Electrochemical polishing is the process of treating the surface of a part by immersing it in an acid solution. The metal product is connected to a positively charged anode, and a current of 10–20 V is passed through the electrolyte. As a result, the metal is covered with an oxide or hydroxide film, under which polishing occurs by smoothing out protruding micro-irregularities. Chemical polishing gives approximately the same effect, but here the workpieces are not exposed to the influence of electric current.

The quality of work depends on the homogeneity of the material. Polishing pure metals results in a smooth, shiny product. Polishing complex alloys does not give such a result. At the end of the work, the treated surface increases its roughness purity by 2 classes.

Polishing of parts is carried out only after their visual inspection. It is not allowed to have deep scratches or holes on them, since such defects cannot be eliminated during the polishing process. The best option is to work with cylindrical parts. Flat workpieces are less amenable to polishing.

At the end of the procedure, the products acquire a number of positive qualities: their corrosion resistance increases, the strength of the surface layer increases and the coefficient of friction decreases.

Package

If packaging materials and product handling processes prior to electrochemical polishing are not properly selected and used, they can create problems during subsequent processing.

In addition, improper packaging may result in damage in transit that cannot be corrected during processing. Bubble wrap is a suitable packaging material, but it should not come into direct contact with the metal component. The chemicals in the wrapper leave a pattern that becomes apparent during processing. The best practice after electropolishing is to wrap the parts in acid-free, sulfur-free paper.

If necessary, parts can be wrapped in bubble wrap over paper.

In metal finishing jobs, it is common practice to return parts in the same packaging in which they arrived. This should be taken into account when preparing parts for sending for electrochemical polishing.

Before electropolishing, protective coatings must be completely removed, especially in areas subject to heat, such as the weld area. Residues of adhesive must also be completely removed; usually the product is wiped with solvent or acetone before machining or electropolishing.

During subsequent processing or installation of equipment, care should be taken to avoid contact with carbon steel or unpassivated stainless steel. Such contact can lead to the transfer of free iron, which impairs the passivity of the part.

Advantages of electroplasma polishing.

Fast and high-quality polishing of stainless steel to a mirror shine is performed using the electrolytic method. This method has proven itself among manufacturers of spare parts, accessories, various metal structures, furniture elements, dishes, appliances and other products. Electroplasma polishing provides:

- preparation of products for further application of decorative and protective coatings;

- removing burrs after cutting metal;

- blunting and leveling of welds;

- annihilation of metal tarnish;

- removing contaminants from the metal surface;

- reduction in the degree of roughness;

- spectacular shine.

Electroplasma polishing is intended for stainless steel structures with different surface areas and shapes. Finished products take on a neat appearance, look solid and are always noticeable against the background of other products. They can be used indoors and outdoors, which is also an advantage.

itself takes only a few minutes . Dimensional products and parts can be processed in two stages to obtain a high-quality decorative and protective layer. In such cases, polishing is performed diagonally. It is also possible to polish elements with a complex surface shape - the quality of processing will not be affected.

If you use an electrolytic 3% solution based on ammonium sulfate, you can quickly and efficiently polish cutlery . This method is suitable for polishing products with a fine-relief surface. They are used if you need to give an aesthetic appearance to stainless steel pallets with low sides up to 3 cm. In each case, the price set for electroplasma polishing will be low, and the quality of the finished finish will be maximum.

Methods for polishing stainless steel

There are several technologies for polishing stainless steel, among which the most common are mechanical, chemical and their varieties.

Mechanical is used to restore the mirror finish of stainless steel directly on site, as well as for workshop repairs and processing of small batches of products. When in-line processing of stainless steel parts at industrial enterprises, as a rule, the method of electropolishing in chemical solutions is used.

You can bring stainless steel to a shine at home using methods and means available to everyone.

Mechanical polishing

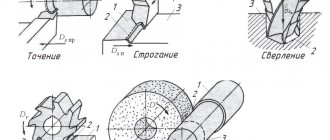

After machining or rolling, longitudinal stripes and grooves remain on the surface of stainless steel products. These irregularities, in the best case, have a roughness class of 6–7, so grinding stainless steel to class 8–10 is a prerequisite for preparing for the polishing operation, since classes 11–14 correspond to this type of processing.

Mechanical polishing of stainless steel can be done manually, without the use of power tools or special devices. This treatment is most common in everyday life and for small volumes of repair and restoration work. The following types of production equipment are used in production plants for polishing stainless steel:

- hand-held electric and pneumatic tools;

- polishing machines;

- drum and vibration devices;

- magnetic abrasive installations.

VIEW Polishing machines on AliExpress →

The most common abrasive materials for polishing stainless steel are various liquid polishes, suspensions and pastes that allow you to achieve the best results in terms of roughness. Most of them are based on technical oils, fats and substances such as paraffin and stearin, which have to be removed from the surface of the stainless steel using organic solvents.

Electrochemical method

A stainless steel product is immersed in it, to which a positive potential is applied, i.e. it is the anode. When direct current is passed through the electrolyte, positive metal ions begin to detach from the surface of the stainless steel.

To a greater extent, this occurs from the tops of microprotrusions, which are thus smoothed out (see figure below). The depth of metal removal during such chemical polishing of stainless steel in an electrolyte is regulated by the magnitude of the current and the duration of the process.

ECP allows you to process any hard-to-reach cavities and complex shaped elements by removing the same layer of metal over the entire surface of the product. Installations that perform chemical electropolishing of stainless steel operate at an electrolyte temperature of 70÷90 °C and a current density of 0.3 to 0.5 A/cm².

Solutions based on a mixture of inorganic acids are used as electrolytes. For this reason, ECP is sometimes confused with chemical etching of metals and even nitric acid is mentioned in articles about them, although the main components of the electrolyte for stainless steel are phosphoric and sulfuric acids.

Electrolytic plasma polishing

But in this case, another physical phenomenon is used - the formation of a vapor-gas plasma jacket around the anode (stainless steel product), in which the process of aligning microprotrusions on its surface occurs.

Electrolyte-plasma installations operate on direct current with voltages up to 400 V and with electrolyte temperatures from 60 to 90 °C. Despite the high voltage, they operate at the same current densities as during electrochemical polishing.

At the same time, they process stainless steel parts several times faster: in an industrial installation, the removal of a layer of stainless steel occurs at a speed of 3 microns/min.

Another advantage of this technology is the low cost and environmental safety of the chemicals used to prepare electrolytes. In particular, when electrolyte-plasma polishing of stainless steel products, safe solutions of ammonium salts with a concentration of 3–6% are used.

