In agriculture, traditionally it is necessary to use a large number of different types of equipment, since the farmer’s craft is one of the most difficult. Farmers have to take care not only of the land, but also of animals and many other objects of their activity.

But the main burden falls, of course, on working with the ground. After all, you have to devote a really large amount of time and, of course, effort to it. The fact is that here you have to perform many complex processes at once, such as loosening, plowing, sowing and much more.

So, without technology, it is almost impossible to fully cope with the totality of these tasks on time.

Description

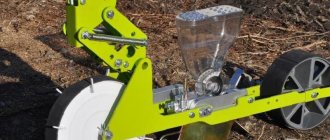

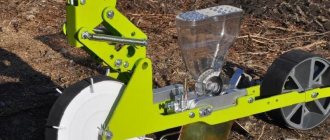

The simplest single-row manual precision seed drill consists of the following parts:

- Funnel-shaped seed hopper with a capacity of up to 1 liter (1-1.5 kg);

- 2 support drive metal wheels with lugs, with protrusions 1-3 cm high;

- A sowing hub (drum) with holes with a diameter of 3-5 mm, located on the same shaft with the drive wheels;

- Wedge-shaped vomer;

- Attachments for cuttings in the form of a tube screwed into the front of the seed hopper.

In addition to this simple design, there is also another, more advanced and reliable one. The single-row model of such a seeder consists of:

- Rectangular frame;

- Seed hopper with a capacity of up to 2 liters with a tight-fitting lid;

- The sowing unit is a bushing mounted on a shaft with a sprocket for a chain drive. In this case, the size of the holes on the bushing ranges from 3-4 to 16-18 mm;

- A coulter with a harrow installed behind it for filling a furrow with seeds placed in it;

- Front drive wheel;

- Drive chain mounted on the sprockets of the front wheel and seeding unit;

- A wide rear press wheel with a bracket for cleaning it from dirt and sticky wet soil;

- Markers for adjusting row spacing;

- Split handle with length adjustment.

These seeders are used to sow vegetable crops such as:

- Eggplant;

- Peas;

- Onion;

- Carrot;

- Cucumber;

- Pepper;

- Parsley;

- Radish;

- Beet;

- Tomatoes;

- Beans.

Also, with the help of such seeders, you can sow honey-bearing grasses in rows: alfalfa, sweet clover.

Manual seeder

Important! To sow non-standard seeds, many practical gardeners buy bushings without any recesses and make holes of the appropriate diameter in them themselves.

Among the types of manual seeders described above, the first ones are used for sowing small beds of small-seeded crops in greenhouses and greenhouses, while the more productive second ones are used for sowing large-seeded vegetable crops in open ground.

Kinds

There are several different types of seeders, which vary depending on how they perform the planting process. After all, there are several different options for delivering grain to the ground with high precision.

Mechanical

The first option, which is considered classic, is a mechanical precision seeder. In this type of seeder, the drive comes from the wheels, without the use of any pneumatic mechanisms.

Mechanical

This method of sowing is time-tested and has been used for a long time, so there is no doubt about its effectiveness.

The design of such a unit is not complicated in any way, and therefore it is more durable than many analogues.

The price range for such agricultural machines is quite high: it starts from several hundred dollars and reaches tens of thousands.

Mini

Mini precision seeders, as well as lawn seeders, are quite common in agriculture, because they are perfect for compact areas that do not require large units. This type of equipment is characterized by its small size and high mobility.

Mini

As a rule, the sowing technology itself is quite simple, which makes it possible to effectively deliver grain to the ground and do this using a trouble-free, time-tested mechanism. The cost of such equipment for sowing with high precision ranges from several hundred to a thousand dollars.

Pneumatic

The pneumatic seeder differs from previous versions by a more advanced mechanism for feeding grain to the ground. For this, a special pneumatic mechanism is used, which directs the contents of the container and, naturally, does this more quickly than it happens mechanically.

Pneumatic

As a rule, such equipment requires more careful maintenance than conventional mechanical ones. Although the pneumatic feed mechanism is also quite reliable and durable. And in agriculture, it is the reliability of the unit that comes first. Purchasing this type of equipment will cost you approximately 1000 USD.

Vegetable

A precision seeding vegetable seeder is equipped with special devices that can accurately direct not only seeds, but also, for example, root crops and even sprouts into the ground. All this requires special feeding technology, so the mechanism here is more complex than on previous types of agricultural machinery.

Vegetable

You can sow a wide variety of vegetables: potatoes, garlic, cucumbers and much more. Prices for such a unit start from 1000 USD. and reach tens of thousands.

Principle of operation

Seeder

A mechanical precision seed drill of the simplest type works as follows:

- A sowing bushing with holes for a specific crop is installed on the drive shaft

- Seeds are poured into the hopper;

- Using a marker (for seeders of the second type described above), the row spacing is set

- The seeder is installed at the beginning of the first row of the sown area;

- The seeder is set in motion with a smooth and jerkless movement;

- The process of sowing seeds, hidden from the human eye, occurs as follows: each seed fits tightly into a hole in the bushing, then when it rotates, it falls into a groove made by a harrow and is filled up.

