Heat treatment of steel 65G

Structural high-carbon steel grade 65G, supplied in accordance with the technical requirements of GOST 14959, is a steel of the spring group. It must combine high surface hardness (for which up to 1% manganese is added to its composition) and increased elasticity. All these characteristics are ensured as a result of proper heat treatment of products made from the steel in question.

Initial chemical composition of steel and requirements for parts made from it

Belonging to the category of sparingly alloyed steel, 65G steel is relatively cheap, which makes it widely and effectively used. Among its main components are:

- carbon (within 0.62...0.70%);

- manganese (within 0.9…1.2%);

- chromium and nickel (up to 0.25...0.30%).

All other components are copper, phosphorus, sulfur, etc. – refer to impurities, and are allowed in the chemical composition of this material in quantities limited by the state standard.

With sufficient hardness (for example, after surface normalization it should be at least 285 HB) and tensile strength (not lower than 750 MPa), 65G steel has a fairly high impact strength for its class - 3.0...3.5 kg∙m /cm 2. This makes it possible to use the material for the production of critical parts of lifting and transport equipment (in particular, running wheels of overhead cranes, rollers), as well as spring washers and springs for non-critical purposes.

It is worth noting that spring parts made of 65G steel are poorly welded and cannot withstand periodically occurring tensile stresses (relative elongation does not exceed 9%), and therefore cannot be used in one-piece structures of machines and mechanisms. When carrying out cold plastic deformation processes, steel becomes very low-plasticity even at small (up to 10%) deformations, therefore, if it is necessary to manufacture large-sized springs from it, it is necessary to use heating of the original blanks, even for sheet stamping. However, even in the hot state, the maximum degree of deformation of 65G steel does not exceed 50...60%.

Chemical composition of steel 65G

Despite the fact that during strain hardening the ultimate tensile strength of the material increases to 1200...1300 MPa, these indicators are not enough to give the final product (for example, springs) the necessary operational strength. Therefore, quenching and tempering of 65G steel is mandatory.

Spring knife

A knife is a great thing that can be useful not only as an excellent tool, but also as a wonderful souvenir. Every boy will be happy with such a gift. If a knife is made by hand, it immediately becomes a unique value in the eyes of the owner.

Adults also do not always use knives exclusively for household purposes - many people collect them. Everyone’s selection criteria are different, but everyone knows that high-quality steel is a prerequisite for a good knife. But a beautifully crafted handle can make no less an impression than a durable blade that can hold an edge for a long time.

Optimal technological processes for heat treatment of materials

The choice of heat treatment mode is dictated by production requirements. In most cases, to impart proper physical and mechanical characteristics, the following is used:

- normalization;

- hardening followed by tempering.

The temperature-time parameters of heat treatment and the choice of its type depend on the initial structure of the steel. This material belongs to the hypoeutectoid type steels, therefore, at temperatures above the lower point of the austenitic transformation - 723 ° C - by 30...50 ° C it contains austenite in the form of a solid mechanical mixture with a small amount of ferrite. Since austenite is a harder structural component than ferrite, the quenching temperature range for 65G steel will be significantly lower than for structural steels with a lower percentage of carbon. Thus, the temperature range for hardening steel of this grade should be within the range of no more than 800...830 °C.

Approximately the same temperature range is used to carry out normalization - a technological heat treatment operation, which is used to correct the structure of the material of the product, to relieve internal stresses, and during subsequent mechanical processing of the semi-finished product - to improve its workability.

Since the impact strength of hardened steel 65G is reduced, after hardening, products made from it, in particular springs, must undergo a high tempering. The martensitic-austenitic transformations that occur during tempering reduce the level of internal stresses arising during hardening, reduce brittleness and slightly increase impact toughness.

The transition to high tempering is excluded from the mode only when the workpiece undergoes isothermal hardening. As a result of high tempering, 65G steel acquires a sorbitol structure, the characteristic features of which are the fine dispersion of the structure while maintaining initially high hardness values, which fully meets the operational requirements.

Temperature selection

For the correct completion of the hardening process, the correct selection of temperature, which depends on the material used, is very important.

