A welder is a metal specialist who joins metal parts into complex structures using electric welding. By the way, in 2022, the ProfGid career guidance center developed an accurate career guidance test. He himself will tell you which professions are suitable for you, and give an opinion about your personality type and intelligence.

Welder is a working specialty and involves working in welding production. The specialist is engaged in connecting metal structures, parts, products, containers and pipelines of various types, composition, purpose and level of complexity. The quality of work and welding seams depends on a professional welder. In his work, mistakes are not made that could lead to catastrophic consequences. The profession of a welder is divided into several specialties: gas welder, manual arc welder, operator of automatic welding machines.

Pros and cons of the profession

Pros:

- high demand in the labor market;

- fairly high salaries for experienced welders.

Minuses

- difficult working conditions (sometimes you have to work in extreme conditions, at high altitudes or under the influence of various meteorological factors);

- heavy load on vision due to the high brightness of infrared and ultraviolet radiation, electric arc (the appearance of the disease electroophthalmia);

- the presence of other occupational diseases due to inhalation of industrial dust (silicosis, pneumoconiosis, bronchial asthma).

Under what conditions do we offer you training?

We offer training both full-time and evening. Students can also come to study on weekends. Groups are formed once every 7 days. Individual situations are taken into account.

Based on the results of listening to the program, each student takes a certification exam. If it is passed positively, the employee receives a qualification and a special state-issued welder certificate. He becomes the owner of a qualification category. If you have such a desire, you can take an additional exam - on fire safety (and then you will be given a fire certificate).

Salary and career

There is a shortage of technical specialists in Russia, so the salary of a first-class welder can exceed the income of a middle manager. Young specialists receive about 20,000 rubles, the salary of experienced high-level workers (the sixth highest category, assigned to highly qualified specialists) averages from 30,000 to 45,000 rubles monthly. But, as with other professions, the amount of a welder’s salary depends on the place of work, experience, hard work and desire to constantly improve their skills. Thus, the lowest salary for specialists is in the housing and communal services sector, and the highest in the oil and gas industry.

Typically, college graduates do not have to look for a job for a long time. Welders without experience are accepted into private service organizations and housing and communal services. With the acquisition of experience, young specialists are already entrusted with more responsible tasks and work in industry and construction sites.

Welder training

Our center for further education "MOSDOR" offers training to become a welder in Moscow. The training program consists of a theoretical part, which will be needed when working with different types of welding, and practical training at our welding site.

In what forms is gas welder training provided?

- In the primary one it takes 160 hours.

- In the form of advanced training.

- In the certification form – 16 hours. The task is to update skills, or (if the document has ceased to be valid) - to extend the validity of the certificate. Passing the certification is annual.

Now, many companies offer to buy a welder's certificate , but this profession is associated with increased risks and dangers, so undergoing training would be the best solution. Training at the MOSDOR training center includes not just theory according to professional standards, but also practical training at our training ground. Once the theoretical basics are mastered, our specialists will demonstrate all welding processes in practice.

Electrical and gas welder training includes the following sections:

- How to read graphs and diagrams correctly.

- Manual arc type welding method and its features.

- Gas-type welding method and its features.

- Techniques and devices for metal processing.

- Devices that allow you to do welding and cutting.

“Types” of welders

In any profession there is a division into narrower specialties. For example, doctors are “divided” into surgeons, dentists, therapists, and a couple of dozen other specialties. Welders have the same “types”. They are divided according to the equipment used to perform welding.

It could be:

- machine-press welding;

- diffusion welding installations;

- electron beam installations;

- thermite welding;

- gas welding;

- electric gas welding.

Each type must be studied separately.

Certification levels and positions of welders

Each certification level imposes certain requirements on the qualifications of welders.

- At the first level, the welder is, in fact, not a master, but an apprentice. Such workers are not usually classified as qualified. They continue to learn and perform relatively simple operations on non-critical structures. The first category is usually assigned to students of vocational schools, technical schools and colleges.

- The second category is received by students of the listed educational institutions. These specialists are sufficiently qualified to perform work with workpieces that are in a vertical or horizontal position. However, the experience and skill of second-class welders is not enough for work on sealing pipelines.

- A third-class verifier is also a graduate who has received a certificate or diploma. At the same time, this master showed higher abilities during training. Welders of the third category can form fillet welds and sealed joints on pipes. In addition, the theoretical training of these specialists should be higher than that of other graduates. They must read blueprints and assemble structures based on them. However, welders of this category do not have production experience.

- A welder of the fourth category can work with structures of medium complexity. Such a master can be called qualified. He will be able to weld in any position, with the exception of the ceiling. This specialist also has the skills to create sealed seams in the process of welding two pipes operating under pressure. The ability to read blueprints is also a prerequisite.

- A welder of the fifth category must have extensive production experience. Such a specialist must work in any position. It must create tight connections, weld metal of various thicknesses, etc.

