Protect your eyes | 09.10.2017

In everyday life it is often necessary to weld products made of non-ferrous metals, in particular aluminum and its alloys. At the same time, proper welding quality can only be ensured by stable arc burning. Without a welding converter and using only an inverter machine, it is difficult to achieve such quality. The solution is to use a welding oscillator, which stabilizes the arc and facilitates its ignition.

Operating principle and purpose

The use of an oscillator allows for non-contact ignition of the arc, which greatly facilitates the welder’s task and also affects the stability of the electric arc during operation.

Although we noted that the device is a separate element, sometimes it is integrated into the welding inverter, that is, the power source and oscillator are in the same housing. With a sufficient amount of knowledge in the field of electronics and electricity, it is possible to make a homemade oscillator. This is what readers usually focus their attention on, since saving money always looks attractive

Let's start by formulating the basic idea of how this device works. When the welding inverter is operating, a voltage of 220 V is supplied to the electrodes. If welding is carried out with alternating current, then its frequency is 50 Hz. “On top” of this voltage, a high potential difference and high frequency are applied in pulse mode. The number of such impulses is usually small. The additional high-frequency current should only ignite the arc. This takes a split second. For a qualitative assessment, it should be emphasized that the amplitude of voltage fluctuations reaches 6 kV, and the frequency is 500 kHz. But due to the short pulse duration, the electric current power does not exceed 300 W.

A laconic question arises among users: “Can an oscillator weld metals using the generated current?” Indeed, this would be logical, but the low power does not allow the metal and additive to melt, so the pulse is used exclusively to break down the air gap. The welder’s task is only to approach the electrode to a distance of approximately 5 mm and press the button. In integrated type oscillators, the button is located directly on the holder. The pulse duration corresponds to the time the button is held. Next, welding is carried out as usual.

High frequency current flows through the dielectric (air) after active ionization. An arc discharge occurs almost instantly. At the same time, the ionized air becomes a conductor, and the main current of the welding machine flows, forming an electric arc. If the welding process is automated and the inverter has a microprocessor, then the oscillator in the process of forming a seam is automatically turned on if necessary, when there is a tendency to extinguish the arc. An example would be a situation with a voltage drop or accidental movement of the welder’s hand to the side. As a result of the operation of the oscillator, you can obtain a high-quality and uniform seam.

Connection

The connection diagram of the oscillator to the main welding machine depends on the design of the device. First of all, the oscillator must be connected to a 220 Volt power supply.

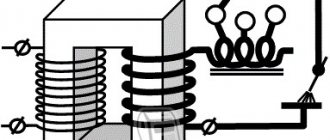

Connection to the welding machine can be of two types: parallel and serial. The figure below shows options for connecting the oscillator, as well as an example of the layout of the device, made in the form of a separate block.

When connected in parallel, the oscillator leads are connected to the welding electrode and the workpiece. In the serial version, the oscillator is connected to a section of the cable supplying the welding electrode.

You can find a large number of diagrams and descriptions of this useful device, using which it is easy to make it yourself. The device does not contain expensive or scarce parts and is accessible for use by a person with basic knowledge of electrical engineering.

Types of installations

Oscillators can be used for different purposes, taking into account the type and characteristics of the work performed. A characteristic common to all installations is the conversion of the current pulse to values up to a maximum of 500 kHz.

Oscillators differ in the time characteristics of high-frequency pulses.

Continuous cycle model supports arc burning. The connection must be made in series - this will protect the technician from the negative influence of high voltages present inside the electrical circuit. The units superimpose high frequency currents on top of the welding currents, ignition occurs quickly and without obstacles, and welding can be carried out at minimal currents. The installations are equipped with inverters and transformers.

The second type of oscillatory devices is used during non-contact arc ignitions. This principle is actively used in argon installations. The tungsten electrode element will quickly become dull during striking, which will reduce the quality of the weld, increase its thickness, and begin to dissipate the arc. Regular sharpening of the needle tip is possible, but it slows down the workflow. The introduction of an oscillator installation with a short-term pulse into the circuit will make it possible to excite an arc without contact with the working surface.

Types, connection

Based on the principle of operation, devices are divided into two types:

- Continuous oscillators.

- Pulse oscillators.

When the first type of oscillator operates, the welding current is summed with a high-frequency high-voltage current. The arc is ignited without direct contact of the electrode with the metal surface. At low current values, the arc remains stable. Metal splashing and electric discharge damage to the welder are eliminated. Such an oscillator can be connected to the network in series or in parallel. When connected in series, the device is connected to the break in the electrode cable. This connection allows you to use the oscillator in a more efficient way. There is no energy loss to provide high voltage protection.