Steels based on carbon content are divided into hypoeutectoid - less than 0.8% and hypereutectoid - more than 0.8%. Steel with carbon less than 0.4% is not hardened due to the resulting low hardness. Hypoeutectoid steels are heated slightly above the temperature of the phase transformation of pearlite and ferrite to austenite. This occurs in the range of 800-850°C. Then the workpiece is quickly cooled. When cooled sharply, austenite transforms into martensite, which has high hardness and strength. A short holding time makes it possible to obtain fine-grained austenite and fine-needle martensite; the grains do not have time to grow and remain small. This steel structure has high hardness and at the same time low brittleness.

Microstructure of steel

Hypereutectoid steels are heated slightly lower than hypoeutectoid steels, to a temperature of 750-800°C, that is, incomplete hardening is performed. This is due to the fact that when heated to this temperature, in addition to the formation of austenite, a small amount of cementite, which has a higher hardness than martensite, remains undissolved in the metal melt. After rapid cooling, austenite transforms into martensite, and cementite remains in the form of small inclusions. Also in this zone, carbon that has not had time to completely dissolve forms solid carbides.

In the transition zone during high-frequency quenching, the temperature is close to the transition temperature, and austenite with ferrite residues is formed. But, since the transition zone does not cool down as quickly as the surface, but cools down slowly, as during normalization. At the same time, the structure in this zone improves, it becomes fine-grained and uniform.

After cooling, high compressive stresses remain on the metal surface, which increase the performance properties of the part. Internal stresses between the surface layer and the middle must be eliminated. This is done using low-temperature tempering - holding at a temperature of about 200°C in an oven. To avoid the appearance of microcracks on the surface, it is necessary to minimize the time between hardening and tempering.

You can also carry out the so-called self-tempering - cool the part not completely, but to a temperature of 200 ° C, while heat will remain in its core. Then the part should cool slowly. This will equalize internal stresses.

https://youtube.com/watch?v=vUaDCaVcjac

Hardening modes of steel 65G

To comply with the characteristics specified by the technical conditions for the operation of parts, when choosing a hardening mode, the following components are taken into account:

- method and equipment for heating products to the required temperatures;

- establishing the required hardening temperature range;

- choosing the optimal holding time at a given temperature;

- selection of the type of quenching medium;

- technology for cooling the part after hardening.

The intensity of heating determines the quality of the resulting structure. For low-alloy steels, the process is carried out quite quickly, since this minimizes the risk of decarburization of the material, and, as a consequence, the loss of the part’s strength parameters. However, too rapid heating causes other problems. In particular, for large parts with large differences in cross sections, this can cause uneven heating of the metal, with the prospect of further appearance of hardening cracks, chipping of corners and edges.

Temperature of the workpiece depending on the color when heated

To achieve the maximum degree of heating uniformity, the steel is first heated in the preliminary chambers of thermal furnaces to temperatures slightly lower than hardening temperatures - from 550 to 700 ° C, and only then the part is sent directly to the hardening furnace. Heating occurs fastest in molten salts, slower in gas furnaces, and even slower in electric furnaces. That is why surface hardening of 65G steel products in induction furnaces is performed quite rarely. The inductor, as a hardening unit, is used only for products with a small cross section. When choosing the type of heating device, the composition of the atmosphere that is created in it is also important. In particular, for thermal furnaces operating on gas, they try in every possible way to reduce the duration of the part’s stay in the furnace, since otherwise some of the carbon in the surface layer will burn out.

Methods for preventing scale formation and critically reducing carbon concentrations

The purpose of steel hardening is carried out taking into account what qualities the part should have. The process of rebuilding the atomic grid is associated with high risks of the appearance of various defects, which is taken into account at the stage of development of the technological process.

Even the most common methods, for example, quenching steel in water, are characterized by the appearance of scale or a significant increase in the fragility of the structure with a decrease in carbon concentration. In some cases, steel hardening is carried out after finishing, which does not allow even minor defects to be eliminated. This is why technologies have been developed that reduce the likelihood of scale or cracks. An example is a technology where steel is hardened in a protective gas environment. However, complex methods of steel hardening significantly increase the cost of the procedure, since the gas environment is achieved when installing furnaces with a high degree of tightness.

