If you have sufficient welding skills and are willing to invest capital in developing your business, then a welding business is perfect for these purposes. The good thing about welding is that you can create a business of any size: either assemble your own team of welders, or just work alone.

In this article we will tell you in detail where to start your own welding business, how to organize work, find qualified employees and make your first profit.

Welding shop premises

When drawing up a plan for starting a business, you should first of all take into account the requirements for premises in which electric welding work is carried out, established at the legislative level. Several workplaces (posts) can be located in one room at the same time, provided that they are separated from each other. Moreover, if electric welding work will be carried out systematically, then the posts should be placed in separate cabins, the walls of which are made of fireproof materials. If manual arc welding will be performed, and this process will be unsystematic, then screens with a height of at least 1.8 m made of non-combustible materials can be installed between the posts.

The room must have a good exchange ventilation system. Ventilation removal of gases and fresh air supply must be provided at all workplaces. The area of a separate area intended for an electric welding installation must be at least 10 square meters. m, of which at least 3 sq. m must be free from equipment and materials. In addition, in order to ensure safety and convenience of work, it is necessary to provide passages with a width of at least 0.8 m. The workshop floor must be made of non-combustible materials. It will be necessary to equip a fire shield and place primary fire extinguishing equipment on it.

Note: it is better to entrust the design of the power supply system to specialists. To create an optimal low-voltage power supply scheme for a workshop, you need to take into account the layout of the equipment, the power of electrical receivers, and calculate the power load.

An electric welding transformer and an input power supply panel must be installed in the workshop. It should be possible to connect each welding machine to a separate switch with a wire of the appropriate cross-section. The housing of any power source and the housing of the welding installations themselves should be reliably grounded. The equipment must be protected by fuses on the supply side. When choosing a room for a welding workshop, it is advisable to contact representatives of the fire inspection service for clarification regarding fire safety requirements. Work cannot begin until the workshop is completely satisfactory, which, by the way, needs to be confirmed.

What else is important

- Staff

At the initial stage, a small enterprise can get by with one team consisting of 1-2 welders and a supervisor.

An important point is the qualifications of the personnel - the quality of work largely depends on it.

The ideal option is universal welders of the 5th category.

To perform some types of work, less qualified workers can be hired, but they must be dexterous, strong and resilient.

Regarding personnel selection, you can contact the Employment Center. It is also useful to consider the issue of obtaining government support (subsidies) for the development of small businesses.

It must be remembered that welding work is a hazardous occupation, therefore it must be adequately paid and provide additional social security. Do not forget about mandatory compliance with safety regulations!

As the company develops, it may be necessary to increase staff. If business progresses and the number of orders increases, more welders will be needed, as well as an office worker who will take care of placing orders and paying customers.

- Office space.

At first, renting an office does not make sense. You can take orders by phone, via the Internet, or go to the client yourself. When customers appear and the business begins to make a profit, the question of renting office space will arise. The presence of an office will streamline the work of the enterprise and will positively affect its status.

A small room equipped with the necessary office equipment is enough. It won't cost much.

- Buying or renting a car.

Welding requires consumables. In addition, not all work is performed in the workshop. There are orders when you need to go to the client, taking equipment and consumables with you.

Having a vehicle will make your business:

- mobile;

- independent of the conditions of delivery of materials.

To transport welders, equipment, and materials to the work site, you will need a van. First you can rent it. In the future, it is better to purchase the car as your own.

Documents for starting a business

A conclusion on the compliance of the workshop premises with fire safety requirements is not the only document that an entrepreneur will need. In addition, it is necessary to obtain a sanitary and epidemiological certificate from Rospotrebnadzor. But you need to start not even with this, but with registering the welding shop as a business with the tax service. You can register either as an individual entrepreneur or as a legal entity. The organizational and legal form should be chosen based on the scale of the planned activity and the range of clients with whom the entrepreneur will work.

Note: before submitting an application for registration of business activity, you should determine the appropriate economic activity codes in accordance with the latest edition of OKVED. The choice of code depends on what materials, devices and objects the welding shop will work with.

