There are quite a lot of tools for cutting metal, however, only a pendulum (or miter) saw provides the ability to make an angular cut.

It is used to make window stops, door frames and many other products that are used everywhere.

However, specifically in this article only a miter (pendulum) saw for metal will be considered.

We will try to answer the questions:

- What features does it have?

- How is it classified?

- What points to pay attention to before purchasing.

general information

Along with circular and circular saws, as well as jigsaws, a miter can cut metal profiles, sheets, and different types of pipes.

The structure of the device is very simple - the key elements are: a gearbox, a saw blade, a frame (base), a handle with a “start” button, and an engine. The latter is divided into two types:

- asynchronous;

- collector

The advantage of the commutator type of saw is ease of maintenance, while the asynchronous type has a long service life and less noise during operation.

The motor and saw blade are connected using a gear or belt drive. They have their own disadvantages and advantages. For example, the belt drive is almost silent. It eliminates vibration of the disc, however, it can slide off the base during prolonged use, forcing the owner to stop the work process. The toothed saw is exempt from this disadvantage, but instead makes noise during operation and gives a slight vibration. The working tool in a miter saw is a disc. It is made from durable types of metals, because it bears the entire main and rather serious load.

On the planes of some removable components of this type of saw there are cuts or wavy lines. This is designed to reduce noise levels during operation, as well as to compensate for deformation that occurs at high temperatures.

By purpose, we can distinguish household equipment, professional equipment and machine tools. The former are distinguished by low power (no higher than 1500 W), compactness and cost in the range of 20-25 thousand rubles. For example, Bosch GKM 18 (battery-powered, cost - 15 thousand rubles).

Pendulum saws: varieties

A crosscut tool is much easier to classify than, for example, a jigsaw, which can be either electric or mechanical. The mechanisms under consideration can be divided according to the following criteria:

- saw blade parameters;

- the presence of a broach function; appointment.

Examples include products such as:

- saw Bosch GKM 18 (battery version, costing approximately 15,000 rubles);

- saw Kolner KMS 210 (price approximately 4,000 rubles);

- domestic trimmer “Caliber PTE-900” with a power of 900 W at a cost of 4,500 rubles.

A cross-cutting machine is equipment not for domestic purposes, used only in enterprises that produce rolled metal products, and are engaged in cutting or processing them every day. Such units are sold for tens and sometimes hundreds of thousands of rubles, their power exceeds 1000 W, and their weight is several centners.

An example would be:

- machines from domestic manufacturers;

- TsT 10−4 (power 3 kW, weight 360 kg, price 105 thousand rubles);

- TsKB-40K (power 5.5 kW, weight approx. 700 kg, cost 340 thousand rubles).

Professional metal miter saws for profiles, sheets and pipes occupy an intermediate state according to the noted parameters. Eg:

Makita LF 1000 (power 1650 W, price from 60 thousand rubles), DeWalt d27111 (power 1500 W, price from 50 thousand rubles).

The presence of the drawing function provides the user with some advantage when working with long slabs or pipes.

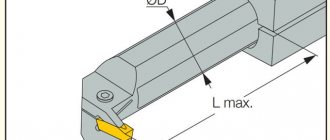

The models have two parallel slats on which a cutting disk is mounted, which moves freely along them.

The device with broaching is distinguished by the solid width of the cut of the part and the additional presence of very small teeth on the disk. In addition, the tool in some cases has a laser pointer for process control and ease of marking.

A metal cutting machine equipped with a broach has a higher weight than usual, and the presence of the option increases the cost by 25-30%.

Blade size is a central classification criterion

The cutting discs have two diameters:

- external (from 20 cm);

- internal (known as landing; approximately 3 cm).

The size of the teeth determines the width and depth of the cut, and the material determines the possibility of using the unit on a particular metal.