The pulse oscillator is connected in parallel and is used mainly in cases where it is necessary to carry out welding work with alternating current. The whole difficulty lies in the fact that the device must respond to a change in polarity, and in a minimum time. Only high-frequency pulsed current can support the arc, increasing its stability. If you use continuous-action machines for such welding, then the arc will be obtained without any problems, but its re-ignition is no longer possible, that is, the oscillator will perform only one of its functions.

The presence of capacitors in the circuit allows you to make a more functional device. The accumulated electric charge makes it possible to produce repeated impulses and ignite the arc during the formation of a seam, if the welder accidentally deflects the electrode over a long distance. In a device circuit you cannot do without feedback. It is the control system that ensures synchronized discharge of the capacitor.

Types of welding oscillators

An oscillator, which, if desired, is easy to make with your own hands, can refer to:

- continuous devices;

- devices with pulse power.

Using oscillators of the first type, a high frequency current (150–250 kHz) and a high voltage value (3000–6000 V) is added to the welding current. The ignition of such an arc can be carried out even without the electrode touching the surface of the workpieces being connected, and the arc burns very steadily even at low values of current supplied from the welding machine. This is possible due to the high frequency of the current that the oscillator produces. What is important is that current with such characteristics is not dangerous for the welder performing work using this device.

Parallel and serial connection of the oscillator

The electrical circuit in which the first type of oscillator is involved may provide for its parallel or serial connection. Devices that are connected to the electrical circuit of the welding machine in series are more efficient. This is explained by the fact that their circuit does not use high voltage protection as unnecessary.

A welding oscillator with pulse power is required primarily when welding is performed on alternating current. In addition to the initial ignition of the welding arc, a device of this type provides its support when changing the polarity of the alternating current, which occurs constantly. Oscillators of the first type, under conditions of constant change in the polarity of alternating current, do not cope well with re-ignition of the arc, which negatively affects the quality of welding operations.

Oscillators, the electrical circuit of which contains capacitors that accumulate charge from a special charger, are also capable of contactless ignition of the welding arc. At those moments when it is necessary to re-ignite the arc, these capacitors are discharged, and the electric current of their discharge is supplied to the arc gap. The electrical circuit of such a welding oscillator contains a device that ensures synchronization of capacitor discharges at those moments when the electric arc current passes through zero.

As for the rules for using oscillators, it is necessary to take into account that welding of aluminum with their help is carried out using alternating current, and stainless steel - using direct current of direct polarity.

Varieties

Those who plan to assemble the oscillator themselves should select the type of welding equipment. The pulse device is used on devices of various types.

There are classifications of factory oscillators for inverters according to various criteria: dimensions, weight, technical characteristics: output voltage, frequency.

Continuous electrical appliances use direct current, and short-term discharge welding devices use alternating current. Depending on the operating mode, devices are connected in parallel or in series. It is better to connect a device made by yourself in series, which reduces the risk of electric shock to the welder if the equipment malfunctions. In the case of a series connection, one of the transformers is supplemented with a smoothing capacitor with a fuse, and the secondary is supplemented with an oscillating circuit connected to a spark gap.

Oscillator connection diagram

Devices for welding cyclic polarity are more often used for welding aluminum, as well as alloys based on it. Stainless steel and non-ferrous metals require direct current. When choosing devices, the characteristics of the workpieces, the type of welder available, and the amount of work to be done are taken into account. Once you have formed a habit of using your existing welding machine, you can expand the capabilities of the equipment yourself.

Types of oscillators

The welding oscillator can only be used as an additional device. By itself, it cannot provide a working process, due to its low power and the inability to independently connect and melt metals. The main purpose of the device is to ignite the arc and maintain its stable state without contact of the electrode with the metal surface.

This result was achieved by generating high voltage at high frequency, capable of breaking through the air space between the metal and the electrode. A zone of ionized air is created, through which the main welding current then begins to flow.

Depending on the operating modes, all oscillators can be divided into the following groups:

- Continuous devices (Fig. 1). Capable of delivering current with voltages of up to 6000 volts and a frequency of about 250 kHz. This additional potential combines with the main welding current to instantly ignite the arc at a certain distance from the workpiece. High frequency ensures stability, regardless of the inverter current parameters. Due to the low power, the additional current is completely safe for the welder. The device is connected to the inverter using a parallel or serial circuit. The latter option is used more often and does not require additional high voltage protection.

- Pulse oscillators (Fig. 2). Very convenient when performing welding work with alternating current. These devices have the ability to constantly maintain an arc with changing polarity of electricity. They easily ignite the arc in the absence of any contact between the electrode and the workpiece. In general, pulsed instruments have some advantages over continuous oscillators.