- If there is a press wheel at the back of the seeder, installed exactly in the center of the row being sown, the soil above the seeds is thoroughly compacted. This improves the contact of the seed material with the soil, accelerates its germination, absorption of nutrients and moisture by the sprout and its root system

- When working with such a unit, the sower must periodically check the amount of seeds in the hopper, filling it with new ones if necessary.

- After sowing is completed, the remaining seeds are poured out of the hopper, the sowing hub, coulter, harrow, and support wheels are removed and cleaned. The drive chain and sprockets are periodically lubricated with special lubricant.

Important! When operating the seeder, it is necessary to check the coulter, which can become clogged with grass or wet soil. If such an operation is not performed, gaps may appear - unseeded places that can only be discovered when seedlings appear.

When operating the seeder, it is necessary to check the coulter

How to make a do-it-yourself corn seeder

A DIY seeder is an easy-to-use piece of equipment. The selection of materials for the device depends entirely on the designer’s flight of fancy, although there are basic principles.

What to use to create a design

To make a seeder with your own hands, it is important to know its design. You will need:

- steel sheets 2.5 mm thick and about 1 m2 in size;

- latch, furniture hinge and glass cover;

- vomer;

- galvanized steel box (seed container)

- M6 screws and M5 bolts;

- 1-2 wheels;

- brush.

Seeder components and step-by-step instructions

For a homemade seeder you will need:

- a hopper into which seeds are loaded;

- one or more wheels for moving the seeder;

- grain dispenser sleeve;

- frame for mounting distribution mechanisms and wheels;

- blindly drilled holes along the edges of the seed sleeve through which filling occurs.

Creation instructions:

- Drill holes in the sowing shaft in 3 rows with different diameters that correspond to the types of seeds.

- Take a seed container and adjust the frame according to its size.

- Insert the sowing shaft into the holes with a diameter of 28.05 mm drilled on the sides from the bottom.

- Secure the grain container with bolts and attach a brush above it to regulate the sowing density.

- Adjust the correct configuration for the trapezoidal container with truncation and required holes.

- Attach the lid to the top of the tank using a furniture hinge and a special latch.

Homemade corn seeder.

Characteristics

Carrot seeder

The manual precision seed drill has the following characteristics:

- The number of sowing units (rows) - for modern models it ranges from 1 to 5-7;

- Type of sowing device - bushing or brush;

Important! The brush sowing unit consists of a drum with brushes and a calibration disk installed outside the hopper. The principle of its operation is as follows: when the drum with brushes rotates, the seeds fill the space between them and are pushed out into a certain hole in the calibration disk, installed opposite the exit window of the sowing apparatus.

- Type of harrow - plate harrows are installed on most manual seeding devices;

- The type of opener is wedge-shaped (pointed);

- Working width - in multi-row (2 or more row seeders) this characteristic averages 7-8 cm. In single-row units, the row spacing is adjusted by changing the length of the marker and can be up to 50-60 cm;

- Seed sowing depth – from 1 to 5 cm;

- Capacity (volume) of the seed hopper – the seed hopper of various units can hold from 0.4-0.5 to 2 liters of seed material;

- Type of rotation transmission from the drive wheel(s) to the sowing unit - direct (the sowing units are located on the same axis with the drive wheels) or chain (the sowing unit is connected to the drive wheel through two sprockets and a chain);

- The recommended speed of the seeder is 3-4 km/h;

- Productivity – from 2-3 to 10-12 hundred parts/hour.

Important! When you type in a search for this unit, the service often gives an option such as “sequivalley seeder” in the search prompt. Following this prompt will not bring any benefit to the user, as it relates to the field of dating, erotic videos, and photographic materials for adults.

Manual precision seed drill

Operating principle and structure of the seeder

This manual seeder is equipped with a special marker, which, when sowing the first row of vegetable seeds, marks the width of the next row (up to 50 cm), thereby you set a certain row spacing, which may be different for different vegetables. The marker can be installed either on the right side of the seeder or on the left, depending on the sowing method.

The seeder has a supporting frame on which a seed hopper (volume 2 liters), two wheels, a front drive and a rear drive for pressing the seeds, are attached. When moving, the chain drive mechanism drives the brush seeding unit, which delivers seeds into the furrow through the seeding hub.

The furrow is cut by a coulter located under the hopper. By lowering or raising the coulter, the sowing depth is adjusted (up to 5 cm). Using the sowing hub, you can regulate the frequency of seed feeding and thereby set the distance between seeds in the furrow (up to 10 cm). If sowing is carried out using a continuous method, this wheel can be turned off.