Electrical equipment, light, lighting

0 votes

+

Vote for!

—

Vote against!

To achieve a shiny metal surface, it is not necessary to varnish the material. You can resort to polishing the metal, which is used as a decorative form of processing the part after coating or during the processing of the product. In one case, it is enough to file the metal; in another, the surface should be brought to a shine by electropolishing. All these manipulations can be done independently at home.

- Micro and macro polishing

Purpose of polishing

Metal parts have an initially smooth, shiny surface. But it fades over time and gets scratched during use. For hidden parts, of course, appearance doesn't matter much, but when metal parts are placed in plain sight, they need to look the part. This is exactly what the glossy surface will look like after you have polished the metal.

Metal polishing is also intended to improve the smoothness and cleanliness of the surface of metal parts and eliminate traces of past processing - irregularities, scratches and dents. Polishing of parts is carried out using emery wheels, grinding powder, special lime paste, polishing solution or electrolyte.

The surfaces of metal parts are finished not only to give them an attractive appearance, but also to protect them from rusting, corrosion by alkalis and acids. Metals such as brass, bronze and copper lend themselves well to polishing. It is impossible to bring stainless steel to a mirror shine, but giving it a matte gloss is easy.

Based on the above, it can be argued that there are two types of polishing - preliminary and final. Preliminary polishing of metals is used for mechanical removal of irregularities, and final polishing is used to create a perfectly smooth and glossy finishing state of metal surfaces and protect it from adverse environmental factors.

Advantages of metal electropolishing

A separate branch of polishing is electropolishing of steel. The procedure has a beneficial effect on the physicochemical, electrical and magnetic properties of metal surfaces, facilitating deep drawing and stamping of certain metals, and also increases the level of their corrosion resistance. This explains the widespread use of electropolishing in laboratory research of metals and in industry.

Electropolishing has a number of advantages over mechanical polishing in terms of simplicity, versatility and speed. For example, it is difficult to polish stainless steel using mechanical methods, as it is a time-consuming and expensive operation. Electropolishing of stainless steel takes several minutes, is a cheap procedure and allows you to obtain a surface with better reflectivity.

Electropolishing reduces the processing time of a product compared to mechanical technology by almost 5 times, although it increases the surface cleanliness by only 1–2 grades. With mechanical polishing, you can achieve the highest surface cleanliness, but the electropolishing process is indispensable when processing products with complex profiles with internal cavities, parts of the diesel fuel system and springs, which are inconvenient and difficult to machine in shape.

Electropolishing is the best method of surface preparation before electroplating because it demonstrates high adhesion strength of the protective coating to the polished substrate. This technique is used for processing parts to improve the sliding of materials that come into contact with a polished surface, for example, thread feeders in textile machines, for sharpening cutting tools in the production of measuring instruments.

Electropolishing, in addition to eliminating the labor-intensive and harmful mechanical operations of grinding and polishing, eliminates the difficulties caused by the hardness or viscosity of the polished product, and the operations of degreasing the products, which are extremely necessary for mechanical polishing. The high productivity of the procedure does not depend on the hardness of the metal. Electrolytic polishing works equally well on aluminum and soft red copper, hardened case-hardened steel and carbide tools.

The disadvantage is increased energy consumption. Some inconveniences are associated with the fact that almost every metal requires its own electrolyte composition. The duration of the process, depending on the current density, reaches 20 - 30 minutes. Typically, during such manipulations, a layer of metal is removed, which has a thickness of 2 - 5 microns.

Electropolishing using wheels

For grinding and polishing work, it is customary to use special polishing machines with an electric motor shaft, which is extended on both sides to secure the polishing tool. Such machines have a regulator that allows you to adjust the speed of rotation of the brushes and wheels within significant limits.

Polishing discs

Products and parts that are subject to electropolishing should not have too deep marks or scratches, because it is extremely difficult and often almost impossible to remove them using this technique. Remember, the softer the metal that is being polished, the easier it is to remove the layer, but the more difficult it is to achieve a uniform surface. Polishing of hard metal is usually carried out with high specific pressure on the surface being treated.

Felt discs, discs made of leather, wool and cotton fabrics are used as polishing wheels. For mechanical polishing, brushes made of bristles and brass are used. For such polishing, mixtures or suspensions are additionally used. Typically, two wheels are needed to polish metal - a felt disc for coarse polishing and a cloth disc for fine polishing.

Felt polishing discs for electropolishing stainless steel or aluminum consist of several layers of felt, which are up to 4 centimeters thick, bonded together with glue. When making a grinding disc, layers of felt are pressed tightly against each other and placed under a press.

After they are glued and the adhesive has dried, it is customary to make a hole in the middle of the circle. After this, the circle is secured to the shaft of the electric grinder using two nuts and washers. Such a grinding wheel can also be easily secured in the chuck of a drill press or electric drill.

A cloth disk can be cut from cotton fabric, broadcloth, calico or cotton wool, after which the layers of the disk are sewn together in several layers. The stitched circles need to be glued together, leaving 3-4 centimeters along the edge. The disc is mounted on the chuck of the drilling device in the same way as the felt disc was attached.

The working process

Press a metal surface against the rotating disc to begin the at-home electropolishing process. When polishing, it is recommended to periodically lubricate the working surface of the wheels with a special polishing mixture, and in a certain dosage.

Remember that the circle will “salt” the part if there is an excess of the mixture; if there is not enough of it, the circle will quickly wear out, and the metal will not receive the desired shine. Therefore, when lubricating polishing wheels, leave approximately a quarter of the working surface free of polishing mixture.

Elastic circles must rotate and be pressed against the parts with a certain force, and the polished part itself must move freely in relation to the circle. Electropolishing using mixtures can be carried out with the end or periphery of the wheel. The products are moved directly using a special device or hand.

The rotation speed of the wheel on a polishing machine is 2000-2800 rpm. Polishing machines with high rotation speeds are used when significant processing quality is required. To achieve a mirror finish, aluminum is electropolished at lower frequencies.

If the products to be polished have a simple shape - flat or square, then you can process them on a universal electric machine with a straight profile polishing wheel installed. Hard and hard wheels are used for rough processing, and soft wheels for fine processing.

Hard wheels are intensively polished, but quickly become greasy, especially when processing soft non-ferrous and precious metals or their alloys. Soft elastic circles are ineffective in preliminary operations and can be deformed and flattened when strongly pressed against the workpiece.