- Devices using storage capacitors. These components are installed in a general circuit and subsequently ensure the operation of the device in charge-discharge mode. The capacitors are filled with energy using a charging module. At the moment of operation, the energy of the charged capacitors is transferred to the arc. They are then disconnected from the discharge circuit and automatically connected to the charging module. If there is a threat of arc interruption, the capacitors are switched to the working circuit of the welding equipment.

Making your own oscillator

Having a ready-made welding machine, using ready-made parts, you can assemble the oscillator with your own hands. Assembly of such a device is possible only if you have basic knowledge of physics, especially the “electricity” section, the ability to read simple circuits, and basic skills in soldering radio components. At each stage: assembly, testing, working with the assembled oscillator, you have to deal with very high voltage. Therefore, it is necessary to study and strictly follow safety regulations.

All modern oscillators, both factory-assembled and home-made, are assembled according to one of two schemes. The first operates on the principle of so-called continuous action. The second is impulse. Devices assembled according to the first scheme are, in practice, considered less efficient compared to pulsed units. Devices assembled according to the second scheme are considered more efficient. This circuit allows for faster arc ignition.

When choosing a specific scheme, you should focus on the following initial parameters:

- Purpose of the device. You need to decide what type of metal you intend to use it for welding (aluminum, stainless steel, and so on).

- The magnitude of the voltage and the type of current used. What current source will be used: direct or alternating current, standard voltage of the electrical network or other energy sources.

- Permissible electrical power. It depends on the power of the input electrical circuits. Typically this power does not exceed 250 watts. Increasing power can significantly increase the price of both individual components and the entire device.

- The generated secondary voltage (usually does not exceed 3 kW).

How the oscillator works

Such devices may have different assembly options, but they are all designed for the same purpose - to excite a welding arc between the end of the electrode and the surface of the product at a distance of 5 mm, without physical contact with the materials. This is achieved by placing the oscillator between the welding current source and the torch with a tungsten electrode. Instead of the latter, there may be a holder for welding with coated electrodes.

The essence of the process is to upgrade the incoming AC voltage with a frequency of 50 Hz into pulses of high frequency and short duration. They are superimposed on the welding current and actively participate in igniting the arc. The oscillator for welding, in most circuit variants, operates in the following sequence:

- The welder presses the control button on the torch.

- The input rectifier receives voltage from the network with parameters of 220 V and 50 Hz. The device rectifies the current and transfers it to the drive.

- The storage capacity collects the discharge.

- The control scheme guides this process. When the mains voltage reaches 0V, a pulse is released for subsequent generation.

- It enters the primary winding of the transformer, where it is converted into a high-voltage pulse.

- At the same time, the control circuit sends a signal to the gas valve and argon is released.

- A short discharge of current occurs, connecting in the air the voltage from the torch and the product to which the mass from the welding machine is attached. The arc is ignited in the already prepared gas cloud, and welding can begin immediately.

- When a welding current with a force of more than 5 A is turned on in the process, the pulse stops its action. Welding is carried out using the parameters that were set on the machine. If contact is lost, the control circuit sends a second pulse to restart the arc.

- After welding is completed, the oscillator adjusts the time of subsequent purging with shielding gas and completes the entire process.

This is very convenient for welding aluminum or alloy steels, where precision in the start of the weld is required, and mechanical cleaning of marks from touching the electrode leaves unnecessary marks. Making an oscillator with your own hands can be simplified to several units. Then, if the welding breaks, you need to start the non-contact ignition action manually by repeatedly pressing the button on the torch.

What are they?

Oscillators are available in the following types:

- continuous operation;

- pulse type;

- with capacitors.

Which device to use is determined by the nature of the work performed and the workpieces to be welded.

Continuous action

Oscillators of this type add a high-frequency current (150-250 kHz) with a significant voltage (3-6 kV) to the output current. The arc is ignited without the stainless or aluminum part coming into contact with the rod. Combustion is stable at low current, which is achieved by the increased frequency of the current coming from the welding machine with an oscillator.

For a working welder, such current parameters are safe.

The oscillator circuit for do-it-yourself aluminum welding provides for parallel or serial connection of the device. The second option is preferable because it does not provide voltage protection due to the unnecessaryness.

Pulse

Pulse-type devices are used primarily for alternating current connections.

In addition to the initial formation of the arc, devices are required to maintain it during polarity changes. Continuous oscillators do not have similar functions, which leads to a decrease in quality.

You can observe the time and amplitude characteristics of the current using oscillograms of the welding inverter, shown by a special device - an oscilloscope.

With storage capacitors

To form an arc without contact, devices with capacitors that collect charge from the charging equipment are also used. If secondary ignition is necessary, the capacitors are discharged, and the released current passes to the arc.

Peculiarities

There are several types of oscillators and they are all used for specific tasks. But we'll start with the characteristics that all types of oscillators have in common. So, all devices are capable of converting current up to 5000V and increasing the frequency up to 500 kHz.