So, if communication systems are being installed, then code 43.22 “Plumbing work, installation of heating systems and air conditioning systems” should be indicated. If welded pipes will be produced, then it is worth including in the application code 24.20 “Production of steel pipes, hollow profiles and fittings,” etc. When registering a business, it is advisable to immediately select the appropriate taxation system. So, if a company will cooperate primarily with legal entities working with VAT, then it is better to use the GST (general taxation system). If the target audience is private customers, then you can choose the simplified tax system (simplified taxation system). It is useful to read which tax to choose for an individual entrepreneur. In the process of carrying out the activities of a welding workshop, additional documents may be required. The need for their presence is determined by the types of welding work, the category of objects where welders will work, and the level of environmental pollution. An approximate list of what may be required:

- approval from a self-regulatory organization (SRO) to carry out welding work

- permit to release harmful substances into the air

- production waste passport

In addition, it is necessary, by orders of the manager, to appoint those responsible for ensuring labor protection, fire safety, and welding work. All welding machines must have passports and certificates of conformity. To carry out work, you must issue a work permit and be sure to keep a briefing log.

conclusions

According to practical experience, the profitability of this business can reach

80%. This is a very high indicator for entrepreneurial activity. Payback depends on the scale of organized production, but on average it is 1.5-2 years. This period is significantly influenced by the quality of the services provided. And it, in turn, depends on the materials used, raw materials, and welding techniques. Not to mention the highly qualified staff. But if you take into account all these nuances, then there is every chance to take your business to a high level.

Workshop staff

Finding employees to carry out welding work is not an easy task, so this point is worth dwelling on in more detail. It is desirable that the enterprise employ generalists. This will allow you to reach a large target audience and provide clients with a wide range of services. The most popular are:

- welders of the third category - craftsmen working with the main areas of metal structures

- welders of the fifth category - carry out welding of important areas, work with high-pressure pipes, steam pipelines, etc.

- welders of the sixth category are the most valuable specialists performing welding work on critical sections of pipelines and metal structures

An employee can only be allowed to carry out orders if he has a number of documents:

- welder's certificate

- electrical safety certificate (group no lower than 2)

- certificate of completion of the PTM (fire-technical minimum) for hot work

A qualified welder must be able to read drawings, use regulatory and technical documentation, set up equipment, carry out welding work with control over compliance with specified parameters. Welding work has a harmful effect on the human body. This fact should be taken into account when setting tariffs for services and determining wages.

Low salaries force people to look for additional income

Hello. I will not give my name and place of residence. I don't want any of my colleagues or my employer to read this story and understand what I do. There is no crime in my occupation, but sometimes I have to take something away from work, for example, material for my products.

The article is addressed to those who constantly whine that when working at an enterprise, you won’t get anything done and you won’t be able to do a part-time job. All those who think that you can only work for the owner and that you cannot combine business with work, read on.

I know how much my work costs, and I consider such a salary humiliating

I am an electric welder by profession and work at a factory. They pay me little - only 20,000 rubles in salary, and about 5,000 rubles in bonuses. Maybe this salary will suit someone, but it’s not enough for me.

My job, which doesn't pay enough.

It's boiling

The owner of the plant earns millions and, anyway, is constantly trying to deceive - to under-deliver something, to fine, with or without reason. When the owner of a factory makes large purchases, for example, a new car for his daughter, the workers’ salaries begin to be delayed by two to three months. He considers his needs more important than ours. And people have loans from banks that won’t wait.

The master gives gifts, but the slaves have nothing to pay the bills.

They pay little, and they also fine

Another feature of our company is the presence of an informer position. I am not kidding. In each workshop there is a special person who only looks at who to fine. As a work unit, this person is nothing. He is not a welder or a craftsman, but his salary is 35,000 rubles. I consider this attitude towards skilled workers unacceptable.

You can, of course, quit, but there is nowhere else to go to work in my area. The situation for people who work with their hands is not easy.

There is no way out except from the grave

But a way out can be found in any situation. I did not put up with this attitude towards myself and found an original way out. Since I am a welder, it is easier for me to organize a business in the industry that I know. Welding work is always and everywhere needed, and a good specialist will not remain idle.

