When connecting wires and microcircuit elements, not a single radio amateur or simply a skilled owner can do without a soldering iron. The abundance of modern models in different configurations on store shelves rather immerses you in doubts than makes it easier to choose the right device. It will be easier to understand if you first familiarize yourself with the main criteria, advantages and disadvantages of each type.

Principle of operation

Parameters are adjusted using a special mechanism. A soldering iron with a thermostat consists of a tip, a housing, a board and a set of resistors in the structure. The design allows for heat adjustment when working with various parts. More expensive samples have variable voltage limits. At each setting, you need to select the appropriate tip to control the outlet temperature. It is important for a novice radio amateur to determine with what parameters a soldering iron is required. Professionals in their field choose reliable models with temperature control. The equipment has good soldering performance, the action is carried out by meeting the necessary criteria. A different load is applied to each product; thermal stabilization allows you to select the boundaries necessary for high-quality soldering of various products.

Network soldering iron with temperature control

The temperature is selected in accordance with the description of the material and method of operation of the equipment used.

Types of soldering irons

Soldering devices are divided into several types, which differ in both structural elements and purpose:

Electric soldering irons

Equipped with ceramic/coil heaters. This is the simplest and most affordable type of device. The design consists of a handle, a body with a tip and a heating element inside. The shape of the tip can be in different designs: needle-shaped, cut at one or two angles, quadrangular, curved. The type of tip is selected depending on the task at hand and the materials being processed.

Another type of electric soldering irons are pulse-type devices. Their cost is slightly higher, however, this is justified by the convenience and quality of soldering on printed circuit boards and microcircuits. The operating mode is activated by pressing and holding the start button.

In just a few seconds the tip heats up to the desired temperature. Modern models are equipped with power and heating regulators, which allows soldering not only small, but also large parts.

Electric models are easy to use; just plug it into a power outlet (voltage 220 V) and set the temperature setting (if the model has a thermostat). They have a simple design; if necessary, you can repair the damage yourself.

The power range (from 25 to 200 watts) makes it possible to choose the best option. Pulse soldering irons are also economical, because energy consumption occurs only when the button is pressed. However, it is worth considering that cheap devices quickly burn out. Repairing them is not cost-effective; it is easier to get rid of a broken device. The flaw of the pulse device is the lack of precise temperature settings.

Modern models of electric soldering irons are equipped with power and heating controls, which allows you to solder not only small, but also large parts

Induction soldering irons

They operate using an inductor coil. The tip of the device is coated with a ferromagnetic composition, which ensures automatic maintenance of the tip temperature in a certain range, without requiring technical support from control electronics and a thermostat.

The cartridge is a thin tube, which, combined with lightweight antistatic material, makes the handle quite ergonomic. When working with such a device, your hand does not strain much, and the design allows you to perform soldering more accurately.

Induction soldering irons have virtually no disadvantages, but experts note that all the difficulties in doing the work are associated with the lack of a thermostat.

Hot air devices

They operate by supplying a stream of hot air through a ceramic or spiral heater into the nozzle. Devices of this type are divided into compressor and turbine. The temperature of the supplied jet reaches high levels (100-500°C).

The advantage of these soldering irons is the formation of a large air flow, which makes it possible to solder parts of different sizes. In addition, the cost of such devices is low.

The disadvantages include: a strong flow can blow parts off the workbench, as well as uneven heating of the surface. It is also worth noting that you will need to change attachments to perform different jobs.

Gas devices

Equipped with a burner. It is very convenient to use such soldering irons in places where there is no electrical network. Compact dimensions and low weight make it possible to perform soldering practically in the field. Open fire is used to connect two surfaces. Refueling is carried out using a regular gas cartridge.

One of the advantages is the autonomy of the device. Among the disadvantages: emissions of combustion products into the atmosphere, fire hazard, the need to replace nozzles depending on the planned work.

It is very convenient to use gas soldering irons in places where there is no electrical network

Hammer soldering iron

Represents the most ancient appearance. In modern versions it can be electric or heated over an open fire. The design is a pen with a thick tip, hence the name. Basically, such devices are used for soldering large parts, large-section wires, pipes, and cans.

