Home / Devices

Back

Reading time: 6 min

0

1515

Corrosion-resistant steel, or stainless steel in everyday life, is the most necessary material in the household.

Household utensils are made from this alloy steel; many car parts are also made from stainless steel.

Alloy steel, which is well used in everyday life, is difficult to heat treat during welding.

Inconveniences are expressed by the existence of an oxide film on the surface of products, which melts at a temperature of at least 2,000° C.

However, there are techniques that allow you to repair or connect stainless steel parts by welding and even at home.

The best way for this operation is considered to be the use of TIG technology - manual welding with a non-consumable rod in an inert controlled atmosphere - argon.

The resulting seams are distinguished by their accuracy and reliability, which is necessary when working with alloyed metal.

- General information

- Apparatus for household work QUATTRO ELEMENT MULTI PRO 2100

- FUBAG IRMIG 200 SYN

- FOXWELD INVERMIG 185

- SVAROG PRO MIG 160 SYNERGY

- AURORA SREEDWAY 175

Difficulty factors for welding stainless steel parts

Welding stainless steel is complicated by the fact that this material belongs to the category of high-alloy alloys, which means that its composition contains elements in fairly large quantities that affect its basic properties. In stainless steel, in particular, this element is chromium. Its content in this alloy can be 12–30%. Chromium, along with elements such as nickel, titanium, manganese and molybdenum, forms the anti-corrosion properties of stainless steel, but at the same time gives it other features that affect weldability.

For those who do not like to read long articles and delve into technical details, we suggest you immediately watch two videos with the most relevant options for welding stainless steel for a home craftsman - with an electrode using an inverter and again with an inverter, but in a shielding gas (argon).

Welding of stainless steel must be carried out taking into account the following specific characteristics of this material.

A fairly high coefficient of linear expansion.

For this reason, welding of stainless steel is always accompanied by significant deformation of the parts being joined. In some cases, when the parts being welded are of significant thickness and there is no gap between them, such deformations can even lead to the appearance of large cracks.

Low thermal conductivity

The thermal conductivity of stainless steel is 1.5–2 times lower than that of low-carbon alloys. This feature of the material leads to the fact that the parts being connected in the welding zone are melted even at lower (15–20%) current strengths than when welding products made of low-carbon steel.

Intergranular corrosion

With strong heating (more than 500 degrees Celsius), so-called intergranular corrosion occurs in stainless steels. This happens because layers consisting of chromium and iron carbide begin to form at the edges of the grains of the metal structure. This phenomenon can be avoided not only by careful selection of the welding mode, but also by forced cooling of the stainless steel parts being welded, for which you can use ordinary water. However, it should be borne in mind that only parts made of chromium-nickel steels that have an austenitic internal structure can be cooled with water.

Overheating of electrodes with chromium-nickel rods

Due to the low thermal conductivity of the materials being joined and their increased electrical resistance, welding of stainless steel parts is accompanied by strong heating of the electrodes, the rods of which have a chromium-nickel composition. To avoid this undesirable phenomenon, use electrodes for welding stainless steel up to 35 cm long.

Welding electrodes Sabaros ME 101 3.2 mm for welding stainless steels

The most common methods of welding stainless steel

Welding of stainless steel products characterized by a high chromium content can be performed using several technologies. This includes, in particular, the following types of welding:

- argon arc (using a tungsten electrode and AC/DC TIG modes);

- performed in MMA mode with coated electrodes;

- semi-automatic arc welding in an argon environment, carried out in MIG mode and using stainless steel wire;

- so-called cold welding for stainless steel, performed under high pressure (the name of this technology is due to the fact that it does not involve melting the metal during the process of joining it);

- seam technology and resistance spot welding.

The technology for welding stainless steel parts involves thoroughly degreasing their surfaces using acetone or aviation gasoline. This is done in order to reduce the porosity of the seam being performed, to make the welding arc more stable, and to thoroughly clean the edges of the parts being joined. Only after thorough cleaning can you begin to perform the operation using the chosen method. There are several basic methods for welding stainless steel parts, as well as technologies that are used quite rarely. In any case, the decision on how to weld stainless steel should be based on the specific conditions and requirements for the joint being formed.

Welding with coated electrodes (MMA)

Welding stainless steel parts using MMA technology, which involves the use of coated electrodes, is the most common technology. This method is quite simple, it can be used at home, but it does not allow you to obtain the highest quality seam.

Conveniently, this kind of stainless steel welding can be done even at home, but for this you will need a special welding machine called an inverter. In order for welding stainless steel with an inverter to produce a highly reliable connection, it is necessary to select the correct electrode for a specific grade of stainless steel. All electrodes used to weld stainless steel products are divided into two main types:

- with a rutile coating based on titanium dioxide (welding with such electrodes, which provide small metal spatter and a stable arc, is performed with direct current and reverse polarity);

- with a coating based on magnesium and calcium carbonate (with such electrodes, stainless steel is welded using direct current of reverse polarity).

To understand which electrodes to use to weld stainless steel, just look at GOST 10052-75, which presents all types of such consumables, and also stipulates which one should be used for working with metal of a specific chemical composition. In order to select stainless steel electrodes that meet the requirements of this GOST, it is enough to know the grade of the metal from which the parts need to be connected.

All requirements for electrodes for welding stainless steel can be found by downloading GOST 10052-75 for free in pdf format from the link below.

