The grinder (technical name is an angle grinder, angle grinder) is used during home repairs and on construction sites.

The list of technological manipulations that it helps to carry out is long, but let’s talk a little about something else, namely: how to choose the right attachments and discs for an angle grinder.

They are selected according to their purpose (depending on the material and purpose of the work) and size.

The range of power tools in stores is large, but not everyone can approach this issue professionally. It is precisely these doubters and those who do not understand that our article is aimed at.

Page navigation:

Main characteristics of cutting wheels

Depending on the material of manufacture and design features, there are three main types of circles:

- An abrasive disc for a wood grinder, used for working with various surfaces. Depending on the thickness, the wheel can be used for cutting and grinding.

- Diamond blade designed for working with stone, concrete and other building materials. Such circles are divided into segmented and solid. The first type, due to better removal of the stump through the slots and more efficient cooling, ensures high productivity. These blades can be used when cutting thin metals.

- A regular circle for a circular saw. However, it is immediately worth noting that it is not recommended to use it for cutting wooden products without experience, since there are many cases where people received quite serious injuries when clamping a disk in an array. If possible, when performing such work, it is better to use another tool, for example a jigsaw, chainsaw, etc.

Diamond blade rating

To compile the review, we tested the cutting tool and compared the results obtained on the main technical characteristics with the parameters stated in the manufacturer’s documentation. The availability of consumables on the market, the opinions of professional builders, installers, and car mechanics were taken into account. Reviews of diamond blades from owners of small home workshops were studied.

The following characteristics were taken into account:

- Size – determines the depth of cut, the possibility of using a grinder or a wall chaser of a certain model, productivity;

- The diameter of the mounting hole - no gaps and a tight fit on the shaft makes work safe and efficient;

- Rotation speed – must correspond to the same characteristics of the power tool;

- Class – professional and semi-professional models are produced;

- Design – equipment is produced with a solid and segmented cutting edge;

- Type of cutting – consumables are used for dry and wet cutting.

Not all equipment met the experts' requirements. Rapid clogging of the edge, low service life of the working layer, defects in the geometry of the plane - products with such defects were excluded from our rating.

The best gas cutters

Circle selection

When choosing discs for sanding wood with an angle grinder, pay attention to the following points:

- The size of the circles should not exceed the maximum permissible diameter for which the grinder is designed. A tool designed for 125mm discs will not work with a 230mm cutting wheel for a variety of reasons. Firstly, the speed of movement of the edge of the angle grinder is significantly exceeded (if it increases significantly, the disk may simply fly apart). Secondly, to work with such a disk you need more power than what a small tool is designed for. Thirdly, to install such consumables, you need to remove the protective casing, which makes the work more dangerous.

- When working with different types of materials, you should choose a disc that is designed specifically for them.

- Pay attention to the maximum permissible rotation speed of the circle (or linear speed). These indicators are indicated on the surface of the circle. According to these values, you should select the operating mode of the grinder.

TOP 5 best grinding discs for grinders

Rating of the TOP 5 best grinding discs in terms of price and quality ratio.

Grinding abrasive disc PRACTICA 773-590

Universal abrasive disc for angle grinders of standard assembly.

Suitable for grinding many types of materials: animal hooves and horns, soft and hard wood, particle boards, stone, brick, rubber, cork, concrete.

The grain in the abrasive mass is large (8). Weighty but easy to use disc.

The main thing: good rotations in the angle grinder (at 12,000 rpm it works perfectly, at 7,500 it slows down noticeably).

When working with soft wood (linden and others), it leaves insignificant marks if the master does not have the skill.

Don't be alarmed if the circle is clogged with tree sap; it's easy to clean out. It grips the material perfectly and can withstand both light pressure and pressure from the entire body.

In a matter of seconds, it strips off paint to putty (of any composition and number of layers), as well as the putty itself.

Specifications:

- outer diameter: 125 mm;

- landing diameter: 22 mm;

- cup type: carbide;

- gross weight: 0.32 kg.

Advantages

- when milling wood, the teeth do not fly off;

- affordable price;

- ergonomics;

- practically does not heat up during the process;

- good grain diameter.

Flaws

- severely wears out the bearings of the grinding machine;

- the coating wears off;

- Not suitable for finishing.

Diamond cup Sparta 729905

This bowl was released by a German hand tool brand. The motto is, so this small but very important detail is distinguished by excellent quality and ease of use.