The main advantages are the availability of self-production and power corresponding to electrical appliances of 100-150 watts. The disadvantages are the lack of temperature control and limitations in use.

The design is a pen with a thick tip, hence the name

Design

When choosing a tool, it is important to select the required setting sizes. It is important to pay attention to the adjustment element; a high-quality soldering iron has a switch with indicated minimum and maximum temperatures. The toggle switch is responsible for switching the voltage; a simple design may not meet the requirements when soldering material. Thermal stabilization allows you to avoid overheating of the tip when the tool is idle for a long time. A soldering iron with temperature control allows you to set the amount of heat generated by the tip during small jobs. Operating modes:

- Operating capacity can vary from 60 to 140 W, the average output voltage is 80 W.

- Power comes from a 220 V power supply.

- The heat range starts from 185 °C, for low-melting solders and soft materials, and reaches 450 °C for more refractory products.

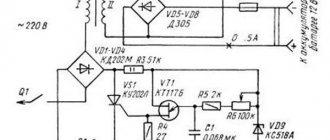

Soldering iron circuit with thermostat

The adjustment is made using a special toggle switch; the format setting error is 10 °C.

Soldering iron 60 W with temperature control 907 (GJ907)

In this review, we will look at one of the most inexpensive Chinese soldering irons with temperature control and replaceable tips: model 907 (GJ907) , 60 W. I’ll say right away that this soldering iron has nothing to do with the Hakko 907 soldering irons for soldering stations. Usually on AliExpress, eBay, Bangood and other Chinese trading platforms this product is called something like “907 60W soldering iron Adjustable 200-450C”. The cost of a soldering iron at the moment (June 2015) is about $10.

For example: in the AliExpress store

Specifications of GJ907 soldering iron:

- Power: 60W

- Temperature: 200…450°C

- Input voltage: 220…240V

- Insulation resistance: 100MΩ

- Length: 240mm

The soldering iron is supplied in a transparent package with some information in Chinese.

The soldering iron tip can be grounded if necessary. And it is necessary! Because There is no decoupling from the mains voltage and interference can kill field-effect transistors, microcircuits and other sensitive elements when soldering. According to reviews on the Internet, such cases have happened. For grounding, a wire with a clamp comes out of the soldering iron.

The power plug, as you can see in the photo, is the most common one; no adapters are needed.

The soldering iron is equipped with a temperature regulator, which can be adjusted from 200 to 450 °C. If the LED is on, then the soldering iron is heating up. Once the desired temperature is reached, the LED goes out. Judging by the diagram, it is thermocouple feedback that is used here, and not stupid power adjustment, which is an undoubted advantage of an inexpensive soldering iron.

The soldering iron tip is removable and non-burnable.

The tip is not compatible with the 900s. For comparison, in the photo below: the tip is 900 at the top, 907 at the bottom. They are different in both length and diameter.

Dimensions of 907 tips:

- External diameter: 7.5 mm

- Inner diameter: 6mm

- Depth: 35 mm

- Length: ~ 56 mm (depending on tip shape)

Dimensions 900 tips:

- External diameter: 5.4 mm

- Inner diameter: 4.2mm

- Depth: 24.5 mm

- Length: ~42 mm (depending on the shape of the tip)

But 907 tips for it are also freely sold on AliExpress. Search for soldering iron tips GJ907 on AliExpress.

According to the manufacturer and many online resources, the GJ907 has a ceramic heater. In the photo below you can see a step, which, according to some radio amateurs, indicates that this is real ceramics. There is a lot of debate on the Internet about what type of heater this soldering iron has: ceramic or nichrome in a ceramic tube. We'll find out later.

The heater itself is labeled 907H 220V 60W and is freely sold on AliExpress for about $2.

There are 4 wires coming out of the heater: two wires for the temperature sensor and two wires for the heating element. On the one hand, the presence of a temperature sensor is a plus, but on the other hand, the fact that it is located in the heater itself is a minus, because There will be inertia and a delay in the activation of heating. The resistance of the heating element is 890 Ohms (two white wires). Thermal sensor resistance at room temperature (red and blue wires): ~4 Ohms. The voltage on the heating element is 220V.

