3M634 Roughing and grinding machine with two wheels on a stand. Purpose, scope

3M634 roughing and grinding machine is designed for cleaning and roughing castings in a production workshop, as well as for performing metalwork work - deburring, chamfering, peeling sprues, for sharpening metal-cutting woodworking and other tools (drills, cutters, knives).

When using appropriate tools, they can be used for grinding and polishing parts.

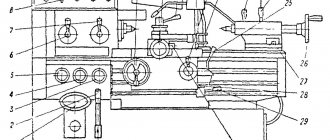

General layout of the 3M634 grinding machine

For stripping (cleaning) cast iron and steel castings, medium-hard (ST2) and hard (T) wheels with a grain size of 20 and 24 units are used.

3M634 type roughing and grinding machine complies with the “H” standard - this means that this equipment is excellent for finishing work.

3M634 machine is equipped with two 400 mm grinding wheels with a width of 40 mm, which are driven by a powerful 2.8 kW motor.

The rotation speed of the grinding wheels ranges from 1398 rpm. In this case, the distance between the centers of the circles is 700 mm.

3M634 roughing and grinding machine is capable of processing fairly large products - the maximum workpiece weight is 20 kg.

For operator convenience, the machine is equipped with small work tables 180 x 130 mm.

Grinding wheel type PP according to GOST 2424-83, GOST R 52781-2007, GOST R 52588-2011 on a ceramic bond.

Location of the main components of the 3M634 roughing and grinding machine

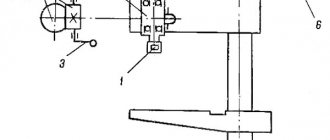

Sketch of a table for a 3M634 roughing and grinding machine

Photo of the 3M634 roughing and grinding machine

Photo of the 3M634 roughing and grinding machine

Photo of the 3M634 roughing and grinding machine

Photo of the 3M634 roughing and grinding machine

Rough grinding machine

» Machine » Rough grinding machine

The function of a traditional roughing and grinding machine is in its name. The intended purpose of such machines is the same, but despite this, they are divided into the following types:

- stationary;

- hanging;

- special equipment.

Roughing and grinding machine

Further details about them:

- Stationary. This category is represented by single- and double-sided peeling units, which are used for finishing small parts. This type of grinding equipment is divided into radial grinding and facing subtypes. The first type is very popular. This is facilitated by its characteristics, among which it is necessary to highlight multifunctionality. The set of such a grinding machine included abrasive wheels with a diameter from 40 to 75 cm. Their grinding intensity varies from 4 to 50 m/s.

- Hanging. This type of roughing and grinding machine is used for finishing medium and large-sized castings. The distinctive characteristics of this machine are that it is suspended. This allows you to unfold a large structure, raise and lower it without much physical effort. A distinctive feature in this case is the high power of the built-in electrical units and the large size of the abrasive ring. Accordingly, the performance indicator of this configuration is quite large.

- Special. This grinding-grinding branch is used by automatic and semi-automatic machines. It should be noted that they are used in the mass production of parts.

In a special roughing and grinding machine, a significant number of actions are performed automatically. A person is only required to install a “rough” version of the workpiece and then remove it after processing.

Mobile machines

Stationary and suspended machines are used for cleaning the casting surface. But the disadvantages of stationary machines include the inability to move. Curved surfaces are difficult to process in this way. For the purpose of self-installation of the grinding head on the working surface, the mobile unit is equipped with a head that is freely suspended on the sleeve pins.

Grinding and grinding machine model 3M634

The roughing and grinding model 3M634 is intended for roughing, casting and sharpening of tools and grinding of workpieces.

Sharpening machine 3K634

Technical characteristics of this roughing model:

- The diameter of the grinding wheels is 40 cm.

- The width of the rings is 4 cm.

- Table dimensions - 15x8 cm.

- The distance between the circular centers is 70 cm.

- The largest weight of the processed product is 20 kg.

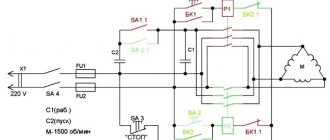

The 3M634 machine is equipped with a three-phase electric motor and is controlled by an irreversible magnetic starter type MPKO - 110.

Download the passport of the 3M634 roughing and grinding machine

Some recommendations for using 3M634:

- grinding wheels must be stored, tested and handled in accordance with the manufacturer's instructions;

- the demolition of the rings should not be different;

- the table must be secured securely upon completion of the next rearrangement;

- Only an instructed person can install the circles;

- rings and flanges should be inspected before installation;

- The casing is periodically cleaned from abrasive dust.

