The Forestner drill has an advantage over conventional drills. In it, the drilling direction is adjusted using the rim, whereas in other types of drills this occurs due to the central tip of the drill.

For amateurs and for professionals who have made carpentry and plumbing their profession, it is very important to obtain neat and accurate holes without chips and with a flat bottom. It will not be possible to do this with a drill of an ordinary design, since it will not work when drilling, for example, wood. This material has a fibrous structure, and chips are inevitable, even when choosing drilling modes and well-sharpened standard drills. In addition, when drilling with a hand tool, it is very difficult to maintain longitudinal feed, especially when drilling holes in the end of a part or at a certain angle, if you use drills of an ordinary design.

View of the original Forstner drill

In addition, its design is such that when drilling, wood or other material is forced out and the hole is almost perfect.

This type of drill was invented by Benjamin Forstner, who patented this shape in 1874. He was a gunsmith and the problem of drill alignment was of great concern to him. This drill is still produced today, the only thing that has changed is the circumference of the ring, which is divided into two halves.

General information

The Forstner drill is very different from the popular and familiar spiral models. It would be more correct to distinguish it as an end mill, because its cutting edge is located at the end. This important feature helps to make blind holes of huge diameter with high-quality alignment according to preliminary markings. This precision is achieved by the centering head of the device.

A well-sharpened drill can guarantee complete cleanliness of the interior of the hole. This type of device is distinguished by high productivity and long service life, subject to operating rules. The tool is easy to use and can be used with complete success both in standard special machines and in a hand-held electric device. At the moment, the Forstner drill is improved by the presence of very durable inserts in the form of a cutting edge. This helped extend its use several times.

Selecting cutters

Which cutters are better to buy - expensive real ones or cheap non-original ones? The choice depends on how often you need to use them in your work. In a workshop where constant production of furniture products is planned, you will have to use this tool quite often. Moreover, cutters of different sizes will be required. But it is unprofitable to purchase expensive tools just for your home needs.

During active use, it is better to choose original products to ensure continuous operation and at the same time keep the tool in good condition for a long time. The high price will pay off over time.

For rare use, it is better to buy a set of 6-7 cutters of standard sizes (including a 35 mm Forstner drill), the price of which will correspond to one expensive original copy. With this kit you can perform many types of work that require creating holes of different sizes. Using these tools, you can create a furniture set with your own hands or simply replace new fittings that require the manufacture of high-quality holes.

https://youtube.com/watch?v=V8JRBTmIz_A

Areas of use

The Forstner drill is widely used in the furniture industry and carpentry. Thanks to the correct design solution, it helps to very quickly and accurately make blind holes and grooves for various types of fittings.

This type of drilling is also used in large centers in cabinet furniture production: for various kinds of mounting fasteners , tie rods, and hinges for furniture. The diameter of model 35 is considered the best. It is also applicable in ordinary carpentry.

In addition to holes for door and other fittings, they are used to repair various natural wood defects: knots, resin pockets, mechanical damage to the structure and inclusions. An element of pure wood of suitable diameter is inserted into the hole using glue. It is made with a special device - the same in diameter as a Forstner drill.

You can purchase a drill in any specialized stores. It helps save expensive dry wood and improve the quality of carpentry. The negative aspects include the difficulty of sharpening the device and the rather high price compared to simple spiral drills. But this can be paid off by the efficiency of its operation at large production volumes.

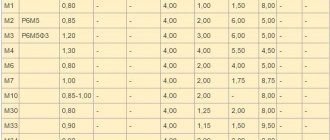

Briefly about sizes

The holes in the furniture product are needed to fit the furniture hinge bowl inside, fix it and ensure a reliable connection between the canvas and the fittings.

The diameter of the special drill used is selected based on the size of the purchased and used furniture hinge. Most often on sale you can find hinge bowls with a diameter of 26, 35 and 40 millimeters. Moreover, in the vast majority of cases, furniture fittings manufacturers use a diameter of exactly 35 mm. It is universal in size, optimal for most types of standard furniture that require hinges. But since there are also non-standard solutions, special hinges are also sold for them. And you can purchase appropriate cutters for these hinges.

No special skills are required for insertion. But experience, even the slightest, will not be superfluous.

Additionally, I would like to remind you of the set of tools for a furniture maker, which are considered basic and most necessary. It's definitely worth including a hinge cutter or just a Forstner drill in this set.

Principle of operation

To position the device correctly, use a centering point. It is placed at a certain point and pressed into the material until it evenly touches the circular plane. At low speeds, drilling begins. Drills are designed for operating speeds in the range of 800-1800 revolutions per minute. The operating procedure is as follows:

- The larger the diameter of the workplace , the slower the cutting speed should be. This mode must be observed to avoid overheating of the special edges. At high speeds there is a risk of the drill breaking.

- For safety and comfort during work , as well as in cases with important parts, it is more convenient to use a Forstner device with a limiter. It stops the device in time and ensures the required depth of the hole.

- If you need to make a hole in thin material , when there is a risk of the centering tip coming forward, you can use two Forstner drills with the same diameter. We start working with a simple tool and create the initial diameter.