Control board. Operator IC2: HA17358 (LM358). A MAC97A8 triac is used to control the heating element (PDF)

The circuit is in many ways similar to the CT-96 soldering iron circuit:

As you probably already saw in the photo, this soldering iron has two trimmers VT1 and VT2. One sets the upper temperature range, the second sets the lower one.

As can be seen from the diagram, there are no scarce parts, SMD is also not used, and in case of failure, the burnt-out part can be replaced. In general, in terms of maintainability, the soldering iron is also quite good, because... and something can be replaced in the board, and the heater itself and the tips are freely sold on AliExpress.

Ceramic or nichrome?

Advantages of a ceramic heating element: - fast heating - durability Disadvantages: - fragile (and more often cracks from uneven heating and incorrect tips than from mechanical influences)

Advantages of a nichrome heating element: - cheap - not afraid of shocks or falls Disadvantages: - not very durable - takes longer to heat up

But if we objectively compare it for use in amateur radio practice or for domestic use, then of course a nichrome heating element will not heat up, say, 10 times longer than a ceramic one, and in practice you will not notice much of a difference in the heating rate. As for the service life, this is also a controversial issue, because in my opinion, this is relevant for repair shops, where they operate a soldering iron for several hours a day. And for an ordinary radio amateur, when used for one hour a day, a cheap soldering iron will most likely experience some other breakdown than the nichrome heater filament burning out. Therefore, if you are a radio amateur, then in any case the nichrome will not burn out in 1-2 years of use.

So what type of heating element is used in this soldering iron?

The photo speaks for itself. Those. It's a nichrome heater stuffed into a ceramic tube. In essence, we have a nichrome spiral, to which is added one of the disadvantages of ceramics - fragility. As you can see, the presence of a step at the end of the heater does not at all mean that this is ceramic!

Well, what else did you want for ten bucks?

Parameter measurements

So, let's measure the power consumption of the soldering iron.

As you can see, an honest 60 watts.

When the set temperature is reached, the heating is turned off, the LED goes out and the soldering iron consumes 600 mW.

The soldering iron tip was connected to a temperature meter (with a K-type sensor). Additionally, the readings were also checked using a thermocouple from a multimeter - no large deviations were found over the entire temperature range.

When set to 200°C (the lowest value), the actual temperature of the tip of the soldering iron was 250°C! Those. as much as 50°C more. I tried to set the lower threshold using adjusters, but the best I could achieve was 235°C, the temperature stubbornly refuses to go below this value.

When the value was set to 450°C, the actual temperature of the tip was about 415°C, i.e. the soldering iron did not reach 35°C. But such high temperatures are, in principle, not necessary, because the sting will burn all the time. If you wish, you can play with the trimmer.

The time it took to raise the temperature from a cold soldering iron to the set temperature of 200°C (real 230-250°C) was just under a minute. At the same time, the inertia of the tip is about 3 seconds, i.e. From the moment the heating is turned on, until the temperature changes on the tip, about 3 seconds pass. The temperature meter itself reacts to temperature changes almost instantly.

conclusions

Cons: - pseudo-ceramic heater - temperature indicators do not correspond to real tip temperature readings - in my opinion, the handle is not very comfortable (maybe a matter of habit, especially after working with a soldering station) - according to reports from some users who have a similar soldering iron - not very reliable

Pros: - honest 60 watts - low cost - ability to adjust temperature - replaceable tips, freely sold on AliExpress - ability to replace the heater in case of failure (also freely sold on AliExpress)

Is it worth buying or not? If you are very limited in money, you can take a risk, but it’s still better to pay an extra $20-30 and take something more reliable.

Tags:

- Soldering iron

- Soldering iron 60 Watt

Equipment

The radio materials tool contains some accessories, the direction and characteristics of which may vary. It is necessary to familiarize yourself with the complete set in order to avoid downtime and poor-quality connections. The average soldering iron with a temperature controller has:

- A set of soldering tips usually consists of 5 items to perform various actions.

- Thermal sensor for own adjustment of the tool.