You need to find your niche

But many companies provide such services that have transport, specially equipped workshops, and a large amount of auxiliary equipment. It is impossible for a single welder, even if he is a top-class specialist, to compete with them.

For business, I had to look for my niche, and I found it - the production of decorative figurines from small scrap metal. Basically, these are men made of bolts and nuts. Such figurines are quite popular souvenir products.

This can be done by a person who is far from welding.

This business does not require highly qualified and special skills from the master. Any beginner can produce such products. It is enough to learn how to cook with dots or potholders. Such skills will be enough to make figurines.

Welding shop equipment

Equipping a welding workshop with the necessary equipment will not be difficult for a person who knows the specifics of this field of activity. A beginner will have a more difficult time making a choice. Therefore, it is worth acting consistently. First, you need to determine the list of work carried out in the workshop and make a list of the equipment and furniture that are needed for this. Next, you need to decide on a budget. Then choose the best options in terms of price and quality. To open a welding workshop you will need:

- welders

- welding tables

- metal working tools

- generators

- protective equipment

The cheapest equipment is Chinese-made. However, it will be significantly inferior in quality to European units. Russian equipment is average in quality and price. It is not necessary to purchase new devices; you can buy used ones, and over time, as your business expands, buy newer and more advanced models.

The welding machine is the main tool in the workshop. It allows you to connect and separate metal parts. Based on the principle of operation, ease of use and functionality, welding machines are divided into several types: transformers, rectifiers, semi-automatic machines, inverters, argon units, devices for spot welding and installations for plasma welding. The welding table serves to ensure the convenience and safety of the work of the master. Generators are necessary to maintain the work process in case of power supply problems. Tools for metal processing (for example, a drill, metal shears, a grinder, etc.) will be needed to perform auxiliary work. Protective equipment - overalls, shields, masks, canvas gloves, balaclavas, etc. - are needed to ensure the safety of welders during work.

How to choose a welding mask

When choosing a mask, rely on the type of work you intend to do. The type of mask that is right for you depends on the task at hand. Let's take a closer look at them.

- Welding shield. The simplest mask, the main disadvantage of which is the need to hold it with your hand. The filter is very dark, so the mask must be constantly raised to follow the seam. At this time, you can injure your neck or face, flashes and radiation enter your eyes. Cheapest model

- Welding helmet with head mount and passive light filter. It is conveniently mounted on the head, which allows you to easily lift the mask and lower it onto your face with a nod. The light filter is very dark and is visible through the mask only when welding, so you have to constantly raise it. The risk of eye injury is quite high.

- Welding helmet "Chameleon" with auto-darkening function when igniting the arc. This model is the most expensive and technologically advanced. It is firmly attached to the head, and sensors are responsible for auto-dimming. Let's take a closer look at its operating principle.

How does the Chameleon mask work?

The main difference between “Chameleon” and other masks is the design of the light filter. It is not made of glass, but of one or more liquid crystal displays separated by polarizing film. The mask works in several stages:

- Invisible radiation sensors react. They are located on the front side of the mask and are directed towards the work area. After igniting the electric arc, they transmit a signal (most often analog) to the electronic board;

- The board receives a signal, and current is supplied to the LCD screens from batteries (lithium or solar batteries).

- The filter crystals are aligned so that ultraviolet and infrared radiation does not pass through the filter;

When the work is finished:

- The sensors respond to the cessation of radiation. After welding is completed, the radiation from the arc and seam disappears, the sensors stop transmitting the signal to the board;

- Power is turned off from the screens. After the sensors react to the completion of welding, the board waits a few seconds (depending on the settings) and turns off the power supply to the crystals. Screens become transparent.

The maximum permissible screen dimming time is 1 millisecond. The shorter this time, the less damage is done to the eyes.

"Chameleon" eliminates the need to adjust the mask to see the result of the work. The electronics themselves darken the screen during operation, and then make it transparent, maintaining a delay so that the radiation harmful to the eyes completely disappears.