- The highest level is the sixth category. A specialist who has reached this level can perform any operation. Moreover, only he can be trusted to carry out welding work, in which it is necessary to connect workpieces from experimental alloys. Achieving the highest category allows the welder to independently determine the welding method and consumables.

Responsibilities at work

The profession of a welder involves performing work in production or construction. The wizard's functions include:

- connecting metal elements (pipes, beams, fittings, assemblies and parts) in the required order using various techniques and equipment;

- performing repair work (surfacing of defects, cracks and cavities, soldering of individual parts);

- metal cutting, including according to specified shapes;

- welding of complex-shaped products in hard-to-reach places.

The responsibilities of employees also depend on their skill level. There are 6 categories in total. The owner of the first can only work with plastics, 2–4 is a manual welder (plasma and arc), 5–6 is a high-class craftsman who owns the most modern equipment and is able to work in difficult conditions.

The welder must:

- understand the design of welding machines (automatic, semi-automatic, manual), their power sources and electrical circuits;

- master several techniques for performing work;

- understand the physical and chemical properties of the metals with which you will have to deal;

- know the types of seams, types of joints, methods of creating a high-quality seam;

- navigate fire safety and labor protection requirements.

How is training to become an electric and gas welder completed at IMEI?

| ⇒ Filling out an application | ⇒ Conclusion of an agreement | ⇒ Tuition payment | Training and certification |

The profession of an electric and gas welder belongs to the category of high-risk professions. Workers in this profession are subject to additional labor protection requirements, including special requirements for training, certification, permission to work independently, instruction in labor protection and periodic testing of knowledge in the profession and labor safety.

Depending on the discharge, electric and gas welders can work with manual electric arc, plasma and gas welding. They can also perform work using automatic or semi-automatic welding.

Estimated cost

Approximate prices for studying to become a welder in educational institutions after graduation are given below:

- In college - 38,000-62,000 rubles per year .

- At a vocational school - about 45,000 rubles per year .

- At the training center - 9800-18000 for the entire course .

The approximate cost of courses depending on the specialization and number of hours is shown in the table below.

| Specialization | Number of classes | Approximate price in rubles |

| Argon welder | 15-20 | 16000 |

| Electric and gas welder | 18 | 10000-12000 |

| Electric welder | 12 | 15900 |

Buying a welding diploma will cost about 18,000-24,000 rubles . This service is usually used by people who cannot get the desired profession or who already have an engineering specialty, but are dissatisfied with the level of their wages.

How to increase rank

Before you upgrade your welder rank, you should know that you can move to the next level based on the results of qualifying exams. If a specialist successfully passes the exam, he will be able to increase his rank. It is also worth noting that the first three categories are assigned based on the results of training at a specialized educational institution.

Before improving the qualifications of a welder, you also need to know that the decision to assign the next category is made by a specially created qualification commission. It is she who issues a certificate that will serve as the basis for increasing the welder’s salary.

What prospects will open up for you after training?

Electrical and gas welder courses are an excellent chance to find a well-paid position in any field related to construction. We can talk about an organization engaged in automobile repairs, or the installation of metal structures, or an institution that carries out repairs and maintenance of buildings and structures.

Already working? Then such a document will confirm your qualification level and accelerate your career growth. A fire certificate will allow you to engage in welding and other fire-hazardous activities.

The demand for the welding profession in Moscow and the regions of Russia is growing every year. You can count on a solid salary and stable job in any economic situation.

Welder

A welder is a metal specialist who joins metal parts into complex structures using electric welding.

The profession is suitable for those who are interested in work and farming (see choosing a profession based on interest in school subjects). Welder is a working specialty and involves working in welding production. The specialist is engaged in connecting metal structures, parts, products, containers and pipelines of various types, composition, purpose and level of complexity. The quality of work and welding seams depends on a professional welder. In his work, mistakes are not made that could lead to catastrophic consequences. The profession of a welder is divided into several specialties: gas welder, manual arc welder, operator of automatic welding machines.

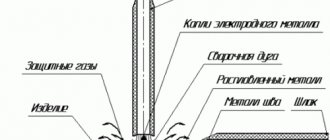

In their work, welders use electric arc welding or a gas torch. In the first case, an electric arc is used to melt metals, and the temperature at the end of the welding electrode reaches 5,000 degrees Celsius. This exceeds the melting point of all existing metals. When using a gas torch, a flame is formed due to the combustion of a mixture of flammable gas (hydrogen, propane, gasoline, butane, benzene, kerosene) and oxygen. This type of welding is usually used when replacing radiators and pipes in residential premises, due to the absence of sparks during the operation.

While working, it is very important for welders to observe safety measures and use special masks with tinted glass to protect their face and eyes. This mask significantly suppresses the brightness of flames and sparks.