- Heating indicator, a regular LED that signals when the set temperature has been reached.

When purchasing, you should pay attention to the length of the wire; the length should be at least 1.5 meters; in this case, you probably do not need to use extension cords. The heating component can be of two types:

- ceramic;

- made of nichrome wire.

Temperature-controlled soldering iron included

The heating device must have a change of tips to perform different processes. Cheap products do not provide such a modification, so you need to choose a tip according to the type of action.

How to choose the right soldering iron

When choosing a soldering iron, you should be guided by basic criteria, such as its power, thermal stabilization and, of course, the price of the device.

Power

This indicator depends on the type of work. A power of up to 25 watts is suitable for soldering small electronic parts, a power of 40 watts is suitable for working with thick wires. Higher power, from 100 watts and above, is suitable for soldering large parts. The advantages of high-power soldering irons are their reliability and a wide range of functions, but their disadvantage is that such devices are not used in everyday life.

The power of a home soldering iron should be from 25 to 40 watts. A lower power rating will result in soldering taking a long time and the quality of the result will be questionable. Excessive power will make it impossible to solder parts that could simply burn out.

Thermal stabilization

Soldering irons with thermal stabilization significantly speed up the soldering process, improve its quality, and it becomes much more convenient to work, as they provide the opportunity not only to accurately set the temperature required for work, but also to maintain it. This is convenient for both beginners and professionals. The temperature regulator can be either in a separate case or built into the design of the soldering iron.

Advantages:

- automatic maintenance of the desired temperature;

- the danger of overheating is eliminated;

- With one soldering iron you can perform work that requires varying degrees of heating;

- there is no need to clean the soldering iron tip from scale.

Flaws:

- the original tip is not universal;

- fakes are common;

- takes a long time to heat up.

Types of regulators

Devices for connecting various types of radio components have several types of characteristics. Soldering stations with heat and load adjustments are produced by the manufacturer with different parameter settings. Main varieties:

- Changing the voltage and power of the node is possible using a triac. This modification is most common when using heating components in radio engineering.

- Thyristor type adjusting element.

- Modification to increase the performance of the device allows you to change the output force to the required values.

- The indication makes it possible to recognize in which mode the heating is being carried out.

- Low-voltage controllers are used in designs designed to operate with a voltage of no more than 36 Volts.

You can probably make components that have adjustable temperature volumes with your own hands. A simple structure without interference is used, which makes it possible to extend the service life of the heating element. The galvanic component is considered reliable; its versatility allows the design to be used with various modifications and models.

Low frequency devices

A design feature of the device is the repair of thin connections that can be burned through in the usual way. Stabilizers for 12 and 36 V are used, depending on the output power. There are options with a microcontroller, which is installed in products when operating with sensitive parts.

It is important to understand that the operation of such devices will be less productive.

The performance is not enough to quickly heat up the tip; the maximum degree of heating does not reach larger mechanisms.

Device selection

When choosing a soldering iron, you should carefully read the technical characteristics and operating features. There are important criteria that a quality device must meet.

Therefore, experts recommend taking them into account so that the purchase turns out to be useful and profitable:

- For home use, it is better to choose universal devices with a power of 20-40 watts

Dimensions. Ease of use depends on the dimensions of the tool, so you should not choose volumetric models for soldering. However, close proximity of the handle can cause your hand to heat up, which can even lead to burns. It is recommended to give preference to medium sizes, which would allow soldering to be carried out safely and comfortably.

- Power. Each type of soldering requires the use of a soldering iron of a certain power. It’s so easy to make a choice knowing the exact parameters of the materials used. For home use, it is better to choose universal devices with a power of 20-40 watts. If you plan to work with microcircuits, then a power of 3-10 watts will be quite enough. A device with a power of 60-100 watts can solder thick wires. To solder large metal parts, you will need power up to 250 watts. It is worth remembering that purchasing a powerful device (over 100 W) for household needs is impractical. It will be inconvenient to work with a massive device, and most likely you will not have to use it for its intended purpose.

- Voltage. There is no exact factor that determines the optimal voltage parameters. In order not to purchase additional equipment (step-down transformer), it is recommended to choose a model designed for a 220 V network. Models 36, 12 and 6 V should be connected only through an optimizer.