Mechanical saw for metal

A band saw is used to cut metal, such as cast iron, steel, or non-ferrous metals. Cutting on such machines can be either straight or at an angle. Machines can be fully automatic (including modern CNC), semi-automatic or manually controlled. The direct cutting part of the machine is a metal band saw, which is a closed solid strip with teeth cut on it. To operate, a mechanical saw is put on pulleys, and the necessary tension is applied to the saw. The part is clamped in a vice (at the required angle) and the cutting process is carried out. The saw may have special carbide attachments - for cutting, for example, especially strong steel.

The place where such machines are used is the widest: in metallurgy, mechanical engineering, energy, construction, etc. - both in large enterprises and in small workshops. You can purchase a band cutting machine by placing an order through our website on the “Products” page, as well as by contacting us directly by phone or mail. There are three types of machines available: single-column, double-column, and with a rotary support. To make the right choice, you can seek advice from our specialists. You can buy mechanical saw equipment profitably by taking advantage of our special offers (see information on the website).

Technical features of some types of machines

Machines with guide posts.

Used in large industrial production. Massive structure requiring the use of lifting devices. The cut occurs in one plane, ensuring high cutting accuracy.

Vertical cutting machine.

There are compact options with a movable table and manual control. This machine ensures high cutting reliability and blade durability. Vertical machines differ: with a fixed frame (cutting occurs by moving the table), or a frame moving along the table.

Another metal cutting machine with a pendulum console.

Very convenient to use. It is used both for cutting a single workpiece and a whole batch of workpieces. The frame of such a machine can be raised and lowered - either manually or automatically. You can cut at an angle or without the ability to change the angle.

Advantages of purchasing a machine from our company

— Our plant has existed for 77 years. The plant's products are recognized and are in high demand. — Powerful design and scientific base in the development and manufacture of products. As well as the high professionalism of the entire workforce; — Factory warranty for trouble-free operation of the product for up to one and a half years; — We always have components in stock for any machines we produce; — Consumer-favorable pricing policy; — Delivery of machines without the need to come to our enterprise; — Tour of the production.

The band cutting machine is a bargain. Guarantee and quality.

| The lineup band saws | Cutting range |

| Model LPS8535 | up to 350 mm |

| Model LPS8542 | up to 420 mm |

| Model LPS8552 | up to 520 mm |

| Model LPS8560 | up to 600 mm |

| Model LPS8580 | up to 800 mm |

| Model LPS85101 | up to 1010 mm |

| Model LPS85130 | up to 1300 mm |

| Model LPS85180 | up to 1800 mm |

| Model LPS8535N | up to 350 mm |

| Model LPS8530V | up to 300 mm |

Manufacturers you can trust

Below are recommendations for which miter saw brand to choose. The data is based on customer reviews and information from forums.

The optimal miter saw regarding comfort, manufacturability and safety during operation is considered to be one of these products; DeWalt; Metabo; Makita; "Interskol". Hitachi; Bosch.

Most of these manufacturers provide an extension of a special table for the workpiece; however, in some cases additional supports are required for cutting large parts. These can be found, for example, in the cross-cutting model LF 1000 . This add-on greatly simplifies the user's experience. In addition, the movable part of the metal saw is included in a stable frame, in which there is space for assembling the cutting angle.

The best trimmer, in terms of stability and reliability, is the one whose frame is made of magnesium or aluminum alloy. They are stable, durable and also have a very reasonable weight. An example is the Bosch GCM 10 , the most popular modification among professional models. With all other advantages, it weighs only 15 kg.

Hitachi is considered the leading manufacturer among hacksaws with a permitted inclination of the cutting edge to the workpiece. While Bosh, Metabo or Makita mostly provide the ability to measure the cutting angle only at 0, 90 or 45 degrees, this Japanese concern provides the operator with the ability to measure at 30; 15; 22 and even 5 degrees. The provided option confronts the operator with the need to add a rotating device to the design of the device. However, the weight of the installation for cutting sheets, pipes or profiles will still not exceed 30 kg. However, the cost will also increase from 15 to 25 percent.