A simpler technology, in which carbon steel is hardened, involves the use of cast iron shavings or used carburizer. In this case, the steel for hardening is placed in a container filled with the materials in question, after which only heating is carried out. The hardening temperature is slightly adjusted taking into account the created shell of chips. The technology involves coating the outside of the container with clay in order to prevent the ingress of oxygen, which begins the oxidation process.

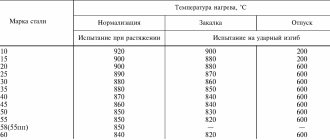

Heating temperature of steel during heat treatment

As previously noted, heat treatment also involves cooling steels, for which not only a water bath, but, for example, a salt bath can be used. When using acids as a coolant, one of the requirements is periodic deoxidation of steels. This process eliminates the possibility of a decrease in the carbon concentration in the surface layer. To carry out the deoxidation process, boric acid or charcoal is used. Also, do not forget that the process of deoxidation of steels leads to the appearance of flames on the workpiece while it is lowered into the bath. Therefore, when hardening or hardening steels using salt baths, the developed safety precautions should be observed.

Considering these methods of heat treatment with subsequent cooling, it should be noted that they significantly increase the cost of the workpiece. However, today cooling in water or quenching while filling the chamber with oxygen does not allow increasing the properties of steel without the appearance of defects.

Steel hardening - technological process

Subsequent release technology

As already indicated, to obtain the sorbitol structure, products made from 65G steel are subjected only to high tempering at temperatures of 550...600 °C, with cooling in still air. For particularly critical parts, an additional low holiday is sometimes carried out. Its temperature range is 160...200 °C, followed by slow cooling in air. This technology avoids the accumulation of thermal stresses in the product and increases its durability. For tempering, you can use not only flame, but also electric furnaces equipped with devices for forced air circulation. The holding time of products in such furnaces is from 110 to 160 minutes (increased time standards correspond to parts with complex configurations and large cross sections).

It is not recommended to use water and aqueous solutions of salts as working media when hardening 65G steel. The acceleration of the cooling process caused by water is often accompanied by uneven calcination.

The final quality control of hardening consists of assessing the macro- and microstructure of the metal, as well as determining the final hardness of the product. The surface hardness of products made from 65G steel should be within 35...40 HRC after normalization, and 40...45 HRC after quenching with high tempering.

Source

Steel 20Х13 - chromium stainless steel - Foundries of Russia

Classification of chromium stainless steelsSteel 08Х13Steel 12Х13Steel 30Х13

Steel 40Х13

Application of steel 20Х13

Steel 20Х13 is used in the manufacture of products for work in mildly aggressive environments:

- atmospheric conditions other than sea;

- aqueous solutions of salts of organic acids at room temperature;

- solutions of nitric acid of weak and medium concentrations at moderate temperatures, etc.

Steel 20X13 is used in cases where products must have sufficiently high strength, as well as high ductility and toughness. 20X13 steel can be welded satisfactorily.

Steel 20X13 is also used as a heat-resistant material at temperatures up to 450-550 °C and as a heat-resistant material - up to 700 °C.

Chemical composition of steel 20Х13

Steel 20Х13 is included in steel type Х13 along with steels 08Х13, 12Х13, 30Х13 and 40Х13. It occupies its own range in carbon content - from 0.16 to 0.25%, the amounts of other alloying elements and impurities are the same as in other steels of the X13 type (Table 1).

Table 1 - Chemical composition of steel 20Х13 according to GOST 5632-72

Steel class 20Х13 according to GOST 5632-72

According to the GOST 5632-72 classification, steel 20Х13 belongs to the martensitic class.

Transformations and microstructure of steel 20Х13

- When annealed steel 20Х13 is heated, the polymorphic alpha-gamma transformation occurs in it in the temperature range from 820 °C (Ac1) to 950 °C (Ac3). The temperature of point Ar1 is 780 °C.

- During isothermal holding or slow cooling in the range of 800-550 °C, austenite decomposes into a ferrite-carbide mixture.

This ferrite-carbide mixture consists of high chromium ferrite and Cr23C6 type carbide. - When 20Х13 steel is rapidly cooled, a martensitic transformation occurs in it. The temperature at which the martensitic transformation begins is 220 °C.

- With an increase in tempering temperature, there is a significant decrease in strength with an increase in ductility, as well as a decrease in corrosion resistance.

