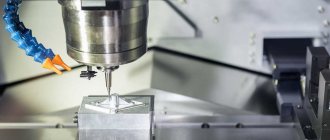

METAL CUTTING MACHINES, machines for making parts of other machines, mainly by removing chips from a workpiece with a cutting tool.

Much of what is produced by human activity today is done on metal-cutting machines or with machines made using such machines. Their range is very wide - from manual planing machines to computerized and robotic systems. More than 500 different types of existing metal-cutting machines can be divided into at least ten groups according to the nature of the work performed and the cutting tools used: cutting, turning, drilling, milling, grinding, planing, gear cutting, broaching, multi-position automatic, etc. Also on the topic:

MACHINES AND MECHANISMS

A cutting tool of one type or another (cutter, milling cutter, etc.) removes chips from the workpiece (metal, plastic, ceramic) in much the same way as what happens when peeling potatoes with a knife. The material of the cutting tool must be much harder and stronger than the material of the workpiece. The machine is equipped with a mechanism, usually consisting of slides, spindles, lead screws and tables with transverse and longitudinal movement, which allows the tool to be moved relative to the workpiece. On manually controlled machines, this relative movement is set by the operator, using feed handwheels to move the support with the tool holder. On computer numerical control (CNC) machines, movements are specified by a program of sequential commands stored in the computer's memory. The program turns on and off drive mechanisms, such as electric motors and hydraulic cylinders, which feed the caliper with automatic adjustment of the relative position of the workpiece and the cutting edge.

Almost all types of machines are available in both manual and CNC versions. In mechanical workshops for consumer services, in amateur home workshops, and in machine-building factories, cutting, drilling, turning, milling and grinding machines are most often found.

Slitting machines

Also on topic:

METALS MECHANICAL PROPERTIES

designed for cutting and sawing long products (rods, angles, channels, beams). The cutting tool is a segmented circular saw, abrasive discs or a hacksaw blade. The main movement is the rotation of the disk or the reciprocating movement of the hacksaw blade. Automatic cutting machines operate at different speeds and are equipped with periodic feed devices and two-axis control systems for the work table.

Drilling machines,

perhaps the most common type of machine. Purpose – drilling and processing of holes, the main movements are rotation and feeding of the cutting tool (drill). The drill is fed manually or automatically with feed and rotation speed switching. Depending on the material of the part and drill, drilling depth and hole diameter, the spindle rotation speed can be constant, have a number of fixed values, or variable.

Also on topic:

GEAR

Drilling machines for wider purposes are equipped with a work table with two slides moving at right angles to each other, a CNC device for moving the table and controlling the feed of the drill, and devices for automatically changing the drill. There are multi-spindle drilling machines that work simultaneously with several drills, and drill heads with multiple spindles are also used, mounted in the chuck of a single-spindle machine.

Lathes.

The main movement of a lathe is to rotate the workpiece, and the cutting tools (usually single-edge) are adjustably mounted on a stationary bed. The cutter can be fed along guides along or across the spindle axis. The workpiece is clamped either in the spindle chuck or in the centers of the headstock and tailstock. The feed rate can be controlled manually or automatically by a series of V-belt or gear drives driving the lead screw and cross slide of the caliper. The rotation speed of the workpiece is adjusted within a wide range in accordance with the selected cutting modes. The drive motor can have both fixed and variable speed. On lathes (and they form the basis of the machine park) the operations of processing cylindrical surfaces, transverse turning and trimming, cutting screw threads and boring axial holes are usually performed.

There are lathes of different types, types and sizes. A turret lathe, often used to produce identical parts, is equipped with several cutting tools mounted in a rotary (turret) support. The control unit of a CNC turret lathe gives commands for spindle movement, rotation and movement of turret supports, and movement of the tailstock. In cases where the weight of the workpiece is very large or its shape is such that it is easier to process the workpiece on a horizontal table, large rotary lathes are used. The work table of such a machine rotates along with the workpiece, and the cutting tools are fed either from the side or from the end of the workpiece.