Now about the differences. There is an oscillator for welding aluminum or any other metal that runs continuously. Thanks to continuous action, a stable arc is ensured. Most modern devices sold in stores belong to this type. This type of oscillator should be connected in series to avoid excessive voltage that could cause you harm. Remember to follow safety precautions in the workplace. With the help of such devices, you can weld using a low current value and easily ignite the arc. Often such an oscillator is installed on a welding inverter or transformer to work with coated electrodes.

Read also: Do-it-yourself protection for a circular saw

There are also oscillators for non-contact excitation of the arc when welding using argon machines. They differ in that they have a gas valve. Typically, argon welding is performed using tungsten electrodes, which can often become dull when ignited using the tapping method. Because of this, the seam turns out to be sloppy and uneven, and the arc burns unstable. You can, of course, continually sharpen the electrode, but we still recommend using an oscillator.

How to use home equipment for beginners

The use of a homemade oscillator for electric arc welding of parts made of aluminum and other materials requires compliance with the following rules:

- The devices can be used both indoors and outdoors. If there is precipitation, the devices cannot be used outdoors.

- The operating temperature range of the equipment is -10…+50 °C. The oscillator can be used at air humidity of no more than 95%.

- The devices are used at atmospheric pressure of 85-105 kPa.

- Do not turn on devices in dusty or gas-filled rooms, or expose device elements to aggressive substances that can destroy metal and insulation.

- It is allowed to work only with grounded devices. Before starting welding, check that the oscillator is connected correctly to the electrical circuit and inspect the contacts.

- The protective housing can only be dismantled after disconnecting the equipment from the network.

- There should be no traces of dust, corrosion or soot on the surfaces of the device. If contamination appears, the elements of the device are cleaned with sandpaper.

Inverter add-on

In this case, along with basic safety precautions, observe the following rules:

- During the welding process, the functionality of the blocking capacitor is regularly checked. If this part is damaged, the operator risks electrical injury.

- The device is configured and adjusted only when disconnected from the network. The same applies to the process of cleaning surfaces from carbon deposits.

- The pulse frequency is constantly monitored. It should not be more than 40 μs.

For plasma cutter

The oscillator is configured in accordance with the parameters of the cutting device in combination with which it will work. Thyristors are selected experimentally, focusing on arc stability. When working with the device, carefully observe safety precautions.

The role of the oscillator in aluminum welding

Welding aluminum is a very complex process, since the welding properties of this metal are far from being at the highest level. Thanks to the effect of this device on the welding machine, it is possible to maintain the parameters of the welding arc in a given position, which may differ from the standard one, for a long period of time. When working with this type of metal, stability of parameters is of great importance, since any deviation can lead to defects. Even a homemade oscillator for aluminum welding may be suitable for such conditions, if it is properly prepared.

It is worth noting that welding with coated electrodes is significantly inferior to the same results obtained through argon-arc welding, so the oscillator is a very popular additional device. The current of the device does not pose a danger to the master if safety precautions are followed. But if you make mistakes, you can get a large current discharge.

Avoiding common mistakes

Compliance with the following recommendations helps to eliminate the occurrence of problems in the operation of a homemade device:

- When assembling simple circuits, it is not always possible to maintain a stable arc. The cause of the malfunction is low voltage in the electrical network. Installing an autotransformer helps eliminate the occurrence of malfunctions in the operation of the welding unit.

- Don't skimp on the throttle. The spark gap supplies a series of damped high-frequency oscillations with a voltage of 1000 V. The secondary winding, which does not have a choke, receives up to 50 V. Because of this, a short circuit occurs. The current coming from the network begins to heat the transformer. To prevent the welding machine from malfunctioning, install a choke.

- When forming the winding, insulating gaskets are used and the cores are impregnated with bakelite varnish.

- A current frequency of 150-300 kHz is considered safe. If a person becomes a conductor, the current does not affect the functioning of internal organs, but causes superficial burns. Proper grounding helps to avoid a traumatic situation.

- The oscillating circuit must be equipped with a blocking capacitor.

Before assembly, it is recommended to consult with a specialist who will find out whether the chosen scheme is safe.

We recommend reading: How to choose a gasoline welding generator

We understand the design and principle of operation of the oscillator

Welding oscillators, capable of working with AC and DC sources, are needed in order to simultaneously increase both the magnitude of the voltage and the frequency of the electrical current. If the voltage at the input of such a device is 220 V and the current frequency is 50 Hz, then the output is already 2500–3000 V and 150,000–300,000 Hz. The duration of the pulses created by the oscillator is tens of microseconds. The power of these devices, with the help of which high-frequency current and high voltage is supplied to the welding circuit, is 250–350 W.