- We grind off the special tip of the second drill . We finish the deepening with it. The tool is held in the hole by its side parts and there is no risk of it coming out. You can leave the minimum acceptable wall.

Purpose

The Forstner drill bit was designed for making blind, flat-bottomed holes in soft and hard wood. Currently, it is also used to work with MDF, chipboard, fiberboard and their modifications.

Blind recesses with a flat bottom are most often drilled for the installation of various furniture fittings (door hinges, locks, eccentric and threaded ties). In production, material is saved, the minimum permissible thickness is used, and through holes for furniture are not practiced.

You need a sufficient hole depth for mounting fittings and smooth and neat edges. A Forstner wood drill bit creates a perfect hole with a flat bottom. In this case, only 1–2 mm may remain before the drill comes out. Conventional screw drills, sharpened to a cone, cannot ensure planeness, and feather and crown drills cannot ensure the cleanliness and accuracy of the side surfaces.

Advantages

This tool, compared to other designs, has two big advantages: the cleanliness of the surface being processed and the ability to perfectly hold a certain direction. This is possible even on overlapped parts or when the diameters of the holes extend beyond the edges of the workpiece.

The quality of cutting the side walls is achieved by cutting the fibers around the circumference even before the main cutting edge begins to touch them. This helps to avoid chipping and tearing of the material beyond the required diameter.

The second advantage is due to the fact that the direction is maintained not by the centering tip, but by the side annular special edge and the entire cylindrical plane of the working surface. After starting to sample the material, the drill is held firmly in the created hole.

Modifications

Currently, many companies produce Forstner wood drills. Some focus on quality materials and traditional configurations, while others try to improve the tool for different conditions. This is how a drill adapted for machine sharpening appeared. His rim behind the central incisors has a larger incision.

Such a drill loses part of the cutting surface around its circumference, which is fraught with increased vibration during operation and possible breakdowns. On the other hand, this design significantly reduces the cost of the tool.

There is a Forstner drill with carbide plates soldered on the inner cutting edges. In other designs, the side circles have teeth, like a saw. The cleanliness of the side surfaces in the material being processed when using such a tool is lower in class, but the drill does not overheat as much and provides a higher drilling speed.

Design features

The Forstner drill has:

- Centering type tip.

- Cutting edges in the amount of 2 pieces.

If you look carefully, you can see that the profile of the cutter is similar to the Latin letter Z. The principle of drilling is to select wood for cutting edges, and accuracy is ensured by a special stop tip.

OLYMPUS DIGITAL CAMERA

When drilling holes, a Forstner drill is characterized by such a positive quality as the ejection of chips, as a result of which the cutter never jams, unlike other analogues.

Various metals are used for manufacturing, but most often high-speed steel, since only it can withstand the heat that occurs during the drilling process.

Recently, some manufacturers have made an interesting addition in the form of carbide brazing, titanium coating or cutting teeth. Thanks to these innovations:

- The quality of drilling improves.

- The possibility of overheating of the metal and, accordingly, darkening of the wood is practically eliminated.

- The speed of work increases without loss of processing purity.

Selection rules

You can select suitable drill bits for use if you take into account all the important points.

- Country of manufacture and brand. Inexpensive products from China do not always live up to the expectations placed on them - they quickly become dull, break, and bend. More reliable options are produced by companies from the USA, Germany, and Russia. Among the market leaders are Metabo, Hawera, Ruko.

- Material of manufacture, presence of coating. For metal work, options made of carbide steel are used, the most durable and productive, with or without coating. Other drills are more suitable for processing wood and composite materials, chipboard and fiberboard. They are made from high-speed tool steel.

- Tail type. It directly determines the compatibility of the tool. For drills and hammer drills, options with a hexagonal or cylindrical tip are best suited. In addition, the length of this part is important. It must correspond to the parameters of the hand and power tools on which the attachment will be installed.

- Dimensions. The diameter of the drill bit is indicated by the manufacturer in millimeters. This parameter is always determined by the dimensions of the working part.

- Type of milling element. It determines which holes can be obtained after processing. The angle of sharpening is also important.

All these factors help to select high-quality and reliable drill bits for working on metal or wood. Combination instruments help to simplify and reduce the number of operations, eliminating the need to change the tip. By refusing to change bits and choosing the right combination product, you can get a result no worse than when performing work using special milling equipment.

The following video talks about drill bits.

Operating rules

They are designed to make work easier and prevent injuries:

- The drill must be installed accurately. To do this, the centering point is pressed into the wood until it touches the outer edge. The nozzle operates at low speeds up to 1800 rpm. Drilling should begin at a minimum rotation speed of 800 rpm;

- The operating speed directly depends on the hole diameter. The larger it is, the less speed it needs to be drilled. This helps maintain optimal temperature on the working part of the tool;

- The Forster drill can be equipped with a depth limiter. This is a useful option designed to record the cutting depth, as well as increase safety measures during work;

- Sometimes the thickness of the material does not allow you to fully use the functionality of the tool. If the sheet of wood is too thin, the centering tip can pierce through it, then two drills are used. The first sets the direction of movement. The second has a sharpened edge. With its help, the required hole thickness is selected.