Types of welders:

- welders on press welding machines;

- welders on diffuse welding installations;

- thermite welders;

- gas welders;

- welders on electron beam welding installations;

- electric and gas welders.

Where to go to become a welder?

In the last decade, a tendency has emerged to choose specialties related to mental work.

Demand for blue-collar professions has fallen among applicants; many consider them “unpresentable.” But labor is always needed, there are fewer specialists in these areas and they become more valuable, i.e. wages rise. The profession of a welder is one of the workers, which is difficult to overestimate in the modern world, where everything, literally, rests on metal structures. Where do you train to be a welder?

In order to acquire a useful and necessary profession as a welder, they enroll in vocational schools (vocational schools) or colleges in the “Welding Production” department. You can enroll after the 9th grade or after the 11th grade, the difference will be in the duration of study. Those who enter with incomplete secondary education study for 2.5 years, and those who complete eleventh grade will study for only a year.

If you have a choice, it is better to go to college, because... A college graduate has a better chance of finding a good job than a college graduate. This is because colleges provide students with more professional experience.

You can also learn to become a welder through vocational training courses. The advantage of a welding course is that it involves learning more hands-on than at a desk, and a short training period of two to four months.

What are future welders taught?

In different colleges and vocational schools, training to become a welder is carried out in the following areas:

- Gas welding. The gas welding machine can be used in any area where there is no electricity.

- Electric arc welding. The electric welding machine is one of the most popular due to its compactness and ease of use. But to work with electric welding you need access to electricity.

- A universal welder must know both the first and second types of welding work; to do this, you need to train as an electric gas welder.

- Argon welding is usually taught in courses for an additional fee. This is an innovative type of welding used for working with rare metals.

- Laser welding training is available to those who have mastered argon welding.

Having decided to become a welder, no matter what direction you choose, you will definitely study:

- occupational safety rules;

- basics of first aid;

- all types and devices of welding machines;

- electrical engineering and electrical safety courses.

For successful work, it is not enough to simply learn to be a welder; experience is a must.

After graduation, the graduate takes exams in theory and practice. Depending on the grade received in the exam, a rank from 2 to 4 is assigned. It is advisable to try to get a higher rank, because the salary of a young welder will depend on this.

The profession of a welder is currently in great demand on the labor market and the average salary in our country is 60-70 thousand rubles. The main thing is not to forget about safety precautions and your health while performing work.

Welder college after 9th grade

College of Architecture and Civil Engineering No. 26 invites school graduates to obtain the profession of “Welder”; training after the ninth stage is 2 years 10 months. Upon graduation from college, graduates are awarded the qualifications of a welder of partially mechanized fusion welding, a welder of manual arc welding with a consumable coated electrode, a welder of manual arc welding with a non-consumable electrode in shielding gas and is issued a state diploma of secondary specialized education.

We train workers for construction organizations, housing and communal services enterprises, public utilities - the scope of application of the acquired skills is quite extensive, because welding work is required in almost any production.

The state educational standard for the specialty “Welder (manual and partially mechanized welding (surfacing)” (training after the ninth grade) provides for the study of many professional and special disciplines, including:

- Basics of Engineering Graphics

- Basics of Electrical Engineering

- Fundamentals of Materials Science

- Tolerances and technical measurements

- Basics of Economics

- Life safety

- Basics of Economics

- Fundamentals of the theory of welding processes

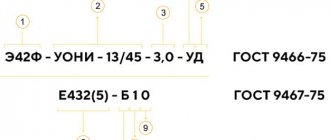

- Welding equipment and welding materials

- Manufacturing technology of welded structures

- Regulatory and technical documentation and certification system in welding production

- Quality control of welded joints

- Technique and technology of gas welding (surfacing)

- Preparatory and assembly operations before welding.

- Technique and technology of manual arc welding (surfacing, cutting) with a consumable coated electrode

- Technique and technology of manual arc welding (surfacing) with a non-consumable electrode in shielding gas

- Technique and technology of thermite welding

- Technique and technology of partially mechanized welding (surfacing) by fusion in shielding gas

- Technique and technology of manual welding with an external source of polymer materials

Features of studying the program and form of preparation

When training to become an electric and gas welder, you can learn more about:

- Features of deciphering drawings.

- Manual arc welding methods.

- Gas welding methods.

- Equipment for arc and gas plasma welding.

- Features of welding and cutting metal.

- Devices and apparatus for cutting and welding.

- Prevention of defects in welding joints and their subsequent elimination.

Electrical and gas welder training is carried out on:

- Based on the Institute of World Economy and Informatization (PI POO IMEI)

- With the teacher visiting the company.

- In remote mode.

Who will benefit from this course?

Training welders in Moscow will be useful for:

- For persons who wish to receive another education, which provides the right to admission to electric or gas welding, cutting of critical metal structures made of low-carbon steels.

- For workers who have welding skills and those who want to improve their skills.