Homemade hand cultivator

It is quite possible to make a manual cultivator with your own hands, without the need for any special tools or materials.

The work may take no more than a day, it all depends on the chosen design and configuration of the future tool. The parts are simple and reliable, but if the tool does break, replacing the broken part will be easy. It can be made from existing materials.

Another advantage of making a device yourself is that it is quite simple to make it even without special education.

https://youtube.com/watch?v=L_Pbf6XC7Ks

Assembly instructions

You can assemble such a device from various available materials, and there are both simple and more advanced options.

An old bicycle that can no longer be repaired can serve as the basis for production; you will also need an old two-handed saw or a head from a used cultivator. The tools you will need are:

- Bulgarian;

- drill;

- saw;

- keys.

From the bicycle you only need to take one wheel and frame. You will need to attach the cultivator head to the frame, and if it is not there, then half the tip of a two-handed saw, or steel rods, or sharp metal rods with sharpened ends. Attach handles based on aluminum or steel pipes to the bicycle handlebars. A transverse jumper is placed between them.

DIY electric cultivator

In a workshop, you can make an electrical device based on an industrial meat grinder. Moreover, the model does not play a role here. And if you approach the work competently, then in the end you will assemble a fairly powerful device

It is important to note that you will need a welding machine for this work.

Manufacturing instructions:

- Two corners are attached to the gearbox, pipes with bends are then welded to the corners, which will serve as handles;

- to increase strength, a steel bridge is welded between the handles;

- the axles of the cultivator wheels need to be welded to the corners;

- provide lugs on the wheels, which can be made on the basis of car springs; they are welded onto the wheels;

- connect the engine. For capacitor starting, the switch is placed on the handle of the device.

Using such a unit under conditions of rapid movement will allow you to roughly plow the ground, and if it works slowly, you will get a fine fraction.

https://youtube.com/watch?v=HHtAjybYc3U

Do-it-yourself Tornado cultivator

The homemade Tornado device will allow you to perfectly loosen the ground due to its twisted teeth. The pipe serves as a lever and is attached to the handle. The pipe must be at least half a meter long. The lever fixed in the pipe should protrude 25 centimeters into both sides of the handle. To strengthen the fastening, you can use electrical tape. Spiral teeth are made on the basis of spring steel, but their diameter should be a maximum of 20 cm. This size is optimal for the convenience of weeding the space between the rows.

Also, the Tornado ripper can be made on the basis of old forks. You only need to prepare a pitchfork and a hammer. The teeth are given the desired shape with a hammer.

It is recommended to warm up the metal before starting welding, but it should not soften too much. When exposed to high heat, steel will lose its properties and will simply break under hammer blows.

In this case, the lever can be a metal or plastic pipe attached with self-tapping screws. Its length should be about 50 cm, and it will act as a handle. As a result, it will be possible to work on different, even heavy soils, and remove weeds even with persistent and branched roots.

Cultivator from an electric meat grinder

In this case, the power unit is borrowed from the meat grinder, but otherwise the concept remains the same. The frame from which homemade cultivators for a tractor or walk-behind tractor are made can also become the basis for autonomous equipment. A special feature of this design is the ability to quickly break soil layers into large clods. If operation is expected at low speed, then the processing will be delicate and will provide a loose cover.

It is necessary to weld two corners to the crankcase of the gearbox removed from the meat grinder. Two pipes are also installed on them, the ends of which must first be bent - in the future they will become handles. The wheel axles are also attached to the base using corners. You should not choose excessively large wheels, as they will cause unnecessary trouble during the processing process. But small ones are also undesirable, as they sink into the soil. Accordingly, the best option is medium wheels with a diameter of 20 cm. A shaft should be machined from mounting scrap. Using a sledgehammer or a large hammer, it is necessary to break off the nozzle of the meat grinder, which will allow you to remove the bushing, which will take the shaft with the lug screw into the structure.