Whether you need to sand granite tiles, stone, marble or concrete, she's here to help.

It easily and quickly removes a thick layer of material, so it is indispensable for roughing. It copes with sanding foundations and brick walls without any complaints.

There is no vibration during the process, so the master’s hands do not get tired ahead of time. The cup type is double-row, its base is stamped.

The number of segments is optimal (20 pcs.), the height of each does not exceed 4.5 millimeters.

Specifications:

- outer diameter: 125 mm;

- landing diameter: 22 mm;

- gross weight: 0.4 kg.

Advantages

- for intensive cleaning work;

- compact;

- strong;

- ergonomic;

- easy to find in the store.

Flaws

- for household use only;

- costs more than analogues.

Grinding abrasive disc PRACTICA 773-606

Another consumable from a domestic brand. You need to adapt to it: if you turn on the grinder at full speed, the result is unlikely to please you, but leisurely and systematic actions will lead you to an ideal result and a clean and smooth surface.

According to the properties catalog, it is suitable for working with products made of stone, concrete, rubber, cork, and fiberglass.

It can be used on different types of wood: it does not get stuck on soft wood and does not come off on hard wood.

It is also possible to remove bitumen mastic and multi-layer oil paint from floors. The grain size corresponds to the grain size of sandpaper.

The standard bore diameter is 22 mm. Flange mounted. Has all the necessary quality certificates. Country of origin: China.

Specifications:

- diameter: 125 mm;

- grain size: 24 R;

- weight: 0.33 kg;

- length: 188 mm;

- width: 153 mm;

- height: 30 mm.

Advantages

- affordable price;

- serve for a long time;

- available for free sale;

- Can process different materials.

Flaws

- working too quickly worsens the result;

- is not going to the Russian Federation.

Diamond cup Sibrtech 72955

Cup 72955 belongs to the classes of household and professional consumables, ideal for both small household and large professional work.

) knows how to keep his finger on the pulse and release a product that most consumers need on time.

With its help, you can remove sagging after formwork and welding seams, remove a thick layer of concrete, clean granite or marble slabs, stone and brick products.

Need to create a rough surface for applying construction adhesive or plaster? Perform rough processing? No problem: you can always buy this inexpensive, but ergonomic and reliable part at your nearest hardware store.

The cutting edge material is synthetic diamonds. Light weight - less than 470 g. Can be used without water cooling. The segment size is 5 mm, there are 14 of them in total. Country of origin: China.

Specifications:

- landing diameter: 22.2 mm;

- outer diameter: 125 mm;

- dimensions of the packaged goods: 130x30x170 mm;

- maximum speed: 12250 per minute.

Advantages

- convenient to grind down uneven surfaces on concrete;

- no big vibrations;

- high number of revolutions;

- sits down firmly;

- inexpensive.

Flaws

- processing dense material requires several approaches;

- you need a powerful grinder;

- Dust extraction is required.

Grinding abrasive disc AlphaDisk 770-069

An innovative product of domestic development: a roughing and grinding abrasive disc with improved performance characteristics.

Made using a unique technology: due to the fact that the disk body is connected to a tungsten carbide mass (pulse crushing crumbs), the service life is doubled compared to similar disks.

Tungsten carbide is non-toxic to people and strong. Grains with a diameter of 4 mm instantly remove the top layers from the treated surface.

Suitable for sanding wooden buildings, making grooves on logs, leveling crown grooves, leveling floors and removing old paint.

The case is metal, the holes protect it from overheating. Easy to clean with a brush.

Specifications:

- diameter: 125 mm;

- bore diameter: 22.2 mm;

- quantity per package: 1 pc.

Advantages

- does not tear on knots;

- sharp grains;

- heavy-duty soldering of abrasive to the body;

- victorious crumb.

Flaws

- cannot be used for processing metal surfaces and hard rocks;

- the price is above average.

Disc outer diameter

One of the important indicators of a cutting wheel is its outer diameter, which is calculated in millimeters and is unified. For domestic purposes, as a rule, a disc for an angle grinder for wood 115-230 mm is used.

The diameter of the tool shaft (seat size) on almost all discs is now the same - 22.2 millimeters, and for installation on outdated models of angle grinders, special intermediate rings are used.

The most universal discs for grinders on wood are 125 mm, 150 mm and 230 mm.

The 125 mm circle is convenient to use when you need to cut metal reinforcement and rods.

A 150 mm grinder blade for wood can not only grind and cut metal, but is also capable of sawing timber or unraveling boards.