All-Russian Classifier of Fixed Assets (OKOF) OK 013-94

The classification of machine tools in the All-Russian Classifier of Fixed Assets is part of the Unified System of Classification and Coding of Technical, Economic and Social Information (ESKK) of the Russian Federation.

OKOF was developed for use on the territory of the Russian Federation to replace the All-Union Classifier of Fixed Assets.

When developing OKOF, the following were taken into account: International Standard Industrial Classification of all types of economic activities (ISIC), International Standard Industriel Classification of all Economic Activities (ISIC), international Classification of Main Products (CPC) Central Product Classification (CPC), United Nations standards according to the international system of national Accounts (SNA), Regulations on Accounting and Reporting in the Russian Federation, as well as the All-Russian Classifier of Types of Economic Activities, Products and Services (OKDP), for which ISIC and CPC are basic.

OKOF was developed in accordance with the State program for the transition of the Russian Federation to the accounting and statistics system accepted in international practice in accordance with the goal of developing a market economy.

The all-Russian classifier of fixed assets OKOF OK013-94, approved by Decree of the State Standard of the Russian Federation No. 359 of December 26, 1994, is intended primarily for the purposes of statistical accounting of fixed assets. It is useful for appraisers when an assessment is carried out during the revaluation of assets or during a frontal assessment of the entire property of an enterprise and orientation is needed both in the structure of fixed assets and in the structure of the types of objects themselves.

Groupings of objects in OKOF are formed mainly according to the characteristics of purpose associated with the types of activities carried out using these objects and the products and services produced as a result of these activities.

The general structure of nine-digit codes for the formation of groupings of objects in OKOF is presented in the following diagram:

X0 0000 000 - section of fixed assets (1 - tangible, 2 - intangible);

XX 0000 000 - subsection of fixed assets, taking into account their importance for the economy as a whole and established traditions (11 - buildings, 12 - structures, 13 - housing, 14 - machinery and equipment, 15 - vehicles, etc.);

Example of coding in OKOF:

10 0000 000 – (section) Material fixed assets;

14 0000 000 — (subsection) Machinery and equipment;

14 2922 000 – (class) Machine tools and equipment;

14 2922 100 – (subclass) Lathe group machines;

14 2922 105 – (type) Center lathes, screw-cutting lathes and lathes.

The division into classes, subclasses and types in OKOF coincides with the classification according to the All-Russian Classifier of Types of Economic Activities, Products and Services (OKDP).

Milling machines.

These are universal machines with a multi-blade cutting tool - a milling cutter; the main movement is the rotation of the cutter. The spindle of vertical milling machines that carries the cutter is vertical, but in many cases it can be installed at an angle to the workpiece. The movement of the table, carried out manually or using a mechanical drive, is precisely controlled by graduated dials on the lead screws and by precision scales with optical magnification.

The milling mandrel (shaft carrying the cutter) of a horizontal milling machine is horizontal. The table on which the workpiece with the necessary equipment is fixed can be either “simple”, i.e. with movement along three axes, or universal, i.e. allowing angular turns.

CNC machines provide automatic control of table movement and spindle speed. In some cases, the spindle itself is mounted on a slide that allows its independent movement in the axial or vertical direction. This type of CNC machine allows serial and high-precision machining of three-dimensional surfaces, such as propeller blades and turbine blades.

Copy milling machines process complex curved surfaces, such as punches and dies for sheet metal stamping, injection molds and extrusion molds. The indicator probe passes along the figured profile of the copier, and the working cutter transmits this profile of the workpiece.

Classification of equipment by type of accuracy

Based on the accuracy that a mounted turning unit provides, it is assigned a grade:

- C. Characterize the equipment with particular accuracy;

- B. Assigned to units that provide high accuracy during operation;

- N. They give machines with normal accuracy;

- A. Assigned to devices that are particularly accurate;

- P. All have machines that provide increased processing accuracy during operation.