The technical capabilities that the oscillator has are provided by its design and the characteristics of its elements.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

The electrical circuit of the device consists of the following components:

- an oscillatory circuit acting as a spark generator of damped oscillations (such a circuit includes a capacitor and an inductor - the moving winding of a high-frequency transformer);

- arrester;

- choke coils in the amount of two pieces;

- step-up transformer;

- high frequency transformer.

Functional diagram of the oscillator

In addition, the oscillator contains elements that ensure the safety of both the device itself and the welder. Such elements include a capacitor, which protects the welder from electric shock, and a fuse, which opens the electrical circuit if the capacitor breaks down.

The oscillator, which is used in conjunction with a welding machine, works according to the following principle. After passing through the windings of the step-up transformer, the voltage enters the capacitor of the oscillating circuit and begins to charge it. When a capacitor is charged to the value provided by its capacitance, it discharges a discharge to the spark gap, which leads to breakdown. After this, the oscillatory circuit becomes short-circuited, which causes the occurrence of resonant damped oscillations. The high-frequency current that forms these oscillations is supplied to the welding arc through a blocking capacitor and the coil winding.

An example of making an oscillator board

The blocking capacitor is designed in such a way that only high-frequency current, which also has a higher voltage value, can freely pass through it. Low-frequency current is not able to pass through such a capacitor due to too much resistance. Thanks to this characteristic of the blocking capacitor, low-frequency current from the welding machine cannot pass through it, which protects the oscillator from short circuits.

We understand the design and principle of operation of the oscillator

Welding oscillators, capable of working with AC and DC sources, are needed in order to simultaneously increase both the magnitude of the voltage and the frequency of the electrical current. If the voltage at the input of such a device is 220 V and the current frequency is 50 Hz, then the output is already 2500–3000 V and 150,000–300,000 Hz. The duration of the pulses created by the oscillator is tens of microseconds. The power of these devices, with the help of which high-frequency current and high voltage is supplied to the welding circuit, is 250–350 W.

The technical capabilities that the oscillator has are provided by its design and the characteristics of its elements.

The electrical circuit of the device consists of the following components:

- an oscillatory circuit acting as a spark generator of damped oscillations (such a circuit includes a capacitor and an inductor - the moving winding of a high-frequency transformer);

- arrester;

- choke coils in the amount of two pieces;

- step-up transformer;

- high frequency transformer.

Functional diagram of the oscillator

In addition, the oscillator contains elements that ensure the safety of both the device itself and the welder. Such elements include a capacitor, which protects the welder from electric shock, and a fuse, which opens the electrical circuit if the capacitor breaks down.

The oscillator, which is used in conjunction with a welding machine, works according to the following principle. After passing through the windings of the step-up transformer, the voltage enters the capacitor of the oscillating circuit and begins to charge it. When a capacitor is charged to the value provided by its capacitance, it discharges a discharge to the spark gap, which leads to breakdown. After this, the oscillatory circuit becomes short-circuited, which causes the occurrence of resonant damped oscillations. The high-frequency current that forms these oscillations is supplied to the welding arc through a blocking capacitor and the coil winding.

An example of making an oscillator board

The blocking capacitor is designed in such a way that only high-frequency current, which also has a higher voltage value, can freely pass through it. Low-frequency current is not able to pass through such a capacitor due to too much resistance. Thanks to this characteristic of the blocking capacitor, low-frequency current from the welding machine cannot pass through it, which protects the oscillator from short circuits.

Scheme of work

Diagram of an oscillator for welding aluminum connected in parallel

Circuit of an oscillator connected in series

The secondary voltage in the step-up transformer was charged during the half-cycle until the spark gap broke down. After this, the oscillatory circuit is in a short-circuit state, which helps create damped oscillations that have resonant purity; such oscillations are applied to the arc gap through a capacitor and winding. The blocking capacitor helps prevent another gap from being bridged to the voltage source by its winding. The choke, which is included in the welding circuit, protects the winding insulation from breakdown. The power of such a device can be about 250-250 W. The pulse duration does not exceed tens of microseconds.

Read also: Magnetizing magnets with your own hands

It is worth noting that sequential switching devices in practice turn out to be more effective, since they do not require the installation of a special protection source in the common circuit. During operation of the oscillator, the spark gap crackles slightly. The spark gap is set using an adjusting screw, but this procedure is only possible if the device is disconnected from the network.

Kinds

There are two main types of oscillators that are used in welding. They differ significantly, both in the connection method and in the type of operation, therefore, you need to accurately determine the right choice. It could be:

- Pulse - this type is used for devices that operate on alternating current. The pulse oscillator is connected in parallel to the main welding machine.

- Continuous - this type is used for devices that operate on direct current. A continuous oscillator is connected as a follower to the main welding machine.