- Heater. The models produced are equipped with ceramic or spiral heating elements. Ceramic heats up quickly, but the device must be handled with extreme caution. If dropped or hit, it may break. Breakage can also be caused by liquid entering the heating element and temperature changes. A spiral heater is more reliable and its cost is an order of magnitude lower. However, the rate of temperature change is slower.

- Soldering iron manufacturers:

- Topex;

- MONACOR;

- Steinel;

- Dremel

- Dayrex;

- Lukey et al.

PSTrading;

Preference should be given to high-quality products from well-known companies, as they value their reputation and provide warranty service.

- sufficient cord length;

It is worth remembering that purchasing a powerful device (over 100 W) for household needs is impractical

Copper fixtures

The structure is made of copper wire twisted in a spiral pattern. Copper is capable of carrying the low current produced by small transformers. The adjustable heating components are equipped with a temperature sensor, which is responsible for controlling the tip. The thermocouple is installed on the working tip, which allows you to adjust the temperature level to the required state. The copper spiral does not pass electric current through itself, the performance of the unit stops, or the load indicator changes. Types of copper heaters:

- with wire wound around the body, preventing voltage from reaching the tip;

- The insulated structure avoids heat loss when using the device.

Homemade thermostat

The quality of copper depends on performance; adding additives in order to save money by the manufacturer can significantly reduce the service life and damage the parts being repaired.

Ceramic heaters

Unlike products equipped with nichrome wire, the ceramic component can last longer than its competitor. The ceramic element allows operation at the maximum permissible thresholds, the resistance is minimal. Electrical voltage spreads along the tip, resulting in heating. Ceramic heaters require attention; under mechanical stress they are destroyed and become unusable.

Soldering iron with ceramic heater

The price of a soldering iron with a ceramic tip is higher, so it is important to choose high-quality material. Durable and reliable operation is achieved through careful use of the component.

Soldering iron cost

Prices directly depend on the characteristics and functionality, type of heater, the presence or absence of a temperature controller, and the brand that produces the device. You can buy an inexpensive soldering iron that has good characteristics and is suitable for home work, or you can choose a more expensive model with additional functions.

Inexpensive and budget soldering irons include devices costing from 80 to 600 rubles. Most often these are electric soldering irons with a copper tip and a power of 40 watts. This also includes ceramic soldering irons with a nichrome heater, a nickel tip and a power of 30 to 40 watts - their cost ranges from 300 to 600 rubles.

Medium-priced soldering irons are pulsed, with a power of 70 watts (from 300 to 700 rubles), wireless and USB soldering irons, with a low power of up to 10 watts (from 300 to 1300 rubles).

A soldering iron with a durable tip and a film-ceramic heater with a power of 50 watts costs from 2500 to 5200 rubles.

Advantages and disadvantages

When choosing a device for soldering radio components, you should pay attention to the technical documentation. You should not ignore the advice of a professional, because... Years of experience can help beginners choose the right device. The choice between a ceramic and a conventional device can lead to a dead end; an inexperienced craftsman should familiarize himself with the negative and positive sides of each product. Advantages of copper tips used with soldering iron temperature control equipment:

- the affordable price makes it possible for a novice master to purchase it;

- resistance to mechanical stress allows you to avoid breakdowns of the mechanism when the process has not yet been fully mastered.

Negative sides:

- Copper wire is not known for its durability due to exposure to high heat levels over a long period of time. It is possible to avoid overheating by pausing during the process; the method under consideration keeps even cheap models intact.

- Slow heating of the electrical connection.

Ceramic soldering irons, including a thermostat, have the following advantages:

- the integral system makes it possible to avoid device failure;

- the configured temperature readings are available immediately after connecting to the network, some models heat up in less than a minute;

- reliable unit subject to operating rules.

When using any device you are faced with a number of negative aspects, ceramic products are no exception. A destroyed tip is replaced only with the original one, due to the design features of each model. If dropped, the heating component cracks and loses its working properties.

Why increase power?

