extinguisher on hand.

A little about the hardening forge. If it is not possible to use industrial equipment, then you can make a forge yourself. To do this, it is necessary to build a fire of such a size that it is possible to evenly heat the workpiece. Next, as the firewood burns and coals appear, a homemade knife is placed on them. You can use a household hair dryer or a pump for inflating mattresses as bellows.

Disk speed and security

Without ensuring high speed of the toothed disk, it is impossible to guarantee the quality of the cut. However, for homemade equipment operated in a home workshop, safety during operation is no less important.

It is necessary to provide protective devices that are traditionally equipped with industrial designs. The opinion that one can completely do without such protection at home does not stand up to criticism.

TB rules are “written in blood.” All it takes is one awkward move to end up on the surgeon's table.

Therefore, security should be given the utmost attention

Vacation

After hardening, the blade must be released. This procedure is carried out with the aim of reducing fragility, as well as giving the saw blade high elasticity. To temper, the blade is cleaned with sandpaper to remove scale formed during the hardening process and placed in a regular oven preheated to 190 degrees. There the blade is kept for an hour, then the oven heating is turned off.

The knife should cool smoothly to room temperature.

After this procedure, the workpiece has the necessary hardness and elasticity.

Releasing the blade in the oven

Sawing out the handle blank and preparing for gluing

To finish working with the knife, you need to make a handle. There may be different variations of materials used as a handle. The most popular material is wood. The wooden handle is impregnated with linseed oil to prevent the harmful effects of moisture on it.

Select a flat plank from the wood of your favorite species. The thickness of the board should be at least half a centimeter for convenience. A thick board can be sawn lengthwise. Using the knife blank as a template, markings are applied to the board, including holes for rivets. For a good fit of the future handle to the shank, it is necessary to create a plane of contact using sandpaper.

Forming the upper part of the handle

The upper part of the handle is prepared in advance for the reason that after gluing the handle to the shank, processing the upper part will be difficult. Also, during the processing process, you can scratch the blade, which is extremely undesirable. Holes for rivets are drilled according to the markings made during the preparation process. A rod of suitable diameter is inserted into them. It allows you to firmly connect both parts of the workpiece and will not allow them to move during processing.

Finished knife handle

Forming occurs using files and sandpaper. At this stage, it is important to remember the permissible dimensions of the limiter and finger recess.

The final processing is carried out using 800-grit sandpaper. Before gluing, all parts must be thoroughly degreased. This can be done with acetone or solvent. Once the degreaser has dried, glue or epoxy can be applied.

Manufacturing of rivets

The adhesive attachment of the handle to the shank is not reliable. To avoid breaking the handle, the wooden plates must be fastened with rivets. The rivets are made of metal that is not subject to corrosion. These can be alloys of non-ferrous metals or stainless steel. You can also use a copper or brass tube as rivets.

Making rivets for a knife

A blank for the future riveting is sawn off from a rod of suitable length. It should be 2–3 millimeters longer than the thickness of the handle. Holding the rivet in a vice, use a hammer to flare one end. It should look like a mushroom at one end of the rod. Next, the rivet, pre-lubricated with epoxy glue, is inserted into the holes in the handle and also flared on the other side of the handle. To flare a rivet made from a tube, it is best to use a ball from a bearing.

Technical information for tool steel circular saws

Circular saws for wood

A circular saw is a rotating cutting tool in the shape of a circular blade with many cutting teeth around its perimeter, which is designed for mechanical cutting of wood and wood-based materials.

The circular saw is made of alloy tool steel, with heat treatment, leveling, calibration, setting and sharpening.

- Material: The circular saw is made of 75Cr1 steel. (DIN 1.2003); (ČSN 19418)

heat treatment: The circular saw is hardened to 44-48 HRc for body thickness up to 3 mm and to 42-46 HRc for body thickness over 3 mm.

- leveling: When leveling the circular saw, deviations from the flatness of the surface are eliminated, i.e. so that the axial (face) runout of the circular saw does not exceed:

- values 0.2 mm for circular saws with a diameter of up to 200 mm

- values 0.4 mm for circular saws with a diameter of up to 500 mm

- values 0.6 mm for circular saws with a diameter of up to 800 mm

- values 0.8 mm for circular saws with a diameter of over 800 mm

The run-out of the circular saw blade changes in the clamped state near the mounting hole, and it is necessary to pay attention to the quality of the clamping flanges, which must be at least 5x√D in diameter of the saw blade. calibration: By properly adjusting the preload, the strength of the saw blades is increased, which allows for higher feed rates and thus improved cutting accuracy and cut surface quality

During manufacturing, circular saw blades are calibrated for a cutting speed of 60 m/sec for smaller thicknesses and 80 m/sec for thicker circular saw blades. The corresponding speeds for which the saw is calibrated are indicated on the circular saw.

calibration: By properly adjusting the preload, the strength of the saw blades is increased, which allows for higher feed rates and thus improved cutting accuracy and cut surface quality. During manufacturing, circular saw blades are calibrated for a cutting speed of 60 m/sec for smaller thicknesses and 80 m/sec for thicker circular saw blades. The corresponding speeds for which the saw is calibrated are indicated on the circular saw.

routing: The amount of routing (on one side) is usually 1/4 of the thickness of the disk body. Only the upper third of the tooth is moved apart. The layout must be symmetrical, otherwise the circular saw begins to deviate towards a larger layout. The layout is always done before sharpening; after sharpening it is only controlled and corrected if necessary. If you use too small a setting, the circular saw overheats, loses strength and moves to the side. If the setting is too large, losses arise from too wide a cut, higher energy consumption and increased roughness of the cut surface. For soft wood we choose a larger layout than for hard wood. For longitudinal cutting, we choose a larger layout than for cross cutting. For wet wood we choose a larger layout than for dry wood. For a frozen tree, we choose a smaller wiring than for an unfrozen tree. If the machine is in poor condition, we choose a larger wiring.

sharpening: For sharpening circular saws, we can recommend a grinding wheel made of white or gray corundum, medium grit and hardness, with a porous or very porous structure with a ceramic or bakelite base. A circle with ceramic binder material is designated:

- A99 60L 9V (white)

- A96 60L 9V (gray)

The most common reasons for short sharpening times:

Overheating of the cutting inserts: manifested by a change in the color of the tips of the cutting inserts, which occurs due to overheating of the material during sharpening. Overheating can occur due to too much pressure (removal of too much material) from the grinding wheel onto the surface being sharpened, from using a grinding wheel that is too hard, a grinding wheel that is too fine in grit, improperly holding the tool, or intense sharpening without cooling.

Sanding and varnishing a knife handle

Final sanding is done using sandpaper. Gradually increasing the grain size, it is necessary to remove all rough marks from paper of a larger grain size. It is enough to complete the process of sanding the knife handle with 600 grit paper. The last step in making the handle will be its impregnation.

There are several ways to impregnate a handle to better preserve it. This is oil impregnation, wax impregnation or varnish coating.

Each method has its own advantages and disadvantages. For example, wax must first be melted by heating it, and heating has a detrimental effect on the strength of the glue that glues the handle. Oils must be updated periodically. And the varnish serves only the function of surface protection.