Features of choosing a unit

If you want to choose a suitable walk-behind tractor model, pay attention to a number of important parameters. Among them:

- processed area;

- type of tasks to be solved;

- equipment power.

If the size of your plot does not exceed 10 acres, then, naturally, it is better to opt for a device for cultivating land. If you own a larger territory, it makes sense to think about buying a full-fledged walk-behind tractor.

As for power indicators, they are selected taking into account the type of work that will be carried out on the site. For seasonal plowing of the soil in the autumn, it is enough to purchase a unit with an engine power of 5.5-6 horsepower. However, if we are talking about processing virgin lands and dry soils, then you will need to purchase a heavier model with a stronger motor. Most likely, it will run on A92 or A95 standard gasoline fuel. There are also diesel developments that consume from 2 to 2.5 liters of fuel mixture per hour of hard work.

If you want to purchase a miniature version of a tractor, give preference to products from trusted brands. It is no secret that small European-made equipment can be equipped with “native” power plants from more well-known manufacturers, so such an engine can serve the future owner for a very long time. If you provide the equipment with proper care and maintenance, it will work freely for about 15 years, and the same amount after a major overhaul in a good service center.

As for Chinese products, they cannot boast of good power, reliability and durability. However, in this segment you can find quite a good solution. Just carefully study the company’s reputation, find out reviews from real customers on forums and portals for farmers.

This is interesting: How to make a light on a walk-behind tractor with your own hands

Useful tips

Before you start manufacturing a device or modifying it, you need to decide why it is needed. For example, units for removing weeds and simply loosening beds can be very different. For greenhouses, you should choose lightweight models with manual control only. If the areas being processed are quite large, then you should opt for options that run on fuel or electricity.

The stages of manufacturing a cultivator are important, but do not forget about the operating rules of this unit. The most important thing is to keep the driving mechanism in working order.

When the cultivator will not be used for a month or more, it must be stored. To do this, you need to remove fuel from it, clean the engine surface and all other elements. It is not advisable to clean parts of the device using strong water pressure. Metal parts must be lubricated with oil to avoid unwanted corrosion. The unit must be stored in a dry and dust-free room.

To learn how to make a cultivator with your own hands, see the following video.

What is needed and how can it be changed

In fact, putting a motor cultivator on wheels is not at all difficult:

First, you need to carefully measure the fit dimensions of the output shaft, paying special attention to its shape (cylinder or hexagon), outer diameter and distance to the hole for the cotter pin. Then you need to visit the nearest gardening store or look online to order hubs (differential amplifiers) that match the dimensions of the cultivator shaft. At the same time, you can purchase wheels (the smaller the diameter, the better) for your future walk-behind tractor. By the way, wheels with hubs and drawbar are often sold in a single set, which is very convenient. We screw the purchased wheels to the hubs; We remove the cutters from the motor-cultivator shaft; We install the wheels on the gearbox shaft. Experts do not advise upgrading low-power cultivators weighing up to 45 kilograms and equipped with a worm gear in this way, since this modification can lead to serious damage. In addition, when converting a motor-cultivator into a walk-behind tractor, you should not use old car wheels (too heavy weight and size)

Experts do not recommend upgrading low-power cultivators weighing up to 45 kilograms and equipped with a worm gear in this way, since this modification can lead to serious damage. In addition, when converting a motor-cultivator into a walk-behind tractor, you should not use old car wheels (too much weight and size).

At the same time, it is worth understanding that a cultivator on wheels, the modification of which will require at least three thousand rubles, may be a walk-behind tractor, but not quite a full-fledged one. Of course, such equipment will be able to move independently, but serious problems can arise with the use of attachments if the cultivator’s motor is weak (less than 6 hp) and the reduction gear is of a worm type, rather than a gear, belt or chain type.