GOST 10052-75 Coated metal electrodes for manual arc welding of high-alloy steels with special properties

Pros and cons of the method

Compared to other welding methods, for example, TIG welding, gas-shielded welding with a consumable electrode MIG/MAG, submerged arc welding, the use of the MMA stainless steel joining method provides a number of significant advantages:

- this technology involves the use of a special welding machine, characterized by a simple design, affordable price and small size;

- RDS is focused on connecting many types of ferrous and non-ferrous metals, and in addition various alloys, regardless of their thickness;

- no need to use additional flux or gas protection;

- This technology is applicable in cases where it is difficult to reach the area being processed due to the small size of a particular welding machine.

However, this method also has certain disadvantages:

- it is necessary to regularly remove the slag formed after creating the seam;

- Considering that the welding current passes in a continuous mode along the entire length of the electrode, it is necessary to set a limit for it, since otherwise the electrode may overheat, and this may result in destruction of the coating;

- Welding with this method requires more time.

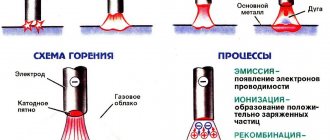

Manual and semi-automatic welding of stainless steel in argon (AC/DC TIG, MIG)

To perform manual welding of stainless steel in an argon environment, tungsten electrodes are used. This technology, even at home, allows you to obtain high-quality and reliable connections for products that are not very thick. Welding with such electrodes on stainless steel is used mainly for installing communications from pipes through which gases or various liquids will be transported under pressure.

Austenitic stainless steel should be welded with particular care and caution

This technology has certain features.

- To ensure that tungsten, from which stainless steel electrodes are made, does not get into the molten metal in the welding zone, the arc is ignited in a non-contact manner. If it is not possible to do this directly on the part, then the arc is lit on a special coal plate and carefully moved to the workpieces to be joined.

- Welding stainless steel using this method can be performed with both direct and alternating current.

- The modes are selected depending on the thickness of the parts being connected. Such modes, in particular, include the parameters of the cross-section of the tungsten electrode, the diameter of the wire used as an additive, current parameters (strength and polarity), shielding gas consumption, and welding speed.

- It is very important that the alloy level of the filler wire is higher than that of the parts being joined.

- During the welding process, stainless steel electrodes should not make oscillatory movements. If this requirement is neglected, this may lead to disruption of the welding zone and oxidation of the metal in its area.

By using this technology, the consumption of tungsten electrode can be reduced. To do this, you need to keep the argon supply open for some time (10–15 seconds) after the welding process is completed. This procedure helps protect the hot tungsten electrode from active oxidation.

Semi-automatic welding of stainless steel in an argon environment, in fact, has few differences from the conventional manual method. Its main difference is that the wire is fed into the welding zone using special equipment. Thanks to mechanization, the process proceeds much more accurately and at greater speed.

Thanks to the use of semi-automatic equipment, the following welding techniques for stainless steel parts can be implemented:

- jet transfer method, which allows you to effectively weld parts of large thickness;

- short arc welding - for connecting parts of small thickness;

- Pulse welding is a universal technology that allows you to obtain high-quality and reliable connections and is the most profitable option financially.

Tig welding of stainless steel

Setting up a semi-automatic machine

To obtain a strong connection between parts, you need to correctly configure the operating mode of the welding equipment.

When choosing options, consider the following information:

- thickness of the workpieces (the thicker the product, the higher the values of welding voltage and current are set);

- connection method (vertical, butt, corner);

- wire cross-section (the choice of this parameter depends on the set voltage and current values);

- the size of the gap between the structural elements being welded.

For example, when making a tight butt joint between workpieces 0.8 mm thick, 0.8 mm electrodes are used, voltage up to 16 V, current 50-80 A.

Other stainless steel welding technologies

There are several other methods of welding stainless steel that demonstrate themselves better in certain situations, that is, they are not universal. This includes the following methods, which involve the use of special equipment.

Welding stainless steel using a laser beam

This welding method, which even looks very impressive on video, has a number of significant advantages: the metal in the welding zone does not lose its strength due to excessive temperature exposure, cools quickly, cracks do not appear on it, and grains of minimal size are formed in its structure . Equipment for laser welding and the technology itself are widely used in various industries (automobile and tractor manufacturing, installation of pipe communications, etc.).

Cold welding under high pressure

This technology does not involve melting of the material in the welding zone, and metal parts are connected at the level of their crystal lattices. Depending on the resulting connection and the configuration of the parts, pressure can be applied to one or both metal workpieces. It is very interesting to watch a video of such a process: two parts, being in a cold state, seem to be pressed into each other.

Contact welding of stainless steel products

Such welding can be performed using spot or roller technology. As a result, thin stainless steel sheets with a thickness of no more than 2 mm can be joined. The same equipment is used as for other metals.

The video below explains in detail and clearly demonstrates the nuances of feeding a filler rod when welding stainless steel with a non-fusible electrode in an argon environment and other nuances of the work.

The need for shielding gas in operation

Gas is often replaced with cored wire.

It consists of the following components:

- top metal layer;

- cores;

- flux.

The flux is located in the inner core. It is released when the top steel layer melts and provides the welding zone with protection from oxidation.

There are some drawbacks to using this element. The seams are not as reliable as when protecting the weld pool with gas.

Therefore, this technology is used only for soldering workpieces in hard-to-reach areas where it is impossible to deliver a gas cylinder with the smallest volume.

We recommend reading: How to weld stainless steel to ferrous metal

In all other situations, work is carried out only using gas and an electrode.