Using different planting methods allows you to get a good harvest. The problem of sowing crops with small seeds is solved by using a manual seeder. Models on sale range from simple attachments to trailed devices for a walk-behind tractor or cultivator. When choosing, they are guided by the number of containers, additional accessories, adjustment parameters, and weight.

Advantages

A manual seeder for small seeds with your own hands allows you to save money and simplifies planting crops. Its characteristics are not very different from cheap purchased devices.

Positive aspects of self-production:

- from scrap materials,

- cheap.

Flaws:

- seeds of only one diameter (one crop),

- single row planting.

Note! Several seeders with different hole diameters practically automate seeding. A universal device is more difficult to make; manufacturing will require skill in working with metal and plastic.

Basic rules and criteria for choosing a finished model

If you can’t make a planter with your own hands for various reasons, you can purchase it at any construction market. However, when choosing a model, you should pay attention to such aspects.

- Productivity . The most effective devices are those with a trailed operating system, since they allow you to process a fairly large area of land. For sowing in small areas, it is more advisable to use manual units.

- Weight . Manual seeders are the lightest, which greatly simplifies the work process and does not overload the farmer. Towed devices carry the heaviest weight, and you need to get used to working with them.

- Functionality . Trailed devices have the richest functionality, which can be used not only for sowing seeds, but also for cultivating, loosening the soil, applying fertilizers, etc. Manual units are considered less functional.

- Adjustment options . Typically, the simplest manual models cannot compete with automated devices in terms of adjusting furrow depth and row width. Trailed planters are equipped with a function for adjusting these parameters, and also make it possible to change the size of the hole in the seed container, which significantly expands the range of seeds sown.

Today, manufacturers offer consumers a huge range of seeders that have excellent functionality, practicality and a long service life. Among the models that are popular with farmers are precision seeding devices “SOR-1/1”, “1001-V”, “SMK-1”, pneumatic models made in China and Poland, and trailing mechanisms made in China, Ukraine, and America.

Constructions

All models introduce seedlings into the ground; they differ in the method of sowing. Spreaders and planting equipment are provided.

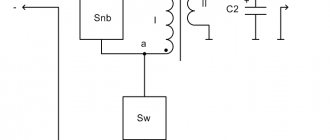

Operating principle of spreaders

There are two types of spreaders:

- Manual: seeds pour out through the holes when you turn the handle of the device; there is a built-in distributor inside. The ability to adjust the diameter of the holes allows us to classify the devices as universal. Usually made of plastic. They are used for spreading fertilizers, but mainly as a manual lawn seeder.

- Mechanical: there is no motor, but there is a moving part. Seeds fall into the ground by periodically pressing a button on the handle while moving. One or more containers for seedlings are attached to the axis.

The main disadvantage of spreaders is the unevenness of sowing, so they are rarely used for vegetables, more often as a disperser for lawn grass.

Precision Fitting Devices

To uniformly sow vegetables, precision sowing devices are used, created on the principle of transmitting torque from the wheel to the shaft:

- Simple: the device moves, the shaft with recesses rotates, the seed from the cone-hopper falls on it, lingers in the recess, and then falls into the prepared groove with a given step. The seeding density depends on the distance between the recesses.

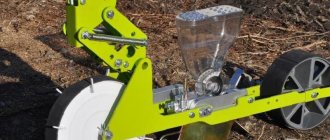

- Complex: the principle of operation is the same, but additional devices are added. Blades or spikes are attached to the front wheel to create grooves during movement, while the rear wheel is made level, which allows you to level the ground after landing. The supply of seeds to the shaft is regulated by a valve, and the seedlings move from the hopper along a special spout .

They are suitable for crops with small seeds, just like a seeder for regular lawn grass.

Note! The device allows you to work in a comfortable position, increases the sowing speed, and the seeds are distributed evenly.

Recycled materials, jars or plastic bottles will be useful when making a simple version of the product, and iron sheets, wheels, etc. will be needed for complex designs.

How the tool works

The operating principle of a simple seeder can be seen in various videos on the Internet. If we describe the procedure step by step, the process looks like this:

- Planting material is placed in a special container.

- When the tool moves, holes are formed for planting, into which the vegetable cloves are placed.

- After this, the planting material is covered with earth.

Attention! A seeder, the basis of which is a motor block, works better on loose soil; in heavy soil the work will not be too easy.

Modern mechanical seeders often have a water reservoir to water the seedlings immediately after planting.

Wood is most often used for hand tools.

Devices for planting carrots

In country garden beds, carrots occupy a small area, so for planting it is enough to use improvised means.

Manual planters

An easy way to spread seeds evenly in the garden is to use common household items to help plant the seeds at some distance from each other. Manual carrot planter includes:

- medicine box with dispenser - sowing is done by squeezing,

- medical syringe - push version,

- old salt or pepper shaker - the holes are widened for planting.

