Modern technology has made it easier to process metals using lathes. Common areas of application: treating surfaces of various shapes, inside and outside. For example, a style or a cylinder, a cone. And each type of lathe has its own characteristics.

The types of machines are so diverse that each buyer has the opportunity to choose an option that meets specific needs. You just need to study the features of each model in advance.

Classification of turning equipment

The classification system for this type of equipment was created in the USSR. According to these rules, machines are units that process metal workpieces, representing the first category. Any device from this group can represent one of the following groups:

- Devices with special purposes.

- Special purpose machines, conventional and automatic types.

- Polishing units with cutters.

- Frontal and screw-cutting types of equipment.

- Models of the “carousel” system.

- Machines that cut material.

- A variety called "revolver".

- Installations with a large number of spindles, fully or semi-automatic.

- Lathe-type units, where there is one spindle. Half automatic, fully automatic.

The following varieties are distinguished depending on the accuracy of processing:

- P – increased level.

- A – high accuracy rate.

- N – normal indicator.

- B – high level accuracy.

- C – special category accuracy.

Certain technical characteristics depend on one category or another. In addition, it becomes easier to determine the appropriate field of application. Marking devices also helps to find out what parameters are typical for a particular model. Such designations may consist of the following components:

- When using a unit as the initial form. It shows that the buyer is dealing with a lathe and not any other.

- Next comes a number indicating belonging to one or another type of model.

- The centers of the fixture have different heights, indicated by the third and fourth numbers.

The marking of units may also contain symbols in the form of letters. They are used to communicate certain design features. This applies to the following parameters:

- Equipped with a CNC system.

- The modification used.

- Fidelity of operations.

- How automated are the actions?

The letter “I” is used to designate devices with screw cutters. “P” – for high level accuracy. Such models are equipped with centers at a height of approximately 110 millimeters. Photos of products also help us understand what exactly is in front of us.

What does a lathe do and how does it work?

The operating principle of the equipment is quite simple. The electric motor generates a supply of energy, which in the gearbox is converted into a force of movement - rotation is transmitted to the spindle or faceplate. These elements cause the workpiece to rotate.

At the same time, the caliper begins to move. Regardless of the level of automation, there are horizontal and vertical devices. This affects which axis of tool movement is the main one.

Thus, there are only two movements - rotation and serve. The operator directs the support to the desired location. The cutting part removes the top layer from the metal surface and chips are formed.

Features of the design and purpose of the machines

The following main components are present in products of any group:

- Electrical part.

Consists of an electric motor with drive. Its power varies and is determined individually for each model. Equipped with additional parts to control performance. Compliance with safety requirements is mandatory for this piece of equipment.

- Transmission.

Helps transfer driving force from the shaft or lead screw to the caliper.

- Caliper.

Secures the cutting element. A support is also needed to feed the tool across or along. And so that this procedure is carried out in compliance with certain parameters. The caliper has carriages located at the bottom. There is only one, but some models come with several. The carriage at the top is where the lathe tool holder is attached.

- Spindle head.

How does a lathe work and what does it consist of?

The design of all installations includes the following components:

- ● Bed. This is a metal base that supports the entire weight of the remaining elements, as well as the workpiece. All other parts are also attached to it.

- ● Apron. Responsible for converting energy into movement.

- ● Grandmas. There are two of them - one is simply responsible for fixing, the other includes a motor and a spindle that holds and simultaneously rotates the workpiece.

- ● Support. He is responsible for the tool - its movement and fixation.

- ● Feed box and other elements that allow you to change the speed and direction of movement of moving units.

- ● Numerical control panel, which, in turn, includes a display, a cabinet with buttons and the program itself.

These are the main parts, but there are also additional systems, for example, the supply of lubricating and cooling fluid or the removal of chips.

Types of turning equipment

Differences between models in designs are the basis of classification.