Grinding and grinding machine 3M636

On the market you can find a variety of offers of grinding equipment. But the 3M636 machine is the most common.

Double-sided sharpening machine 3M636

3M636 is designed for cleaning and roughening parts in industrial environments. Its excellent performance has resulted in high market demand. It is called a standard that confirms reliability.

In terms of class accuracy, this equipment is classified as standard “H”, and this becomes evidence that the described technique is used for the final finishing option. This machine was equipped with a pair of 60-centimeter grinding discs with a width of 7.5 cm. They are driven by a seven-kilowatt powerful motor. Grinding discs of version 3M636 rotate at speeds from 950 -1420 rpm. The distance between their centers is 102.5 cm.

3M636 machines can process fairly large castings. The maximum weight of a part can be 30 kg. This is quite enough to complete all the tasks that need to be solved in foundry production.

This peeling equipment comes with an oversized work table (11×20 cm). The overall dimensions of the machine are: 127.5x75x135 cm, and it weighs 860 kg. It is clear that it is difficult to transport such peeling machines. And it is recommended to take this into account when shopping.

Operating restrictions

Persons operating the machine must know its design, operating rules within the scope of this manual and safety requirements.

It is not allowed to operate the machine if it is mechanically faulty, if the grounding is damaged, or if there are no protective covers or safety devices.

Only persons of the appropriate profession, specialty and qualifications who have undergone instruction and training should be allowed to operate the machine.

The deflection of V-belt drive belts should be within 25-30 mm, when pressing the belt with a force of 70-90 N.

Before installation on the machine, new grinding wheels must be tested for compliance with the requirements of GOST 2424 “Grinding wheels. Technical conditions" and GOST R 52588 "Abrasive tools. Safety requirements".

It is prohibited to use grinding wheels with cracks on the surface, as well as those without a mechanical strength test mark or with an expired shelf life.

Before installing new grinding wheels on the machine, it is necessary to test them on a bench.

Installation of grinding wheels should only be carried out by specially designated and instructed workers. The fastening flange screws should be tightened sequentially in pairs using a normal-length wrench. The gap between the circle and the lower edge of bracket 15 should be no more than 6 mm.

You can start working on the newly installed circle only after a 5-minute test at idle speed.

It is forbidden to slow down the rotating circle by pressing on it with any object.

It is prohibited to reinstall the tool rests while the machine is running.

The machine and the devices included in its composition must have reliable grounding. The quality of grounding is checked by external inspection and measuring the resistance between the metal parts of the machine and the grounding clamp at the input to the machine. Grounding resistance is no more than 0.1 Ohm.

Preparing the machine for use

Before operating the machine, check:

- serviceability and completeness of the machine;

- serviceability of grounding, supply cable and plug;

- reliability of fastening of grinding wheels, protective covers and supports;

- serviceability of the dust collector exhaust device.

The tool rests must be installed so that the upper point of contact of the workpiece with the grinding wheel is above the horizontal plane passing through the center of the wheel, but not more than 10 mm. The gap between the edge of the tool rest and the grinding wheel should be less than half the thickness of the work being sanded, but not more than 3 mm.

Hand rests must be securely fastened. Rearrange the tool rests only when the machine is stopped.

Technical characteristics of the 3M634 grinding machine

| Parameter name | 3M634 | TS-4 (Stankograd) | TS-4 (Orsha) |

| Basic machine parameters | |||

| Number of grinding wheels | 2 | 2 | 2 |

| The largest outer diameter of the circle, mm | 400 | 400 | 400 |

| Maximum height (width) of the circle, mm | 40 | 50 | 50 |

| Wheel diameter, mm | 203 | 203 | 203 |

| Diameter of worn circle, mm | — | ||

| Unbalance class | 2/1 | ||

| Height of centers from base, mm | 850 | 900 | 950 |

| Distance between circles, mm | 700 | ||

| Table dimensions, mm | 150 x 80 | ||

| Number of tables, mm | 2 | ||

| Spidel | |||

| Rotation speed, rpm | 1398 | 1440 | 1440 |

| Maximum cutting speed, m/s | 30 | ||

| Electrical equipment | |||

| Power supply | ~380 V 50 Hz | ~380 V 50 Hz | ~380 V 50 Hz |

| Drive electric motor, kW | 2,8 (1420) | 7,5 | 7,5 |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 900 x 600 x 1200 | 1014 x 676 x 1301 | 1000 x 620 x 1315 |

| Machine weight, kg | 450 | 510 | 560 |

- Passport for roughing and grinding machine 3M634,

- Alperovich T.A., Konstantinov K.N., Shapiro A.Ya. Design of grinding machines, 1989