It is not advisable to purchase several options for performing soldering work of various types. Increased intensity is used for short-term exposure to elements; fragile parts may not withstand high temperatures and become unusable. Burnt tracks located near the controllers can affect the operation of the part being repaired.

Soldering station with thermostat

Less power output contributes to slow heating and low temperatures. With the presented indicators, during the soldering process it is necessary to act on the material longer before melting begins. Long-term heating can also have a detrimental effect on the board. To avoid serious consequences, you should correctly select the level of return through regulation. For example, to adhere massive objects, it is necessary to increase the intensity until the time of exposure to the elements is less than the melting point and provided that the appropriate solder is used.

How does a soldering iron work?

Normal operation of a soldering iron is possible if two basic conditions are met: it must melt the solder and maintain the most suitable temperature. It is necessary to take into account the wide range of melting temperature 150-320C, as well as the degree of heat resistance of the elements being connected. With prolonged heating, many parts become inoperative, their insulation properties are reduced or completely lost. Connecting elements with a large area and mass increases the dissipation area of the contacts, so in such cases a power and temperature reserve is required.

Conventional unregulated electric soldering irons are not capable of meeting the conditions required for normal soldering. In this regard, increasing or decreasing the temperature is carried out using a special regulator connected directly to the device. It is based on resistors, due to which changes in temperature, voltage and power occur.

There are recommendations for choosing the most optimal operating temperature:

- During normal soldering, without using parts sensitive to overheating, the tip of the device should, on average, heat up 10C above the melting point of the solder, when all of it becomes liquid, and not just some part.

- In the case of connecting large contacts, it is not the heating that should be increased, but the power of the soldering iron itself. A device with low power, although it maintains a high temperature, will still not be able to overcome dissipation. Compensation for massive parts is carried out due to the appropriate sizes of the tip, heated by high power.

- Before soldering, you need to carefully study the technical data sheet for each radio component, which displays the maximum permissible heating temperature of the housing. It is recommended to change the temperature at which soldering is performed by adjusting the power, rather than simply increasing the degrees. This will reduce the contact of the part with the sting to a minimum. That is, in a short period the solder melts, and the temperature of the case only rises slightly.

Switches and Dimmers

A simple type switch allows you to select a position in two directions. The unit is operated at minimum and maximum output values, allowing only to save energy. At the minimum level, the tip is maintained by the required degree of heating on the stand; pressing the switch warms it up. With a product equipped with the specified type of switch, it is difficult to perform high-quality fusion of metals, because There is no full parameter setting. Dimmable varieties of adjustable devices allow you to select important parameters.

Homemade dimmer for soldering iron

The device includes a dimmer, which is present in the grid between the power cable and the heating element. The adjustment is made by monitoring the voltage; these mechanisms are popular among beginning radio amateurs due to their low price.

Top Ten

Today there is a rating of soldering irons from the best manufacturers, which includes high-quality and popular devices:

KVT XZ-1 - 10th place

Non-contact multifunctional gas soldering iron. Well suited for soldering in hard to reach places. It has three modes of operation - like a soldering iron, like a heat shrink hair dryer and like a gas burner. Its maximum temperature is 1300 degrees, and the temperature is 580 degrees. The design has a built-in system for smooth adjustment of the operating temperature, and the kit includes a case and 4 nozzles. Its cost is from 1900 to 2912 rubles.

Soldering iron KVT XZ-1

Learn more about the soldering iron in the video:

Gas soldering iron. It is a universal soldering station suitable for home soldering. It heats up quickly, and its continuous operation time is 75 minutes. Its maximum heating temperature is 1200 degrees, the device comes complete with 4 replaceable nozzles, and its cost ranges from 2680 to 4609 rubles.

Dremel VersaFlame Soldering Iron

Sigma 200W - 8th place

A pulse soldering iron made in the shape of a gun with a shock-resistant body. It has a built-in transformer, and the tip of this soldering iron is made of high quality steel. The set includes 3 replacement nozzles. The maximum heating temperature is 400 degrees. Its cost is about 800 rubles.