Therefore, the next stage of converting the cultivator into a walk-behind tractor should be replacing (if necessary) the gearbox. The cost of this part in stores is comparable to the price of a new cultivator. However, you can try to make a simple gearbox with two opposite shafts at home, if the owner of the cultivator has the skills of a good mechanic/designer and has:

- measuring instruments (ruler, caliper);

- spare parts and consumables (bearings, gears, belts or chains, pulleys, shafts, gaskets, seals, pipe for bearings, bolts, etc.);

- welding machine;

- drill and drill bits of different diameters;

- “grinder” or hacksaw for metal;

- set of screwdrivers and vice.

If all this is available, then you can start manufacturing the gearbox:

- We draw or search on the Internet for a suitable sketch and calculate the gear ratio, taking as a basis the number of engine idle speeds plus 10%.

- We cut a metal sheet with a thickness of at least 5 mm to obtain a blank for the lid and body of the future part.

- We cut the pipe and, using welding, install the seats for the bearings.

- We assemble the body and protect it with paint and varnish.

- We install bearings.

- We produce and process shafts from round steel bars.

- We install shafts with the simultaneous installation of sprockets or pulleys, chains or belts.

- We make a gasket between the body and the cover, and also insulate the shafts using seals.

- Fill the housing with lubricant (oil) and install the cover.

- We place the homemade gearbox on the cultivator frame and connect it to the engine via the output shaft.

- We adjust the operation of the gearbox with the engine turned on, but without any special loads, so that the parts can be worn in.

A homemade gearbox will greatly expand the capabilities of the cultivator, which can work with almost any attachment.

How to sharpen a homemade cutter correctly?

Manufacturers of motorized cultivators sell equipment with already sharpened standard cutters. However, what should a person who has made cutters for an existing cultivator do on their own? In this case, you will need to sharpen the cutting knives of the device yourself.

To sharpen the equipment, you will need a grinder equipped with a diamond wheel with a diameter of 12.5 cm. Otherwise, you can use a sharpening machine, but it will be difficult to use due to the dimensions and direction of bending of the knives. If the manufactured cutters are equipped with small-sized knives, then you can use fine-grained sandpaper to quickly sharpen them.

It is necessary to sharpen the knives of a homemade cutter for a cultivator strictly at an angle of 45 °. In this case, it is necessary to independently determine the side that goes deeper into the soil. There is no need to remove too much metal from the knife; 1-2 sharpenings per season are sufficient. In some cases, the frequency of sharpening the cutter knives may vary - it all depends on the intensity of use and the type of soil being processed.

If you work intensively with the cultivator in wet weather, you will need to monitor the condition of the cutters. To prevent the formation of corrosion, they should be treated with a special anti-corrosion compound, which can be found in almost any auto parts store.

It is also very important to try to prevent the cutter from getting on stones and other hard objects - this will help extend the service life and reduce the need to sharpen the cutting knives of the device

Continuous tillage cultivator for walk-behind tractor. What is a cultivator?

Continuous tillage cultivators usually have tines with arched and S-like posts attached to them. The blade has a certain angle of inclination relative to the horizontal plane. The blade grip width is usually 270-300 mm. Such paws perfectly loosen even fairly dense soil and cut weeds well. The cultivation depth is up to 120 mm. The paws may have spring struts. They loosen the soil to a depth of 16 cm. During cultivation, they constantly vibrate due to springs and self-clean, throwing off the remains of the stems.

Image 2. Cultivator KPS-4.

Tines with S-shaped tines can be used in rocky areas of the field. The total working width of the KPS-4 cultivator (image No. 2) is 4 m. A hitch of several such units is attached to a 14 kN class tractor. Additionally, harrows are also attached. Modifications of this unit:

- KPS-4 - trailed cultivator;

- KPS-4-02 - a mounted structure with pointed legs;

- KPS-4-03 is a mounted cultivator equipped with ripper tines with arched racks;

- KPS-4-05 is a mounted cultivator equipped with ripper arms on S-shaped stands.

Creation of a rotary modification

By creating such a modification, you can easily loosen the top soil layer, level the surface and remove massive parts of soil from the garden.