Steel range 20Х13

The following products are produced from steel 08Х13:

- thick sheet according to GOST 7350-77;

- thin sheet according to GOST 5582-75;

- tape and roll according to GOST 4986-78;

- long products according to GOST 5949-75;

- hot-deformed pipes according to GOST 9940-81;

- cold-deformed and heat-deformed pipes according to GOST 9941-81;

- wire according to GOST 18143-72.

Mechanical properties of steel 20Х13

The mechanical properties of steel 20Х13 in various types of products are presented in Table 2.

Table 2 - Mechanical properties of steel 20Х13 at 20 °С

The effect of decreasing and increasing temperature on the mechanical properties of a rod made of steel 20X13 after normalization from 1000-1020 °C and tempering at 730-750 °C is shown in Table 3.

Table 3 - Mechanical properties of steel 20Х13 at low and elevated temperatures

Corrosion resistance of steel 20Х13

Steel 20Х13 is highly resistant to atmospheric conditions (except for the sea atmosphere), river and tap water.

Special properties of steel 20Х13

For parts operating at elevated temperatures for a long time, the maximum operating temperature is 450-475 °C, for short-term operation - 500-550 °C.

The density of steel 20Х13 is 7.76 g/cm3.

Heat treatment of welds of steel 20Х13

After welding, tempering of welded joints or products is carried out. The tempering temperature depends on the level of mechanical properties required. Tempering at 680-760 °C is most often used.

Technological parameters of steel 20Х13

Steel 20Х13 has good processability during hot plastic deformation. The temperature range of hot plastic deformation ranges from 1100 to 875-950 °C. Heating for rolling and forging to 780 °C is carried out slowly. After hot deformation, slow cooling is used.

For steel 20Х13, softening annealing is usually used at 750-800 °C with cooling in a furnace to 500 °C. Final heat treatment - hardening from 950-1000 °C with cooling in oil or air and tempering to a given hardness and corrosion resistance.

Alloy composition

Minor additives include:

- chromium, which increases the hardness of the material, the degree of its heat resistance is 0.25%;

- nickel, which imparts anti-corrosion properties and ductility - up to 0.25%;

- copper, increasing corrosion resistance – 0.20%;

- sulfur and phosphorus – 0.035% each.

The last two elements refer to harmful impurities, the presence of which is inevitable. Phosphorus reduces the ductility of the alloy and increases its brittleness. Sulfur causes the phenomenon of red brittleness, that is, the appearance of cracks in the metal during intense heating. However, their concentration in the alloy does not exceed the value permissible for a high-quality material.

A small amount of alloying additives ensures that the alloy is relatively cheap, which makes it extremely popular. The chemical composition determines the physical and technological properties of 65G steel:

- hardness at 20°C – 285 HB;

- elastic modulus – 84 GPa;

- high tensile strength – 750 MPa;

- good impact strength – 3.0 – 3.5 kg*m/cm2;

- specific gravity – 7850 kg/m3;

- temperature range for hardening – 800 – 830°C;

- forging temperature range – 760 – 1250°C.

40ХН2МА steel properties

σ4551/10000=686 MPa, σ4551/1000=137 MPa, σ5901/10000=13 MPa, σ5901/1000=29 MPa.

| Mechanical properties of steel 40ХН2МА | ||||||||||

| GOST | Delivery condition, heat treatment mode | Section, mm | KP | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) | NV, no more | |

| GOST 4543-71 | Bar. Hardening 850 °C, oil. Vacation 620 °C, water | 25 | — | 930 | 1080 | 12 | 50 | 78 | — | |

| Bar. Hardening 850 °C, oil. Temperature 620 °C, oil. | 25 | — | 835 | 980 | 12 | 55 | 98 | — | ||

| GOST 8479-70 | Forgings. Hardening. Vacation | 500-800 | 440 | 440 | 635 | 11 | 30 | 39 | 197-235 | |

| 300-500 500-800 | 490 | 490 | 655 | 12 11 | 35 30 | 49 39 | 212-248 | |||

| 100-300 300-500 | 540 | 540 | 685 | 13 12 | 40 35 | 49 44 | 223-362 | |||

| 100-300 300-500 500-800 | 590 | 590 | 735 | 13 12 10 | 40 35 30 | 49 44 39 | 235-277 | |||

