Buyers of rolled metal products are unlikely to object to the correctness of the production of I-beams, GOST standards for which precisely regulate the composition of raw materials, the shape, and dimensions of the products.

An I-beam, or I-beam, is a profile with an “H”-shaped section. The main advantage is strength, the ability to withstand severe bending loads and vibrations.

Products are produced in two ways:

- hot rolling (rolling is carried out in accordance with GOST 535-88);

- welding.

The latter is used due to the limited capabilities of rolling mills.

This type of beam, like a channel, can have parallel and inclined flange edges, be narrow-flange, normal, or wide-flange.

Length varies from 4 to 12 meters or more (on special order). They are classified and labeled.

Metal beams

Any metal I-beams are manufactured in strict accordance with the requirements of GOST and TU, so they have a regulated shape and composition. Thanks to this, having the necessary documentation, you can easily calculate the required dimensions and parameters of I-beams required for a specific design.

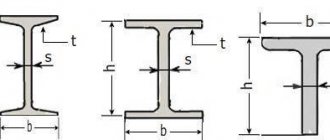

Geometric characteristics are:

- Height is the distance between two flat areas, called flanges, in the section of an I-section.

- Width is the length of the I-beam shelves.

- Wall thickness is the thickness of the middle plane located between the shelves. This parameter is one of the most important, since the load-bearing capacity and strength of the I-beam directly depends on the wall thickness.

- Average shelf thickness. The I-beam shelves are not rectangular, but have an irregular shape. Towards the ends of the shelf they narrow, and in the middle of the shelf, where it abuts the wall, they expand inward. Therefore, the average thickness of the shelf is calculated using the following formula: shelf width minus wall thickness divided by four.

- The radius of internal rounding is the parameter for rounding the shelf at its junction with the wall. Due to the fact that the shelf does not adjoin the wall at a right angle, but along a radius, its strength characteristics increase. The radius of curvature of the shelf. Since such thickness is not required at the ends of the flange and the main load goes to the center of the beam on the wall, the flanges of the I-beam taper along the radius.

- Slope of the inside of the shelf. The shelf can also run at a certain angle along the inside, widening towards the center.

The technical characteristics of the I-beam directly depend on these parameters, so all of them are specified in GOST and must be performed in strict accordance with them.

I-beam

An I-beam, or colloquially an I-beam, along with a channel and a steel angle, is one of the main types of rolled metal used in construction and the manufacture of steel structures for both load-bearing and auxiliary purposes. Due to the optimal ratio of “I-beam weight – longitudinal stiffness”, rolled steel is widely used as the main structural elements for bridge spans, trusses, support assemblies and reinforced concrete floor slabs.

Regulatory documents for I-beams

The I-beam is a composition of a central vertical flat beam and two supporting shelves, upper and lower.

The technology for manufacturing rolled products is such that there are no welds in it, so initially there are no residual stresses or plastic deformations in the structure.

Therefore, the calculation of building structures for load-bearing capacity is simplified; it is enough to correctly determine the conditions for applying the load. The remaining data, moment of resistance, length and weight, are from the assortment table.

Today, I-beams are produced in several versions according to the following standards:

- I-beam for general technical and special purposes in accordance with GOST No. 19425-74;

- Hot-rolled steel beams according to GOST No. 8239-89;

- I-beams made of steel for special purposes as defined by GOSTs No. 535-88 and No. 19425-74.

For your information! In addition to state standards, many metallurgical enterprises produce I-beams according to their own technical standards, which may differ from the standards established by GOST.

The strength and load-bearing capacity of a structural element depends on the weight of the rolled product, the dimensions of the flanges and the relative proportions of the profile. The easiest way to determine the weight of 1 meter of I-beam is from the table given in the assortment or any engineering reference books.

As a rule, the standard length of a beam is considered to be 13 m, but in practice the length of the rolled product is determined by customers, so metal depots and manufacturing plants can implement a wider range of sizes for logistics and transportation needs. Most often, heavy I-beam purlins are purchased in sections of 10 m and 4 m.

Lighter beams are cut into sections that are multiples of 4 m.

Weight of I-beam

If you plan to purchase rolled steel for low-budget construction, for example, a boathouse or warehouse, it will be useful to know the mass of the beam in a standard section.

It’s worth mentioning right away that transport company specialists work in tons, and designers work in I-roll lengths.

Therefore, to the question of how much a 30 metric I-beam weighs, in the first case the answer will be - 27 meters per ton, in the second - 36.5 kg, implying the mass of one meter.

How different are the linear masses of beams of adjacent size ranges? The weight of 1 meter of I-beam 27 will be only 31.5 kg. For the next size No. 33, the weight is 42 kg, and the weight of the I-beam 40 is already 57 kg.

It turns out that as the size of the run increases, the mass and moment of resistance grows much faster than the geometric height. For comparison, here is the ratio of the masses and sizes of beams widely used in home construction:

- I-beam 12, the weight of 1 meter is 11.5 kg, the moment of resistance is 39.7 cm3;

- I-beam 14 weight of 1 meter -13.7 kg, moment - 81.7 cm3;

- I-beam 16 weight of 1 meter is 15.9 kg, the moment of resistance is 109 cm3;

- I-beam 18 weight of 1 meter is 18.4 kg, the moment relative to the profile base is 143 cm3.

Weight of I-beams of the construction group, used in industry, in the construction of load-bearing frames, floors of multi-story buildings and bridges:

- I-beam 20 weight of 1 meter 21 kg, moment of resistance - 184 cm3;

- I-beam 24 weight of 1 meter 27 kg, moment of resistance - 289 cm3;

- I-beam 30 weight of 1 meter 36.5 kg, moment of resistance - 482 cm3;

- I-beam 40 weight of 1 meter 57 kg, moment of resistance - 953 cm3.

An observant person will immediately notice that the rental number actually corresponds to its height. The size range is designed so that each subsequent profile increases the moment of inertia or moment of resistance by 10%. The size range of I-beam heights from 10 to 40 comes in increments of 3 mm; for a profile above 40 cm, the increment increases to 5 mm.

The design of an I-beam and features of its design

The I-beam structure is shown in the diagram. To determine properties and characteristics in GOST and assortment, at least four additional characteristics are used:

- The arrangement of the shelves is parallel or with a slope;

- Dimensions of the horizontal shelves of the I-beam relative to the vertical stand;

- Weight of 1 meter of I-beam and standard rolled length;

- The accuracy class of profile manufacturing, increased accuracy is marked with the letter “A”, ordinary or ordinary – with the letter “B”.

In addition, the assortment distinguishes the height and width of the vertical lintel into separate categories.

At first glance, these parameters also have a fairly significant contribution to the strength and rigidity of the profile; in fact, they are given only in order to know the geometric dimensions of the beam when designing the structure.