On the front side of the mask there are adjustments for the filter sensitivity and delay time. You can change the indicators even while working without removing the mask, so it’s convenient to perform different types of work in the Chameleon. Such welding masks can be purchased on the website https://optoweek.com.ua/svarochnye-maski-i-ochki.

Search for clients

In order for welding as a business to generate high income, you need to choose the right direction of activity. Among private clients, services for the production of barbecues, frames for greenhouses, fencing, fences, gratings and various decorative products are in demand. A popular area is car body repair. It is also beneficial to cooperate with large construction companies. Experienced welders are needed at any stage of building construction.

To promote the services of a welding shop, you can use advertising on social networks and on large advertising sites. It is recommended to print flyers and/or business cards with contact information and a list of services and place them in the mailboxes of people living in the private sector. It must be said that such a business does not need active advertising. If the first few people who use the workshop’s services are satisfied, then an influx of new clients is guaranteed. The so-called word of mouth is the main engine of this business.

How to start the production of metal structures on the site of an old workshop

In an interview with Kontur.Zhurnal, Konstantin Podsyadlo explained why he trusts only himself in business, where he looks for effective promotion channels, how he saves on advertising and fights seasonal downturns.

“Architectural Foundry Company” is a participant in the “I am a businessman - 2014” competition. The video can be viewed at the link.

Your own boss

I was born in the Urals in the city of Zlatoust, Chelyabinsk region, where every schoolchild is familiar with cast iron and casting. Metalworking is a key area of activity for every Ural city, so I knew the foundry craft firsthand.

In 2007, I graduated from the South Ural State University in Chelyabinsk with a degree in Economics and Management of a Mechanical Engineering Enterprise and almost immediately left for Kaliningrad to look for myself. There, at the other end of Russia, my sister lived, I often visited her and managed to fall in love with this Western city.

While working for hire, I constantly experienced psychological discomfort; I was oppressed by the constant orders of my superiors. I did not know how to obey, and it was difficult for me to build my career. I always had my own opinion, and not everyone liked it. Apparently this was inherent in me at the genetic level: my father was an entrepreneur, albeit not a very large one. I watched how my father spent his time, what advantages working for himself gives. And at some point I realized: this is probably how it should be. In general, I started working at the university, was a sales manager, drove a car to clients and collected applications.

In Kaliningrad, he got a job in a company producing outdoor advertising and a year later became the head of the production department. At the height of the financial crisis in 2008, the company closed, I went to one of the largest furniture factories in Russia - Lazurit. Everything was going well for me there: I again rose to the rank of head of the department, received a good salary by local standards, but I still felt psychologically uncomfortable there, thoughts about my business haunted me.

From salesperson to production worker

I started my own business in 2011. I decided to take an unconventional path: usually manufacturers first build industrial processes and then “add” sales there, but I immediately started with dealership - promoting products. A year later, in 2012, he launched his own production.

Now I have a small metal structures factory. It produces all possible metal products that surround us in everyday life: fences, railings, stairs, fences, window bars, technical parts. The range is constantly expanding. In addition, we work a lot on individual orders, which is always associated with additional difficulties: something is wrong here, something needs to be redone.

We rented an old workshop in Kaliningrad. All equipment was gradually selected and purchased ourselves. First a welding machine, then an old drilling machine. The starting capital was about 600,000 rubles. The bulk of the money was provided by the family, and I raised a little more from the sale of my own car. We recouped these investments in a year and a half, and broke even a year later.

We managed to optimize the initial investments through the purchase of inexpensive equipment; we do not have machines costing 2-3 million rubles.

Based on their acquaintance, the guys recommended a man who sold the machine inexpensively. I went and bought it. Working on old machines in Russia is a common practice, because the bulk of the Russian machine park was produced before 1970. And there are companies that work on machines captured from the Germans during the war.