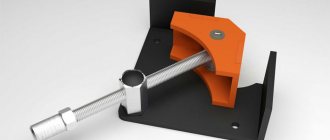

This version contains: disc, axial side, bushing, two brackets (large and small), rod, handle and pipe.

Stages of creative work:

- The working mechanism here is disks. They are welded to the plane of the bushings. The bushings themselves are threaded onto the axial part. Cotter pins are used to mount the axle to the main part.

- A handle is attached to the plane of the pipe. With its help you can control the cultivator.

The creation of this modification is complicated by the deformation of the disks. It works because the extreme sides of the steel pieces are forgotten

It is important that the central side is shaped like a bowl

If you use special nuts in this model, you will be able to adjust the discs during operation.

How to make different elements

To expand the functionality of the motor cultivator, additional attachments are attached to it. For the manufacture of such nozzles, diagrams and drawings are used.

Creeper

A useful accessory for the cultivating device is the stroke reducer. It is intended to reduce the speed of movement of the cultivator, which is necessary to redirect power not to speed properties, but to torque or traction.

You can easily make such a product yourself using the following components:

- Generator housing.

- Rotor shaft.

- Flange bearing.

- Steel parts.

- Screws.

- Pulley.

- Gear.

Before starting work, you need to make several calculations. The role of a generator can be played by a part from the domestic Ural motorcycle. The main thing is that it is powerful and demonstrates stable torque.

The next stage involves constructing a drive shaft based on the shells of two bearings that will drive the gear. Flange bearings are placed on the opposite side of the gearbox, and a metal washer is left inside.

The gear is fixed on the driven shaft, and at the end of the work, the pulley with the driven shaft is secured. To do this, use a spring nut and washers.

After completing the installation work, the creeper must be checked by connecting it to the coupling of the unit with the wheels. If everything is done correctly, after starting the device, the wheels will spin more slowly, and the unit itself will press to the ground.

Milling cutters

The main task of cutters for a cultivator is to destroy weeds. The cutting elements are also capable of plowing the soil, mixing soil layers and leveling the surface of the garden.

Milling cutters are particularly useful when cultivating clayey, wet or hard substrates. They are often used for gardening on virgin lands or pastures.

Due to the simplicity of the design, you can assemble the cutting element yourself. Before this, you need to draw up drawings or find a ready-made diagram that indicates the dimensions, the required number of materials and elements.

Experts do not recommend making cutters with a diameter greater than 50 cm.

Plow

By creating a plow with your own efforts, you can achieve the operating parameters that are necessary for field conditions. These include:

- Blade angle.

- Quality and depth of soil cultivation.

- Capture area.

- Efficiency.

Depending on the power of the unit, the desired plow design is selected. During the manufacturing process, you need to use high-quality materials that can withstand heavy loads without compromising performance.

Wheels

You can put wheels from an old walk-behind tractor, moped, bicycle or other vehicle with suitable dimensions on a homemade motor cultivator.

Lugs

The accessory is necessary to improve the adhesion of the cutting elements to the ground. It helps the unit function freely in difficult conditions and cultivate the soil without stopping.

Trailer

The presence of a trailer will make the cultivator as useful and functional as possible. But before you make such a structure, you need to make sure that the machine can drag it.

Hiller

The product is necessary for hilling potatoes or other garden crops. There are such options for homemade hillers:

- Listerny.

- With variable working width.

- Disk.

- Propeller.

Adapter

Any work in the garden requires a lot of effort. To make the process comfortable, you should create a special seat - an adapter.

Types of motor cultivators

Before you start assembling your motor cultivator, you need to familiarize yourself with the types of equipment. This will determine what components the homemade product will consist of and what tasks it can perform.

Differences between cultivators by engine type

On homemade cultivators, you can use two types of motors:

- An electric motor is installed provided there is a three-phase network. This technique is more suitable for small dachas, since the cable will constantly drag behind the cultivator, and you will not be able to travel long distances with it. An electric motor is used with a power of at least 2 kW.