It is also worth highlighting the main models of this equipment, which are produced for welding and are often used in industry.

| Parameter | OSP3-2M | OSCV-2 | M-3 | OSPP3-300M |

| Drop voltage, V (all operate on alternating current) | 220 | 65 | 200 | |

| Secondary voltage at idle, V | 6000 | 2300 | 2600 | 6000 |

| Arc current | Constant, variable | Variable | Constant, variable | |

| Type of network connection | Parallel | Consistently | ||

| Device power consumption, kW | 0,045 | 0,08 | 0,14 | — |

| Weight, kg | 6,5 | 16 | 20 | — |

DIY oscillator for aluminum welding

The oscillator circuit for welding aluminum with your own hands should correspond as closely as possible to the factory model. The development of a spark gap is considered one of the most difficult moments, since it is in it that the electric spark passes. It is also necessary to select a blocking capacitor along with an oscillating circuit. There are many creation schemes and the basis for success is to select the right components. Thus, in the end you can get the same pulsed or continuous oscillators. When choosing the second option, the circuit must still have high voltage protection. Pulse is easier to manufacture and more efficient in operation due to its simplicity.

Naturally, safety precautions in this matter should come first, since if the circuit is connected incorrectly or the elements are incorrectly selected, everything can deteriorate and become dangerous to human life and health. The manufacture of these items should only be carried out by a specialist with extensive experience.

Classification of oscillators

All such devices are divided according to technical characteristics and type of power used.

The main technical characteristics by which I distinguish oscillators include:

- the primary used, that is, the input voltage;

- secondary voltage value (measured without load);

- power consumption;

- weight and size characteristics.

Based on the type of food used, they are divided into two categories:

- continuous action (they use direct current);

- with pulse power supply (alternating current is used).

The first type of device is connected in series. The current it creates has a frequency, depending on the design, of 250 kHz. The voltage reaches 6000 volts.

general information

A welding oscillator for welding aluminum or any other metal is a device that generates high frequency current. Thanks to this current, the electrode interacts better with the metal surface. To use the oscillator you need a welding machine and an electrode holder. In this case, the oscillator is installed between them. The most famous oscillator models: OSSD 300 and OSSD 400, OP 240, OP 400.

In general, such devices operate on the following principle: the oscillator generates a short-term electrical pulse, igniting an arc. The pulse disappears immediately after ignition of the arc. In this case, there is no need for physical contact between the electrode and the metal surface. From the outside, this impulse looks like a small lightning bolt between the end of the electrode and the surface to be welded. By the way, you can make an oscillator yourself.

Principle of operation

The device not only generates an electrical impulse, it changes the incoming voltage, increasing its frequency and voltage. This whole process takes a second. Let's take a closer look at the principle of operation of the oscillator.

First, the electrical circuit is started by pressing the torch button. The rectifier equalizes the incoming current, transforming it into a unidirectional state. The current is then stored in capacitors. Subsequently, the current is released and enters the oscillating circuit. This is where the voltage increases. If the device is intended for argon welding, then the gas valve opens at the same time.

The same impulse is formed, which in appearance resembles lightning. It connects the end of the electrode and the surface of the metal being welded. The ground cable is pre-connected to the metal. That's all! A welding machine included in this circuit allows parts to be welded. And the welding oscillator (for example, model OSSD 300 or OP 240, OP 400) ensures stable arc burning.

DIY welding oscillator

There are many industrial designs of welding oscillators. For example, the UVK-7 model, used to power DC and AC welding machines. The disadvantage of such a device is that it is unsuitable for an inverter, since it requires a power supply of no more than 80 V versus 220 V, from which welding inverters operate.

The OSSD-300 model is designed for an open circuit voltage of at least 60 V and will definitely require a ballast rheostat, which raises the bar for power requirements for the welding machine. Similar restrictions apply to the popular oscillator OP-240 “Ognivo”.

The initial data for making an oscillator with your own hands are:

- Purpose (for aluminum or stainless steel).

- The type of current used is alternating, direct and its voltage.

- Power consumption is usually no more than 200...250 W, otherwise the cost of circuit components will increase sharply.

- Secondary voltage, which must be no lower than 2500 V, otherwise making a homemade oscillator will not pay for itself.

It is easier to start work if you have a welding converter: in this case, the oscillator can be made not pulsed, but continuously operating, and connected to the welding network using a simpler serial circuit. Finally, at a high current frequency, the arc will be ignited without contact of the electrode with the surface to be welded, and stable arc burning is guaranteed even at relatively low current values.

The layout of the oscillator on a rectangular board is best done as follows. On the left is a high-frequency transformer, fuses and a control circuit, on the right is a choke, in the center is a spark gap, an oscillating circuit capacitor and a blocking capacitor, which will cut off the low-frequency current from the welding circuit.