Periodically remove the disc from the metal part to evaluate the quality of the polish created. When you are satisfied with the appearance of the metal and the part becomes perfectly smooth, shiny and even, you can stop the process. After this, repeat the procedure on a rag disk, which can remove any remaining polishing agent from the metal surface.

Electrochemical polishing

Electrochemical polishing is a process that is characterized by chemical reactions between the workpiece and an electrolyte under the influence of an electric current. This procedure leads to a decrease in roughness and the appearance of a mirror shine.

Micro and macro polishing

To carry out electrochemical polishing, the workpiece, which is the anode connected to the plus of the current source, is placed in a bath with an electrolyte. The second electrode is copper cathodes. Thanks to the special composition of the electrolyte for electropolishing and the created conditions (formation of a film of increased resistance), uneven dissolution is recorded.

The most protruding points will dissolve first, as a result of which the roughness decreases, and then disappears completely, and the surface of the part will become shiny and smooth. Selective dissolution of such protruding elements occurs simultaneously with the production of shine.

The process of removing large ridges is called macro polishing, and dissolving small bumps is called micro polishing. If these two processes occur simultaneously, the metal surface will become smooth and shiny. There are situations when these qualities are unrelated to each other, that is, shine is achieved without smoothing and vice versa.

During the electrochemical polishing process, a hydroxide or oxide film is formed on the anode surface. If it covers the surface evenly, then the conditions necessary for micro-polishing are created. The outer part of such a film will continuously dissolve in the electrolyte.

Therefore, a successful procedure requires conditions in which there is a balance between the rates of oxide film formation and its chemical dissolution so that the film thickness remains constant. The presence of a film implies the possibility of an exchange of electrons between the part being polished and electrolyte ions without the risk of destruction of the metal by an aggressive electrolyte.

The macro-polishing process depends on the presence of an anode film, which is thicker in the recesses and thinner in the protrusions. Such a film promotes rapid dissolution of the protrusions, because a high current density is created on them, and the electrical resistance above them will be less than above the various recesses.

The effectiveness of the anode film increases with increasing its internal resistance. Electrolytes that contain complex salts or salts of weakly dissociating acids can increase the resistance of the anode film.

Electrolytes and solvents

In addition to the near-anode film, the course of the electropolishing process is also influenced by other factors, such as the movement of the anode, which consists of mechanical mixing of the electrolyte. Electrolytes of some composition are able to function normally only when heated. The general rule is as follows: an increase in temperature can reduce the rate of neutralization and increase the rate of film dissolution.

Significant factors that influence the course of the electrochemical polishing procedure are voltage and current density. Depending on the metal being processed and the composition of the electrolyte, it is customary to polish in modes that correspond to different sections of the curve. For example, polishing copper in phosphoric acid is carried out at the maximum current mode without the formation of oxygen.

The most widespread are electrolytes made on the basis of sulfuric, chromic and phosphoric acid. To increase the viscosity of the solution, methylcellulose and glycerin are added to it. It is customary to add triethanolamine and sulfureide to the electrolyte as etching inhibitors.

To clean products after the electropolishing procedure, it is customary to use solvents that are based on chlorinated hydrocarbons - perchlorethylene and trichlorethylene.

These substances are non-flammable, their ability to remove pastes and grease from products is higher than that of ethyl alcohol or gasoline. The products must be loaded into a bath, treated with a soft hair brush, and transferred into a vessel with heated ammonia, where the remaining pastes and grease are removed.

Alkalies (caustic potassium, caustic soda), potash, soda and ammonia are used as an alkaline detergent. In recent years, detergent compositions based on various surfactants have become increasingly popular. You can successfully use baths in which the cleaning process is carried out in an ultrasonic field, which significantly increases the productivity and quality of surface cleaning.

Electropolishing baths

It is customary to make special baths for electrochemical polishing. Remember that they are very dangerous to health, especially at high temperatures. For polishing products made of non-ferrous and ferrous metals, in particular carbon steel, the most popular is the universal electrolyte.

Its composition is as follows: phosphoric acid (65%), sulfuric acid (15%), chromic anhydride (6%), water (14%). Operating mode: temperature about 70-90 degrees Celsius, voltage at 6-8 V, anode current density about 40-80 A/dm2, holding time 5-10 minutes.

Electropolishing of stainless steel - chromium-nickel and chromium-nickel-molybdenum is usually carried out in the following solution: orthophosphoric acid (65%), sulfuric acid (15%), chromic anhydride (6%), glycerin (12%), water (13%).

Operating mode of this solution: temperature is about 45-70 degrees Celsius, anode current density is about 6-7 A/dm2, voltage level is 4.5-6 V. Keep the part in such a bath for 4-30 minutes: for stamped products 4-30 minutes is enough 6 minutes, for parts after heat treatment or welding 10-12 minutes, for cast sandblasted steel products - half an hour.

For polishing products made of aluminum or its alloy, a well-proven electrolyte of the following composition is used: phosphoric acid (65-70%), chromic anhydride (8-10%), water (20-27%). Operating mode: temperature at 70-80 degrees, in a freshly prepared solution the current density should reach 10-30 A/dm2, in a solution saturated with salts - 10-20 A/dm2. Hold the part for 5 minutes or more.

For electropolishing of duralumin parts, the following solution composition is required: sulfuric acid (40%), orthophosphoric acid (45%), chromic anhydride (3%), water (11%). Operating mode: temperature within 60-80 degrees Celsius, anode current density at 30-40 A/dm2, voltage level 15-18 V, holding time - a couple of minutes.

Thus, if you need to electropolish parts at home, you can go in two ways - make special equipment with an electric motor shaft and polishing and grinding wheels, or equip a polishing bath and prepare the electrolyte needed for this case. What is closer is up to you to choose!

Electrochemical polishing – equipment and technologies

To order electropolishing services, you can fill out the form below or refer to our article in the “Services” section: Electropolishing service.

The process complements finishing machining

The use of electropolishing of steels has been practiced commercially since the 1930s, mainly concerned with imparting visual appeal to consumer goods such as dishes and pens, fittings, etc. In recent years, the emphasis has shifted to the processing of engineering equipment, especially in the food, medical, pharmaceutical and semiconductor industries. Electrochemical dissolution of the metal surface is used to improve the smoothness, reflectivity, cleanliness and passivity of steel products

or some combination of these surface characteristics. When applied to piping system components, electrolytic polishing helps achieve and maintain desired surface roughness indexes.