The vertical lintel does not make a significant addition; moreover, in some custom-made brands of rolled steel beams are made with a large number of holes in the vertical lintel.

Features of the I-beam device

The main document defining the design of rolled products is GOST 19425-74. The state standard describes all brands of I-beams used in construction.

It is clear that the same beam is not used for the construction of supports or as suspended guides for mining equipment.

In accordance with the requirements of the regulatory document, all profiles are divided into several categories:

- Beams of normal design with parallel flanges, the letter “B” is used in the rental designation;

- Narrow flange profile, used for the manufacture of composite spans of long length, the designation contains the letter “U”;

- Wide-flange plane-parallel beams with increased dimensions of the upper and lower flange elements, letter “Ш”;

- Special types of profile: “D” - additional, with a width occupying an intermediate value between the normal and wide series.

In addition to the listed types, there are also column profiles - “K”, with a maximum flange width equal to the height of the vertical lintel, and “M” - special I-beams used as a suspension system for trolley supports.

It is clear that design features affect characteristics such as the mass of one meter and the moment of resistance. To simplify the situation, let’s compare the change in the mass of non-standard I-beams.

For example, the weight of 1 meter of I-beam 20b1 is 21.3 kg, and the weight of 1 meter of I-beam 20sh1 with wide flanges is almost 30% more - 30.6 kg. Similarly, the 25sh1 I-beam, the weight of 1 meter is 44 kg, and in the normal version the weight of 1 meter of the 25b1 I-beam is only 25.7 kg.

The difference is more than significant.

For illustration, you can look at a non-standard I-beam of category “M” - an I-beam of 24 m, the weight of 1 meter is 38 kg, an I-beam of the same height, but in its normal version weighs only 27 kg.

What is the strength of an I-beam

The I-beam was conceived as a structural or construction element with optimal stress distribution in the profile.

Why is it so important to know all the given elements of an I-beam? The main characteristic of an I-beam—the moment of resistance—depends on the geometry, dimensions and relative position of the horizontal and vertical elements.

Conventionally, it can be represented as the cross-sectional area of the I-beam multiplied by the distance from the base to the geometric center of the H-shaped figure.

It is clear that the profile with the greatest moment of resistance will not have the largest mass, but the one whose cross-sectional area is at the maximum distance from the bottom flange. This is why I-beams are so different.

The main contribution to the bending strength of a beam belongs to the horizontal flanges. The classic method of application is to force it to bend with maximum load on the horizontal elements.

For illustration, you can use the table above and compare the moment of resistance of the I-beam in the vertical and horizontal directions.

It can be seen that when bent about the X axis, the I-roll offers resistance almost twice as strong as when loaded about the Y axis.

The exceptions are profiles of categories “Ш” and “К”. For wide-flange I-beams, the moment of resistance along both axes has approximately comparable values. This profile is installed in structures where loading conditions are more complex than simple bending. A wide-flange I-beam is capable of absorbing complex spatial loads without loss of stability.

Category “K” rolled products, or column profiles, generally fall out of the general range of I-beams.

They are used primarily as supporting elements - piles or columns, therefore, to assess the load-bearing capacity, the moment of inertia is used primarily, which characterizes the stability of the profile under an axial load.

The dimensions of the shelves and vertical lintel are selected so that when loaded along the longitudinal axis of the profile, the I-beam is loaded evenly and does not bend in an arc.

Beams of the “K” series can be used as load-bearing columns in the construction of large warehouses, in low-rise construction, especially if the building has to be installed on a site with complex terrain and a large slope. In this case, the columns are connected directly to the elements of the pile foundation.

It is worth mentioning separately the I-beam of the “M” category, one of the most popular in private construction. In fact, an I-beam is used as a supporting monorail for suspended transport.

The lower shelf is made of increased thickness and with a minimum fillet size. Such beams are convenient to use for assembling any home structures; they are lighter and stronger than conventional I-beams.

This profile is ideal for making ceilings in garages, sheds, utility rooms and utility rooms where high strength ceiling slabs are required. I-beams are laid on the walls in increments of 80-100 cm, and the gaps between the bars are filled with concrete slabs or sections of asbestos-cement pipes.

What to consider when calculating an I-beam

To minimize waste and simplify the design, it is necessary to correctly perform the calculation. Such calculations can be performed independently, or they can be ordered from a design office.

The calculation is performed based on the following data:

- the length of the span in which the beam is planned to be used;

- load size - standard and design;

- calculated resistance, by default it is taken equal to 210 MPa;

- it is necessary to calculate the moment of axial resistance.

Having received the calculation results, you can select the required type of profile using the I-beam assortment table.

But, the designer must also take into account the fact that I-beams work very poorly in torsion, in comparison with a round beam.

Features of I-profile

I-beam is a type of rolled metal. The I-beam profile is characterized by an H-shaped cross-section. This design is used to redistribute the load vertically and horizontally. I-beams of various sizes and weight categories.

To designate profiles, special numbering and markings have been introduced, which facilitates the selection of a structural element. Since when choosing the dimensions of the beam, the features of the object being built and the design loads on the building structure are taken into account.

Beams are characterized by resistance to increased loads and lack of response to changes in the external environment.

Due to its characteristics, I-beams are widely used in the construction of frame buildings and structures.

In addition to metal I-beams, there are beams made of wood, which also have a varied range of sizes. The use of wooden profiles reduces the load on the foundation, speeds up the construction process and reduces costs when constructing a foundation.

Production of welded I-beam

Welded products are made from sheet metal. The quality of the finished beam depends on the welding equipment used for its production. During production, the following operations are carried out:

- Cutting steel sheets on CNC machines (less commonly, thermal cutting equipment is used for this).

- Welding of workpieces on automated lines using hydraulic clamps.

- Editing the product to achieve the prescribed geometry.

IMPORTANT: I-beams made using outdated equipment from low-carbon steel grades lead to the fact that such building elements have low performance characteristics. Welded beams produced on modern equipment are not inferior in their properties to hot-rolled analogues. With the correct technology for their manufacture, they will help to achieve the necessary conditions for the construction of all types of buildings and structures.

The use of welding in the production of such metal products makes it possible to produce beams with different widths and thicknesses of shelves. The customer can receive a welded I-beam of a certain length, with holes and cutouts ready for fastening the structure.

I-beam channels have universal characteristics:

- Optimal shape for material consumption.

- High strength indicators.

- The parameters are specified in standards and specifications.

The disadvantages of hot-rolled metal structures of this kind are:

- Low resistance to torsion (this indicator is 400 times lower compared to a round beam).

- The difficulty of producing large sizes and their shortage on the market.

- High metal consumption of production.

Most sizes of hot rolled I-beams are available on the same day of purchase. Welded elements are most often produced to order. Therefore, you have to wait until the manufacturer finishes working on your beams.