If the diameter is more than 230 mm, then such circles have industrial purposes.

The 230 mm wood grinder disc has a wider range of applications, as it can be used when processing products made from metal alloys of various brands.

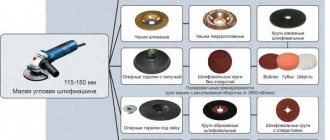

For large, medium and small angle grinders

The power classification into small, medium and large is closely related to dimensions and weight. The greater the power, the greater the weight and overall dimensions.

So, for example, grinders with disks of 115 mm - 125 mm and a power of 0.6 kW to 1.2 kW are classified as small equipment.

Angler grinders with discs of 150 mm - 180 mm and a power of up to 2.0 kW belong to the middle class of such equipment.

Professional angle grinders with a power of up to 3.0 kW and a disc diameter of 230 mm conventionally belong to large angle grinders.

Shape of abrasive discs

Abrasive wheels differ in their shape. There are:

- Standard flat discs.

- Curved discs (in the form of a plate). They can be used when performing work in hard-to-reach places. With this circle shape, the locking nut is hidden, making grinding work more convenient.

When purchasing a disc for an angle grinder for wood, pay attention to the marking (for example, A 40 L), which allows you to find out the following information about the product:

- The first letter (or two) indicates the type of abrasive used. For example: A - corundum, AS - electrocorundum, C - silicon carbide, which is used when working on granite and stone.

- The numbers allow you to find out the grain size of the abrasive. Moreover, the larger it is, the faster the work will progress. However, this will reduce the cleanliness of the cut or grind. A disk with a coarse grain is used, as a rule, for processing soft (non-ferrous) metal, and a disk with a fine grain is used for steel.

- The last letter in the marking indicates the hardness of the ligament of the base of the circle (those letters that are located at the beginning of the alphabet mean that the ligament is softer). When purchasing, it is recommended to follow this rule: when working with soft material, use a disc with a soft bond and vice versa.

Almost all manufacturers of abrasive wheels use color marking of their products. Green is for stone, blue for metal work. It is also worth mentioning about the inner seat ring. For wheels intended for cutting, it is made of hard metal, while for polishing or grinding, cutting discs with a softer washer are used.

Marking

The choice of the right tool is facilitated by the presence of markings. It contains the technical parameters of consumables in encrypted form. For example, this is what an alphanumeric set of markings for a cutting disc looks like, produced by a Russian manufacturer:

- — The image shows the tool manufacturer — Luga Abrasive Plant (Luga, Leningrad Region).

- — Tool name:

- cutting wheel - in Russian;

- cut –off – wheel – in English translation.

- — Purpose: for processing steel (inscriptions “steel”, “steel” on the circle).

- — The dimensions of the circle are indicated (outer diameter x thickness x bore diameter):

- in mm – 200 x 2.5 x 22.23;

- in inches – 8”x 1/10”x 7/8”;

- digital designation "41". This is a characteristic of the design of the circle - here it is flat.

- — The circle is designed for 7650 rpm, while the maximum peripheral speed should not exceed 80 m/s.

- — Technical parameters of the wheel material are determined from the designation “A 30 S BF”, where:

- A – means that the abrasive is based on white electrocorundum, which is specifically used for metal processing;

- 30 – abrasive grain size, here it is average;

- S – hardness of the circle, here the circle is hard;

- BF - denotes the type of bond, here synthetic resins with glass fiber reinforcement.

- — Rules for safe work in the form of signs indicating the required action.

- - GOST 21963 - 2002, GOST R 52588 - 2011, EN 12413 - Russian and European regulatory documents to which this tool complies.

The marking of a foreign manufacturer of tools for angle grinders is as follows:

- — Tools under the NORTON VULKAN brand are produced by the Saint Gobain corporation, headquartered in France.

- —The purpose of the cutting disc (the company produces only such a tool for angle grinders) for processing steel (in addition, for visualization purposes, the label for wheels intended for metal processing is blue) is duplicated in several languages.

- — The circle is designed for 12250 rpm with a maximum peripheral speed of 80 m/s.

- — The dimensions are the same as on the Russian disk - in mm and inches.

- — The digital designation “41” has been added to the technical parameters of “A60S – BF41”. This is a characteristic of the design of the circle - here it is flat.

- — Methods of safe work must be indicated.

- — The regulatory documents to which the instrument complies are issued by the European Union.

