A grinding machine is a device used to process workpieces made of various materials with an abrasive tool and can provide surface roughness from 0.02 to 1.25 microns. Grinding machines, which can have different designs, allow you to effectively solve problems associated with processing the surfaces of parts made of different materials.

One of the many types of grinding machines

Why do you need a grinding machine?

The purpose of the grinding machine is clear from the name itself - it is designed for grinding. That is, this mechanism is designed to process material (be it wood or metal). The goal is to achieve the lowest possible degree of roughness of the product. In some cases, grinding machines are also used to adjust any objects to the required dimensions (for example, you need to reduce the radius of a part).

Grinding machines are actively used in construction work. They are used when you need to polish boards and give them the smoothest surface possible. Most often, such “operations” are carried out before varnishing - in order to coat wood with any impregnation, you first need to clean it of wooden burrs.

Grinding machines are also used in factories. If a product or part turns out to be too large during production, it can be sanded. This will remove the excess layer of material and the product will acquire the desired appearance.

Grinding machine

Features of the devices

The portal-type processing center is available to the consumer in several versions. The table on which the workpiece is fixed can be movable or fixed. In the first case, it moves independently, in the second, a portal with processing tools moves along it.

Movable options involve mechanical processing of large metal workpieces. Structurally, such models are made according to the traditional scheme. In this case, the portal is stationary, and the longitudinal table moves inside it. The first one is made in the form of a load-bearing beam with a transverse-vertical spindle head.

The sizes of movable tables vary, which allows you to choose the most suitable option in accordance with certain parameters. If the unit is equipped with a tool head that rotates 90 degrees, then it becomes possible to process parts of the most complex shapes.

The high degree of automation, which is achieved through numerical control, guarantees excellent device performance. A portal CNC machining center minimizes human participation in the technological process.

Models from domestic and foreign manufacturers are presented on the market. In some cases, it may be advisable to purchase modifications made in China. The equipment is not inferior in quality to equipment from world brands, while its cost is acceptable to the consumer.

Types of grinding machines

Depending on their purpose, grinding machines are divided into several types. Each of them is different in structure and internal characteristics. Let's look at the main types of grinding machines:

- Cylindrical grinders. Used to process cylindrical products. They themselves are also universal and non-universal. In universal models, it is possible to rotate both the work table and the workpiece itself, and in some cases, the grinding wheel. Non-universal models do not have this function.

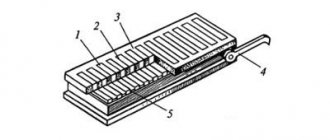

- Surface grinding. Designed for grinding flat surfaces that have a minimum angle of curvature.

- Centerless grinding. This type of machine is intended for mass processing and grinding of surfaces.

- Honing. Used for “delicate” grinding. During operation, the machine removes small layers of material from the surface of the product (their thickness can be only a few hundredths of a millimeter).

Main types of grinding machines

Video - Review of tabletop belt-disc sanding machines for wood

Surface grinding machine with round tables

Machines with round tables are designed for processing surfaces of round workpieces: rings, flanges, disks and other products with a roughness tolerance of 1.25–0.02. The table rotation is realized using a high-precision mechanism powered by an electric drive.

From us you can purchase machines with round tables measuring 200–400 mm with a maximum distance to the spindle center of 180–30 mm. If necessary, surface grinding machines of this type can be equipped with programmable controllers to control the movement of the table in the vertical plane.