| 100-300 300-500 | 640 | 640 | 785 | 12 11 | 38 33 | 49 44 | 248-293 | |||

| 100-300 | 685 | 685 | 835 | 12 | 38 | 49 | 262-311 | |||

| Up to 100 100-300 | 735 | 735 | 880 | 13 12 | 40 35 | 59 49 | 277-321 | |||

| Up to 100 100-300 | 785 | 785 | 930 | 12 11 | 40 35 | 59 49 | 293-331 | |||

| Mechanical properties of steel 40ХН2МА depending on tempering temperature | ||||||||||

| Temperature, °C | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) | HB | ||||

| Hardening 850 °C, oil | ||||||||||

| 200 300 400 500 600 | 1600 1470 1240 1080 860 | 1750 1600 1370 1170 960 | 10 10 12 15 20 | 50 50 52 59 62 | 59 49 59 88 147 | 525 475 420 350 275 | ||||

| Mechanical properties of steel 40ХН2МА at elevated temperatures | ||||||||||

| Test temperature, °C | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) | |||||

| Hardening 850 °C, oil. Vacation 580 °C. | ||||||||||

| 20 250 400 500 | 950 830 770 680 | 1070 1010 950 700 | 16 13 17 18 | 58 47 63 80 | 78 109 84 54 | |||||

| Sample 5 mm in diameter, 25 mm long, rolled. Deformation speed 2 mm/min. Strain rate 0.001 1/s | ||||||||||

| 700 800 900 100 1100 1200 | — — — — — — | 185 89 50 35 24 14 | 17 66 69 75 72 62 | 32 90 90 90 90 90 | — — — — — — | |||||

| Endurance limit of steel 40ХН2МА | ||||||||||

| σ-1, MPA | J-1, MÏÀ | n | Heat treatment | |||||||

| 447 392 519 | 274 235 | 106 | Section 100 mm. Hardening 850 °C, oil. Vacation 580 °C, σв=880 MPa. Section 400 mm. Hardening 850 °C, oil. Temperature 610 °C, σв=790 MPa, σ0.2=880 MPa, σв=1080 MPa | |||||||

| Impact strength of steel 40ХН2МА KCU , (J/cm2) | ||||||||||

| Т= +20 °С | Т= -40 °С | Т= -60 °С | Heat treatment | |||||||

| 103 | 93 | 59 | Hardening 860 °C, oil. Vacation 580 °C | |||||||

| Mechanical properties of steel 40ХН2МА depending on the section | ||||||||||

| Section, mm | Sample cutting location | σ0.2 (MPa) | σв(MPa) | δ4 (%) | ψ % | KCU (J/cm2) | HRCE | |||

| Bar. Hardening 850 °C, oil. Vacation 620 °C | ||||||||||

| 40 60 80 100 120 | Central Central 1/2R 1/2R 1/3R | 880 830 730 670 630 | 1030 980 880 850 830 | 14 16 17 19 20 | 57 60 61 61 62 | 118 127 127 127 127 | 33 32 29 26 25 | |||

| Hardening 850 °C, oil. Vacation 540-660 °C | ||||||||||

| up to 16 16-40 40-100 100-160 160-250 | Ts ts ts ts | 1000 900 800 700 650 | 1200-1400 1100-1300 1000-1200 900-1100 850-1000 | 9 10 11 12 12 | — — — — — | 90 50 60 60 60 | — — — — — | |||

| Hardenability of steel 40ХН2МА | ||||||||||

| Distance from the end, mm | Note | |||||||||

| 1,5 | 3 | 6 | 9 | 12 | 15 | 21 | 27 | 33 | 42 | Hardening 840 °C |

| 49-59,5 | 40,5-60 | 50-60 | 50-59,5 | 49-59 | 48-59 | 45-56 | 41,5-53 | 41-50,5 | 36,5-48,5 | Hardness for hardenability strips, HRC |

| Amount of martensite, % | Critical hardness, HRCе | Critical diameter in water | Critical diameter in oil | |||||||

| 50 90 | 44-47 49-53 | 153 137-150 | 114 100-114 | |||||||

| Physical properties of steel 40ХН2МА | ||||||||||

| T (Grad) | E 10-5 (MPa) | a 10 6 (1/Deg) | l (W/(m deg)) | r (kg/m3) | C (J/(kg deg)) | R 10 9 (Ohm m) | ||||