While conventional machining processes are macro metal removal processes, electropolishing is a micro process. Thus, it is not a competitor to processes such as grinding, blasting, sandblasting and mechanical polishing, but rather a complement.

Almost all metals and alloys can be electropolished, but in practice stainless steel accounts for the largest portion of commercial electropolishing. Stainless steel's inherent strength and corrosion resistance make it the material of choice for process equipment and many consumer products.

Electrochemical metal polishing technology

Electrochemical polishing of products.

Technological process of electroplasma, electrolytic and chemical treatment of metal to add shine to the product. Electrochemical polishing is the process of treating the surface of a part by immersing it in an acid solution. The metal product is connected to a positively charged anode, and a current of 10–20 V is passed through the electrolyte. As a result, the metal is covered with an oxide or hydroxide film, under which polishing occurs by smoothing out protruding micro-irregularities. Chemical polishing gives approximately the same effect, but here the workpieces are not exposed to the influence of electric current.

The quality of work depends on the homogeneity of the material. Polishing pure metals results in a smooth, shiny product. Polishing complex alloys does not give such a result. At the end of the work, the treated surface increases its roughness purity by 2 classes.

Polishing of parts is carried out only after their visual inspection. It is not allowed to have deep scratches or holes on them, since such defects cannot be eliminated during the polishing process. The best option is to work with cylindrical parts. Flat workpieces are less amenable to polishing.

At the end of the procedure, the products acquire a number of positive qualities: their corrosion resistance increases, the strength of the surface layer increases and the coefficient of friction decreases.

Electrolytic polishing

You can place an order for electropolishing of products by filling out the form below or by referring to our article in the “Services” section: Electropolishing service.

Electrolytic polishing is a process used to polish a metal surface using an electric current and a chemical solution, using a container equipped with electrodes. This process produces a mirror-like surface by selectively removing the surface from the steel.

This selective removal is carried out by controlled electric current and special electrolyte solutions. Electrical parameters are adjusted using the INVERTER technology built into our CLINOX products, while an electrolytic solution called E-polishing Bomar is used with our E-polishing Box, made from acid-resistant plastic and carbon electrodes. fibers to ensure better performance and complete safety.

Thanks to this combination of products the following results can be obtained

Electroplasma polishing in Russia

In Russia it is quite difficult to find a company engaged in electroplasma polishing. The use of technology is limited by several factors:

- you need a current source with a power of several tens of kilowatts;

- equipment is sensitive to the quality of the supply network;

- the polishing mode for each part requires precise individual settings;

- high requirements for the qualifications of the installation operator.

Successful development of technology is demonstrated by St. Petersburg. The geography of service provision is not limited to North-West Administrative Okrug. The list of ACIA clients includes companies and individuals from almost all regions of Russia.

Comparison of electroplasma and electrochemical polishing.

The use of toxic components forced us to abandon electrochemical processing in favor of electroplasma . Acid fumes are destructive to equipment and dangerous to operating personnel. And electrochemical polishing does not remove small marks and burrs that may be on immersed parts. Special disposal of waste solutions, which pose an environmental hazard to the environment, is also required. Unlike electrochemical polishing, electroplasma polishing is considered environmentally friendly . The installations do not include additional cleaning systems, which reduces the cost of the equipment and, accordingly, the service itself. Processing time is reduced by 2-3 times, which has a positive effect on productivity. The polishing is uniform even in areas with microrelief or in areas with residual deformation or welds.

+7 912 394 85 32

Polishing electrolyte adjustment

The components of the electrolyte, consumed during the polishing process, change its composition. Electrolyte monitoring is carried out by daily measurement of electrolyte density and its periodic chemical analysis. At the end of the shift, water is added to the bath, bringing the level to the required level.

During the operation of the bath, iron accumulates in it, which must be taken into account when making adjustments. The density of the electrolyte when passing an amount of electricity with a threshold of 75 A·h/l is assumed to be 1.75±0.01 g/cm3, and if this threshold value is exceeded, it is 1.77±0.01 A·h/l.

To remove accumulated over 1.5% chromium oxide Cr2O3, its anodic oxidation is carried out by processing at an annon current density of 4 ... 5 A/dm2, voltage 10 ... 12 V and electrolyte temperature 30 ± 10 C, using lead both as anodes and as cathodes. In this case, the cathodes must be insulated with a diaphragm made of porous ceramics. At the end of the work, the electrolyte is heated to 100±10C and maintained at this temperature for an hour, or the electrolyte is cooled naturally, but a break in operation is taken for 8 ... 10 hours.

The polishing bath is operational until 5 ... 7% Fe2O3 accumulates in it, after which it needs to be completely replaced.

Description of the method

The electrochemical polishing procedure is based on anodic dissolution of the surface of the workpiece. During this process, the protrusions on the surface with a rough topography quickly dissolve. In the depressions of the part, dissolution occurs in a slow manner. The rough side becomes smooth due to the unbalanced dissolution rate, resulting in extra shine.

The process of electrochemical polishing of a part occurs in several stages:

Manufacturing of electrolytic baths intended for polishing the surface of a product. They contain universal electrolytes: phosphoric acid, sulfuric acid, chromic anhydride and water. When polishing products made from stainless steel, glycerin is additionally used. The creation of baths occurs at temperatures up to 90° C, anode current density up to 80 A/dm2 and voltage up to 8 V. Electrolytic baths heated to high temperatures pose a danger to human health. If solutions come into contact with the skin, there is a high risk of chemical burns. Preparing the workpiece for processing. Products should not have deep patterns or large scratches on their surface that are not subject to electrochemical polishing

It is important that the part is made of soft metals. This parameter affects the degree of effective polishing

The harder the metal, the more difficult it is to achieve a uniform surface when smoothing the rough sides of the workpiece. Interaction of the part with electrolyte solutions. In this case, the metal workpiece acts as an anode - an electrode with a positive charge, and the electrolytic bath acts as a cathode. The exposure time of the product in the solution depends on the type of material. Aluminum blanks are kept for 2 - 3 minutes, cast stainless steel parts - up to 30 minutes. As a result of the reaction, roughness gradually smoothes out due to the appearance of a hydroxide or oxide film. Polishing occurs due to the exchange of particles between the anode and the electrolyte. After completion of electrochemical polishing, the surface of the workpiece becomes uniform and acquires a mirror shine.