Which is the best grinding machine to choose in 2022

Buying a machine is an individual decision for everyone. Therefore, it is impossible to single out any best grinding machine. So, for budget buyers, the best option would be the Einhell TC-US 400 or Zubr ZShS-330. For frequent use, it is worth purchasing a Holzstar ZSM 405 or JET 31A 2685033 machine. For those who have not yet decided on their choice, we have specially collected all the models discussed in the article in one comparative table:

| Name | Weight, kg.) | Belt rotation speed (rpm) | Cost, rub.) |

| 7,6 | 2950 | 6.500–7.000 |

| 7 | 2850 | 8.000–8.500 |

| 12,9 | 1450 | 9.000–9.500 |

| 18 | 1420 | 9.500–10.000 |

| 17 | 1450 | 11.000–11.500 |

| 20 | 1450 | 14.000–14.500 |

| 19 | 2850 | 15.000–16.500 |

| 34 | 1430 | 18.000–19.000 |

| 13 | 2000 | 25.000–28.000 |

| 145 | 2950 | 65.000–70.000 |

| 44 | 1400 | 70.000–75.000 |

| 80 | 1440 | 80.000–85.000 |

| 115 | 2400 | 90.000–96.000 |

Purpose

Internal grinding machines can machine conical or cylindrical, through or blind holes. They are in demand in the mechanical engineering industry , as they can be used in the production of the following products:

- gear or smooth shafts;

- ball or roller bearings;

- projections or recesses for inserting O-rings inside the shafts;

- cutting tools: cutters, drills, attachments, reamers.

Internal grinding machines can be used in various areas of production where flat, round internal or external grinding is required. Due to the ability to install abrasive wheels of the desired shape, it is possible to achieve optimal performance, as well as obtain the required level of roughness.

The equipment allows you to perform the following manipulations:

- rotation of the disk around an axis relative to a stationary part;

- rotation of the workpiece, the disk does not rotate;

- providing longitudinal or transverse feed.

Tips and tricks when choosing a grinding machine

In order not to make a mistake when choosing a grinding machine, you need to know some nuances. Now we will give tips that will help you when choosing a quality device:

- Before choosing, be sure to inspect the machine for mechanical damage. If they are present, then perhaps the machine is used (not new);

- Also, before purchasing, you should definitely start the device and check its performance. Very often, buyers do not do this when purchasing, and they may be sold low-quality, defective goods;

- When choosing, you should also take into account the characteristics of the machine. You need to pay attention to the maximum engine power, the presence of safety systems, the strength of the body and the resistance on the frame. Also important indicators of the machine are its endurance during long-term operation and resistance to temperature changes.

Video - Choosing a grinding machine for the workshop

Design and principle of operation

The structure of the internal grinding machine is as follows:

- bed;

- rack;

- spindle;

- Desktop;

- grinding disc;

- electric motor;

- controls or CNC unit;

- cooling system;

- frame;

- unit for fastening the workpiece.

The operating principle is as follows:

- the part is fixed;

- a grinding wheel of suitable size and parameters is installed;

- the machine starts;

- the circle is slowly inserted into the workpiece so that a certain part of the surface layer is removed;

- first, rough processing is carried out with the removal of large roughness, then fine;

- the number of passes of the circle inside the workpiece is determined by the requirements for the result, as well as the complexity of processing.

How does internal grinding work?

Voting for the best grinding machine

Which grinding machine would you choose or recommend?

JET 31A 2685033

0.00 % ( 0 )

Holzstar ZSM 405

0.00 % ( 0 )

Jet 10-20 PLUS 628900M

26.67 % ( 4 )

VISPROM BKL-3000

0.00 % ( 0 )

Triton TSPST450 TR894303

6.67 % ( 1 )

JET JDS-12X-M 10000490M

6.67 % ( 1 )

Record Power BDS150-EP

13.33 % ( 2 )

JET JSG-64

13.33 % ( 2 )

Proma BP-100 25702100

6.67 % ( 1 )

Encore Corvette-51 90510

6.67 % ( 1 )

Einhell TC-US 400

6.67 % ( 1 )

JET JDBS-5-M 10000470M

13.33 % ( 2 )

Specifications

Characteristics of machines for grinding internal surfaces:

- diameters of machined holes from 6 to 800 mm;

- engine speed from 12 thousand rpm. up to 80 thousand rpm;

- electric motor power from 1.5 to 11.5 kW;

- grinding head stroke length up to 500 mm;

- workpiece rotation speed from 10 to 2000 rpm;

- grinding speed up to 35 m/s;

- processing accuracy up to 1 micron;

- disc roughness from 0.08 microns.