Rolled I-beam length

Among the variety of types of rolled metal, I-beams have the most distinctive features. This applies to both reliability and price. Construction, carriage building and production of special equipment - all these industries are active consumers of this profile.

Not to mention bridge construction, which accounts for about 50% of all I-beams produced.

But what caused this? What standard sizes are included in the standard range of I-beams? What should you pay attention to when choosing a profile size? You will learn about all this by reading the article below.

Characteristics

An I-beam is a metal profile with an H-shaped cross-section. Standard sizes, their deviation limits and the shape of I-beams are regulated by state standards GOST 8239-89 and GOST 26020-83. The marking procedure and types of materials used are also indicated there.

https://www.youtube.com/watch?v=uxnNg1vN0SY

Compared to other rolled metal products, I-beams have the highest degree of specific strength and rigidity. This is due to its cross-sectional shape.

It corresponds to the most correct stress distribution over the beam area, which allows you to significantly reduce the volume of material used.

Thus, the temporary tensile strength of an I-beam and a solid bar with similar dimensions is almost the same, and the mass of the H-shaped profile is more than 10 times lower.

Assortment of corners according to GOST 8509-93

I-beams are produced by rolling. They are supplied to production in blanks from 3 to 12 meters. At the customer's request, the rental footage can be significantly increased.

Types of I-beams

Modern industry presents a huge variety of I-beams. Depending on the cross-sectional shape, they are divided into the following categories:

- Hot rolled steel I-beam GOST 8239-89. It is an H-shaped profile, the flanges of which form an angle of 8-12 degrees with the wall. Most often used as a support crane beam for hoist lines.

- The I-beams are normal. Their range is fully presented in the table of GOST 26020-83. It is distinguished from the previous type of profile by the parallelism of the edges of the shelves to each other. This simplifies the manufacturing process on the one hand, and on the other, although slightly, reduces the resistance to deformation of the profile. In design documentation it is usually designated by the letter “B”.

- Wide-flange I-beam GOST 26020-83. The width of the shelves in this profile is increased by almost 1.5 times compared to the above types of I-beam assortment. This increase in cross-sectional shape has a positive effect on the strength, rigidity and durability of the beam. On average, it can withstand 40% more load compared to a normal I-beam. Marked with the letter "Ш".

- Column I-beams have even wider shelf widths. The wall thickness has also been increased. The exact dimensions of the I-beam are given in GOST 26020-83. This modification allows you to increase the strength value by almost 100%. Used in particularly critical structures. Denoted by the letter "K".

In addition to the cross-sectional shape, the range of rolled profiles includes a different range of materials from which I-beams are made. The most used of them are:

- Carbon steels of ordinary quality. Mechanical properties and chemical composition correspond to GOST 380-2005. According to the degree of deoxidation, they are divided into calm, boiling and semi-calm. Eighty percent of the market is represented by these steels due to their optimal price ratio, technological and strength characteristics.

- Construction steels GOST 27772-88. They have higher requirements for harmful impurities. The main range of these steels is represented by such grades as C235, C245 and C255.

- Low alloy rolled steels. A complete list of mechanical characteristics is available in the main table of GOST 19281-89. These steel alloys are additionally alloyed with manganese, silicon and aluminum, which makes them more resistant to dynamic loads.

- Steel for bridge construction GOST 4784-97. An even stronger alloy. Has increased resistance to cyclic loads. Used in particularly critical structures.

- Aluminum alloys GOST 4784-97. This includes their various brands: Amg5, D16 and others. They are used in cases where lightness is a priority for the design. Also, the range of I-beams made from this material is distinguished by higher aesthetic and corrosion-resistant properties.

Options

As stated earlier, the stiffness value of an I-beam is most influenced by the size and shape of the section, which are characterized by such parameters as:

- Height and wall thickness;

- Shelf width and thickness;

- The moment of resistance and the moment of inertia are quantities that show the resistance of the geometry of a shape to deformation. Their values can be found in the table of the reference book on material weights or other technical literature;

- Rounding radius.

The value of these parameters is selected based on the following technical conditions:

- Distance between supporting ends;

- Load type;

- The force on the beam is concentrated at one point or distributed over its surface;

- Load value;

- The type of material from which the beam is made.

Application area

The main industry for consuming I-beams is still construction. It is mainly used as span beams in industrial and civil premises. The I-beam is an important part of arched ceilings, bridge and gantry cranes.

https://www..com/watch?v=uxnNg1vN0SY

The beam is also actively used in the construction of bridges and in the production of some special equipment: excavators, diggers and others. In the automotive industry, I-beams are used as an element of the frames of heavy-duty vehicles - trucks. They also serve as a supporting part of railway cars.

Special I-beam steel.

The most commonly used I-beam has an “H”-shaped profile in section, or two connected “Ts”. A profile in the shape of a “T” is called a brand. Hence the name - “I-beam”.

The I-beam is divided according to the shape of the flanges, which can be parallel to each other (according to GOST 26020-83) or be sloped (according to GOST 8239-89).

With parallel edges of the shelves, they are marked as follows:

"B" - normal,

“K” – columned,

“Ш” – wide-flange beam.

The length of a standard beam can be measured - from 400 mm to 12,000 mm, unmeasured and multiple. The special beam has a measured length - from 400 mm to 13,000 mm, and also has such length standards as: measured with remainder and multiple measured with remainder.

Depending on the needs of the consumer, the length may vary. The accuracy parameters are the same for both standard and special products. Permissible deviations range from -3 to +5 percent in weight and 0.2 percent of length in curvature.

There are also several accuracy classes. So for a standard beam the following accuracy classes are applicable:

"B" - increased and "C" - normal.

For special accuracy classes:

"A" - high and "B" - normal. Regulatory documents: GOST 19425. Design and dimensions. GOST 535. General technical requirements.

Types of beams

The beam is classified according to its main purpose:

column (K),

suspended tracks (M),

and also by production method (hot-rolled steel); They also differ in such characteristics as the thickness of the wall and shelf and the location of the edges of the shelves:

wide-flange,

with parallel edges, etc. - hot-rolled steel I-beam - hot-rolled steel I-beam with parallel edges - I-beam made of carbon and low-carbon steel - metal beams for suspended tracks - wide-flange beam - column beams

- normal beams

This offer is not a public offer and is for informational purposes only. Please check product availability and prices with managers.

It’s easy to buy an I-beam - call us

tel. +7; 268-68-29; 268-68-26

or write: e-mail

Supply contract.

Enterprise card.

© MetalTechService | Privacy and Personal Processing Policy data

In what structural elements is it used?

Such metal products are opening up new areas of use every day. Demand for them will encourage manufacturers to improve the process of creating beams. Today they are used not only in multi-storey buildings, but also in private construction.