Theoretically, the mechanism of electrochemical polishing is explained by the viscous film hypothesis. In accordance with the hypothesis, polishing of the part is carried out after the formation of the anode surface as a result of the dissolution of particles of a viscous film, which includes anodic dissolution products. The film surface has high resistance values, the thickness of which varies at the depressions and protrusions of the workpiece. Due to the difference in the resistance of the viscous film and the ability of the current to collect on the tips, the rate of dissolution of roughness changes in different areas of the product. As a result, the rough side is completely smoothed and acquires a uniform surface.

Electrochemical polishing of parts can be carried out at home. To do this, you need to purchase equipment with an electric motor shaft and grinding wheels or create an electrolytic bath and make a chemical solution from the appropriate substances.

After this process is completed, the workpiece is placed in an alkaline solution and connected to a charged electrode. The electrochemical polishing procedure includes macropolishing: dissolving large protruding peaks, and micropolishing: smoothing small surfaces of the product.

The polishing process can be accelerated under the following conditions:

- the thickness of the processed film is the same over the entire surface of the part;

- stirring and increasing the temperature of electrolytes;

- the presence of complex salts or salts of weakly dissociating acids in the composition of electrolytes;

- increasing voltage and current values.

These factors reduce the size of the surface layer of the workpiece, which allows the polishing procedure to be carried out in a shorter period of time.

Chemical and electrochemical polishing

Chemical and electrochemical polishing are fundamentally different from mechanical polishing. Parts treated with these polishing methods also acquire a shiny, attractive and smooth surface. Chemical and electrochemical polishing is carried out with solutions containing active additives.

Chemical polishing

Chemical polishing involves immersing the workpiece for some time in a vessel with a chemically active solution, where, as a result of the resulting chemical and local electrochemical processes, the metal dissolves.

Surface roughness is reduced or completely eliminated, and the treated surface becomes shiny. All chemical polishing processes are accompanied by the violent release of gases and vapors of acids or alkalis. During the polishing process, it is recommended to mix the solution or shake the parts in a container. This makes it possible to eliminate the accumulation of gas bubbles in certain areas of the parts, since gas bubbles reduce the quality of polishing. One of the main advantages of chemical polishing is its simplicity. To obtain the required result, it is enough to immerse the workpiece in an appropriate solution for several minutes, without the use of electric current, without mechanical impact. The method does not require complex equipment.

The disadvantages of such polishing include the difficulty of adjusting (maintaining exact ratios of all elements in the solution by adding a spent element) solutions and their short service life. The solutions used are extremely dangerous to human health, and such polishing cannot be carried out at home without appropriate preparation. The surface gloss is less than with electrochemical polishing. Chemical polishing is mainly applied to brass or aluminum parts of complex configurations and small sizes that do not require a mirror finish.

Electrochemical polishing

Electrochemical polishing is the process of finishing the surface of metals, leading to a decrease in roughness and the appearance of a mirror shine using an electrochemical method.

To carry out electrochemical polishing, the workpiece, which is the anode (i.e., the electrode connected to the positive pole of the current source), must be placed in a bath of electrolyte. The second electrode is cathodes made of copper. The diagram shows the flow of the electrochemical polishing process. Due to the specially selected composition of the electrolyte and the conditions created (formation of a film 2 of increased resistance), the dissolution is uneven. First of all, the most protruding points 3 (protrusions) dissolve, as a result of which the roughness decreases and then disappears, and the surface of the part becomes smooth and shiny. Selective dissolution of protruding elements occurs with the simultaneous production of shine.

Removing large protrusions 3 is called macro-polishing, and dissolving microscopically small irregularities 4 is called micro-polishing. If macro- and micro-polishing occurs simultaneously, the surface becomes smooth and shiny. In some cases, these qualities may be unrelated to each other, i.e. Shine can be achieved without smoothing, and smoothing can be achieved without gloss.

During the process of electrochemical polishing, an oxide or hydroxide film is formed on the surface of the anode (the part being polished). If this film evenly covers the surface, it creates the conditions necessary for micro-polishing to occur. The outer part of this film continuously dissolves in the electrolyte. Therefore, for the process to be successful, it is necessary to create conditions in which there would be a balance between the rates of formation of the oxide film and the rate of its chemical dissolution so that the thickness of the film is maintained constant. The presence of the film makes it possible to exchange electrons between the metal being polished and electrolyte ions without the danger of local destruction of the metal by an aggressive electrolyte.

Macro polishing is also a process that depends on the presence of an anode film. Being thicker in the recesses and thinner on the protrusions, this film contributes to their accelerated dissolution, since a higher current density is created on the protrusions, and the electrical resistance above them is less than above the recesses.

The effectiveness of the film increases with increasing its internal resistance. Electrolytes containing salts of weakly dissociating acids or complex salts increase the film resistance.

In addition to the action of the near-anode film, other factors also influence the course of the electrochemical polishing process, in particular mechanical stirring of the electrolyte (or movement of the anode), which favor thinning of the film due to its dissolution or reduction in the thickness of the diffusion layer. Electrolytes of some compositions function normally only when heated. The general rule is that increasing the temperature reduces the rate of neutralization and increases the rate of dissolution of the anode film.

Significant factors influencing the course of the electrochemical polishing process are also current density and voltage.

The figure shows a typical dependence of current density on voltage in a bath during electrochemical polishing.

In the AB section, the increase in current density is almost proportional to the increase in voltage. In the BV section, the regime is unstable, fluctuations in current and voltage are observed. The limiting current corresponding to the SH section characterizes the process of formation of a passive film on the anode. In this case, an increase in voltage over a fairly wide range is not accompanied by a change in current density. Upon reaching the voltage corresponding to the turning point G on the curve, a new process begins - the formation of gaseous oxygen.

Depending on the composition of the electrolyte and the metal being processed, polishing is carried out at modes corresponding to different sections of the curve. Thus, polishing copper in phosphoric acid is carried out at the limiting current mode, when no oxygen is formed.

Bath recipes and modes for chemical and electrochemical polishing

ATTENTION!!! BATHS for chemical and electrochemical polishing are VERY HAZARDOUS for health, ESPECIALLY AT HIGH TEMPERATURES. Therefore, do not try to do this at home, especially if you do not have the necessary skills, knowledge and equipment!!!

Chemical polishing of carbon steel parts.

Chemical polishing of carbon steel parts can be performed in a variety of solutions. One of them (in weight %): 15-25% phosphoric acid, 2-4% nitric acid, 2-5% hydrochloric acid, 81-60% water. Operating mode: operating temperature 80° C, holding time 1-10 minutes. This solution is also used for polishing stainless steel. Chemical polishing of steel parts will also be carried out in the following solution: 25 g of oxalic acid, 13 g of perhydrol, 0.1 g of sulfuric acid, up to 1 liter of water. Operating mode: operating temperature 20° C, holding time 30-60 minutes.