Video review of the soldering iron:

Hot air soldering station with a power of 350 watts and a maximum temperature of 480 degrees. It has an impressive weight, but at the same time it is simple and easy to use. The set includes a stand and holder for the hair dryer, which is equipped with an automatic shut-off function. Suitable for soldering microcircuits, as well as for repairing household appliances and electrical equipment. The device is equipped with a thermostat, and its cost ranges from 5250 to 6590 rubles.

Soldering iron Lukey 852D Plus

REXANT ZD-708 — 6th place

This is an electric soldering iron with a ceramic heater, equipped with a power regulator ranging from 30 to 50 watts. The conical tip heats up quickly, and the device itself is reliable. Its heat-resistant handle is made of transparent plastic. The maximum heating temperature is 200-450 degrees. Its cost is from 590 to 1099 rubles.

Learn more about the soldering iron in the video:

Hot air soldering station, with a powerful air flow, adjustable power of 350 watts and a temperature of 480 degrees. The temperature is also adjustable, and the price of the device ranges from 449 to 5890 rubles.

Soldering iron Lukey 852D Plus FAN

CT-96 (CT-Tools) - 4th place

Ceramic soldering iron with temperature regulator - a special sensor sets the operating temperature (from 100 to 400 degrees), heating occurs within two minutes and the set heating level is stable during soldering. Its power is 50 watts, and the cost is about 530 rubles.

Soldering iron CT-96 (CT-Tools)

PROXXON EL 12 (28140) - 3rd place

An electric soldering iron with a temperature controller that provides constant, stabilized heating of the tip. Heats up quickly, within 10 seconds. The body of the soldering iron is protected from heat; in addition, the device is equipped with a backlight, is lightweight, and has an operating temperature of 250 degrees. The cost of such a soldering iron is from 1300 to 1550 rubles.

Soldering iron PROXXON EL 12 (28140)

REXANT HT-019 (ZD-210) — 2nd place

Electric soldering iron with vacuum suction of molten tin, well suited for home work. Much more convenient than soldering irons with conventional solder suction. The handle of the device is made of impact-resistant plastic. The power of the soldering iron is 40 watts, the operating temperature is 450 degrees, and the cost is from 280 to 520 rubles.

Soldering iron REXANT HT-019 (ZD-210)

Dremel VersaTip - 1st place

Dremel VersaTip non-contact gas soldering iron. Convenient, lightweight, it is versatile and can perform the functions of a soldering iron, gas torch, hot knife and hair dryer. The operating time at minimum power is 90 minutes, and at maximum power – 30 minutes. Warming up occurs quickly, its maximum temperature is smoothly regulated, and reaches a maximum of 1200 degrees. The kit includes 6 nozzles, and the price of the device is from 2545 to 3199 rubles.

Dremel VersaTip Soldering Iron

Video review of the rating leader:

Control units

More advanced systems have a control unit consisting of a set of regulators and microcircuits. The compactness allows you to place the drawing in the handle of the soldering iron, which is very convenient in the process. The control sensor is located outside the housing, which makes it possible to select an indicator without interrupting the soldering process.

There are soldering irons that have an external power supply. This device makes it possible to work with a stable voltage on a rectified current.

The unit adjusts the parameters of the potential differences in the electrical network, regardless of the modes; with some actions this condition must be observed. The varieties of control units can be confusing; if mobility is important, it is better to pay attention to the internal arrangement. External blocks allow for better contact; a type of soldering station that includes a hair dryer is provided.

Thermostats: simple and complex

The degree of complexity of the design of a particular thermostat for a soldering iron primarily depends on its purpose.

They are available in the following versions:

- The simplest ones, operating in two ranges. Switching the temperature of the soldering iron and operating modes occurs in two fixed positions - minimum and maximum. In the first position, the heating of the device is simply maintained in the intervals between operations, and in the second, the soldering process itself is performed.

- Devices with dimmers connected to a 220 V network through a break in the cable supplying power. Heating adjustment is carried out due to voltage drops. At the same time, there is a reduction in power, which makes this system ineffective.

- The regulator, placed in the housing, is installed in soldering irons with a complex heating circuit. The power supply is also located inside the case along with the regulator. The circuit is considered quite efficient, but does not provide high power for operation.