The seeds, having fallen into the furrow, are covered with earth by a raker and rolled with a pressure wheel. After sowing, the soil, if necessary, is mulched and watered. After field work, the manual vegetable seeder must be cleared of soil and the remaining seeds removed. Store in a place with low humidity, lubricate all rubbing mechanisms.

This seeder is made in the Republic of Poland from high quality steel and painted with a protective paint coating. In our online store you can always buy a manual seeder for precision seeding of vegetables and melons at a low price. We deliver throughout Russia, Belarus and Kazakhstan. Discounts are provided for wholesale buyers.

EASY, ECONOMICAL AND FAST! HAND SEEDER IS YOUR RELIABLE ASSISTANT IN YOUR GARDEN!

Adjustment

In manual seed drills, before sowing the following settings are performed:

- Seeding rates;

- Seed placement depths;

- Row spacing.

Lawn seeder

These settings are very important for quality sowing.

Seeding rate

The accuracy of the seeding rate on different types of seeding devices is regulated in its own way:

- In bush sowing devices, the seeding rate is regulated by selecting a bushing with the corresponding holes and the pitch between them;

Important! In order to make a bushing with non-standard holes and pitch, you can buy a blank and, having marked it according to the given parameters, make recesses (holes for seeds) of the required diameter.

- In brush sowing devices, the seed sowing rate is adjusted using a calibration disk with holes. The seeding rate is regulated by installing a corresponding hole on the calibration disk opposite the outlet window of the sowing apparatus.

Planting depth

The depth of seed placement is adjusted in seeders with a chain drive of the sowing apparatus. The adjustment process occurs as follows:

- The seeder is installed on a flat area;

- Place a board under the rear press wheel with a thickness equal to the planned sowing depth;

- Using the adjusting bolts, the coulter is lowered until it touches the floor. In this case, it is not the tip of the opener that should touch the floor, but its entire lower plane.

Row spacing

The row spacing is adjusted by changing the distance between the sowing units or extending the marker. The latter option is more convenient and allows you to create large row spacing when sowing, for example, a crop such as corn.

Do-it-yourself manual seeder

You can make a homemade precision seeder with your own hands using the following technology:

- A seed hopper of the required volume with a lid is made from tin;

- A hole is made in the lower part of the bunker for the shaft of the sowing apparatus;

- Two bearings are welded to the outside of the hopper on both sides. They are welded in such a way that the center of their inner diameter coincides with the center of the hole for the sowing apparatus shaft.

- An asterisk is welded to a metal axle 4-5 cm longer than the seeding wheel. On the other side of the shaft, a hole is made for a stopper - a cotter pin.

- A seed box with a coulter from an old pneumatic seeder is attached to the bottom of the bunker;

- A rectangular frame with two cross members is made from a corner or plates. The short end sides are not welded.

- A convenient two-horned handle with length adjustment is welded to the frame;

- A wheel from a clamshell bicycle with an asterisk is mounted in the front part of the frame;

- A wide metal wheel is attached to the rear of the frame;

- The hopper with the seed box and coulter is welded to the frame crossbars;

- Sowing bushings with holes for various crops are made from round sections of ebonite or dense plastic blanks. A hole of the same diameter as the driven shaft with the sprocket is drilled in the center of the resulting bushing.

- The sleeve is inserted into the neck of the hopper, a shaft with an asterisk is passed through it, which is locked with a cotter pin from the outside;

- A chain is put on the sprockets of the seeding unit shaft and the drive wheel;

- Before starting work, the chain and sprockets are lubricated with a special lubricant.

Important! You can make a spacious and convenient seeder from a separate section of an old corn or vegetable seeder. To do this, you need to make a handle in the rear part and install a wheel with a sprocket in the front part of the section and connect it with a chain to the shaft of the sowing device. Due to its heavy weight, such a seeder is not convenient for a girl, a physically weak teenager, or an old man. At the same time, its reliability and durability will be many times higher than that of other homemade analogues.

A manual seeder for vegetable crops and small seeds (grass and lawn mixtures) is a convenient device that will greatly facilitate the sowing campaign both in a small plot or in a greenhouse, and in medium-sized plots where there are no access points for tractors. Anyone in the household can use such a seeder, even a teenager. It has no dangerous moving parts and is easy and time consuming to set up. This technique is economically beneficial - each vegetable grown using it will have less labor and cost compared to manual sowing.

0 0 votes

Article rating

Manual seeder for precision seeding

A manual vegetable precision seeder is designed for single-row sowing of seeds of various vegetable crops, including beets, carrots, cucumbers and watermelons, tomatoes and zucchini, as well as other vegetables.

It allows one person to effectively sow a prepared plot of land of 10 acres in 1 hour without much effort. Precision seeding allows you to reduce seed consumption during sowing and evenly distribute planting material on the land plot. Thanks to the adjusting disk of the seeder, which has holes of different diameters from 1 to 10 mm, a different size is selected for each vegetable crop and this achieves the optimal seeding rate and seed savings.