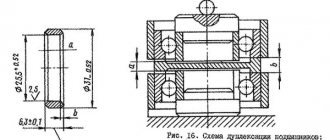

Kinematic diagram of profile grinding machine 395M

Kinematic diagram of profile grinding machine 395M

The 395M profile grinding machine can grind flat and round surfaces with complex profiles. The size of the sanded plane is 10 X 10 mm. The size of the plane during combined processing using standard tiles is 150 x 60 mm, the maximum thickness of the sanded product is 48 mm.

Several form-building executive movements are created on the machine:

- movement of cutting speed - rotation of the grinding wheel

- reciprocating movement of vertical feed - movement of the slide in the direction of the thickness of the workpiece 1

- profile feed - mutually coordinated movements of the upper 2 and lower slides 3 of the grinding headstock.

The kinematic group of cutting speed movement is simple . Its internal connection consists of one rotational kinematic pair between the grinding wheel spindle and the grinding head 4 mounted on the slide. The external connection is a belt drive between the motor shaft and the wheel spindle. All parameters of this movement are constant and cannot be adjusted. The grinding wheel with a diameter of 125 mm has 3000 rpm.

The kinematic group of movement of the vertical feed of the slider is simple , with an internal connection in the form of one translational kinematic pair between the slider 5 and the body of the grinding headstock.

An external connection transmits movement from the D1 engine through a belt drive to a pulley with a diameter of 110 mm and then through the is1 box and the rocker mechanism to the slider 5. This movement is simple, with an open trajectory and must be adjusted according to four parameters. In fact, the adjustment is made: to the path - by turning the eccentric bushing, which changes the position of the rocker pin, to the speed - by the feed box is1 of the slider (two stages of 45 and 85 stroke/min are possible), to the initial position - by changing the position of connecting the rocker to the slider through the lead screw on the slider; The direction of movement is not adjusted, since grinding occurs in both directions.

The kinematic group of the profile feed is complex , creating a two-element executive movement. Its internal connection, located between the upper slide 2 of the grinding headstock and the lower slide 3, includes not only the gear wheels of the gearboxes, but also the DC motors D2 and D3 and the worker himself, who looks at the screen and controls the rotation speeds of the motors D2 and D through rheostats. D3. Using an optical system, the screen displays a drawing of the workpiece profile, enlarged 50 times (the profile is drawn in dissected form with thin lines 0.2 mm thick), and the actual position of the contours of the wheel and the workpiece during grinding, also enlarged 50 times. The profile drawing of a part on the screen is like a copier, to the contour of which the worker tries to bring the circle closer. This internal connection is not purely mechanical; it also includes a person as an element of a biological connection, and such a connection, apparently, can be called biomechanical. Engines D2 and Dz are also in internal communication and, thus, external communication merges with internal communication. The accuracy of the work of this group mainly depends on the worker himself.

If a worker operates the machine manually with engines D2 and D3 turned off, then he is not only an internal communication element that coordinates the speeds of linear movements P3 and P4, but also a source of movement. The gearboxes of this group have built-in planetary mechanisms with a recessed key that connects the lead screw either directly to the worm wheel (fast movement) or to the left central wheel (slow movement).

Manual, vertical, longitudinal and transverse movements of the table 6 with the part to be ground are auxiliary movements, mainly necessary to obtain the correct image of the part on the screen.

The grinding head can be installed inclined in two planes.

To grind shaped bodies of rotation (round shaped cutters), a special device with its own motor is installed on the table, which allows you to rotate the part being ground (not shown in the figure).

The machine has a device for straightening the wheel.

Since grinding different sections of a part’s profile often requires the use of grinding wheels of different shapes, each wheel has its own flange to quickly change them during operation.