Screw-cutting lathes

Equipment of this type easily copes with the following functions:

- Changing parameters for non-ferrous and ferrous metals.

- Development of modular, metric threads.

Models of a universal type, which are used both in industry and in the creation of individual products. Production assumes the same type of layout for all parts. The structure includes the parts described earlier.

Turret lathes

The main purpose is the processing of products from calibrated rods. The equipment performs a wide range of various operations:

- Deployment.

- When forming threads.

- Shaped turning.

- Drilling.

- Countersinking.

- Turning, boring with standard parameters.

The name of the machine comes from the mounting method used for the tools. They are mounted using a special holder, which can be driven or static. The drive variant gives owners the most options. It allows you to create threads with various parameters, carry out milling and drilling.

CNC lathes

Modern machines often involve the use of such equipment. Ease of operation and precision, high productivity are among the main advantages.

The implementation of CNC systems is accompanied by the use of the following systems:

- Self-adjusting. They allow you to correct all information based on indicators that appeared when previous details were processed.

- Closed type. With two information flows coming from the reading and measuring mechanism.

- Open. Only one information flow is used. First, the data is decrypted, then the commands are transmitted to other mechanisms.

In addition, machines are divided into several types based on the way the production process is controlled:

- Contour. The unit works without interruption. The user sets certain parameters only once.

- Rectangular. Used for step-shaped workpieces. With automatic shifting between gears lengthwise and crosswise.

- Positional. With fastening of parts in specific positions. The next step is to move on to the main workflows.

Vertical lathes

An excellent solution if you need to process large products. The following functional features are worth describing:

- Possibility of carving.

- Grinding operations, milling, trimming.

- Development of grooves giving certain configurations.

- The equipment will allow you to sharpen surfaces in the form of cones and cylinders.

Special types of tables are sold in sets with machines; the faceplates are located on their surface. The crossbars move along the racks, with additional supports in the structure.

Lathes

They process parts with the shapes of cones and cylinders, of the frontal type. It is assumed that the axis on which the workpiece rotates is placed horizontally.

Backing lathes

Backing is a special method used for sharpening. This is especially true for the back surfaces of various instruments. The operation is necessary so that even with prolonged use the original shape is preserved.

History of the appearance and development of equipment

According to historians, lathes (or rather, the primitive ancestors of such devices) were invented and began to be used by man in the middle of the 7th century BC. Of course, such a device had a simple design, but it made it possible to effectively process wood or bone products. In order to carry out such processing, the part was clamped in two centers, which were mounted coaxially with each other. It was rotated manually, and the cutting process was carried out using a hand cutter, which was manipulated by a separate “operator”. Thus, the product was given the required shape and size.

The next stage of development that the equipment of the turning group underwent was equipping it with a drive necessary to impart rotational movement to the part. Initially, a bow string was used as such a drive, which was looped over the workpiece. And a little later (in the 14th century) a foot drive for turning equipment was invented.

Antique foot operated lathe

The design of such a drive, very reminiscent of the drive mechanism of a foot sewing machine, consisted of a fixed cantilever wooden pole connected to the workpiece using a strong rope. When you pressed the pole with your foot, the rope was stretched, which led to the rotation of the workpiece by 1–2 turns. After the leg was removed from the pole, the rope was released and rushed upward, which entailed the rotation of the workpiece in the other direction.

Despite their simple design, such lathes already made it possible to perform processing with fairly high quality. Their advantage was that servicing the devices was very simple.

A. Nartov's turning and copying machine, 1729

The lathe of the 16th century group already had a steady rest and centers made of metal in its design, which made it possible to use it for processing workpieces with complex configurations. However, due to the low power of such a device, it was not yet possible to use it for turning metal workpieces.

The history of the lathe received a strong impetus in the 1700s, when the Russian Andrei Nartov created a device on which a mechanical support was installed. It should be noted that it was this innovation that served as the strongest impetus for the development of all equipment designed for processing metal workpieces. A major contribution to the development of turning units was made by French engineers, who by the middle of the 18th century created a device that was highly versatile. By the end of this century, French industry began to use a specialized unit on which it was possible to cut threads on metal screws.