Grinding machines.

Such machines, the main movement of which is the rotation of the spindle of the grinding wheel, allow the processing of parts with a high degree of accuracy and cleanliness. The workpiece is fixed on the machine table, which can be moved in different directions using micrometric screws. The abrasive wheel material is usually silicon carbide or aluminum oxide, but boron carbide is used for grinding hardened steel, and natural or synthetic diamond is used for grinding glass and ceramics.

The abrasive wheel of a surface grinding machine for processing flat surfaces rotates on a horizontal mandrel above the table on which the workpiece is fixed. The fast reciprocating movement of the table, combined with a slower cross feed, ensures that the entire surface of the part is machined. Cylindrical grinding machines are similar to lathes (there is also grinding equipment for lathes). The workpiece rotates and a rapidly rotating abrasive wheel is brought into contact with its outer or inner cylindrical surface; sometimes two wheels are used, processing both surfaces at the same time. The centerless grinding machine is designed for high-precision external processing of the surfaces of steel shafts and pipes. The part, rotating between two feed wheels and held under the grinding wheels, is fed slowly until the entire length of the part has been covered. Shaped grinding is the surface treatment with a grinding wheel that has a complex profile (partially spherical, stepped), which is transferred to the part. The shaped profile is maintained by “diamonding” the grinding wheel.

Commodity nomenclature of foreign economic activity of the Customs Union (TN VED CU)

Commodity nomenclature of foreign economic activity of the Customs Union (TN FEA CU) - Classification of machine tools used by customs authorities and participants in foreign economic activity (FEA) for the purpose of carrying out customs operations. Adopted by the Customs Union Commission, the Federal Customs Service of Russia participates in the development and addition.

The Commodity Nomenclature for Foreign Economic Activity is an expanded Russian version of the Harmonized System (HS), developed by the World Customs Organization and adopted as the basis for commodity classification in the countries of the European Union and others. Each product is assigned a 10-digit code (for some products a 14-digit code is used), which is subsequently used when performing customs operations, such as declaring or collecting customs duties. This coding is used to ensure unambiguous identification of goods transported across the customs border of the Russian Federation, as well as to simplify the automated processing of customs declarations and other information provided to customs authorities when carrying out foreign economic activity by its participants. The classifier consists of 21 sections and 99 groups (77, 98 and 99 groups of the Commodity Nomenclature of Foreign Economic Activity are currently reserved and not used).

The 10-digit product code according to the Commodity Nomenclature of Foreign Economic Activity is:

2 first digits (for example, 72 - ferrous metals) - commodity group of the Commodity Classification of Foreign Economic Activity 4 first digits (for example, 7201 - pig iron and mirror, in ingots, blanks or other primary forms) - commodity item 6 first digits (for example, 720110 - cast iron unalloyed pig iron, containing 0.5% or less phosphorus) - commodity subposition 10 digits, full product code, which is indicated in the cargo customs declaration (for example, 7201101900 - unalloyed pig iron, containing more than 1 wt.% silicon) - commodity subposition.

The classifier “Commodity nomenclature for foreign economic activity” of the Commodity Nomenclature of Foreign Economic Activity and the Commodity Nomenclature of Foreign Economic Activity of the Customs Union is of interest primarily for appraisers who have to evaluate customs value. With the development of export-import operations, including those related to equipment, this classifier is becoming increasingly used.

An example of coding in the Tax Code:

XVI. (section) Machinery, equipment and mechanisms; electrical equipment; their parts; sound recording and sound reproducing equipment, equipment for recording and reproducing television images and sound, their parts and accessories.

84 - (group) Nuclear reactors, boilers, equipment and mechanical devices; their parts;

8458 — (position) Metal-cutting lathes (including multi-purpose lathes);

8458 11 — (subheading) Metal-cutting lathes (including multi-purpose lathes) with numerical program control;

8458 11 2000 — (subheading) Multi-purpose turning machines.