Chemical polishing of stainless steel parts.

Chemical polishing of parts made of stainless steel grade X18N9T is carried out in a solution of the following composition: 40 cm3 of nitric acid, 70 cm3 of hydrochloric acid, 230 cm3 of sulfuric acid, 10 g/l wood glue, 6 g/l sodium chloride, 6 g/l acid black dye . Operating mode: operating temperature 65-70°C, holding time 5-30 minutes.

Chemical polishing of parts made of aluminum and its alloys.

To polish small aluminum parts, use the following solution composition: 60 cm3 of orthophosphoric acid, 200 cm3 of sulfuric acid, 150 cm3 of nitric acid, 5 g of urea. Operating mode: operating temperature 100-110° C, holding time 15-20 s. Polishing of parts made of aluminum-magnesium alloy AMg is carried out in one of the solutions of the following composition: 500 or 300 cm3 of orthophosphoric acid, 300 or 450 cm3 of sulfuric acid (battery), 150 or 170 cm3 of nitric acid.

Chemical polishing of parts made of copper and its alloys.

Chemical polishing of parts made of copper and its alloys is carried out in the following solution: 800 cm3 of sulfuric acid; 20 cm3 nitric acid; 1 cm3 hydrochloric acid; 200 cm3 perhydrols; 20-40 cm3 of chromic anhydride. Operating mode: operating temperature 20-40°C, holding time up to 1-2 minutes. A solution can also be used: 250-270 cm3 of sulfuric acid, 250-270 cm3 of nitric acid, 10-12 cm3 of sodium nitrite. Operating mode: operating temperature 30-40° C, holding time 1-3 minutes.

Chemical polishing of nickel parts.

For chemical polishing of nickel parts, a solution (in weight%) of 45-60% phosphoric acid, 15-25% sulfuric acid, 8-15% nitric acid, 10-20% soda is used. Operating mode: operating temperature 65-70° C, holding time 0.5-1 min.

Electrolytic polishing of carbon steel parts.

The most popular is the so-called universal electrolyte for polishing parts made of ferrous and non-ferrous metals. Its composition is as follows (in weight %): 65% phosphoric acid, 15% sulfuric acid, 6% chromic anhydride, 14% water. Operating mode: operating temperature 70-90° C, anode current density 40-80 A/dm2, voltage 6-8 V, holding time 5-10 min.

Electrolytic polishing of stainless steel parts.

Stainless steel parts (chromium-nickel and chromium-nickel-molybdenum) are polished in a solution (in weight %): 65% phosphoric acid, 15% sulfuric acid, 5% chromic anhydride, 12% glycerin, 3% water. Operating mode: operating temperature 45-70°C, anodic current density 6-7 A/dm2, voltage 4.5-6V, holding time 4-30 minutes (for stamped parts 4-6 minutes, for parts after welding or heat treatment 10 -12 min, for cast sandblasted parts made of steel X18N9T about 30 min).

Electrolytic polishing of parts made of aluminum and its alloys.

For polishing parts made of aluminum and AMg and AMts alloys, an electrolyte with the following composition (in weight %) has proven itself well: 65-70% orthophosphoric acid, 8-10% chromic anhydride, 20-27% water. Operating mode: operating temperature 70-80° C, current density in a freshly prepared solution 10-30 A/dm2, in a solution saturated with salts 10-20 A/dm2. Exposure time is 5 minutes or more. Reversing when using a freshly prepared solution tа-10 sec, tk — 2 sec; when using a solution saturated with salts, tа - 10 sec, tk - 5 sec. For polishing parts made of D16-T duralumin, the following solution composition (in weight %) is recommended: 40% sulfuric acid, 45% phosphoric acid, 3% chromic anhydride, 11% water. Operating mode: operating temperature 60-80° C, anode current density 30-40 A/dm2, voltage 15-18 V, exposure time - several minutes.

Electrolytic polishing of parts made of nickel and nickel coatings.

For polishing nickel parts, the following solution is recommended: 1200 g/l sulfuric acid, 120-150 g/l phosphoric acid, 15-20 g/l citric acid. Operating mode: operating temperature 20-30° C, anode current density 30-50 A/dm2, holding time up to 1 min. A 70% sulfuric acid solution is also used for polishing. Anode current density 40 A/dm2, temperature 40°C, process duration 30 seconds.

Electrolytic polishing of parts made of copper and its alloys.

To polish these parts, the following electrolyte is used: 1200 g/l orthophosphoric acid, 120 g/l chromic anhydride.

Operating mode: operating temperature 20-30°C, anode current density 35-50 A/dm2, holding time 0.5-2 min. A one-component solution of orthophosphoric acid is also used at a temperature of 18-25°C; anodic current density for parts made of copper 1.6 A/dm2, for parts made of copper alloys 0.8-1 A/dm2, exposure 10-20 minutes. Literature:

Bartle D. Mudrokh O. Technology of chemical and electrochemical processing of metal surfaces. - M., 1961. Garber M.I. Decorative grinding and polishing. - M., 1964. Jacquet P. Electrochemical and chemical polishing. - M., 1959 Maslovsky V.V. Dudko P.D. Polishing of metals and alloys. - M., 1974. Pyandrina T.N. Electrochemical processing of metals. - M., 1961. Tegart A.S. Electrolytic and chemical polishing of metals. - M., 1957. Shchigolev P.V. Electrochemical and chemical polishing of metals. - M., 1958.

When using material from this site, you must install active links that are visible to users and search robots.

Applications

Due to its ease of operation and usefulness for polishing irregularly shaped objects, electropolishing has become a common process in semiconductor manufacturing.

Since electropolishing can also be used to sterilize parts, the process plays an important role in the food, medical and pharmaceutical industries.

It is commonly used in the post-production of large metal parts such as washing machine drums, marine and aircraft hulls, and automobiles.

Although almost any metal can be electropolished, the most commonly polished metals are 300 and 400 series stainless steel, aluminum, copper, titanium, and nickel and copper alloys.

Ultra-high vacuum (UHV) components are typically electropolished to have a smoother surface to improve vacuum pressure, gas removal rate, and pumping speed.

Electropolishing is commonly used to prepare thin metal samples for transmission electron microscopy and atom probe tomography because the process does not mechanically deform surface layers as does mechanical polishing.