- The design of the remote power supply is one of the most productive and efficient. It can operate from a 220 V network and has adjustments over a wide range. If necessary, the exact temperature value is set. Provides any power.

- The most multifunctional device is a soldering station. This device can be used not only at home, but also in other conditions. The station is equipped with a control and monitoring module, as well as a spring holder. Additionally, there are tweezers for ease of working with small parts, a hair dryer for heating the soldering area, a heat emitter that warms up the board before group soldering and other elements.

DIY temperature regulator

Making a soldering iron with do-it-yourself adjustment requires knowledge of electrical engineering. If you have experience, it is proposed to make the mechanism from a conventional heating element with a power of 60 watts. High-quality connections can only be made when using a heating value balancer. Assembly is carried out by implementing some modifications and involves the use of available materials. The simplest system includes:

- thyristor model KU101G;

- resistor SP – 1;

- diode operating at a current of at least 1A.

Thermostat circuit for a low-voltage soldering iron

Installation of the model is possible without the use of a board, in a power supply housing of any size. The connection is placed on the resistor body, to which the connector for adjusting the degree of heating is adjacent. The result is an adjustable device with an output power of up to 60 watts. Schematic drawings for more powerful devices include slightly different components. Assembly is carried out on a circuit board; variable resistor R2 is responsible for adjustment, which operates in the range from 50 to 100%. The maximum permissible load is 300 watts, sufficient for a household device. Circuit options depending on the power limiter The power of the device can be adjusted in several ways; the differences lie in the use of a semiconductor controller that performs the necessary tasks. Schemes can be built using several components, depending on the purpose:

- The thyristor works like an electronic switch; the current starts in one direction. The structure is made with three outputs, a cathode, an anode, and a control electrode. Applying a pulse to the electrode causes the thyristor to open; closing occurs after stopping the supply or changing the direction of the current.

- Semiconductors that conduct current in both directions are called triacs. The housing has a control gate and power electrodes; the operation is essentially similar to two connected thyristors.

- The design of control sensors uses parts known to radio amateurs, such as a resistor, diode, capacitor, and microcontroller.

In most cases, a thyristor or triac is used, the precise debugging is regulated using a microcontroller added to the circuit.

Operating rules

It is easy to learn how to use a soldering iron, but even the simplest types of work have rules, the observance of which guarantees a high-quality connection of elements and a long service life of the device.

First of all, you should acquire the necessary materials and tools, the use of which will ensure strong soldering. The main components are solder and flux.

In addition you will need:

- tweezers;

- mounting awl;

- foil fabric;

- special solution for removing flux;

- cotton pad;

- fireproof stand.

The list can be supplemented with other auxiliary tools, depending on the work being performed.

Before turning on the device, you should study the instructions and strictly follow its points. When performing work, the following rules are observed:

- Work must be done away from hot gases and flammable mixtures;

- do not direct the hot stream at a person;

- avoid mechanical impacts with the sting on a hard surface;

- do not touch the soldering iron with wet hands;

- do not immerse the tip in water to quickly cool;

- when choosing a temperature regime for soldering, you need to take into account the thermal conductivity of the material being processed;

- in case of contamination of the working element, carry out cleaning and irradiation in a timely manner;

- use high-quality flux, it is this that determines the ease of soldering metals;

- The surfaces to be treated must be degreased before joining.

The main thing during operation is not to overheat the soldering iron. This will shorten its service life. Choose only good quality consumables.

After soldering, the device remains on the fireproof stand until it cools completely. Before placing in the case, the working parts should be cleaned.

If you need to replace any element of the soldering iron, you should use only original spare parts. Experts do not recommend modifying the device; this can lead to electric shock or failure of the device.

Recommendations for testing and adjustment

When the adjustment knob is rotated, the voltage changes; the test is performed under load, i.e. with the soldering iron turned on. Accurate readings can be obtained using a multimeter. Also, the load level is determined by the connected incandescent light bulb; when the parameters are changed, the light intensity changes. A do-it-yourself voltage regulator helps with soldering work, regardless of the type of material. Varieties of circuits allow you to select exactly the modification that allows you to make a high-quality connection.