The saw manufacturer DeWalt stands out for its XPS system, which allows you to project a clear line. Before starting work, a shadow is projected from the saw blade, which makes sawing the metal more precise. Domestic models are, from a design point of view, very simple, since they have:

- disk

- start button

- engine

- handle

- base

Additional advantages of the device are that they are very affordable (you can choose models from 5,000 rubles) and easy to hold in weight.

To cut a metal sheet, profile or pipe, you will need to rotate either the disk or the table. The disk can rotate along its axis and against it, which is very convenient for the master’s work.

Before making a purchase, we recommend that you pay attention to the models of the above manufacturers and weigh all the advantages and disadvantages.

Recommendations for choosing a product brand

The best miter saw in terms of safety, manufacturability and work comfort is a product from one of the following companies:

- Metabo;

- Makita;

- Bosch;

- DeWalt;

- Hitachi;

- Corvette;

- Interskol.

Most of them offer table expansion for the workpiece, but cutting large parts sometimes requires additional supports. These are found in, for example, the LF 1000 model. This simplifies the user’s work. In this case, the moving part of the makita metal saw enters a stable frame, in which there is an area for setting the cutting angle.

The best trimmers in terms of reliability and stability are those whose frame is made of aluminum or magnesium alloy. They are durable, stable, but at the same time they weigh acceptable. An example is the Bosch GCM 10, popular among professionals, weighs only 15 kg.

A master works with a Bosch GCM 10 miter saw

The leader among saws with a possible inclination of the cutting edge to the workpiece is Hitachi. While Bosch, Metabo or Makita mostly allow you to set the cutting angle to only 0, 90 or 45 degrees, the Japanese concern offers the user the ability to rotate by 15; 22.5; 30 degrees. This option forces you to add a rotating device to the design, due to which, however, the weight of the installation for cutting profiles, sheets or pipes will still not exceed 30 kg. The price increases by 15-25%.

The DeWalt manufacturer is distinguished by the presence of an XPS system (clear line projection). Before work, a shadow is projected from the saw blade, which makes sawing metal more accurate.

Domestic Interskol models are structurally simple (have a disk, handle, base, motor, start button), inexpensive (from 5,000 rubles), and lightweight. To cut a metal profile, sheet or pipe, you will need to rotate the table or disk. The latter can rotate in both directions.

Before purchasing, pay attention to the models of these manufacturers. Now - to recommendations for wisely investing money in equipment.

Tips for choosing a miter saw

Now let’s touch on recommendations for the optimal investment of money in equipment. The tips below are required reading for every potential user before purchasing a tool.

For infrequent and short-term activities, select household equipment according to the following parameters:

- low power;

- compactness;

- cost no more than 15,000 rubles.

For permanent work, it is recommended to purchase professional equipment. Optimal parameters for it:

- costing from 15,000 rubles and above;

- power - over 1 kW.

The more powerful the engine, the less it will heat up during operation, the more significant the performance of the tools will be, and accordingly, the larger the disk can be, which can be installed with your own hands. This may be necessary if replacement is necessary.

Some discs contain manufacturer's recommendations regarding the material to be cut or its type (for pipes, sheets or profiles). This is also worth paying attention to.

Saw models equipped with a spacious blade for larger and more comfortable work are sold more expensive, but cutting metal with such units is incomparably more convenient. In their design, when choosing, the presence of a cut depth limiter is also welcome - this way you can select the optimal groove for processing the workpiece in width.

Decide whether you will need such options as broaching, laser illumination and the like in your work or in the future. If they are not expected to be needed or likely to be in demand, then there is no need to overpay for more complete modifications of the models. If the protective casing does not cover the disc during operation, you should know that this is the worst option for a tool, since it is dangerous to work on it.

The wider the workpieces that are intended for metal cutting, the wider the diameter of the disk should be.

It is necessary to select from several models that are suitable for all parameters the one that weighs less, this will help save more effort and get less tired during the work process. Of course, this will affect the cost - lighter analogues are more valuable, but believe me, it’s worth it.