| 20 | 2.15 | 39 | 7850 | 331 | ||||||

| 100 | 2.11 | 11.6 | 38 | 490 | ||||||

| 200 | 2.01 | 12.1 | 37 | 506 | ||||||

| 300 | 1.9 | 12.7 | 37 | 522 | ||||||

| 400 | 1.77 | 13.2 | 35 | 536 | ||||||

| 500 | 1.73 | 13.6 | 33 | 565 | ||||||

| 600 | 13.9 | 31 | ||||||||

| 700 | 29 | |||||||||

| 800 | 27 | |||||||||

| Brief designations: | ||||||||||

| σв | — temporary tensile strength (tensile strength), MPa | å | — relative settlement at the appearance of the first crack, % | |||||||

| σ0.05 | — elastic limit, MPa | Jê | — ultimate torsional strength, maximum shear stress, MPa | |||||||

| σ0.2 | — conditional yield strength, MPa | σben | — ultimate bending strength, MPa | |||||||

| δ5,δ4,δ10 | — relative elongation after rupture, % | σ-1 | — endurance limit during bending test with a symmetrical loading cycle, MPa | |||||||

| σсж0.05 and σсж | — compressive yield strength, MPa | J-1 | — endurance limit during torsion testing with a symmetrical loading cycle, MPa | |||||||

| ν | — relative shift, % | n | — number of loading cycles | |||||||

| sв | — short-term strength limit, MPa | R and ρ | — electrical resistivity, Ohm m | |||||||

| ψ | — relative narrowing, % | E | — normal modulus of elasticity, GPa | |||||||

| KCU and KCV | — impact strength, determined on a sample with concentrators of the types U and V, respectively, J/cm2 | T | — temperature at which properties were obtained, degrees | |||||||

| sT | — proportionality limit (yield strength for permanent deformation), MPa | l and ë | — thermal conductivity coefficient (heat capacity of the material), W/(m °C) | |||||||

| HB | — Brinell hardness | C | - specific heat capacity of the material (range 20o - T), [J/(kg deg)] | |||||||

| H.V. | — Vickers hardness | pn and r | — density kg/m3 | |||||||

| HRСе | — Rockwell hardness, scale C | A | — coefficient of thermal (linear) expansion (range 20o - T), 1/°С | |||||||

| HRB | — Rockwell hardness, scale B | σtТ | — long-term strength limit, MPa | |||||||

| HSD | - Shore hardness | G | — modulus of elasticity during torsional shear, GPa |

xn--402-8cd3de9c.xn--p1ai

Description of steel grade 65g

65 is the carbon content in the alloys in hundredths, and “g” is manganese (the alloying element).

Steel forging temperature: start - 1250 °C, end - 760−780°C.

65 g is a wear-resistant, tough, durable, elastic material with good tear resistance and shock resistance.

Mechanical properties of steel - the following categories:

Quenching temperature - 830 °C, oil. Temperature: 470°C.

There are several types of supply of 65 g steel, one of them is the following:

Application

Steel 65G is widely used in mechanical engineering. The plastic properties of this brand have made it possible to make it a standard in the production of springs, springs, and thrust washers. Thanks to its hardness, it became possible to manufacture parts with increased wear resistance from it:

Steel 65G has been used in workshops for many years to make knives. This is due to the high hardness and low cost of the material.

However, there is such a huge drawback as susceptibility to rust. Therefore, the products require special care. More often, this steel is used to make throwing knives, sports or tournament weapons (swords, sabers, checkers).

Peculiarities

Due to its properties, 65g steel is not suitable for welding. But it is worth noting that the range of uses is quite wide, even if you do not take into account edged weapons. Various springs, springs, bearing housings, components and metal structures are made from it. It has found application even in trucks - this particular material is used to create rear axle springs.

In order for the material to retain its properties and not become rusty, it must be kept in a dry room, and the products must be periodically coated with oil.

Due to its low cost and fairly decent properties, 65g steel is used as analogues of such materials as: 55С2, 60С2, 70, 70Г, У8А, 9Хс.