Diamond cutting wheels for grinders

Depending on their purpose, diamond discs can be divided into several types:

- Concrete. Circles of this type can easily cope with monolithic structures, including concrete and reinforced structures.

- Granite. Such discs are used when working with particularly hard stones.

- Asphalt. Cutting wheels are best used when processing concrete and, accordingly, asphalt.

- Construction Materials. Discs of this type can be used for cutting ceramics and bricks.

Diamond cutting wheels from some manufacturers are also color coded:

- Green is granite.

- Blue - concrete, marble.

- Yellow - plaster, tile.

- Gray - ceramics.

Segmented diamond cutting wheels are used for cutting materials using the dry method. When using solid discs, wet cutting (water cooling) is used. This is primarily due to the very high heating of the continuous surface of the cutting wheel.

There are models that have partial segmentation. These are so-called turbo discs, in which the slots are located in the body of the circle (they do not extend to the outer edge). Such products can be used at higher speeds than fully segmented ones.

So, by choosing the most suitable cutting disc for a wood grinder in all respects, you can perform any work efficiently and safely.

Which diamond blades are better?

Our experts selected products from the world's best manufacturers, considering offers in all categories. High-quality universal discs exist, but they are more suitable for home craftsmen who have decided to make major renovations to their home or build an extension. Professionals should use a specialized tool, and each category has its own leader. We recommend the following brands of diamond blades:

- Makita B-28092 – for cutting concrete on a construction site;

- Graff GDD 17 125.10 – for low-cost brick work;

- Dremel DSM540 – for high-precision cutting on ceramic tiles;

- Di-Star 1A1R Decor Slim (11115427010) is a good choice for the decorator;

- Hammer 206-232 – for wet cutting of metals;

- DeWALT DT40252 – for intensive work with any metals;

- Bosch Standard for Universal 2608615059 is a durable and reliable universal.

Good equipment means high productivity, operational safety and high-quality cutting. Only the best wheels, distinguished by their thoughtful design, perfect edge quality and heat resistance, are worthy of this high title.

Safety regulations

When working with an angle grinder, regardless of what type of disc is installed, it is necessary to strictly adhere to safety requirements.

- The tool must be equipped with a stop handle and a protective casing.

- All work must be performed in special clothing and using personal protective equipment. It is also necessary to be very careful when choosing glasses or a mask, because eye damage (statistically, this is the most common injury) can be caused even by small shavings or a fragment of the circle itself.

How to replace

The grinder disc is a consumable item. Therefore, it has to be changed frequently. There is a simple algorithm in which an important role is played by the original design of the key supplied to the consumer along with the grinder.

- — The protruding rods of a special key are installed in the grooves of the fastening nut.

- — At the same time, press the lock button located on the gearbox housing. It will lock the rotor from turning.

- — Turn the key counterclockwise to release the fasteners of the worn disk.

- — The old disk is replaced with a new one of the same technical characteristics and size. The new disk is installed with the markings facing out to remind you of the disk parameters and for other good reasons (see explanation in the video above).

- — The fastening nut is first tightened by hand and finally tightened with a special wrench.

The Bulgarian is ready to continue fulfilling its functional purpose.

How to unscrew a disc on an angle grinder if it is jammed

During operation, for one reason or another, a nuisance may occur - the disk may jam. We offer you two ways to solve this problem:

First way

- We find, in our arsenal, a piece of metal plate no more than 1 mm thick.

- Clamp the plate in a vice.

- Break the remaining disk. It's better to use pliers.

- We insert the plate between the upper nut, the one that secures the disk, and the lower nut.

- Let's start cutting.

- The remains of the disk between the nuts will wear off, and the nut will begin to move freely.

- Remove the nut

Second way

- We break the disk.

- Using a gas wrench, fix the lower nut so that the spindle does not rotate.

Using a standard wrench, we begin to unscrew the top nut. As soon as the top nut moves out of place, you can unscrew it by hand.

Each type of work has its own disk

It is important to use your own disk for each type of work. Cutting wheels cannot be used for stripping and vice versa. Based on this, it is possible to divide the types of disks by type of work.

- If it is necessary to cut or saw, then use cutting discs.

- If you have to cut wood products, use saw blades.

- If you need to peel off old layers of paint and varnish materials and primer or make the surface smooth, you need a roughing or grinding disc.

- You can process metal, wood, and plastic products with a flap disc.

- For final polishing of surfaces, a polishing disc is best.