I-beam structures tolerate bending resistance well. It is advisable to include them in the design of load-bearing elements:

- Column.

- Overlapping elements.

- Suspended tracks.

- Structures of frames of cars, cars and special equipment.

- Frames of mines and tunnels.

In the designs of moderately loaded trusses, a wide-flange I-beam is used. In order to reduce the cost of construction without reducing the strength of the structure, accurate calculation and selection of beams is necessary. This procedure must be entrusted to specialized architectural or design firms. Specialists of these bureaus will carry out calculations according to:

- Standard load (the corresponding GOST is used).

- The number of elements used in one beam.

- Average resistance value (according to steel grade).

When using floors made from beams of this profile, reinforced concrete, metal or brick columns and walls serve as support. Installation of formwork and construction of supports is carried out using measuring equipment. I-beams are mounted on supports so that they extend onto the support by at least 20 cm.

If it is necessary to join elements, the requirement of SP 16.13330.2011 is used. It prescribes three methods for this procedure:

- Butt welding of pre-milled ends.

- Bolted or welded linings.

- Flanges and bolts.

The I-beam is connected to the column with bolts. Installation is carried out using temporary connections, which are then replaced by the main ones. After installing such a beam, it must be protected from corrosion. For this purpose, special paint and varnish compositions are used. Until the main fastening is installed, the beam cannot be used. Designs using such elements are highly reliable and durable.

| Normal I-beams (without slope of the internal edges of the shelves | |||||

| Profile dimensions | Sectional area, F, sq.cm | Weight 1m, kg/m | |||

| b | s | t | R | ||

| mm | |||||

| 100 | 5,5 | 8 | 11 | 27,16 | 21,3 |

| 124 | 5 | 8 | 12 | 32,68 | 25,7 |

| 125 | 6 | 9 | 12 | 37,66 | 29,6 |

| 149 | 5,5 | 8 | 13 | 40,8 | 32 |

| 150 | 6,5 | 9 | 13 | 46,78 | 36,7 |

| 174 | 6 | 9 | 14 | 52,68 | 41,4 |

| 175 | 7 | 11 | 14 | 63,14 | 49,6 |

| 199 | 7 | 11 | 16 | 72,16 | 56,6 |

| 200 | 8 | 13 | 16 | 84,12 | 66 |

| 199 | 8 | 12 | 18 | 84,3 | 66,2 |

| 200 | 9 | 14 | 18 | 96,76 | 76 |

| 199 | 8,8 | 12 | 20 | 92,38 | 72,5 |

| 199 | 9 | 14 | 20 | 101,27 | 79,5 |

| 200 | 10 | 16 | 20 | 114,23 | 89,7 |

| 220 | 9,5 | 13,5 | 24 | 113,36 | 89 |

| 220 | 10 | 15,5 | 24 | 124,75 | 97,9 |

| 199 | 10 | 15 | 22 | 120,45 | 94,6 |

| 200 | 11 | 17 | 22 | 134,41 | 105,5 |

| wide-flange I-beams | |||||

| 150 | 6 | 9 | 13 | 39,01 | 30,6 |

| 175 | 7 | 11 | 16 | 56,24 | 44,1 |

| 200 | 8 | 12 | 18 | 72,38 | 56,8 |

| 201 | 9 | 15 | 18 | 87,38 | 68,6 |

| 249 | 8 | 11 | 20 | 83,17 | 65,3 |

| 250 | 9 | 14 | 20 | 101,51 | 79,7 |

| 299 | 9,5 | 12,5 | 22 | 112,91 | 88,6 |

| 300 | 10 | 16 | 22 | 135,95 | 106,7 |

| 300 | 11 | 18 | 24 | 157,38 | 123,5 |

| 300 | 11 | 15 | 26 | 145,52 | 114,2 |

| 300 | 14,5 | 17,5 | 26 | 176,34 | 138,4 |

| 300 | 15,5 | 20,5 | 26 | 198,86 | 156,1 |

| 300 | 16,5 | 23,5 | 26 | 221,38 | 173,8 |

| column I-beams | |||||||

| Profile designation | Profile dimensions | Sectional area, F, sq.cm | Weight 1m, kg/m | ||||

| h | b | s | t | R | |||

| mm | |||||||

| 20K1 | 196 | 199 | 6,5 | 10 | 13 | 52,69 | 41,4 |

| 20K2 | 200 | 200 | 8 | 12 | 12 | 63,53 | 49,9 |

| 25K1 | 246 | 249 | 8 | 12 | 16 | 79,72 | 62,6 |

| 25K2 | 250 | 250 | 9 | 14 | 16 | 92,18 | 72,4 |

| 25K3 | 253 | 251 | 10 | 15,5 | 16 | 102,21 | 80,2 |

| 30K1 | 298 | 299 | 9 | 14 | 18 | 110,8 | 87 |

| 30K2 | 300 | 300 | 10 | 15 | 18 | 119,78 | 94 |

| 30K3 | 300 | 305 | 15 | 15 | 18 | 134,78 | 105,8 |

| 30K4 | 304 | 301 | 11 | 17 | 18 | 134,82 | 105,8 |

| 35K1 | 342 | 348 | 10 | 15 | 20 | 139,03 | 109,1 |

| 35K2 | 350 | 350 | 12 | 19 | 20 | 173,87 | 136,5 |

| 40K1 | 394 | 398 | 11 | 18 | 22 | 186,81 | 146,6 |

| 40K2 | 400 | 400 | 13 | 21 | 22 | 218,69 | 171,7 |

| 40K3 | 406 | 403 | 16 | 24 | 22 | 254,87 | 200,1 |

| 40K4 | 414 | 405 | 18 | 28 | 22 | 295,39 | 231,9 |

| 40K5 | 429 | 400 | 23 | 35,5 | 22 | 370,49 | 290,8 |

| I-BEES WITH SLOPE OF THE INNER EDGES OF THE SHELVES | |||||||

| Profile designation | Profile dimensions | Sectional area, F, sq.cm | Weight 1m, kg/m | ||||

| h | b | s | t | R | |||

| mm | |||||||

| GOST 19425-74 | |||||||

| 24M | 240 | 110 | 8,2 | 14 | 10,5 | 48,7 | 38,3 |

| 30M | 300 | 130 | 9 | 15 | 12 | 64 | 50,2 |

| 36M | 360 | 130 | 9,5 | 16 | 14 | 73,8 | 57,9 |

| 45M | 450 | 150 | 10,5 | 18 | 16 | 98,8 | 77,6 |

| GOST 8239-89 | |||||||

| 60 | 600 | 190 | 12 | 17,8 | 20 | 138 | 108 |

Main characteristics of an I-beam with a slope of the internal edges of the shelves

Previously, the production of these products was regulated by GOST 8239-89. Today it has been cancelled, but since the new standard has not been adopted, in certain cases the old regulatory framework is used. The difference between this H-shaped profile is that the inner edge of the shelf forms a small angle with the wall. Such products are in demand as elements of roofs, crane trestles, and overhead tracks. It is used for reinforcing large-sized concrete structures.