It’s useful to know, read: — Choosing a manual seeder for small-seeded crops.

A do-it-yourself carrot planter can be made from different materials:

- from a plastic bottle: you can drill or punch a hole in the cap using a nail or screwdriver. For sowing, a tube is inserted and the seeds are mixed with sand. If you cook a paste from flour or jelly from starch, and then add seedlings to it, then the tube will not be needed;

- from a block: screw or nail bottle caps to the board at a distance of 1.5–2 cm. They squeeze out holes in the garden bed, fill them with seeds, water them and cover them with soil. If the lids are replaced with wooden pins 5 cm long, you will get a manual garlic planter;

- from a wooden rake: the teeth are fixed perpendicular to the ground, they are used to make holes in a loosened bed, and plant a vegetable.

Seeders for garden beds

A more convenient way of planting is to make simple devices. A do-it-yourself carrot seeder includes a roller and consists of a round body, an axis of rotation and a handle-handle. In the body, the central hole provides the ability to rotate around an axis, and the diameter of the holes is for planting crops. The handle sets the roller in motion, the body rotates, and the seeds fall out.

Note! When using a homemade roller, you do not need to bend towards the ground. The height of the handle is adjusted to the height of the person. Allows you to plant other crops with small seeds.

A manual carrot seeder, made with your own hands: metal tubes that are bent at an angle depending on the height of a person are suitable for the work; the container for grains is made in the form of a cone or funnel from a sheet of iron. A hopper (one or several) with the top down, wheels and handles are attached to a metal axle.

Rules of application

It is recommended to sow the lawn in dry soil in calm weather. Before you start sowing, you need to loosen it with a fan or regular rake and level it. The surface soil layer must be compacted with a roller or roller.

The operating principle of the hand-held device is very simple and looks like this:

- Pour the seeds into the hopper.

- Operate the seeder using pushing movements while simultaneously rotating the handle.

For maximum uniform seeding, you can use the cross method. To do this, the number of seeds must be divided in half: one half should be sown lengthwise, and the other half crosswise.

Important! To prevent the crops from being dense and the seeder from clogging, you should not immediately pour a large number of seeds into the box. It's better to add them gradually.

The principle of operation of mechanical devices is the same as that of manual ones. But you don’t need to turn the handle in them. The diffuser is activated by pressing a button. Adjustment of the dispenser occurs without much effort. Professional machines are controlled using levers and buttons. After the seeds are scattered over the area, the ground must be leveled with a rake, covering them with a layer of 5 mm. It is also recommended to carry out compaction.

So, you can get the perfect lawn at your dacha if you sow it using a seeder. For small areas, hand-held devices are suitable, which you can buy or make yourself from improvised means. If you have to cover a large area with a grassy carpet, then it is better to purchase a mechanical unit.

Let's make a seeder from a plastic bottle

This seeder is inexpensive and simple.

Prepare a used plastic bottle and tool. A suitable bottle will be the one that suits you in volume: 0.5 liters, 1 or 2 liters.

Holes in the bottom of a plastic bottle can be drilled or pierced with a hot nail. To avoid getting burned, hold the nail with pliers over a fire or heating device. Holes must be made all over the bottom: first, a little and check by pouring the seeds, shake over the pan, if this is not enough, do more.

See the diagram for hole diameter:

Manufacturing

- Drill a hole right through the middle of the plastic jar, and make another one on the side to fill in rectangular or triangular seeds.

- Make a lid from a tin that will cover the second hole. Make sure that it fits tightly to the jar and that the seeds do not spill out through it. It is best to secure it at the bottom and leave the top part movable. To add the seeds, you only need to slide this lid.

- Insert the metal tube into the plastic one and place it in the center of the jar, making a kind of shaft on which the jar with seeds will rotate.

- Secure these tubes with a bolt, placing washers on both sides so that the container rotates freely.

- Using a hot nail, we make holes of the required diameter at the required distance along the side of the can. It is clear that these sizes will depend on what crops you will sow with its help.

- The seeder is ready, all that remains is to screw it to the wooden handle. For greater efficiency and automation, it can be placed on the front of the chopper. In this case, after sowing, you will immediately cover the seeds with soil using a hoe.

Do-it-yourself precision fit device

The model is made according to a drawing prepared in advance. A simple version is made from a plastic or metal round jar with holes in diameter, their size is for the seeds of the planted crop, a pusher handle and an axis of rotation.

Another option is an axle with attached two wheels, a shaft, a grain hopper and a pusher handle. Notches are drilled into the shaft, but not holes. The seeds fall out of the hopper and are evenly distributed throughout the row thanks to these depressions. It is better to make the bunker out of plastic so that you can see the number of seeds, but a box made of wood or metal will also work.