Other machines.

These include, in particular, planing, broaching and gear cutting machines. The latter are intended for cutting gears of various types - cylindrical with straight and oblique teeth, bevel, chevron, worm - used in modern mechanical engineering. Broaching machines are used for precise processing of the external and internal surfaces of any profile with a special multi-bladed tool, the teeth of which remove the entire allowance in one pass.

A multi-purpose machine (machining center) is similar to a milling machine, but has more movement axes and is always equipped with a CNC system. Milling centers allow rapid transition from one cutting process to another, for example from one drill to another or from a drill to a tap (a tool for cutting internal threads). Multi-tasking machines are usually designed to perform a combination of operations such as drilling, reaming, tapping, trimming, face milling, grooving, boring, etc. Models are available with vertical and horizontal spindles. Many manufactured machines can perform precise machining on four or five sides of a prismatic part simultaneously. When machining complex parts, such as a cylinder head or gearbox housing, that require a certain sequence of different operations, multi-task machines replace several machines of different types.

Introduction

In the structure of the machine park of enterprises, all pieces of equipment are systematized and classified using various classifiers . Classification of machines is needed to organize the collected price and technical information, as well as to quickly find the necessary information about similar objects in the existing arrays of Information.

Multi-purpose classifiers include:

In addition, there are private, industry catalog and other classifiers used in various nomenclature catalogues, directory catalogs and price list catalogs for certain types of machinery and equipment.

The classifiers listed above are built according to a hierarchical classification method, which provides for the sequential division of a set of objects into classification groups subordinate to each other: classes, subclasses, groups, subgroups, etc. In this case, a consistent decimal coding system is used, when for each characteristic (grouping) a certain number of decimal places is allocated.

FLEXIBLE PRODUCTION SYSTEMS

A production system is a group of machines that sequentially process one workpiece. For mass production of, for example, automobile parts, specialized production systems called automatic lines are used. Such a line consists of separate machines (milling, drilling, boring), interconnected by a system for moving parts from one machine to another. Automatic lines make it possible to reduce the cost of mass production of similar parts.

However, in mechanical engineering, serial and individual production predominate, requiring frequent re-adjustment of equipment. The use of conventional automatic lines in such production is ineffective. The basis of integrated mechanization here is group technology, CNC machines, industrial robots, and automatic transport and storage systems. On their basis, with the use of coordinating computers, quickly reconfigurable automated complexes are created, called flexible production systems (GPS). In the production of, for example, diesel engine cylinder heads, the GPS is capable of processing cylinder heads from 5 to 100 different sizes and types, and their blanks can arrive in a random order.

All-Russian Product Classifier (OKP) OK 005-93

Industry classifier of metal-cutting machines OK 005-93

The classification of machine tools in the All-Russian Product Classifier OKP OK005-93 is used to solve problems of product cataloging, including the development of catalogs and systematization of products in them according to the most important technical and economic characteristics. This purpose of the classifier is of interest for valuation activities, in particular for the construction of price list catalogs and databases containing price information.

OKP is the most detailed classifier of machine tools, including types of products. The structure of six-digit codes is as follows:

XX 0000 - product classes;

XX X000 - subclasses;

XX XX00 - groups;

XX ХХХ0 - subgroups;

XX XXXX - species.

Example of coding in OKP:

38 0000 – (class) Metalworking and woodworking equipment;

38 1000 – (subclass) metal-cutting machines;

38 1100 – (group) Lathe group machines

38 1140 – (subgroup) Lathe-backing machines, combined lathes and lobe lathes;

38 1148 – (type) Chuck lathes and screw-cutting lathes.

Using OKP codes helps you quickly find the information you need, which is very important when revaluing. As databases are created for individual types of machinery and equipment, the task of integrating them on the basis of a single classifier of assessment objects, for which it is advisable to use OKP, becomes increasingly important.