I-beam assortment table with the slope of the internal edges of the shelves

| I-beam No. | h | b | s | t | r | F | M | P |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Dv. 10 | 100 | 55 | 4,5 | 7,2 | 7 | 12 | 9,46 | 19,2 |

| Dv. 12 | 120 | 64 | 4,8 | 7,3 | 7,5 | 14,7 | 11,5 | 23,52 |

| Dv. 14 | 140 | 73 | 4,9 | 7,5 | 8 | 17,4 | 13,7 | 27,84 |

| Dv. 16 | 160 | 81 | 5 | 7,8 | 8,5 | 20,2 | 15,9 | 32,32 |

| Dv. 18 | 180 | 90 | 5,1 | 8,1 | 9 | 23,4 | 18,4 | 37,44 |

| Dv. 20 | 200 | 100 | 5,2 | 8,4 | 9,5 | 26,8 | 21 | 42,88 |

| Dv. 22 | 220 | 110 | 5,4 | 8,7 | 10 | 30,6 | 24 | 48,96 |

| Dv. 24 | 240 | 115 | 5,6 | 9,5 | 10,5 | 34,8 | 27,3 | 55,68 |

| Dv. 27 | 270 | 125 | 6 | 9,8 | 11 | 40,2 | 31,5 | 64,32 |

| Dv. thirty | 300 | 135 | 6,5 | 10,2 | 12 | 46,5 | 36,5 | 74,4 |

| Dv. 33 | 330 | 140 | 7 | 11,2 | 13 | 53,8 | 42,2 | 86,08 |

| Dv. 36 | 360 | 145 | 7,5 | 12,3 | 14 | 61,9 | 48,6 | 99,04 |

| Dv. 40 | 400 | 155 | 8,3 | 13 | 15 | 72,6 | 57 | 116,16 |

| Dv. 45 | 450 | 160 | 9 | 14,2 | 16 | 84,7 | 66,5 | 135,52 |

| Dv. 50 | 500 | 170 | 10 | 15,2 | 17 | 100 | 78,5 | 160 |

| Dv. 55 | 550 | 180 | 11 | 16,5 | 18 | 118 | 92,6 | 188,8 |

| Dv. 60 | 600 | 190 | 12 | 17,8 | 20 | 138 | 108 | 220,8 |

Peculiarities

The main feature of the I-beam is its shape. Thanks to it, it has unique physical and technical characteristics. This form is very convenient to use - because it has two parallel flat edges (shelves).

Therefore, its application is very wide. It is used both in the construction of vertical (supports, walls) and horizontal structures (floors). Another feature of the I-beam, depending on the shape, is its physical characteristics. It has high strength to dynamic and static loads.

For example, a metal I-beam is seven times stronger and 30 times stiffer than a rectangular or square profile of the same weight. And its rigidity directly depends on the length and thickness of the wall.

Features of I-beam production

The most common methods for producing I-beam products are hot rolling and welding techniques. Other methods (for example, pressing) are used much less frequently and only for certain types of products. Mills are used in the production of hot-rolled models. They may or may not have universal cages.

The use of mechanisms with two- or three-roll stands makes it possible to obtain products with parallel shelves, the size of which is up to 420 millimeters in height and up to 260 millimeters in width. For the production of small-sized products, the method of rolling through four-roll gauges is used. It is divided into three options:

I-beam design

- rolling in closed passes with unregulated rolls;

- processing in asymmetrical calibers;

- sequential deformation of an I-beam in three stands with four-roll gauges.

These techniques require the use of very large workpieces, so it is unprofitable to produce large models in this way. When producing large-sized products, open universal systems are used.

An I-beam is a rolled metal product with a cross-section in the shape of the letter “H”. Due to the presence of an additional shelf, it has greater rigidity, therefore it is used to give strength to the structure.

Purpose

Metal I-beams are the basis of many modern structures. They have been widely used in past centuries, earning a reliable reputation. Therefore, their use can be found almost everywhere.

They are used in the construction of residential, industrial and commercial premises, hangars, various technical structures, mechanical engineering, automotive industry, carriage building and so on.

Due to their high strength, resistance to dynamic loads and load-bearing capacity, they are also used:

- during the construction of supports for structures with high loads (towers, high-rise buildings, platforms, etc.);

- in the construction of railway and road bridges;

- in the mining industry, during the construction of mines.

Types of hot-rolled I-beams depending on the steel grades used

The material for the manufacture of I-roll products is selected in accordance with the planned climatic conditions, the nature and magnitude of the loads. Possible options:

- In the mass production of I-roll products, designed for operation in standard climatic conditions and under moderate loads, carbon steels of ordinary quality are used. Their characteristics are regulated by GOST 380-2005. According to the degree of deoxidation, they are divided into calm (the highest quality), semi-calm and boiling. In modern production, approximately 80% of metal products are made from steels that comply with GOST 380-2005 due to the combination of moderate cost and good performance characteristics.

- Construction steels complying with GOST 27772-2015. Such grades for shaped and long products are of higher quality compared to steels produced in accordance with GOST 380-2005, due to strict requirements for the chemical composition.

- Low-alloy steels from which high-strength rolled products are made, corresponding to GOST 19281-2014. These alloys are alloyed with small amounts of aluminum, silicon, and manganese. Products made from low-alloy steels are more resistant to dynamic loads and low operating temperatures.

- Structural alloy steels for bridge construction are used for rolled metal products that comply with GOST 55374-2023-12.

Advantages and disadvantages

First of all, it should be said that according to the production method, a distinction is made between welded and hot-rolled I-beams. Hot rolled ones are made by rolling steel and shaping a metal blank into an I-beam shape.

Welded ones are obtained by welding three separate flat elements that form the wall and shelves. Each of them has its own advantages and disadvantages.

The advantages of hot rolled steel are:

- solidity;

- no seams;

- simplicity and low cost of production.

As a result, it has higher strength and reliability.

The disadvantages of hot rolled steel include:

- Large wall thickness. Due to the thickening of the walls, the mass of the I-beam itself increases, and consequently the entire structure as a whole. Which can lead to increased construction costs (for example, when pouring a foundation, reinforced belt).

- Limited sizes. Russian factories produce beams with a flange width of no more than 400 millimeters. In addition, they are produced in a certain length - 12 meters. And if, for example, you need a smaller beam, you will have to cut off the excess and throw it away. In this case, its cost increases.

- Possibility of production only at large enterprises. If the construction site is located in the city where such a plant is located, then this is a plus. But if not, then the cost of a monolithic beam also includes transportation costs.