- Alperovich T.A., Konstantinov K.N., Shapiro A.Ya. Setup and operation of grinding machines, 1989

- Dibner L.G., Tsofin E.E. Sharpening machines and semi-automatic machines, 1978

- Genis B.M., Doctor L.Sh., Tergan V.S. Grinding on cylindrical grinding machines, 1965

- Kashchuk V.A., Vereshchagin A.B. Grinder's Handbook, 1988

- Kulikov S.I. Honing, 1973

- Lisova A.I. Design, adjustment and operation of metal-cutting machines, 1971

- Loskutov V.V. Metal grinding, 1985

- Loskutov V.V. Grinding machines, 1988

- Lurie G.B. Grinding machines and their adjustment, 1972

- Lurie G.B. Design of grinding machines, 1983

- Menitsky I.D. Universal sharpening machines, 1968

- Mutsyanko V.I. Bratchikov A.Ya. Centerless grinding, 1986

- Naerman M.S., Naerman Ya.M. Guide for training grinders. Textbook for vocational schools, 1989

- Popov S.A. Grinding work, 1987

- Tergan V.S. Grinding on cylindrical grinding machines, 1972

- Shamov B.P. Types and designs of main components of grinding machines, 1965

Bibliography:

Related Links. Additional Information

- Classification and main characteristics of the grinding group

- Repair, restoration and modernization of grinding machines: the American approach

- Cylindrical grinding. Processing on cylindrical grinding machines. Grinding Methods

- Setting up a cylindrical grinding machine when installing parts in centers

- CNC grinding machines

- Marking of grinding wheels

- Testing and checking metal-cutting machines for accuracy

- Grinding machines. Market of grinding machines in Russia

- Directory of grinding machine manufacturers

- Directory of grinding machines

- Directory of factories producing metal-cutting machines

- Articles on the topic

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Roughing and grinding machines

The function of a traditional roughing and grinding machine is in its name. The intended purpose of such machines is the same, but despite this, they are divided into the following types:

- stationary;

- hanging;

- special equipment.

Roughing and grinding machine

Further details about them:

- Stationary. This category is represented by single- and double-sided peeling units, which are used for finishing small parts. This type of grinding equipment is divided into radial grinding and facing subtypes. The first type is very popular. This is facilitated by its characteristics, among which it is necessary to highlight multifunctionality. The set of such a grinding machine included abrasive wheels with a diameter from 40 to 75 cm. Their grinding intensity varies from 4 to 50 m/s.

- Hanging. This type of roughing and grinding machine is used for finishing medium and large-sized castings. The distinctive characteristics of this machine are that it is suspended. This allows you to unfold a large structure, raise and lower it without much physical effort. A distinctive feature in this case is the high power of the built-in electrical units and the large size of the abrasive ring. Accordingly, the performance indicator of this configuration is quite large.

- Special. This grinding-grinding branch is used by automatic and semi-automatic machines. It should be noted that they are used in the mass production of parts.

In a special roughing and grinding machine, a significant number of actions are performed automatically. A person is only required to install a “rough” version of the workpiece and then remove it after processing.

Scope of application of roughing and grinding machines

Rough grinding is used to remove the defective layer of material from workpieces on castings, forgings, rolling, stamping and welding workpieces. In this case, the surfaces of the workpieces are cleaned without shaping them.

To increase the efficiency of rough grinding, a sharp increase in the volume of metal removed per unit time is used at high operating speeds, longitudinal feed rates and high clamping forces in the processing zone. This makes it possible to reduce the overall allowances for mechanical processing of heat-treated workpieces of increased hardness, and in some cases eliminate milling, planing, and fire cleaning when removing allowances of up to 10 mm or more per pass.

This method of high-speed rough grinding is widely used in mechanical engineering when processing workpieces by grinding without preliminary turning, in the metallurgical and foundry industries when preparing and finishing rolled products, and cleaning castings. With this method of rough grinding, a line of special rough grinding machines is used, operating at an operating speed of 60-80 m/s, a longitudinal feed speed of up to 60 m/min, a clamping force of 6000-10000 N, and a main drive power of 75-160 kW.

To operate on these machines, hot-pressed grinding wheels with outer diameters of 500, 600 and 800 mm are produced from zirconium electrocorundum with grain sizes of 160, 200 and 250.

The effectiveness of casting processing depends on the speed of action of the abrasive tool and the forces with which the abrasive tool acts on the surface of the casting. The higher the cutting speed and force, the more efficient the machining process. Processing efficiency is measured by the amount of metal removed from the casting per unit of time (usually per minute). The higher quality the casting is made, i.e., the fewer fills, tides and burns it has, the less labor intensive the processing of rough rough grinding.