Advertising Wars

Initially, I focused on the premium segment market. But without a name and brand, it was difficult to work in this niche; orders did not come in. Gradually I switched to the mid-price range, and later to economy. 80% of my customers are private owners, people who build country houses and cottages. Our company somehow doesn’t work out with government orders: a year and six months ago I went knocking on the doors of the city administration and institutions involved in the improvement of the city. But without connections this activity is useless. If the right person doesn’t lead you by the hand to the right office and say, “Here, now we will buy from him,” then nothing will happen.

At the start, I advertised outdoors and promoted myself in local publications. These channels were very expensive and ineffective.

Then I got an idea from a friend of mine: I started driving around in the evening and hanging signs on trees in traffic jams and cottage villages. It was, so to speak, inconsistent advertising. The administration even gave me a couple of fines for this, but such advertisements actually worked. The effectiveness of illegal advertising turned out to be many times higher than the costly “agreed” one. This is how I got a client base, and then word of mouth started working. Many people did something for themselves and recommended it to their friends. My clients are not always “disposable”. After all, a country house is a complex system: you did one thing, and six months later you decided to improve something else.

Another effective promotion channel is partnership with interior designers. Many of my clients work with them. For my part, I try to encourage designers (I guarantee them a 10% commission) to subcontract casting orders to me. If the partnership is successful, one designer can bring me several clients. But relationships with decorators are a long, systematic work. To gather a base, I went to professional parties, but this was of little use. E-mail newsletters to email addresses that I was looking for, for example, in glossy magazines, worked effectively.

Cyclical production

The number of customers varies greatly from month to month: today I have one order, and tomorrow I have ten. The check ranges from 20,000 to several million rubles. As a manager, I put in my pocket an average of 50,000 to 300,000 rubles. The variation is due to the seasonality of the business. High season is from May to October. In autumn and winter, external work and cottage construction stop, leaving only internal work, and this is only part of our business.

Now the break-even point of my production is 500,000 rubles. If we receive orders for this amount per month, then we will cover all expenses. But, unfortunately, this does not always happen.

I still don’t have confidence that my business has taken off and is operating stably. There are ups, there are downs. This August there was a lull in the construction sector. At such moments, probably, any entrepreneur is seized with fear, you begin to think: “Maybe you should have stayed employed and received your unfortunate 30-40-50,000 so that your head wouldn’t hurt?”

I don’t feel like confidence will ever come; there’s always some swing in business. The company manages to survive due to exclusive offers. There is no cast iron in Kaliningrad, so I survive here. And without a “chip” in this business you can’t stay and make money. The competition is too high. Gradually, I want to create mass production, launch a line of finished metal products and not depend on seasonality.

Personnel decides everything

Today I employ 17 people. But the company constantly experiences a shortage of production personnel. Finding normal workers is very difficult. Sometimes it comes to funny things: the customer calls and says: “Your people have come to install the gates, but they don’t knit the bast!” What will they do to me here?!” Where can I get others? Our young people don’t want to work with their hands; they are all managers or lawyers. There are still men over 40 and over 50 who like to drink. There are only three “white collar” workers (managers) in my company: me, the production manager and my deputy. I found the latter myself: I came to a local institute, talked with the teachers, asked to recommend me a smart student who would be proficient in 3D Max, Corel, Photoshop and was savvy.

In business, you only need to trust yourself and your instincts. As soon as you start relying on the specialists around you, problems immediately emerge. The blacksmith will beat himself on the chest and promise: “Yes, I am such a specialist, I will do everything well, just don’t worry.” As soon as you relax and trust such a “specialist,” problems will immediately arise. I advise you to do only as you see fit.

Price policy

The cost of welding work is calculated separately in each case and depends on:

- type of equipment required

- amount of work

- speed of order fulfillment (urgency)

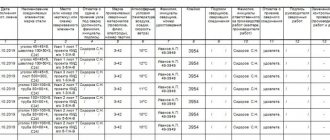

The average price for basic services is shown in the table:

| Name of service | Price |

| Welding steel water pipes | 150 RUR/joint |

| Welding metal parts | 20 rub./cm |

| Making a steel fence | 800 rub./sq. m |

| Production and installation of decorative grilles | 2000 rub./sq. m |

| Manufacturing of heating registers | 800 rub./linear meter |

If the work is not carried out in the workshop itself, but on the customer’s premises, then the specialist’s visit to the site is paid separately.