The undoubted advantages of welded ones are:

- Possibility to choose the right sizes. Thanks to this, you can order a beam of the desired length, shelf width and wall height. As a result, the client pays only for what he needs and of almost any size.

- Additional design features. Depending on the customer’s requirements, the welded beam can be manufactured with different flanges, flange connections, additionally reinforced with stiffeners, perforated and have a bimetallic composition.

- Relatively light weight. A welded beam is a lighter structure, which allows you to save additional money during foundation work and construction of walls.

The disadvantages of welded are:

- Presence of seams. This significantly reduces the strength of the structure. Especially if the welding is defective. But if necessary, it can be reinforced with stiffeners.

- Use of additional parts for reinforcement. The use of reinforcement or other material when creating stiffeners leads to additional costs of money and time, which leads to increased costs.

Differences between hot rolled and welded products

In addition to the above differences, products differ in the method of their manufacture. There are two large groups:

- Made by rolling metal (hot rolled).

- Made by welding.

What are the differences between them? Let's start with the fact that the first group is absolutely monolithic. This allows the products to withstand heavy loads. But welded profiles are made of 3 parts welded to each other (2 shelves and a wall). Here are some other differences:

- the maximum height of hot-rolled products is 60 cm, while welded structures can have sizes from 2 to 4 m;

- profiles made by hot rolling have a strict ratio of dimensions (shelf and wall). This applies to the width and height of the walls. Non-standard hot-rolled products according to GOST are not produced. But as for welded products, they can be made of any standard size. Thanks to this, the consumption of metal during creation is reduced, but the strength characteristics are not.

Welded I-beam

A welded I-beam product is produced by welding three basic components. Welding is carried out on both sides so that the product is as reliable and durable as possible. It is important to ensure that the elements fit as tightly as possible and are strictly perpendicular to each other. When welding, there is a need to use additional elements to recreate the stiffeners, and serious labor resources must be involved in this process; all this must be taken into account at the design stage during construction. It is worth noting that the introduction of additional ribs, for reinforcement, reduces the thickness of the wall and lowers its overall metal consumption; since the required amount of metal is reduced, the cost is reduced, and all mechanical properties remain unchanged.

For manufacturing by welding, materials such as profile and metal sheets are used; for belts, bent profiles, channels and much more can be used.

Advantages of a welded I-beam

- An undoubted advantage is that the lighter weight of the beam product allows you to reduce the total weight of the metal product, and therefore reduce the overall cost of the construction project.

- An important advantage of welded beam products is that it is produced according to a given technical specification, and on an individual order. Let's consider an example, for the construction of a certain structure it is necessary to erect metal structures, where the length of the beam should be 10.55 meters, then a profile with exactly this length will be welded. Thus, the customer will avoid additional waste, and therefore costs.

- According to the technical specifications for individual projects, this type of profile can be made perforated, which reduces the weight of the structure, can have a truncated shape, have unequal flanges, with flange connections or additional stiffeners; complex architectural structures can be created from such rolled metal. A beam product of such shapes cannot be obtained at a metallurgical plant.

- It is possible to weld metal products with a variable cross-section; this will allow the metal to be distributed in such a way that in loaded areas of the structure, the rigidity will be higher, reducing the cost of the structure without losing quality characteristics.

The procedure for manufacturing a welded I-beam

The following main phases of welding are distinguished:

- cutting and cutting sheets into strips;

- processing of edges on a machine, which is necessary to improve weldability;

- positioning and fixing strips on the machine to avoid shifts;

- the welding process itself;

- trimming and straightening on a machine;

- cleaning from rust, dirt and oil.

Disadvantages of a welded I-beam

Despite all the above advantages, welded production will never be able to displace rolled production from the market, since the speed and production volumes of welded beams are several times inferior to rolling production. And the speed of construction work throughout the country is very high, thus, the demand in the market for this type of metal products can only be covered by the combined volumes of both welding and rolling production.

What is an “I-beam”?

For many companies today, the priority is to build reliable and inexpensive houses, and in a relatively short time. And these problems are solved to a greater extent by the building materials used.

Until recently, the I-beam in Russia was used only in the industrial sector, but today it is becoming more and more popular. The emergence of new types of I-beams in recent years has made it possible to successfully use them in the construction of ordinary residential buildings.

In construction, an “I-beam” is a wooden or metal profile that has a cross-section similar to the letter “H”. The term itself comes from “taurus,” which means “bull horns.”

The assortment of I-beams on the domestic market is still small, because the product itself is still little known and few manufacturers represent it. But abroad, quite interesting types of it are used, where engineering thought and the laws of physics are combined.

How to find out the exact weight of a construction I-beam?

An important part of metal fabrication that needs to be mentioned from a technical perspective is calculating the weight of the I-section used for each project. The calculation is based on the profile number, which can be found in the assortment of I-beams, where you can also see the mass and cross-sectional area. It is worth paying attention that the table shows the mass of one linear meter.

In order to find out the weight of an I-beam, you can weigh the material.

It is important to understand that this procedure is carried out only during the shipment of the construction I-beam in order to find out exactly how much the supplier is releasing to the customer.

However, there are some cases when weighing beams is not possible in principle. In this situation, mathematical calculations will help. To do this, take individual I-beams and calculate them by multiplying the length by the weight of one linear meter. It is important to understand that the entire footage of the product in such specific cases can be found out by measuring the length. The specific gravity of an I-beam metal structure is calculated using one of the following methods:

- Look at the values of the characteristics specified in the table of the state standard.

- Calculated manually.

It is worth knowing that the values of the linear meter of the beam were determined manually using calculation methods. Calculations were used for beams with a nominal size, and the metal density was taken to be absolutely identical to the average value. Real materials are often produced in slightly different sizes than the base ones. It is precisely this difference that is allowed according to GOST, and is called the maximum possible deviations during production.

Types of I-beam sizes in accordance with new regulatory documents

The Federal Agency for Technical Regulation and Metrology decided to cancel two metallurgical standards regulating the production of I-beams from November 30, 2018:

- GOST 8239-89 - regulated the dimensional characteristics of an I-beam with a slope of the internal edges of the shelves;

- GOST 26020-83 - determined the assortment of I-beams with parallel edges of internal shelves.

GOST 26020-83 was replaced by GOST R 57837-2017, which defines specifications for a hot-rolled beam with parallel internal flange edges. The new regulatory document fully takes into account modern achievements of science and technology, advanced Russian and foreign experience. The production of I-beams with sloped internal edges is currently not regulated by law.

Types of I-beams

The I-beam can be found in two variations - hot-rolled and welded. Each of these two types offers its own advantages and disadvantages.

Let's look at each group in more detail.