Selection principles

When choosing machines for internal grinding of parts, the following criteria must be taken into account:

- availability of necessary processing modes;

- rotation speed of the workpiece or working tool;

- headstock rotation angles, stroke length;

- availability and level of automation;

- maximum diameter of installed parts;

- processing accuracy parameters;

- equipment cost;

- availability of parts for sale, difficulty of maintenance;

- installed engine power;

- requirements for operating conditions.

Advantages and disadvantages

Advantages of grinding machines:

- high accuracy rates;

- wide possibilities for selecting grinding discs;

- performing processing of various materials;

- grinding of holes of any type;

- unpretentiousness of the equipment in operation;

- long service life of mechanical components;

- low cost of processing;

- availability of models with different levels of automation;

- adjusting the rotation speed of the workpiece or working tool.

The disadvantages of this type of equipment are the following:

- relatively small processing depth, complicating the preparation of large parts;

- lack of visual control of grinding;

- limitation on the diameter of the disks used;

- Corner angle processing up to 600.

High processing precision

Manufacturers and cost

The following companies are engaged in the production of internal grinding machines in Russia:

- OJSC "Moscow Grinding Machine Plant";

- JSC Saratov Machine Tool;

- JSC Lubensky Machine Tool;

- Voronezh Machine Tool Plant LLC;

- Lipetsk machine tool enterprise.

The cost of the machines is as follows:

- industrial ZL228 - from 2.5 million rubles;

- Spitzen SIG-80 with CNC, used in mechanical or instrument making, small-sized - from 4.2 million rubles;

- SI-6/1-AS small-sized universal for cylindrical and flat grinding - from 500 thousand rubles.

Varieties

Depending on the type of workpiece or disk feeding, internal grinding machines are of the following types:

- with a circular one, in which the workpiece rotates;

- with longitudinal with reciprocating movement of the part relative to the circle or vice versa;

- with a transverse one, in which the headstock is periodically shifted relative to the center line of the circle.

By automation method:

- manually controlled;

- automated, equipped with CNC.

Location of controls for profile grinding machine 395M

Location of controls for profile grinding machine 395M

- Grinding head lower turntable clamp handle

- Grinding head middle turntable clamp handle

- Handle for moving the lower support of the grinding head

- Screw for changing the gear ratio of the planetary mechanism (lower support)

Screw in position:

- a) the highest speed of movement of the caliper

- b) the planetary mechanism is turned off, the caliper is moved by handle 3

- c) the lowest speed of movement of the caliper

- Handwheel for manual movement of the upper caliper. For one revolution of the flywheel, the caliper will move 0.02mm

- Handle for tilting the movable glass frame

- Handle for clamping tracing paper together with a movable glass frame

- Flywheel for raising and lowering the product table

- Product Table Lift Column Clamp Handle

- Top light switch

- Bottom light switch

- Network switch

- Handle for longitudinal movement of the product table

- Clamping handle for the lower slide of the product table

- Handle for transverse movement of the product table

- Clamping handle for the upper slide of the product table

- Diamond grinder longitudinal movement screw

- Cross movement screw for diamond cutter

- Toggle switch for changing the direction of movement of the lower support of the grinding head

- Automatic control handle for the lower support of the grinding head

- General switch for upper and lower lights

- Spindle start and stop buttons

- Automatic control handle for the upper support of the grinding head

- Toggle switch for changing the direction of movement of the upper support of the grinding head

- Diamond grinder swing handle

- Clutch shift handle for changing the number of double strokes of the grinding spindle slide

- Spline groove for changing the stroke length of the grinding spindle slide

- The clamping handle of the grinding head after turning it to the back angle

- Hole for rotating the grinding head by the angle of the side edges

- The clamping handle of the grinding head after turning it to a side angle

- Screw for changing the gear ratio of the planetary mechanism (upper caliper)