The transformer is selected according to its required current characteristics in the secondary winding. It is more reliable to assemble a double inductor: when two oscillatory circuits are connected in series, the supply of current and voltage is more stable, and the protection of the oscillator from failure is more reliable. Both parts of the contours are identical and consist of:

- a capacitor designed for less than double the voltage reserve (at least 450...500 V for the first part and at least 4 kV for the second) with a capacitance of 0.3 mF (in the second stage it can be up to 1 mF);

- a varistor with a voltage not less than that required for the voltage on the secondary winding - 90...100 V (in the second stage it can be up to 140...150 V);

- an inductor, which is a ferrite rod onto which a wire with a cross section of 15...20 mm2 is wound with a gap of at least 0.8 mm. The number of turns in the first stage must be at least 7, in the second - less. The second coil serves as a kind of filter against possible current fluctuations of greater amplitude, which can lead to unstable arcing;

To manufacture the arrester, a board with stiffening ribs is selected, which should lower the temperature when triggered. As tungsten electrodes, you can use welding electrodes with a diameter of at least 2 mm. The ends of the electrodes are preliminarily trimmed so that they are strictly parallel. The gap must be adjusted using a screw.

To increase the stability of operation, a coil from any stun gun is connected to the secondary winding of the second stage. True, to power this coil, a voltage of 6V is required, which can only be obtained from a battery, but this is even better: a homemade oscillator still needs to be subjected to routine maintenance from time to time.

The first cascade is connected to the clamps of the welding inverter, and the second - to the part being welded and the welding torch. The oscillator should be assembled in a waterproof case, which is equipped with ventilation holes.

How to make an oscillator for welding with your own hands

They are assembled from ready-made components and common parts that are easy to purchase or extract from other electrical devices and old electrical equipment. It is impossible to make a homemade oscillator from scratch. The scheme is too complex.

Manufacturing diagram of a welding oscillator

The device is based on an input step-up transformer. Instead, craftsmen use an ignition coil. This unit is necessary to convert the low-voltage voltage coming from the battery into high-voltage. A car coil is capable of creating a voltage of up to 400 V. Due to this, an electric pulse is generated on the spark plug. The second coil acts as a filter and protects against possible significant current fluctuations.

The manufacture of an oscillator intended for manual or argon welding involves forming a printed circuit board with your own hands. Typically the blocks are arranged as follows:

- an oscillatory circuit is placed in the middle, filtering out low-frequency current;

- on the left side there is a step-up transformer that converts standard power supply with high-frequency current; install fuses, mount the control unit;

- on the right is an inductive coil, it is better to make a double version, then the circuit will work stably.

The capacitor must have double the voltage reserve. For the first circuit, the optimal parameter is 500 V (select a capacitance of 0.3 mF), for the second - 4 kV (capacitor 1 microfarad).

When choosing a varistor, you should take into account that you need a winding for the second cascade with 150 volts; for the first, 100 is enough.

You can make inductors yourself. These are ferromagnetic alloy rods wrapped in wire (diameter up to 2 mm). On the first one they make 7 turns, on the second only 6 (this is a filter that smoothes out amplitude jumps).

Difficulties arise during the manufacture of the arrester. It forms a powerful spark and is part of an oscillatory circuit. It's better to find a ready-made unit. The assembled board is placed in a housing that protects the parts from dust. It is advisable to provide a cooling fan.

After assembly, the welding oscillator must be checked. One contact is output to the clamp, the other to the holder or welding torch. A properly assembled welding oscillator with your own hands will work for a long time; homemade ones sometimes last longer than their factory counterparts.

Design and operation

While it is not so difficult to understand the purpose of the oscillator, understanding its operation will require some knowledge of physics. The first thing you need to understand is that with the help of this device we get remote ignition of the arc and, during the welding process, a stable arc that is static with respect to the changing gap between the electrode and the metal surface.

The oscillator fundamentally consists of several blocks:

- The step-up transformer is used to convert the voltage amplitude.

- An oscillatory circuit with a classical structure. It consists of a capacitor and an inductor. High-frequency oscillations occur in this circuit.

- Arrester. Its main element is the air gap in which the spark occurs.

Naturally, we have not taken into account various sensors that provide autonomy and control systems. When implementing an integrated circuit, when the oscillator is an integral part of an argon-arc inverter, the device is equipped with a gas supply valve. The latter is controlled by a microprocessor and supplies argon at the right time. The oscillator is equipped with a safety system that ensures uninterrupted operation of the electrical circuit, as well as the safety of the life and health of the welder. A capacitor protects against electric shock. In the event of a breakdown, a fuse comes into operation, opening the circuit when the current is exceeded.