About raw materials, prices and profitability of production

Now we need to talk about the raw materials from which these products will be made.

Any scrap metal is suitable for my products.

Almost everything is made from scrap metal

To make figurines, any small or not very small bolts, nuts, pieces of metal, springs, various wires, elements of bicycle and other chains, and other small metal that can be found in a landfill will be useful. Of course, in our time, no one will let you manage a landfill, so you will have to purchase scrap metal at a price of 20 to 30 rubles per kilogram.

Places where you can purchase raw materials:

- various car services,

- auto analysis,

- repair shops where electromechanical tools are repaired.

I bring most of the material from work, so I won’t give my name and place of residence. I carry not one kilogram at a time, but many. This is how I compensate for the greed of the factory owner. But this is my choice, and I do not recommend following it.

Product prices

The wholesale price for my figurines starts from 500 rubles. This is the cost of the smallest figures. The price of figurines does not depend on weight, but on the composition and complexity of the work. If the figurine has a composition of three or more figures, then its price increases accordingly.

- 500 rubles is the wholesale cost of a figurine with one figurine.

- 700 rubles - with two.

- More complex compositions cost from 800 to 1,500.

The wholesale price starts with the purchase of three units by the intermediary.

Practical souvenirs made from scrap metal

I make not only decorative figurines, but also things that have practical applications. These are, for example, photo frames, ashtrays and stands for business cards.

Original photo frame made from pieces of metal. Price - 1,500 rubles. Cost - 300 rubles.

Retail price

The retail price of products starts from 700 rubles per piece; it is not worth selling cheaper. When I started making figurines, I was a little complex and tried to sell them inexpensively. It was a mistake.

When a souvenir is cheap, the buyer is looking for a catch. If the price of a souvenir is high, then it sells better.

Product cost calculation

The average weight of the product is 400 grams. The price of good scrap metal is 30 rubles per kilogram. If we take into account that the production of one product will require a kilogram of metal, even if we have to cut off a lot, then we will budget 30 rubles for the workpiece. We will budget another 100 rubles for carbon dioxide, welding wire, discs, varnish, paint, electricity consumption and other consumables. As a result, we get the cost of production - 130 rubles. I took a very high cost amount, in fact, the products can be obtained much cheaper.

Ashtray. Price - 1,200 rubles. Cost - 300.

Profitability

The profitability of such a business ranges from 200 to 1000%. It all depends on how to sell the products - if in bulk, then the profitability will be lower, and if in retail, then, accordingly, the profitability will be maximum.

Calculations

To open a small workshop with an area of 30 sq. m, designed to organize two workplaces, you will need about 500 thousand rubles. This amount will be spent on paperwork, creating the necessary conditions in the workshop, purchasing equipment, etc. It is useful to read how to get subsidies for starting a small business. The current costs of the workshop consist of rent, utilities, salaries, taxes and the purchase of consumables (electrodes, wire, etc.). In total, a small workshop, depending on workload, spends about 45-50 thousand rubles per month, not counting the salaries of welders. The earning potential in this area is unlimited. If you believe the reviews of entrepreneurs involved in a business such as welding, profitability can reach 80%, which is considered a very high figure. The money included in the opening budget can usually be returned after only 6-8 months from the start of work.

Welding business in a garage

An important stage in organizing a business is choosing and equipping a room for a welding shop. It will store equipment and carry out some of the work. Primary requirements:

- low rent;

- size of at least 25 sq.m to accommodate equipment and create workspaces;

- powerful hood, as well as separate hoods for each workplace;

- high partitions between workstations;

- suitable electrical power;

- convenient access routes;

- all coverings are made of durable and non-flammable materials;

- presence of fire alarm;

- heating in winter.

A garage is quite suitable for starting a business. In this case, it will be easier to attract your first customers. Neighbors in garages, if they need the services of a welder, will choose you because the workshop is nearby. High-quality fulfillment of the first orders will guarantee an increase in the flow of customers through word of mouth channels.