Electrochemical metal polishing technology

When electropolishing metal, its surface becomes shiny. The technological process consists of a number of operations:

- The workpiece is first subjected to mechanical processing in order to bring the surface roughness to class 6–7.

- Flushing to remove dirt.

- Degreasing.

- Connection to a positively charged electrode.

- Electrochemical polishing.

- Washing in an alkaline environment to eliminate acid residues.

- Drying. For this, hot air or sawdust is used.

- Soaking parts in hot oil heated to a temperature of 120 °C.

Polishing removes irregularities from the surface of the part. Therefore, any process is accompanied by:

- Macropolishing. At the same time, large protruding peaks are dissolved.

- Micropolishing. Small irregularities are smoothed out.

The metal is polished directly under the film. It is carried out through the exchange of electrons and ions between the anode and the electrolyte. The thickness of the formed film is always less on the protruding parts of the peaks of the irregularities. It is here that enhanced dissolution of the metal occurs. In the recesses the film layer is thicker, and here the exchange of charged particles is reduced.

The formation of a viscous film is thicker in the depressions of irregularities

There are other factors that affect the speed of surface polishing:

- stirring the electrolyte;

- an increase in its temperature;

- increase in current and voltage.

All these factors reduce the surface layer, which speeds up polishing.

Each product has its own time mode. Depending on the duration of the procedure, the removed layer of metal increases proportionally. This should not be allowed, because the surface roughness, having reached its level, remains unchanged. Unnecessary dissolution of the product layer occurs, which does not affect the quality of the surface.

Electrolytic plasma polishing

During electrolytic plasma polishing, similar processes are observed. However, here solutions of ammonium salts are used as a medium. Under the influence of a high voltage of 200–350 V, a vapor-gas shell is formed on the surface of the part, which is the anode. It is formed due to the boiling of the electrolyte. An electric current constantly flows through it, causing the appearance of plasma discharges, which have an effect on smoothing the surface. As a result, the polishing time is up to 5 minutes, and the removal of small burrs takes a few seconds.

Electroplasma polishing

Differences between electropolishing and chemical polishing

Electropolishing, like electroplasma processing, differs from a chemical process in that an electric current is supplied through the electrolyte.

When chemical polishing, the product is lowered into a container with a chemical solution of acid or alkali. This is where the surface layer dissolves. This is accompanied by rapid boiling of the contents of the vessel. The part acquires the desired roughness in a few seconds. Unlike electropolishing, this method is less expensive. No sophisticated equipment is required here. But there are also disadvantages:

- Difficulty in controlling the progress of the process.

- Without the use of electric current, the quality of the resulting product is lower. It has no shine. Therefore, non-ferrous metal products that have a complex configuration and are not subject to high requirements are more likely to be subjected to this processing method.

Electroplasma polishing equipment.

The set of electroplasma polishing equipment includes:

- steel bathtub with a special protective casing and lifting mechanism; this layer protects from vapors, and the mechanism ensures convenient and safe immersion of metal products;

- a transformer with a certain power range is connected to the bath (the range is selected in accordance with the performance of the installation, the total area of polished surfaces);

Additionally, a stand with a control element and monitoring sensors is installed.

The installation allows both mechanical and automatic control. It must be equipped with a protective relay that turns off the equipment in case of overheating. Electroplasma polishing of stainless steel is considered the most effective and safe.

The installation itself is connected to an industrial power supply with a voltage of 380 V and a standard frequency of 50 Hz. The transformer has a power of 400 kW, which corresponds to the size of the submersible metal structures. The bath is connected to a pipeline with running water and a compressed air supply system. Must be equipped with a hood. The entire installation takes up 10 m2 in area.

- There is no need to specially pour a foundation under the EPP.

- The device itself has a simple control system.

Features of electroplasma polishing.

Using EPP, you can not only remove burrs and roughness from the surface of a product, but also achieve the highest possible cleanliness class. After processing, even small inclusions of abrasives disappear, scale and irregularities in the areas of welds are removed. There are also no traces of discoloration that spoil the aesthetic appearance.

Thanks to the proven technique, electrolyte-plasma polishing is completed in a few minutes. Ion plasma polishing is considered especially effective in relation to steel alloys with a high chromium content - it is this element that allows you to achieve a beautiful mirror shine. Also applies to all other stainless steels.

Proportions for creating a chemical composition

Polishing is carried out in special baths

It is important to remember that their components are toxic substances and hazardous to health, especially if heating is used, so all components must be handled with the utmost care, observing the required safety precautions

Products made of non-ferrous or ferrous metals can be processed using a universal composition that will have the necessary effect. To do this, add all the components, observing the proportions. Phosphoric acid makes up the base - 65%. Sulfuric acid should be 15% and 14% ordinary water. Chromic anhydride occupies 6%.

Stainless steel can be polished with a similar composition, only it should contain 13% water, and you should also add glycerin in a ratio of 12%. Parts can sit in the bath for up to half an hour, although stamped items require less processing time.

Equipment and materials

To electropolish metal, you need direct current sources with low voltages and tools to adjust the electrical mode. Electrolytic baths must be equipped with heaters that maintain the temperature of the chemical solution. They are placed in a durable shell located on the inner surface of the bath, lined with chemical and heat-resistant materials.

To comply with safety regulations in laboratories, glass, porcelain and ceramic materials are used for lining the internal structures of the electrolytic bath. In laboratory conditions, the current source is rectifiers made of selenium or germanium. Depending on the required voltage, it is possible to install several rectifiers.

Polishing steel workpieces requires adjusting equipment. To adjust the current value in industrial conditions, use the primary winding of a transformer connected to rectifiers. With its help, stepless current regulation is carried out by changing voltage values.

Electrochemical polishing of metals is carried out using electrolytes based on sulfuric, phosphoric and chromic acids. Additionally, glycerin is added, which increases the total viscosity of the solution. All electrolytes must be mixed in the correct proportions. The following table shows the ratio of acids for polishing parts made from different types of metals:

Carbon steel Stainless steel Aluminum Duralumin

Phosphoric acid 65% 65% 70% 45%

Sulfuric acid 15% 15% – 40%

Chromic anhydride 6% 6% 10% 3%

Water 14% 12% 30% 11%

Glycerin – 12% – –

Fundamentals of electrolyte-plasma processing of metal products

The electrolyte is an aqueous solution of salt. The type of salt, solution concentration, and type of additives are selected depending on the type of metal being processed.