The oscillator operating algorithm can be represented as a sequence of processes. The operating voltage of the household network is supplied to the primary winding of the step-up transformer. After converting the current, an EMF of a given value (5-6 thousand volts) is induced on the secondary winding. At the moment, the current frequency is equal to the industrial frequency, that is, 50 Hz. An oscillating circuit capacitor is connected to the winding of the secondary coil. It begins to charge, but since the natural frequency of the oscillatory circuit exceeds the frequency of the current on the winding, oscillations occur in the circuit. Initially, the circuit is open, but the breakdown in the spark gap plays the role of a kind of key and closes the circuit. Current fluctuations in the circuit flow to the electrode.

One of the remarkable properties of a capacitor is the transmission of alternating electric current. Capacitance decreases with increasing frequency. The blocking capacitor blocks the low-frequency current that feeds the inverter itself, but allows high-frequency current to pass through. This protects the oscillator from short circuits.

Device

The schematic diagram of the welding oscillator assumes the presence of the following blocks:

- A step-up transformer that converts the primary voltage values of the household network - 220 V, 60 Hz - into high-frequency oscillations with a frequency of up to 250 kHz, while simultaneously increasing the voltage to 5...6 kV.

- A spark generator of damped oscillations, which is a single-circuit spark gap whose contacts are erosion-resistant tungsten electrodes.

- The control branch, which includes an external power supply stabilizer, a ballast and a feedback line with a current sensor. During long-term operation, a gas valve will be required to prevent the oscillator from overheating.

- An output transformer, through which high voltage and high frequency current is transmitted to the contacts of the welding machine. In parallel, this transformer is connected to a current sensor.

- A safety unit that protects the welder and equipment from unacceptable excess current or arc voltage.

The design of the welding oscillator depends on the intensity of its use and the type of welding machine used. Thus, for welding aluminum, when direct current and reverse polarity are more often used, a serial connection is considered more profitable, and for short-term operations, as well as welding stainless steels, a parallel connection. Accordingly, the scheme will be different.

A series-connected welding oscillator consists of one transformer. A fuse and two smoothing capacitors are included in its primary winding, and a spark gap and an oscillating circuit (capacitor + inductor) are included in the secondary winding. The circuit of a welding oscillator with parallel connection is more complicated: it must have two transformers. In the primary winding of the first of them there is a double oscillatory circuit, and the secondary winding, together with a parallel-connected spark gap, constitutes the primary winding of the second, high-frequency transformer, from which the arc is powered. In addition to the complexity of assembly and adjustment, the parallel circuit requires special protection against exceeding the permissible voltage.

Safety

To understand what an oscillator is and what it is needed for, you need to have minimal welding skills. The main differences between the devices under consideration and the principle of their operation are given above. When working with such devices, certain safety precautions must be observed.

It is necessary to constantly monitor the correct connection to the welding circuit and check the contacts for serviceability. In addition, you should work using a protective cover, which must be removed and put on when the device is unplugged. It is also necessary to periodically check the condition of the surface of the spark gap (clean it from carbon deposits with sandpaper).

Rules for using a homemade oscillator

It is clear that the main requirements are the safety and reliability of the device.

Schematic diagram of the oscillator.

To comply with them you need:

- Check the operation of the blocking capacitor on a regular basis. If it is not in order, you may be injured by low frequency welding current.

- Make it a rule to adjust and configure the device only when it is disconnected from the network.

- Clean carbon deposits from the electrodes, do this constantly.

- The pulse frequency from the oscillator should not exceed 40 µs: keep an eye on this.

We wish you reliable capacitors, parallel electrodes and high-quality windings in your transformers. And good orders!

Operating principle of the oscillator

When welding involving non-ferrous metals, argon-arc machines are usually used, in which tungsten electrodes melt the edges and create a kind of pool. Aluminum material and stainless steel are stitched together when the source of voltage and current is an inverter.

In all cases, the same problem is observed - the initial ignition of the arc. When working with non-ferrous metals, an electrode is tapped on the surface, resulting in the formation of cracks and marks that require further processing. An oscillator is what you need for argon welding.

The assembly of these devices may be different, but they are all necessary to excite the welding arc between the electrode and the product at a distance of about five millimeters. The oscillator is placed between the current source and a torch with a tungsten electrode.

The operating principle is to change the incoming voltage into high-frequency short pulses. These pulses are added to the welding current and take an active part in ignition. You can assemble such an oscillator for an inverter with your own hands.

These devices can be powered by AC or DC current and increase both the voltage value and the frequency of the electrical current. If a voltage of 220V with a current frequency of 50 Hertz is applied to the input of the device, then the output voltage will be from 2500 to 3000V at a frequency of 150,000 to 300,000 Hertz. The resulting pulses have a duration of tens of microseconds.