Maudsley Lathes (click to enlarge)

The year 1794 is considered to be a truly breakthrough in the development of turning equipment, when Henry Maudsley created a machine that served as the basis for the further development of all turning units. What is noteworthy is that the company founded by Maudsley was also engaged in the production of dies and taps, with the help of which threads were cut on his equipment.

They began to think about automating a lathe in the 19th century, and American engineers took the lead in this matter. This process followed the path of equipping units with additional automation elements, which ultimately led to the creation of the first machine with a turret. It was on the basis of such devices that later they began to create universal automatic machines, the first of which (the Spencer machine) was presented to the public in 1973.

Machine markings

Machine tools are characterized by the use of numbers and letters equally. The first digit is to designate a group of machines. The third and fourth are to indicate one of the important characteristics. For example, the height of the centers above the bed, or diameters. If there is a letter after the first digit, it means that the model has been improved compared to the previous version. In some cases, serial numbers are used.

Tips for choosing equipment

Metalworking machines

The choice of a metal cutting machine is always based on the characteristics of its future application. This is what its performance characteristics depend on (power, electrical parameters, list of available functions, accuracy, overall dimensions).

Particular attention should be paid to the following factors:

- Functional. It is worth considering in advance the list of technological operations that will be required to complete production tasks.

- Level of automation. The higher it is, the more expensive the equipment will be. But with an increase in the level of automation, the accuracy of the operations performed, their complexity and speed also increases.

- Tooling of the machine. It is important to take into account the minimum and maximum dimensions of the workpieces being processed, the amount of movement along the axes, the maximum diameter above the support and frame, and the spindle rotation speed.

- Software. When purchasing a CNC metalworking machine, the ability of the equipment to work in conjunction with other devices and its compatibility with CAD/CAM technologies becomes fundamentally important.

- Manufacturing company. When choosing any equipment, it is important that the manufacturer provides full warranty and service maintenance; during operation, there are no problems with the supply of components or consumables.

Safety precautions

The specialist must follow certain rules. Here are just a few before you start:

- Checking the position of buttons on specialized clothing.

- A separate inspection of the machine is carried out according to the condition of the technical plan. The services of technicians and adjusters are relevant if additional maintenance is required due to malfunctions and failed parts. But simple operations are available for the owner to perform independently.

- The last stage is the issuance of technical specifications. It needs to be studied carefully.

You cannot start work if the rotation mechanisms and guards of various components with malfunctions appear.

In addition, there are other prohibitions on:

- So that other persons carry out the work. And leaving switched on equipment unattended.

- Carrying out complete independent repairs of equipment.

- Using clamps and fixtures that are not in good condition.

- Operational actions for equipment with obvious signs of malfunction.

- Carrying out work on the same day as servicing the machines, setting them up, and checking them.

Each machine has its own weight. This applies even to miniature varieties of machines that are purchased for use at home. Such units can weigh a minimum of 13.5 kilograms, and a maximum of 400. The greater the mass, the larger the other dimensions will be.

Machines weighing no more than 50 kilograms are suitable for home workshops. These are compact and versatile models that do not cause trouble during installation. The location is easy to change if the need arises.

Power is another parameter that needs to be taken into account when choosing. 2.25 kW is a standard figure for small units. There are other types of devices that are called low-power. Their drive has a rating of 0.15 kW.

To make the right choice, the buyer must decide on the destination. The smaller and thinner the workpieces, the less powerful units are required to process them. The rule also applies in the opposite direction.

From a technical point of view, even desktop installations for domestic use are considered complex. Therefore, it is recommended to pay attention to the overall quality of the components.