Hot rolled I-beams

When you need to make an I-beam, the easiest way to do this is to use hot rolling mills. By using blanks, subjecting the material to the compressive action of numerous rolls, the blank eventually elongates and then acquires the recognizable H-shaped profile.

Now let's look at the advantages and disadvantages of using the material.

| Advantages | Flaws |

| solidity, since the beams do not have connecting welds | various marks quickly remain on the surface of the beam |

| their production is relatively simple | limited assortment leading to pre-agreed custom size and single production, which increases waiting time |

| higher levels of rigidity and strength than conventional metal structures | There is no way to reduce the cost of the material due to the combination of different types of steel. |

Welded I-beams

The technology for producing welded I-beams is somewhat different: strips are cut from a sheet blank of the required thickness. Then they are welded into an H-shaped structure of the required configuration.

Welding seams must be carefully checked for strength and quality. To do this, they undergo ultrasonic testing, are polished, and the product is coated with a protective layer.

Welded I-beams are preferred when it is necessary:

● obtain a clean surface of the product;

● produce beams with different widths/thicknesses, not specified in GOST standards;

● use different types of steel for specific purposes (to give special properties, reduce the weight of the structure, and also to reduce cost).

I-beam

An I-beam or I-beam is a type of rolled metal, which is a long profile with a cross section in the shape of the letter “H”.

It is formed by two parallel shelves and a wall connecting them. This section works well under the influence of bending loads, therefore it is used as beams and columns in construction. I Beam Weight: Main Series | With a slope of the internal edges of the shelves | Series Ш | Series K | Series D

Characteristics of hot rolled I-beam

Several types of I-beams are used in construction and mechanical engineering. Depending on their geometric features, they can be divided into two large groups:

- an I-beam, the internal edges of the shelves of which are inclined relative to the external ones;

- an I-beam made with parallel edges of the shelves.

Beam with flange slope

This type of product is produced in accordance with the requirements of GOST 8239. Historically, it was the first to be mastered, since rolling shelves with a slope of 6-12% is technologically simpler than without a slope. Products are marked with the word “I-beam” and the I-beam number, which displays the height of the product (wall size) in centimeters.

Enterprises produce I-beams from No. 10 (height h = 100 mm, flange width b = 55 mm, wall thickness s = 4.5, nominal flange thickness t = 7.2 mm) to No. 60 (h = 600 mm, b = 190 mm, s = 12 mm, t = 17.8 mm). The length of the products is 4-12 m.

Products can be made from ordinary quality carbon steels such as St3sp (technical requirements in accordance with GOST 535), high-quality structural and alloy grades (technical requirements for high-strength rolled products in accordance with GOST 27772 or GOST 19281). Rolled products of increased (B) and normal (C) precision are produced. The product is regulated by dimensional deviation, wall deflection, shelf skew, position and dimensions of flanges, length curvature, blunting of edges and other parameters.

In addition, the category with a slope of the internal edges of product shelves includes I-beams of a special series in accordance with GOST 19425, which are intended for reinforcing the shaft of a shaft (marked with a number indicating the height in cm and the letter “C”) and for arranging suspended tracks (indicated by the value of the height of the product in cm and the letter “M”). According to this standard, the following standard sizes of beams are produced:

- from 14 C (h = 140 mm, b = 80 mm, s = 5.5 mm, t = 9.1 mm) to 36 C (h = 360 mm, b = 140 mm, s = 14 mm, t = 15 .8 mm);

- from 18M (h = 180 mm, b = 90 mm, s = 7 mm, t = 12 mm) to 45M (h = 450 mm, b = 150 mm, s = 10.5 mm, t = 18 mm).

Beam with parallel flanges

An I-beam with a parallel flange is considered more economical in terms of the ratio of weight and load-bearing capacity of the product. It is produced according to the requirements of GOST 26020 with a length of up to 24 m.

Three large groups of standard sizes are available:

— normal I-beams are marked with a number (height in cm), the letter “B” and a standard size number (several standard sizes of the same height can be produced, slightly differing in the dimensions of the shelves and walls).

In terms of the ratio of the height to the width of the shelf (h/b about 2), this type is similar to beams with a slope of the internal edges of the shelves.

Standard sizes are available from 10B1 (h = 100 mm, b = 55 mm, s = 4.1 mm, t = 5.7 mm) to 100B4 (h = 1013 mm, b = 320 mm, s = 19.5 mm, t = 32.5 mm);

— wide-flange I-beams are marked according to the same principle, but are designated by the letter “Ш”.

This type has a shelf height to width ratio h/b of about 1.5, that is, it resists torsion better and is more economical at high loads on the beam.

Standard sizes are available from 20Ш1 (h = 193 mm, b = 150 mm, s = 6 mm, t = 9 mm) to 70Ш5 (h = 718 mm, b = 320 mm, s = 23 mm, t = 36.5 mm) ;

- column I-beams have the same marking principle, but are designated by the letter “K”. This type has a flange height to width ratio h/b of about 1 and, as the name suggests, can be effectively used for the construction of columns. Standard sizes are available from 20K1 (h = 195 mm, b = 200 mm, s = 6.5 mm, t = 10 mm) to 40K5 (h = 431 mm, b = 400 mm, s = 23 mm, t = 35.5 mm);

— I-beams of the additional series are marked in the form of the letter “D” before the letter designation of the beam type, for example, 27DB1 or 40DSh1.

It should be noted that Russia also uses the STO ASChM 20-93 standard, issued by the Chermetinform Association. This document contains almost the same standard sizes as in GOST 26020 with minor differences in geometric parameters.

Technology for the production of hot-rolled I-beams

Hot rolled beams are produced by the hot rolling method, which is widely used for other types of shaped and long products.

The essence of this method is the gradual deformation of a workpiece (usually a bloom of rectangular cross-section) from a rectangle into an H-shaped profile by compression by pairs of drive rollers combined into a rolling stand.

The rolling stands, in turn, create a rolling mill line in which the steel takes its final shape.

Each roller has special ring-type grooves called calibers. During rotation, the metal is drawn into the gauges, compressed and changes its shape.

IN several stages, the steel is redistributed between the shelves and the wall, the grain is crushed, and the strength of the metal increases.

Preheating the workpiece to 1100-1200°C makes the metal ductile, which allows it to be rolled with greater reduction and, accordingly, ensures high productivity of the process and quality of rolling. Because of the heating, the process got its name - hot rolling.

Hot rolling of an I-beam was first patented by Alphonse Halbow (1849) from the Forges de la Providence company, which began to develop this method.

The I-beam profile became especially popular during the active construction of skyscrapers, as it made it possible to create relatively light and durable structures.

The main manufacturer that promoted this type of building materials was the Bethlehem Steel plant (the legal successor is the well-known company ArcelorMittal)

Now the process is carried out on linear and universal type rail and beam mills. Such equipment is available at KMK, NTMK, OKMK, Chusovsky plant and MMK.