- The best option is a cultivator with an internal combustion engine. The equipment will be completely unattached to an outlet. You can travel far into the field or transport cargo. Engines are petrol and diesel. If you can find an engine with a power of more than 4 hp. p., then the homemade product will make an excellent walk-behind tractor.

Important!

Air-cooled engines are optimal for a homemade motor cultivator. The water cooling system is complex, so it is better to avoid such units. Having decided on the type of motor, you can begin to think about the design and functionality of the future cultivator.

Differences between motor cultivators according to the method of movement and soil cultivation

Depending on the method of movement, there are two types of equipment:

- Self-propelled vehicles are equipped with a driven wheel pair;

- Non-self-propelled cultivators do not have drive wheels. Instead, working attachments, for example, cutters, are mounted on a rotating shaft. With their help, the unit threshes the soil and at the same time moves forward.

Self-propelled vehicles are difficult to manufacture. Even 2 gearboxes can be installed here. One of them uses expressway. It is needed to rotate the rotary attachment, which loosens the earth. The drive wheels are driven by the second gearbox.

Attention! Flat cutters can be attached to a motor cultivator with drive wheels.

Non-self-propelled cultivators have the simplest device. Movement occurs due to the rotation of the cutters. The unit has two wheels, but they are not driving, but simply serve as a stop for simplified movement. In general, a motor cultivator cannot be built without support wheels. It will constantly burrow into the ground. In addition, support wheels help regulate the depth of soil cultivation.

Important! The easiest way to make a homemade product is without drive wheels, but during operation you will have to put a lot of effort into holding the cultivator.

If you have already decided to assemble a motor cultivator with your own hands, then it is better to spend more time making a model with drive wheels.

Tips and tricks for working independently

If you decide to assemble such a tool yourself, do not forget to follow the necessary safety precautions. Above all, take care of your eyes, especially when welding, no matter what type of welding.

Thus, when arc welding, the danger is represented by the intense light obtained as a result of combustion and arc, as well as scale that appears at the site of the frozen weld seam. When the metal cools, it can suddenly break off and fly to a great height.

If you use gas welding to heat metal for processing or cutting, do not forget to wear gloves and face shields, since the work is carried out at high temperatures. You also need to remember that oxygen, when in contact with oil, creates an explosive mixture that does not even require a spark.

When you decide to make your own farm equipment, you can save money on purchasing it.

And even if you do not have experience or special skills, you can make your own cultivator from an old bicycle of the simplest type and provide yourself with good help when cultivating the land.

Device

Lightweight hand cultivators are in greatest demand among farmers and summer residents. As a rule, they weigh about 20 kilograms, are small in size and have high productivity. The cultivator is capable of loosening the soil, removing weeds, and thinning out plants. It is even used to apply fertilizers. This unique device simplifies not only planting, but also the process of caring for plants.

The work of cultivators largely depends on what cutters come with it, because they are the ones who perform loosening and a number of other operations. Among the working attachments for hand-held models, the following are quite often used:

- for loosening the earth;

- for cutting;

- for hilling;

- for making furrows for sowing;

- for breaking a strong earthen crust (special needle disk);

- for feeding plants (with dispensers).

When it is clear which cultivator is needed for certain tasks, you can choose what parts it will consist of. Drawings of a homemade device can help with this. The main part of the cultivator is the engine, which can be electric or internal combustion. It is best to give preference to reliable and durable installations. If necessary, you need to provide a cooling system, since it is not always built-in.

The gearbox is responsible for controlling engine torque. This part reduces the speed and also facilitates the operation of the power take-off shaft. As for the frame and portal for attachments, they can be made from what is at hand. Even the simplest two-wheeled wheelbarrow will do for this. The main thing is to think about the diagram in advance in order to have a good idea of how and where the individual elements will be placed.

Comfort and adjustability are important parameters for a control lever. It should not only be comfortable, but also adjustable.

Manufacturing technology

From forks of the “Tornado” type

You can safely make such a cultivator yourself using a regular pitchfork.