- a) the highest speed of movement of the caliper

- b) the planetary mechanism is turned off: the caliper is moved by handle 35

- c) the lowest speed of movement of the caliper

Screw in position:

- A. Lower rotation scale of the grinding head

- B. Average rotation scale of the grinding head

- B. Upper rotation scale of the grinding head

- D. Rotation scale for the grinding head to set the lateral angle

- D. Grinding head rotation scale to set the clearance angle

- E. Diamond grinder rotation scale

Information about the manufacturer of the profile grinding machine 395M

Manufacturer of the universal profile grinding machine 395M is the Leningrad Machine Tool Plant named after. Ilyich , founded in 1924.

Since 1984, the Ilyich plant has been a member of the Association of Precision Machine Tools as the parent enterprise, and since 1993 it has been registered as the St. Petersburg Precision Machine Tools Plant, SPZPS .

Machine tools produced by the Leningrad Machine Tool Plant named after. Ilyich.

Currently, the St. Petersburg Precision Machine Tool Plant, SPZPS

- 3a10p

cylindrical grinding machine Ø 15 - 312m

cylindrical grinding machine Ø 200 x 500 - 395M

profile grinding machine 20 x 20 - 395MF10

profile grinding machine with digital display 20 x 20 - 3951VF1

profile grinding machine with digital display 50 x 50 - V-88

cylindrical grinding machine Ø 140 - LA155f30

- CNC longitudinal turning lathe Ø 16

Exploitation

When working on grinding machines, the following rules must be observed:

- the disk and the workpiece must be installed tightly, coaxially, without free rotation;

- the level of beats should not exceed the permissible values specified in the technical documentation;

- be sure to use protective shields to prevent operator injury;

- Before starting, you need to make sure that the protective system is working;

- It is forbidden to touch rotating components, mechanisms, workpieces with your hands;

- it is important to carry out technical inspections, replace damaged parts, and perform timely lubrication;

- if a cooling system is provided, then it is required to monitor its serviceability;

- It is unacceptable to use a heavily worn or damaged wheel;

- if overheating above +600C is detected, you need to stop work, find out the cause, and eliminate it;

- the optimal sized top layer should be removed in one pass, without causing overloads or malfunctions of the machine.

If there is a lack of power, you will need to replace the engine with a new one or install a gearbox or gearbox. The second option is more profitable, but the complexity of the design will increase several times.

DIY making

Creating a machine with your own hands will require at the initial stage to understand what characteristics it should have, and then select a ready-made drawing or find a ready-made suitable one in specialized literature. Next, you need to create a cost estimate based on detailing, assess the need to manufacture original parts, or purchase ready-made analogues.

To create an internal grinding machine, you will need to prepare the following components and tools:

- the frame, which is the basis of the structure, the minimum size must be 180x160 mm, constructed of wood or steel plate;

- the base is made of thin sheet steel, the thickness of which is at least 0.5 mm;

- select a suitable electric motor, wiring, switch;

- purchase fasteners;

- construct steel guides for moving the frame;

- purchase handles for adjusting the position of the cutting disc relative to the workpiece;

- vice for fastening the workpiece;

- grinding disc;

- attachments for the grinding disc.

Build process:

- A steel frame is being manufactured. A place is cut out on it for installing a platform with an engine.

- The base is attached to the lower part.

- On the side opposite from the engine, a vice or a clamping drum for workpieces with bolt-on mounting is installed on the frame. The position is centered relative to the centerline.

- The slides are installed parallel to which the engine is mounted on a special platform.

- A flange is attached to the motor shaft for installing a grinding disc.

- A drum is attached to the engine platform, designed to displace it relative to the fixed workpiece.

- The wiring and start button are connected to the engine.

- Protective screens are installed.

- The machine is put into place for its operation, and a test run is performed. If problems are found, the problems are fixed.

To ensure accurate movement of the working tool relative to the workpiece, it is necessary to use screw guides. When the drum rotates, the disc will move smoothly inside the workpiece.