The elasticity of the metal during forging allows you to make edged weapons and blades at home. It is for this reason that 65g steel has become widespread in this industry. This applies to manual production not only of sports equipment or tools for reconstruction, but also for domestic use - in the kitchen.

Minuses

As noted above, steel belongs to the carbon group and is susceptible to corrosion. Therefore, do not forget two important rules: keep the blades dry and clean and periodically lubricate them with castor oil. Caring for knives made from 65G steel is comparable to caring for knives made from Damascus steel.

Heat treatment modes

The temperature range for hardening steel 65G is in the range of 800-830 °C. Subsequent high tempering at 160-200 °C with further cooling in still air makes it possible to obtain a steel hardness of 45-47 HRC. This grade of steel is not afraid of overheating, however, when hardened at high temperatures, the impact strength of the steel begins to decrease.

Throwing knives made of steel 65G

Throwing knife "Luch-B"

Made of 65G steel with braid Manufactured by the company “AiR”, Zlatoust, Russia The knife is made of 65G steel, ...

Throwing knife "Viking"

Made of 65G steel with braid Manufactured by the company “AiR”, Zlatoust, Russia The knife is made of 65G steel, ...

Throwing knife "Katran"

Made of 65G steel with braid Manufactured by the company “AiR”, Zlatoust, Russia The knife is made of 65G steel, ...

Throwing knife "Luch-S"

Made of 65G steel with braid Manufactured by the company “AiR”, Zlatoust, Russia The knife is made of 65G steel, ...

Manufacturing a chamber for hardening metal

The main materials for the manufacture of home furnace bodies for steel hardening are solid refractories in the form of blocks of various sizes and fireclay clay. In such a furnace, a temperature of over 1200 °C is reached, so it is possible to harden products not only from carbon or tool steel, but also from high-alloy steel. When making home stoves from fireclay clay, a cardboard frame is first made according to the shape and size of the working chamber, which is then covered with a layer of fireclay. A heating coil is wound over it, and then the main heat-insulating layer is applied.

With this design, the heating area is isolated from the heating element, which is important when it is necessary to harden steel that is sensitive to oxides and carbon burnout. The most common design of home hardening furnaces are installations whose thermal bodies are made of fireclay bricks or similar refractories

The operating temperature of such materials is more than 1400 °C, so in such furnaces it is possible to harden almost any type of steel and many refractory alloys. Structurally, such a home oven is similar to a conventional wood-burning oven, only it is much smaller in size. The metal in it is heated using an electric spiral placed in grooves along the perimeter of the internal space. If it is necessary to qualitatively harden steel, it must be heated to a precisely specified temperature, so most of these homemade products are equipped with thermostats (they can be freely purchased on Aliexpress).

The video below shows the design of such a home furnace with end loading and a thermostat, which allows you to harden steel with precise temperature conditions. Its thermal body is made of mullite-silica refractory plates ShPT-450.

A detailed description of the design and recommendations for creating a top-loading furnace, in which you can harden products up to 54 cm in length, can be seen in the following video. Here the thermal body of the furnace is made of fireclay bricks (ShB type) and a thermostat is also used. In addition to the top loading, a special feature of this device is a kanthal spiral, which lasts many times longer than traditional nichrome and fechral.

Common parameters

The substances included in this material and its further heat treatment provide:

- high wear resistance;

- good impact strength;

- tensile strength;

- high resistance to impact.

The absence of a large number of alloying elements allows for a relatively low price of this steel.

To obtain the specified parameters, 65G steel is hardened at a temperature of 800 to 830 ºC. Tempering is carried out at a temperature of 160 to 200 ºC; this tempering is called high. Cooling is performed in air. Such heat treatment modes make it possible to obtain a product with a surface hardness of 45-47 HRC.

The technologist, when designing the heat treatment process, must remember that 65G steel and its analogues are not afraid of overheating, but when hardening is performed at the upper points of the temperature range, the impact strength may decrease.

Results

To summarize, it is worth noting that such steel is often used for sporting edged weapons, as well as weapons for tournaments. After all, it is precisely in this scenario of use that shock resistance and low cost of the product are required.

Knives will be made from this steel for a long time, but still in more specialized industries. Although knives made from such steel are almost never used in the kitchen, especially recently, there are plenty of people who like to make blades from the remains of such an alloy.