To do this, you will need a plastic attachment, which is usually used for forks, shovels, in the shape of a handle. We slightly modify the nozzle so that the handle looks like a horizontal pipe. For it, take a piece of plastic pipe measuring 0.5 m.

Please note: in order for everything to fit together, the diameter of the pipe must be slightly larger than the diameter of the nozzle.

So:

- A cut is made along the pipe so that when turned out, it fits onto the handle.

- For reliability of the coupling and further practical use, secure everything with electrical tape.

- All that remains is to twist the forks into a corkscrew shape. To do this, bend the teeth in the desired direction with a hammer.

Bicycle based

In order to make a homemade cultivator from available materials, you will need an old bicycle frame and

Assembly method:

- The cultivator head is attached to the frame, which is either ready-made spare parts from an old machine, or made independently from steel rods. A small plow is suitable for the frame. And for ease of control, the handle is made of steel pipe.

- The crossbar is made from a pipe with a diameter of 2-3 cm.

- The entire structure is secured with bolts; nothing should be loose.

- For convenience, take a medium-sized wheel and secure it with locknuts.

- This type of cultivator is designed for weeding the soil between the beds.

Assembly diagram of a homemade cultivator based on a bicycle (click on the photo to enlarge)

Disc rotary

Discs for rotary cultivator

This type is designed for breaking up hard pieces and leveling the soil. The main working element is a disk in the shape of a sphere. The whole difficulty lies in their manufacture.

The work order is as follows:

- Spherical plates 4 mm thick are made of metal. The bowls are knocked out with a hammer in the center of the plate itself.

- Discs are welded to the bushings, replacing them on the axles.

- The edge of the axle is secured with special cotter pins in brackets.

- The ledge is made in a bracket that is larger in size; a pipe and a handle are passed through it.

- In a smaller bracket, a rod with a diameter of 25 mm and a length of 26 cm is made. A rod 15 mm thick is also screwed into it.

- The convex corners of the cultivator are fixed using wing nuts.

- Due to the rotation of the convex angles, the large bracket bends, the rod rises, and the angle of the elements changes.

Chainsaw cultivator

Materials you will need:

- metal corner;

- fuel tank;

- a tube;

- rubber wheels;

- sprocket for the intermediate shaft (41 teeth);

- moped sprocket.

First you need to weld a cube frame using metal corners for a walk-behind tractor. The frame size is 32 by 32 cm, the engine is mounted on top of the transverse corners, and the fuel tank is mounted on brackets below. Then the intermediate shaft is mounted on the corner vertical stands. For the running shaft, bearings are attached to longitudinal angles. From all this comes a walk-behind tractor resting on the surface of the wheel.

For handles, pipes with a diameter of approximately 30 mm are used. Good wheels will come out of rubberized ones. Here you will need a sprocket for the intermediate shaft with 41 teeth and a main sprocket (a moped sprocket will do). All that remains is to assemble all the parts into one mechanism, and you will get a garden cultivator from a chainsaw (by the way, you can read how to choose a chainsaw here).

This can be done even without drawings. In addition, the cultivator is not very demanding on materials for refilling, unlike purchased models.

Cultivators significantly facilitate land work, help to properly cultivate the land before planting, fight weeds, and are simply irreplaceable for large areas. And if you don’t have the funds to buy these expensive machines, then you can easily make them yourself.

This video explains in detail how to make a manual cultivator from a bicycle:

How to make a flat cutter

Many people are looking for a cultivator for weeding. You can make such a weeding machine yourself. A profile pipe made of metal or steel is used as the basis for the frame. This base must be made of 2 parts. You need to weld at an angle of 30 degrees. A wheel fork made of a steel pipe or plate 3 millimeters thick is welded to the frame. The wheel itself can either be made independently or purchased. The steering wheel must be made of 2 steel pipes fixed to the frame.