Characteristics and production technology of welded I-beam

A welded I-beam has geometric characteristics similar to an I-beam with parallel flange edges.

Typically, the production of such products is carried out by small metal structures factories and other metalworking enterprises.

The workpiece is sheet steel, which is welded using automatic submerged arc welding. Naturally, the production of welded I-beams is small-scale or piecemeal, which affects its price.

The method has the following advantages:

— in addition to products with dimensions in accordance with GOST 26020, any type of I-beams can be produced according to customer drawings;

— there are technologies for manufacturing I-beams with reinforced elements, when in certain areas the wall or flanges are thickened - this makes it possible to produce beams for specific projects with calculated loads;

— a bimetallic I-beam can also be produced, the elements of which are made from different grades of steel.

Application of I-beam

The I-beam, characterized by good resistance to bending loads, finds its main application in construction.

It is used for arranging beams in private homes, auxiliary buildings, in the construction of civil, industrial and infrastructure facilities, in bridge construction and other areas.

The I-beam plays an important role in the design of heavily loaded buildings and structures, for example, in the construction of skyscrapers and other high-rise buildings.

Mechanical engineering is another major consumer of I-beams. A special type of I-beam is used for fastening mine workings and in arranging overhead tracks for winches and other lifting and transport equipment in factory premises, car washes, workshops, etc.

Assortment

For construction needs, I-beam is a universal material that may be needed for different purposes. As a rule, the products are used in a number of industries - metro construction, bridge construction, etc.

The production of I-beams is regulated by GOST 8239, GOST 19425, etc. They indicate the main dimensions, maximum deviations, as well as rules for marking products.

Hot-rolled I-beam with flange slope

This type stands out among others due to the small internal slope of the shelves relative to the wall - we are talking about the range of 6-12%.

Depending on the quality of rolling, the following are produced:

● beams with increased accuracy – there is a letter “B” in the marking;

● beams with normal accuracy – designated by the letter “B”.

Such beams are used, for example, for suspended tracks in various structures that work in bending.

There are beams made of the same material, but with a greater slope of 12-16% (GOST 19425). According to GOST, it can withstand compressive loads well and is used to strengthen powerful structures, for example, mine shafts and subways. They are designated by the letter “M”.

The following three types of hot-rolled products have one common feature - the absence of slope of the shelves and their parallel edges.

I-beams are normal

This type of pipe offers characteristic classic dimensional ratios, when the width of the I-beam flange is half the height of the profile.

Normal I-beams are designated by the letter "B". They have proven themselves well in construction as supports or elements of lattice columns. They are also in demand in mechanical engineering, where they are used to create frames for trucks and wagons, and in the industrial sector, where they are used to create crane tracks for electric bridge cranes and other metal structures.

| I-beam number | h | b | s | t | Weight 1m, kg | Meters per ton |

| Normal | ||||||

| 20B1 | 200 | 100 | 5.5 | 8 | 21.3 | 46.9 |

| 25B1 | 248 | 124 | 5 | 8 | 25.7 | 38.9 |

| 25B2 | 250 | 125 | 6 | 9 | 29.6 | 33.8 |

| 30B1 | 298 | 149 | 5.5 | 8 | 32 | 31.3 |

| 30B2 | 300 | 150 | 6.5 | 9 | 36.7 | 27.2 |

| 35B1 | 346 | 174 | 6 | 9 | 41.4 | 24.2 |

| 35B2 | 350 | 175 | 7 | 11 | 49.6 | 20.2 |

| 40B1 | 396 | 199 | 7 | 11 | 56.6 | 17.7 |

| 40B2 | 400 | 200 | 8 | 13 | 66 | 15.2 |

| 45B1 | 446 | 199 | 8 | 12 | 66.2 | 15.1 |

| 45B2 | 450 | 200 | 9 | 14 | 76 | 13.2 |

| 50B1 | 492 | 199 | 8.8 | 12 | 72.5 | 13.8 |

| 50B2 | 469 | 199 | 9 | 14 | 79.5 | 12.6 |

| 55B1 | 543 | 220 | 9.5 | 13.5 | 89 | 11.2 |

| 55B2 | 547 | 220 | 10 | 15.5 | 97.9 | 10.2 |

| 60B1 | 596 | 199 | 10 | 15 | 94.6 | 10.6 |

| 60B2 | 600 | 200 | 110 | 17 | 105.5 | 9.5 |

Wide-flange I-beams

The width of the shelves has been almost doubled, which is reflected in the marking using the letter “W”. Its strength and rigidity indicators are also significantly higher than the standard one.

Thanks to these properties, wide-flange I-beams are used for the manufacture of the following structures:

● support, rafter beams;

● frames for cars, trailers;

● foundation piping, etc.

| I-beam number | h | b | s | t | Weight 1m, kg | Meters per ton |

| Wide shelf | ||||||

| 20Ш1 | 194 | 150 | 6 | 9 | 30.6 | 32.7 |

| 25Ш1 | 244 | 175 | 7 | 11 | 44.1 | 22.7 |

| 30Ш1 | 294 | 200 | 8 | 12 | 56.8 | 17.6 |

| 30Ш2 | 300 | 201 | 9 | 15 | 68.6 | 14.6 |

| 35Ш1 | 334 | 249 | 11 | 20 | 65.3 | 15.3 |

| 35Ш2 | 340 | 250 | 9 | 14 | 79.7 | 12.5 |

| 40Ш1 | 383 | 299 | 9.5 | 12.5 | 88.6 | 11.3 |

| 40Ш2 | 390 | 300 | 10 | 16 | 106.7 | 9.4 |

| 45Ш1 | 440 | 300 | 11 | 18 | 123.5 | 8.1 |

| 50Ш1 | 482 | 300 | 11 | 15 | 114.2 | 8.8 |

| 50Ш2 | 487 | 300 | 14.5 | 17.5 | 138.4 | 7.2 |

| 50Ш3 | 493 | 300 | 15.5 | 20.5 | 156.1 | 6.4 |

| 50Ш4 | 499 | 300 | 16.5 | 23.5 | 173.4 | 5.8 |

Scope of application

Since the I-beam is a load-bearing element and gives strength and rigidity to any structure, it is used everywhere in the construction of objects for a wide variety of purposes.

This reinforcement is irreplaceable wherever it is necessary to withstand high loads under vertical transverse impact. The product is used in the construction of:

- bridges;

- overhead tracks;

- underground passages, parking lots;

- railway tunnels;

- crane tracks;

- stadiums, sports swimming pools;

- overpasses

The I-beam is part of the floors between floors of buildings, roofs, and plays an important role in the construction of heavily loaded buildings, for example, skyscrapers. I-beams are also used in the construction of pit wall structures and monorails.