When the metal is lowered into the electrolyte, under the influence of current lines converging on the part from all sides of the bath, the electrolyte boils at the surface of the part, forming a vapor-gas shell, which begins to separate the surface of the part from the electrolyte, stopping the current. At this moment, the entire operating voltage is applied to a thin layer of the vapor-gas shell, causing the movement of gaseous ions. At the same time, steam condenses on the electrolyte adjacent to the surface of the part, and the thickness of the vapor-gas shell decreases.

At a certain moment, the electrolyte in the form of a bridge touches the protrusion of the part, a current surge occurs, the electrolyte bridge boils, and as a result, the surface of the part is affected and the insulating properties of the vapor-gas shell are restored.

These phenomena occur on the entire surface of the part immersed in the electrolyte, eliminating protrusions and polishing the metal surface. In this case, the surface cleanliness improves by three to four grades, small protrusions are removed and large ones are smoothed out, the part acquires a stable (long-term) metallic shine, sharp edges are dulled, and burrs with a base thickness of less than 0.3 mm are removed.

During processing, fatty contaminants, some types of paint and varnish coatings, electrochemical and vacuum plasma coatings are completely removed from the surface of the part.

The embedded abrasive and other foreign inclusions of metal are also removed, which, together with polishing the surface and exposing the pure structure of the metal, provides good preparation for the subsequent application of various types of coatings to the surface of products.

These features make electric pulse polishing technology suitable for use in mass and serial production. It has the ability to fully automate the technological process, simplicity and availability of devices for its implementation. The simplicity and versatility of the process, the high quality of polishing, the possibility of simultaneous polishing of a large number of parts in a given bath and, accordingly, the high productivity of the process distinguishes and distinguishes this method of polishing from others as a progressive and highly effective process.

In terms of productivity and economic effect, it is 3–4 times higher than the mechanical method and 5–6 times higher than the electrochemical method.

Before polishing products (especially if they are coated with grease, etc.), it is advisable to degrease their surfaces. This is due to the fact that fatty contaminants settle on the walls of the bathtub in the form of a black coating. Degreasing can be carried out in any way; it is only important that no foreign substances are introduced into the polishing bath along with the parts.

For degreasing, the following solution composition can be recommended:

| caustic soda, GOST 22-63-79 | 20-40 g/l, |

| soda ash, GOST 5100-73-40 | 40-50 g/l |

| sodium phosphate (tri-mixed), GOST 201-76 | 20-40 g/l |

| water, GOST 2874-82 | rest |

The electrolyte in the working bath during the polishing process should have a temperature of about 80°C. This is the most optimal temperature to ensure high-quality polishing process. The electrolyte is heated by heating elements built into the working bath. It is possible to heat the electrolyte by the polishing process itself, using small parts in the form of thin pins, placing them vertically.

During the processing, due to the formation of a vapor-gas shell and its constant condensation on the electrolyte surrounding the part, a large amount of heat is released, which heats the electrolyte and can bring it to a boil.

As the temperature rises, the current consumption decreases, the metal removal correspondingly decreases and the processing time lengthens. When the boiling point of the electrolyte is reached, the polishing process practically stops. Therefore, the electrolyte must be cooled during operation. This is done due to the presence of a cooling jacket in the bath.

During operation of the installation, hydrogen is released around the perimeter of the bath, and oxygen and water vapor are released onto the parts, so work on the installation is allowed only with appropriate ventilation.

The current consumption during processing depends on the area of the parts immersed in the electrolyte and on the temperature of the solution. As the area of the parts increases, the current increases; as the temperature of the solution increases, the current decreases.

In this regard, a situation may arise when, with a hot electrolyte, a certain number of workpieces consume the permissible processing current. If the same number of parts is immersed in a cold electrolyte, the current will exceed the permissible level for the installation several times, which will create an emergency mode and trigger the current protection.

Likewise, it is prohibited to apply voltage to a lowered suspension with parts in the electrolyte; this will lead to a significant current overload, since the rated current is only intended to maintain the existence of a vapor-gas shell, which is created around the part during slow lowering. When voltage is applied to a lowered part, a significant amount of energy is required to create the entire vapor-gas shell. Therefore, it is necessary to apply voltage to the raised suspension with parts, and then slowly lower it into the electrolyte.

For a stable anodic process to occur, it is necessary that the cathode area be at least 5 times larger than the area of the processed products. The electrical contact between the current conductor and the workpiece must be rigid and ensure heat-free current flow through the workpiece.

Polishing “sustainably” is carried out for products of various configurations - flat, curved, complex profile. The presence of deep holes (where the depth exceeds the diameter of the holes) in the product does not ensure high-quality polishing throughout the entire depth of the thin holes. Inside deep holes (1 > d), polishing of the walls does not occur as they “deepen”; the resulting steam bubbles eject the electrolyte from the hole, which leads to intense splashing. It is possible to close the hole with a special plug made of polyethylene, fluoroplastic, etc., but you need to take into account that the plug will be in a “seething” electrolyte and will experience hydrodynamic shocks. Due to the effects of temperature and changes in size, the plug may pop out, resulting in a sudden overcurrent.

A significant factor influencing the quality of polishing is the outer size of the product. Firstly, the dimensions of the product must be such that when completely immersed in the electrolyte, the product does not touch the walls and bottom of the working bath. Secondly, its surface area should be several tens of times smaller than the surface of the bath. The maximum polishing area is determined by the size of the working bath and the electrical power of the transformer.

Small-sized products are completely immersed in the electrolyte. Larger products can be processed with up to half immersion followed by turning over and processing. A small brown mark that remains at the immersion boundary can be removed by short-term treatment (immersion).

When polishing flat stainless steel surfaces, metal removal is about 2 µ/min per side, and from a sharp edge of a right angle - about 4 µ/min, i.e. twice as much. This explains the rapid dulling of sharp edges.

When processing the surface of parts, the removed metal remains in solution in the form of small particles (iron hydroxide if steel is processed), gradually settling to the bottom of the bath, forming sludge, which is a valuable raw material for paint and varnish and other types of industry.

Electric pulse treatment in an electrolyte can find additional application if it is necessary to remove fatty contaminants from the surface of a part, some types of paint and varnish coatings, electrochemical and vacuum plasma coatings; and also for removing abrasive inclusions from the surface.

The electric pulse method can be used not only for finishing surface treatment and decorative polishing of a wide range of products, but is also very promising in preparing the surfaces of various metals for subsequent coating.

An important factor for the quality of polishing is the correct composition and concentration of the electrolyte.