The horizontal part of the frame is an adapter for the cutting attachment. Then you need to install a knife, which is made of steel tape 2-3 millimeters thick. Then the knives are sharpened. The sharpening angle can be changed or adjustable knives can be installed. If there is an old bicycle on the farm, then all the spare parts can be taken from it. Due to the large diameter of the bicycle wheel, the ride becomes very easy when working. The knife is made in the form of an inverted letter “P”, or T-shape. It should be noted that a T-shaped knife must be used very carefully between rows, as there is a possibility of spoiling the harvest.

A special subtype of the flat cutter is the design with forks. This device has several knives that are attached to a fork. It is made of steel rods, and they, in turn, are curved in a special way.

For such a device you also need to make handmade knives with your own hands. Drawings of these devices can be found in various thematic forums and blogs.

The design has a fairly easy movement. A similar device can be used by both a fragile girl and a small child. Loosening occurs at the highest level, but weed roots are practically not cut off. To do this, you need to choose what is more important: high-quality loosening or removing pests from the soil.

Equipment based on the ST-8 starter from GAZ-51

To make electric cultivators and walk-behind tractors with your own hands, more powerful engines from machines are also used. An ST-8 starter from a GAZ-51 is often installed.

The starter intended for the cultivator needs to be modernized. It is necessary to shorten its shaft, make a new front cover from duralumin and press bearing 204 into it. The rear cover with the bearing remains the same, only an oil can with lithol is attached to it.

Many small holes are drilled into the two covers for ventilation. The air is driven through them by a fan, which is mounted on the electric motor shaft and protected by a duralumin casing. The casing is connected to the starter with a strip of duralumin.

Part from the K-125 motorcycle - the drive sprocket is connected to the hub-hub and attached to the shaft shank. The same sprocket is installed on the input shaft of the gearbox. They are connected by a chain bush-roller connection. Another 4 sprockets, each having 11 teeth, are mounted on the output gear shaft - 2 on each. They are connected by bushing-roller chains. Cultivator cutters are mounted on the ends of the working shaft.

What is needed to assemble a motor cultivator

To assemble the cultivator yourself, you will need drawings of all components. An example of a diagram with dimensions is shown in the photo. You can look for other drawings of cultivators or develop them yourself.

The internal combustion engine for the cultivator is suitable from a moped, a powerful chainsaw or a motorcycle. If you decide to make an electrical installation, then the motor will be suitable from an industrial ventilation or compressor.

A gearbox is needed for any type of motor cultivator. The engine speed is too high. The gearbox reduces the speed, thereby increasing the rotational force of the working shaft.

All components of the cultivator are mounted on the frame, and the equipment is controlled using handles. These elements are welded from a pipe or profile. The structure must be durable. Excess weight is not a hindrance. This will only result in better traction between the wheels of the motorized cultivator and the ground.

Option #3: disc rotary cultivator

Making a rotary cultivator with your own hands is not at all easy. This requires special skills and good physical preparation. If you have all the listed qualities, you can try to build this tool, which will be much more effective than all the previous ones. With its help, you can not only cultivate, but also harrow the soil, deftly breaking large clods.

The rotary disk cultivator consists of: 1 - disk, 2 - axis. 3 - sleeve, 4 - large bracket, 5 - small bracket, 6 - rod, 7 - pipe, 8 - handle

The working parts of this cultivator are convex disks, which must be welded to bushings placed on the axle. The axial ends are secured with cotter pins, which are secured in a large bracket. After which a hole is cut in the upper part of this bracket. Handles with a crossbar are attached to it. A rod 25 cm long and 24 mm in diameter will have to be welded to a small bracket. A rod of 16 mm diameter is screwed into it. Part of the rod protrudes above the crossbar.

It is not so easy to give a 4 mm thick disk the desired spherical shape. To do this, you need to be able to deftly handle a hammer. A strong and precise blow to the center of the disc transforms it into a bowl. This is the work that will require the main physical effort. Special wing nuts located on the crossbar regulate the angle of inclination of the spherical disks relative to the direction of movement of the cultivator itself.