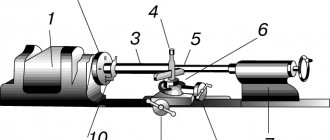

Diagram of a lathe with all the main devices

After the verbal description, let's look at the actual drawing of the product:

In the image we see a universal device, which is equipped with the ability not only to perform turning, but also to cut threads.

Here is another schematic photograph of a real unit:

On it we see, in addition to the main and secondary components:

- ● Front and rear cabinets. This is the element of the frame that bears the main load. When designing, the surface area is also taken into account. Their second task is to provide sufficient height for comfortable work of the turner.

- ● On the apron there is a wheel and a handle for moving the longitudinal and transverse slides.

- ● There are also screws for fixing on the tailstock.

- ● In the middle we see a movable block, which is equipped with a handle for attaching the tool holder and a tightening head - this is where the tool is installed.

Main technical characteristics

All lathes of the turning group differ from each other in the following technical parameters:

- maximum spindle speed (the higher it is, the better the quality of surface treatment, the higher the cleanliness class);

- force on the shaft in various gears (this parameter depends on the power of the traction motor, so it is customary to talk about the total power of the machine);

- the maximum diameter of the workpiece being processed (the digital parameter in this case is an indicator of the height of the centers of the machine - the clamping points of the workpiece;

- an indicator of what type of machine it is (screw-cutting, turning-milling, face-to-face, etc.);

- presence and degree of automation (determined by the presence and “advancement” of a numerical control module).

In general, the main technical characteristics of a lathe can be gleaned from the markings on its nameplate (see the section “Notation systems and decoding”).

What accuracy classes exist and how do they differ?

The accuracy class is a generalized characteristic of measuring instruments, which is determined by the limit of errors (main and additional), as well as a number of properties that influence the accuracy of measurements made with their help.

The error limit is the greatest error of the measuring device at which it is suitable for measurement. The limit of permissible basic error is expressed in the form:

- absolute;

- relative;

- given

Errors. The class characterizes the property of accuracy of measurements using this device. And the accuracy of measuring instruments is the quality of a measuring device, which indicates that the error of the measurements is close to zero.

If we are talking about the class of accuracy that is provided, for example, by a lathe, then here we mean the class of surface finish of the part that this equipment is capable of providing during the processing of the workpiece.

Measuring instruments, as well as processing equipment, have the following accuracy classes: 0.01; 0.015; 0.02; 0.025; 0.04; 0.05; 0.1; 0.15; 0.2; 0.25; 0.4; 0.5; 0.6; 1.0; 1.5; 2.0; 2.5; 4.0; 5.0; 6.0. In addition, there are several categories of accuracy classes:

Special

This “Class C” is the highest class of equipment accuracy (both measuring and processing). This class includes machines (in our case, lathes) that must process workpieces to obtain the highest class of surface finish (0.01-0.015).

High

For example, jewelry, medical and laboratory scales have a high level of accuracy. Another name for such equipment is precision. It is marked “class B”. If we are talking about turning equipment, then a high class of cleanliness (0.02-0.025) is provided by polishing lathes.

Normal

The normal accuracy class (the marking is “class H”, but as a rule it is not placed) means such a characteristic of equipment or a part that ensures identical results in no less than 98% of obviously identical objects. The absolute indicator of the normal cleanliness class is in the range (2.0-0.6).

Particularly high

Equipment of a particularly high accuracy class is marked “Class A” for this indicator. When designing high-precision equipment, increased attention is paid to the quality of spindle bearings.

Here, rolling bearings are mainly used, also of high accuracy classes, and sliding bearings are made in the form of adjustable tapered bushings. (All standards here are established by GOST 1969-43).

Increased

This accuracy class is marked “class P”. The use of elements of a higher accuracy class (primarily bearings) increases the cost of the finished product processed on such turning equipment.

However, if it is necessary to obtain a higher class of workpiece processing, then elements of a higher accuracy class are used for positioning machine shafts, where higher accuracy and rotation speed are required.