You can attach a coulter to form furrows; to level them and cover them with soil, use a piece of foam rubber or a hoe. If several bins are installed on the axis, the planting width will increase.

Important! Before sowing, adjust the planting depth, row spacing, and seedling consumption rate.

A homemade seeder allows you to plant different crops with small seeds, beets, phacelia, etc.

The small seed model is suitable for small areas or greenhouses. It speeds up and simplifies the planting process and is safe to use. Depending on the budget, the device is purchased or made independently. Spreaders are suitable for planting lawns and alfalfa; precision sowing or universal models are suitable for vegetables.

Average cost of equipment in Russia (RUB)

| City | RDA 600C | RDA 800C |

| Moscow | from 2,500,000 | from 5,000,000 |

| Ufa | from 2,300,000 | from 4,500,000 |

| Kazan | from 2,350,000 | from 4,750,000 |

| Nizhny Novgorod | from 2,450,000 | from 4,650,000 |

| Krasnodar | from 2,500,000 | from 5,000,000 |

The cost of the equipment indicated in the table is given approximately, since it is unrealistic to cover all offers. The cost of sowing equipment may fluctuate in one direction or another depending on the condition of the equipment, model, configuration and region in which the seeder is located. You can purchase used equipment in excellent condition relatively cheaply. And even if you need to carry out some repair work, there are no problems with spare parts for the seeders of this series - they can be purchased from the manufacturer’s official dealers.

Review of the precise seeding seeder STV 12

A field with even seedlings and regular rows - with the advent of the latest improved technology, was no longer the dream of a great farmer. The highest precision of the pneumatic mechanism of the STV-12 seeder allows farmers to plant with an accuracy of up to mm. What personality does the STV 12 seeder have, reviews and videos from users in one article.

Combined seeder Amazone Primera DMC 9000 in Germany

| Year of issue | 2012 |

| Country of residence | CompanyMERKANTIL EXPORT-IMPORT GMBH Hunt down this dealer Are you tracking this dealer? Stop tracking This Amazone Primera DMC 9000 combination seed drill is offered for sale by a dealer in Germany. You can find the dealer’s contacts above on this page, to the right of the photo of the machine. You can call the merchant at the indicated telephone number, or write through the request form. Before purchasing this Amazon Primera DMC 9000, it is important to check the correspondence of the information indicated in the ad with what is actually on the merchant’s site. It is also better to make sure of the reliability of the merchant himself. We wish you a successful search and a profitable purchase together with Mascus! Recommend on Facebook Send by e-mail Your message has been sent. Oops, something went wrong... |

Amazone Primera DMC grain seeder: technical properties, reviews

The product range is updated from time to time with new models of versatile and productive pneumatic seeders. Several modifications of different performance Amazone Primera DMC were made taking into account the experience gained from operating previous products, as well as customer reviews and wishes.

- The grain seeder of this brand is characterized by wide functionality, providing the opportunity to choose a technology for processing complex soils in various weather conditions.

- Classic cultivation methods in combination with new progressive no-till and mini-till surface mulching systems provide good results when exploiting problem soils.

- The Amazone Primera DMC seeder combines in its own design the advantages of a parallelogram suspension of depth-adjustable chisel coulters and effective REMOVAT protection against hard inclusions.

The modification made it possible to reduce the duration of loading downtime from 30 to 15 minutes, increase the time of non-stop sowing of seeds and fertilizers from one and a half to 3 hours, and also increase the daily productivity indicator from 250 to 300 hectares. The bunker system makes it possible to introduce seed material and two types of mineral fertilizers into the soil at once in one pass of the unit.

Device and technical abilities

Thanks to their compact dimensions and low overloads on the base, seeders with certain restrictions can be towed on public roads with hard asphalt or asphalt concrete surfaces. There is space for rapid readjustment of the product from transport to working position.

- The high-performance and easy-to-maintain Amazon Primera DMS seeder provides the highest sowing performance at speeds of up to 15 km/h. The integrated computer unit Amalog+ monitors all working actions and displays data on the filling of the bunker, the speed of movement of the seeder, and the number of hectares of cultivated area on the electric screen.

- Thanks to the transparent caps of the distribution heads, visual control of the supply of seeds and fertilizers to the working bodies is simplified. Optionally, the all-round Amazon seeder is equipped with a loading auger driven by the tractor's hydraulic system.

- A special coulter system guarantees the exact depth of seed placement, as well as a given dose of seed material, regardless of its shape and size.

Obstacles associated with the huge amount of organic matter in the soil left after harvesting previous crops, including in areas with complex surface microrelief, are completely eliminated. A direct sowing seeder can be used with equal success to apply mineral fertilizer to legumes and grain crops.

Technical properties of the wide-cut seeder DMC 9000

The pneumatic seeder of this version combines, in its own parameters, the highest productivity with a compact design and advantages corresponding to this series, namely, the introduction of tractor tractors with engines with power from 270 hp.

- The dimensions of the product do not exceed the specified characteristics. The length of the 9000th model seeder in transport and working versions is 9600/8800, width - 9200/4800 and height - 3580/3630 mm.

- Together with a light dose of seeding rates ranging from 2 to 400 kg/ha, the seeder provides a measured seed placement depth of 80 mm.

- The sowing complex weighing 8.5 tons is equipped with 12 coulter modules with a total of 48 pcs. The row spacing is 18.75 cm. The shares are installed at intervals of 750 mm with a clearance in the area of 500 mm, the pressure on any share is within the limits of 52 kg.

The usual hopper capacity of 4200 kg can be increased by installing additional sides. The unit is equipped with quick-release metering rollers for various seeding rates.

Similar dispensers are available as options for sunflower, corn, legumes and granular fertilizers.

The adjustment of seed rates is carried out using a maintenance-free Vario continuously variable gearbox. Self-calibration of dosing parts does not require special qualifications or equipment.

Photo: Amazon seeder in action

Modifications

The range offered by Amazon contains versions with working widths from 3 to 12 meters, which allows you to choose a model in accordance with the traction characteristics of the tractor.

- Namely, Amazone Primera DMC 3000 products can be coupled with 80 hp tractors.

- Amazon DMS 4500 is aggregated with tractors from 130 hp.

- Modification 602 is used with tractor power from 180 to 250 hp.

- For the most productive model 9000 this figure is 270-300 hp, and for 12000 this figure varies between 350-400 and more hp. depending on the density of the soil.

In any case, a supply of traction traits in the range of 15-20% is required. Different versions of this model differ in different working widths, productivity, specific ground pressure, number of coulters and loading hopper capacity.

4.56912Transport width, m34.534.54.5Total weight (empty), kg480056006400850015000Weight (full), kg8200900098001190020100Trailed hitchNumber of openers1624324864Number of opener modules46812 16Distance between rows of coulters, mm840840840840840Row spacing, cm18,7518,7518,7518,7518,75Distance between shares in a row, cm7575757575Road clearance in the coulter area, mm500500500500500Central adjust. depth of coulter modulesdadadadadaShare pressure (constant), kg/share5252525252Seed hopper and fertilizer hopper volume4200 l. (3/4 seed material. 1/4 fertilizer) 4200 l. (3/4 seed material. 1/4 fertilizer) 4200 l. (3/4 seed material. 1/4 fertilizer) 4200 l. (3/4 seed material. 1/4 fertilizer) 6000 l. (3/4 seed material. 1/4 fertilizer) Operating speed, km/h 10-1810-1810-1810-1510-15 Tractor power, kW/hp 60/8095/130133/180200/270260/350 Recommended tires 700/ 45-22.5 PR700/45-22.5 PR700/45-22.5 PR700/45-22.5 PR700/45-22.5 PRAdvantages and disadvantages

Amazone Primera DMC are modern seeders that have a number of important advantages over their analogues of the same type. This:

- saving fuel and lubricants and working time by an average of 15%;

- significant reduction in operating and depreciation costs;

- environmental friendliness of sowing technologies and preservation of the structure of problematic soils;

- stability of water balance on cultivated areas;

- the possibility of introducing anti-erosion, very gentle technologies for cultivating various types of leguminous crops.

The unit system eliminates the sticking of seeds and fertilizers in the bunkers, which is more possible at high air humidity. For partial drying, the heat generated during operation of the on-board hydraulic system is used.

Among the shortcomings, it is necessary to emphasize the low comparability of agricultural machinery imported from other countries, including seeders with tractor tractors made in Russia and near abroad.

Almost all owners negatively perceive the high cost of the products themselves, the price range of service, consumable devices, and the lack or low qualifications of professionals in setting up computer equipment.

Video: review of the Amazon DMS seeding complex

Host reviews

Over three seasons of operation, the Amazon 8000 model seeder showed its best performance. Concerns regarding the wear resistance of working parts turned out to be in vain. After processing 16 thousand hectares, the output of coulters is low. Our most massive tractors are the T-150K and Belarus-2122 with the Amazon seeder; we have to cooperate with the owners of massive John Deere and New Holland machines. Vladimir Anatolyevich

Last year, the agricultural company’s fleet of suspended units was replenished with 3 imported Amazon seeders. Two machines with a 6-meter grip have already worked for a full season without any problems. The property of sowing work is at the highest level. We will use the most powerful tractor for the most productive model 9000 seeder. The seeder system is intuitive; the description was required only to clarify certain points. Our experts believe that the cost of the resulting sowing equipment when renting it out for a short-term lease can be compensated within 2-3 years. Eugene