Modernization of a homemade design

The Arkhipov walk-behind tractor is extremely popular among a wide audience of summer residents and gardeners due to its versatility. Very often it is used as a plow or cultivator. To expand the functionality, it is enough to replace the removable parts for the plow with parts with removed moldboards for the cultivator. As it moves around the garden, the device will deepen furrows into the ground, placing potato tubers there. To plow the planting material, it is enough to equip the unit with dumps and walk again between the planted rows.

Hilling up of sprouted plants occurs in a similar way. The agricultural walk-behind tractor is characterized by excellent productivity and ease of use, even for purposes such as harvesting. To change the working width, it is enough to use different blades. In addition, the unit is capable of collecting missed potatoes and remaining tops in the presence of a rake or harrow.

The universal design is indispensable not only for work in the agricultural sector. It can also be used for snow removal in winter. Such a faithful assistant will be a good tool when clearing paths and garden areas from leaves or debris. It is enough to equip it with a roller with a round brush and an additional star, which will allow you to clear sidewalks.

Every self-respecting summer resident sooner or later comes to the question of buying or manufacturing a motor cultivator. Such a unit is a truly valuable find for people involved in organic farming. With its help, you can cultivate both small gardens and large areas of 30 acres.

Despite its compact dimensions, such a miniature “truck” is not inferior in productivity to some tractors. The powerful engine is capable of processing the heaviest soil, and ease of use allows you to operate it even in the absence of specific experience. In addition, making such a device is much easier than it might seem at first glance.

It is enough to pay attention to the existing instructions and use the recommendations of professionals

DIY electric cultivator

An electric tool can be made from scrap materials in 2 days, but you need to prepare in advance.

To assemble it you may need: a motor from a washing machine, a gearbox, sprockets and a chain from a children’s bicycle, bearings, cultivator blades welded from car springs, angles, wheels, a cable about 50 m long, a piece of tin to protect the motor from the soil . Instead of a washing machine engine, you can use a powerful Soviet drill, plus a gearbox from a burnt grinder, or an electric meat grinder.

A structure assembled from one or another of the proposed elements will look something like this: a metal frame with two wheels on both sides. The motor from a washing machine, meat grinder or drill is in the center. It needs to be connected to the cultivator blades and ensure rotation using a chain and “sprockets” from a children’s bicycle.

On two handles you can attach a cable with a trigger mechanism.

- First, the main parts are made and fastened, then a frame is made for them. The dimensions depend on the available materials you use.

- A gearbox with a transmission mechanism is welded to the engine housing.

- Blades are attached to the output shaft of the gearbox. You can use sharpened and fastened car springs or any other metal.

- The engine is attached to a frame made of angles with clamps and bolts.

- There should be an axle along the central axis with wheels on the sides.

- Handles and cable are welded on top.

- lightweight and convenient electrical design;

- environmentally friendly, unlike gasoline-powered mechanisms. This means that it can be used in greenhouses and greenhouses.

- welding must be used during manufacturing;

- not suitable for processing large areas.

Mechanical improvements not only make labor easier, but also increase the efficiency and speed of tillage. Any of the considered farmer's tools is indispensable when working on the land and is easy to use.

Assembling a cultivator with an internal combustion engine

So, a motor cultivator needs an air-cooled internal combustion engine. In our example, we will take the D 8 model from an old moped. The photo shows a diagram of the cultivator. From it you can determine the location of all nodes.

Assembling a motor cultivator has almost the same steps that were taken in the case of using an electric motor. First, a frame with handles is made, and then the motor is mounted. It is designed for air cooling, but the cultivator moves at low speed and this is not enough. You need to install a fan in front of the engine or install a metal container for water around the working cylinder. The device is primitive, but it will prevent the cylinder block from overheating.

The gearbox for this motor-cultivator is a two-stage chain gearbox. The sprocket is taken from a moped, and the other is from a bicycle. All rotating mechanisms are covered with a steel casing.

The video shows the process of making a motor cultivator: