03/09/2020 Author: VT-METALL

Issues discussed in the material:

- Features of welding stainless pipes

- Basic technologies for welding stainless steel pipes

- What is necessary when welding stainless pipes

- Types of welding of stainless steel pipes

Today, welding of stainless steel pipes is in great demand, since this material is actively used in those industries where its anti-corrosion properties are necessary. For example, stainless steel pipelines are used in food production, as well as in public utilities.

It is welding that makes it possible to obtain a high-quality technological seam that ensures 100% reliability. Welding work on stainless pipes is carried out using special technologies. We will tell you in our article exactly what recommendations are put forward and how to make installation easier.

Main characteristics of the material

Before considering the question of how stainless steel is welded, it is necessary to find out what characteristics this material has. The composition of the metal includes carbon, alloyed chromium and iron. Thanks to chromium, the metal withstands environmental influences and resists corrosion. Chromium oxide gives the material durability because it covers it with a special protective film. Alloying can also occur with the help of other metals: cobalt, nickel, titanium.

Welding stainless steel with an inverter is also possible, since steel is easy to process, withstands environmental factors and lasts for a long time. It is also widely used due to its aesthetic appearance.

Benefits of technology

Cutting a stainless steel sheet is carried out under the influence of a laser beam of energy. High-tech equipment makes it possible to quickly perform operations and achieve high accuracy, as well as the absence of unevenness on the edge. The sheet being processed is burned with a beam in the form of holes of the required diameter. Then the entire surface is cut along the specified contour using a laser machine. Such work with stainless steel is indispensable when processing large volumes of material in a short time.

The process of cutting stainless steel using other methods is quite labor-intensive. With the help of a laser, it turns into an easy procedure that makes it possible to obtain an ideal result.

What kind of steel is there?

For stainless steel welding to be successful, it is important to consider the characteristics of the metal and what type is used. Among the most common types are the following:

- Austenitic

- Martensitic

- Ferritic.

The name of the first type is associated with the main phase. It always contains a high content of nickel and chromium. As an example, consider food grade steel, which is used in a wide variety of industries: for the manufacture of durable dishes, cutlery and even chimneys. Nickel accounts for 10% of the content, and chromium - up to 18%. It is resistant to chemical attack and is also difficult to mechanically deform. They are ductile, so welding on stainless steel most often does not cause difficulties.

The second type is distinguished by the specificity of the material structure itself. It can only be examined through a microscope. It contains a small amount of carbon (less than a percent), and chromium no more than 12%. And although the hardness index is quite high, this type of steel is brittle, so it is most often used to make cutting tools or fasteners where there is not much exposure to the environment.

Often used for the production of alcoholic beverages. To obtain optimal impact resistance characteristics, heat treatment is used.

The third group is not subject to heat treatment at all. The fact is that the chromium content here is higher than other representatives, so the metal is not susceptible to mechanical or environmental influences. Welding for stainless steel in this case is especially difficult, so it is most often used for mechanical engineering, the manufacture of various parts: fittings, bushings or shafts.

Prices for cutting stainless steel

| thickness, mm | up to 100 m.p., meter | from 100 to 500 m.p., meter | over 500 m.p., meter |

| ferrous metal/structural steel | |||

| 0,7 — 0,8 | from 30 rub. | from 25 rub. | from 22 rub. |

| 1,0 — 1,2 | from 32 rub. | from 26 rub. | from 23 rub. |

| 1,5 | from 33 rub. | from 30 rub. | from 26 rub. |

| 2,0 — 2,5 | from 39 rub. | from 37 rub. | from 34 rub. |

| 3,0 | from 41 rub. | from 39 rub. | from 36 rub. |

| 4,0 | from 50 rub. | from 48 rub. | from 45 rub. |

| 5,0 | from 58 rub. | from 53 rub. | from 51 rub. |

| 6,0 | from 67 rub. | from 65 rub. | from 62 rub. |

| 8,0 | from 78 rub. | from 74 rub. | from 72 rub. |

| 10,0 | from 92 rub. | from 89 rub. | from 85 rub. |

| 12,0 | from 188 rub. | from 179 rub. | from 168 rub. |

| 16,0 | from 305 rub. | from 288 rub. | from 277 rub. |

| 20,0 | from 449 rub. | from 435 rub. | from 422 rub. |

| non-ferrous metal/stainless steel steel/aluminum | |||

| 0,7 — 0,8 | from 44 rub. | from 35 rub. | from 33 rub. |

| 1,0 — 1,2 | from 47 rub. | from 37 rub. | from 35 rub. |

| 1,5 | from 55 rub. | from 47 rub. | from 45 rub. |

| 2,0 — 2,5 | from 65 rub. | from 58 rub. | from 56 rub. |

| 3,0 | from 100 rub. | from 80 rub. | from 77 rub. |

| 4,0 | from 145 rub. | from 95 rub. | from 91 rub. |

| 5,0 | from 155 rub. | from 110 rub. | from 107 rub. |

| 6,0 | from 188 rub. | from 145 rub. | from 141 rub. |

| 8,0 | from 300 rub. | from 225 rub. | from 200 rub. |

| 10,0 | from 545 rub. | from 498 rub. | from 397 rub. |

*The cost depends on the complexity of the work performed. For detailed information, please contact the manager by phone.

| Metal | Thickness of cut metal | Cost of laser cutting of metal, 1 linear. /meter/rub. |

| Stainless steel (AISI 430,AISI 304, AISI 321, etc.) | 1.0 - 10.0 mm | From 56 rub. |

Features of the welding process

Welding stainless steel and steel deserves special attention because the materials have the ability to expand linearly. This means that as a result of heat treatment, the steel may begin to deform, change shape and size. To avoid possible difficulties, it is recommended to carefully consider the process itself and leave the correct distance between the parts that you plan to weld.

It is also worth taking into account that due to exposure to high temperatures, steel begins to lose its optimal properties. It ceases to be as strong as possible against the occurrence and spread of corrosion. Therefore, the seam must be cooled in time. Due to low thermal conductivity, it is important to reduce the current strength by about 25%.

Also among the features of welding stainless steel, it is worth considering the correct selection of the length of the electrodes. Excessive length may result in overheating. There is still a difficulty. Carbide may form on the surface of the metal, which is difficult to melt, or intercrystalline corrosion may occur.

Welding stainless steel (stainless steel)

Welding stainless steel has its own distinctive features. From our article you will learn a lot of useful information about this process in a few minutes. In one place we have collected basic data on welding methods and important nuances when carrying out work. Read and apply the acquired knowledge in practice. The Tiberis welding equipment store is always happy to share its secrets with you and is happy to help with practical advice.

Content

- Stainless steel - what kind of material is it?

- Where are the different types of stainless steel used?

- What methods are used to weld stainless steel?

- Features of welding stainless steel or how to avoid defects when welding stainless steel

- What quality stainless steel welding equipment should be like?

- Processing products before welding - what and how to do

- How are stainless steel products processed after welding?

- Features of welding stainless steel with other materials

- conclusions

Stainless steel - what kind of material is it?

At all times, the main enemy of iron products was rust. It can turn the most durable structures into a pile of useless scrap metal. Due to oxidation in the open air, precision instruments become unusable and huge structures are destroyed.

But just over a century ago, people managed to find an excellent rust remover. In 1913, English researcher Harry Brierley created the world's first (according to officially recognized version) stainless steel. It contained 12.8% chromium and 0.24% carbon. Although the first experiments with iron and chromium alloys began to be carried out back in 1820.

Stainless steel has pronounced anti-corrosion properties. Stainless steel acquires these characteristics when certain metals are added to its melt. Most often, chromium, nickel, manganese and molybdenum are used for such purposes.

There are 3 main groups of stainless steel according to their chemical composition:

- Chromium (have increased strength) These are the cheapest types of stainless steel. They are less amenable to processing due to low ductility.

- Chrome-nickel (differ in greater ductility). The most popular and widest group of stainless steel. The addition of nickel stabilizes the alloy structure and gives the steel weak magnetic properties.

- Chromium-manganese-nickel. Adding manganese to the alloy increases strength while maintaining the ductility of steel.

Each of these groups contains dozens and even hundreds of grades of stainless steels, which can differ significantly in their properties. For example, chromium steels with the minimum permissible (12-14%) chromium content are widely used in the manufacture of valves in units and in the production of ordinary kitchen utensils. At the same time, chromium steels with a chromium content of 25-33% have excellent heat resistance. Therefore, they are used in metallurgy to create equipment for metal smelting.

In addition, stainless steels are differentiated by their physical structure. Among the many types, the most famous are ferritic, austenitic and martensitic steels.

Where are the different types of stainless steel used?

The scope of application of stainless steel affects literally all aspects of human life. The most popular chromium-nickel authensitic steels are used in large quantities for the production of fasteners (bolts and nuts). Coins are often made from these alloys, for example, Ukrainian 1,2 and 5 kopecks. Autensites are quite easy to heat treat, including welding.

Ferritic alloys are widely used in the chemical industry. High resistance to many types of acids and high temperatures allows these types of steel to be used for the manufacture of huge tanks in chemical plants. But welding ferritic steel products is much more difficult. Significant resistance to high temperatures makes these alloys inconvenient for welding with the most common welding methods (MMA, MIG/MAG, TIG). But at home, ferrites are very rare.

Martensitic steels are widely used in the production of tools. Kitchen knives are made from martensitic steel grades. Like their authentic counterparts, they can be welded without any problems.

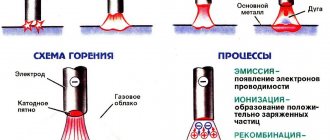

What methods are used to weld stainless steel?

Stainless steel can be welded in a variety of ways. But 3 main technologies are most often used:

- Manual arc welding with consumable electrodes (MMA). This method is most common at home, because... inverters for RDS are affordable for every welder. It is of the lowest quality, so it is practically not used on an industrial scale.

- Semi-automatic wire welding in a protective gas environment (MIG/MAG), semi-automatic welding machines are perfect for this. The most effective method: fast, forming an even seam. Better suited for thicker parts.

- Welding with non-consumable electrodes in an inert gas environment (TIG), most often using inverters for argon arc welding. More preferable when welding thin workpieces. Recommended for welding high pressure pipes..

In addition, stainless steel welding can be carried out using less common methods. These include:

- Spot and roller welding.

- Plasma welding.

- Laser welding.

But the use of these technologies is limited by the high cost and complexity of the process. Therefore, they are used exclusively when it is necessary to weld parts that require high precision or when processing difficult-to-weld materials.

Features of welding stainless steel or how to avoid defects when welding stainless steel

Welding stainless steel has its own nuances, which are determined by the properties of this material:

- The presence of chromium in the steel composition. This metal, when exposed to high temperature, reacts with carbon to form chromium carbide, thereby reducing the strength of the welded joint. Therefore, the welding site is quickly cooled (sometimes even with ordinary water).

- Reduced thermal conductivity. In this connection, the welding current must be reduced by 15-20% compared to the process of processing conventional steel.

- Increased metal expansion coefficient. Therefore, it is necessary to constantly monitor the size of the gap between the parts being welded.

- High electrical resistance. For this reason, electrodes with chromium-nickel rods have a limited (up to 350 mm) length.

These four main features of stainless steel welding must always be taken into account when starting work. Only by fulfilling the above conditions can you achieve high-quality results. Otherwise, you are guaranteed the formation of defects.

What should high-quality equipment and materials be for welding stainless steel?

The choice of equipment for welding stainless steel should be made based on the characteristics of this material.

It is best to use welding electrodes made from the same grade of stainless steel as the work being welded. Then the process of melting the metal occurs evenly, providing a high-quality result.

When welding with wire, it is also necessary to select it based on the material of the workpieces being welded. The main difficulty is that it is impossible to determine “by eye” a specific grade of stainless steel. To do this, you need to carry out complex spectral analysis in a specialized laboratory. If you encounter such a problem, it is best to look for information on the website of the manufacturer of the product being welded.

Processing products before welding - what and how to do

Processing of stainless steel products before welding is carried out in the following order:

- The surface of the product is cleaned of dirt. A steel brush is usually used for this.

- Treatment is carried out with a solvent (white spirit, special liquid or acetone). The absence of grease on the surface of the part increases the stability of the arc.

- The surface to be welded is treated with an anti-spatter agent. As a result, after welding, the need for mechanical surface treatment simply disappears.

The only significant difference in the preparation of stainless steel products is the need for a gap between the edges of the parts. It provides free shrinkage.

How are stainless steel products processed after welding?

Stainless steel after welding is subject to mandatory additional processing. Ignoring this rule can very quickly lead to negative consequences: corrosion and a decrease in the strength of the product.

Pre-treatment after welding can be performed by the following methods:

- Mechanical cleaning of the weld. This operation is mainly intended to improve the appearance of the product. Produced with hard steel brushes.

- Sandblasting. Pursues the same goals. After doing this, the seam looks even more beautiful.

- Grinding. Allows you to achieve a perfectly smooth seam surface.

But all these pre-treatment methods only affect the appearance of the product. To effectively protect the welding site from destruction, more effective methods are needed - passivation and etching.

Pickling is the treatment of the welding site with chemically active substances (acids or special liquids). Acids eat away scale, which can cause rust.

Passivation is the application of a special agent to the welding site, under the influence of which a protective film of chromium oxide is formed on the metal surface.

Only after chemical treatment can the welding site reliably resist corrosion.

Features of welding stainless steel with other materials

The main danger when welding stainless steel with other materials lies in mixing them. As a result, the properties of a dissimilar weld may deteriorate sharply. The seam becomes hard and brittle, and cracks form in it.

To avoid such a development of events, it is necessary:

- Use high-alloy or nickel-based alloys as an additive.

- Be sure to calcinate the electrodes before welding and thoroughly clean the surfaces of the products.

- Do not preheat the welding area before starting work.

- Use electrodes designed for welding high-alloy steel.

In the weld, it is desirable to achieve as little as possible the presence of the base metal (particles of the original products melted during welding). Its component should not exceed 40% of the total mass. The rest is electrodes or filler wire, depending on the type of welding.

conclusions

Welding stainless steel, although it is a rather complex process, can be carried out efficiently even at home.

For a positive result you need:

- Correctly take into account the characteristics of stainless steel welding.

- Select the most suitable (available) welding method.

- Carefully treat the welding area before and after finishing work.

- Use high-quality welding equipment and consumables.

All these points can be easily implemented if you have the desire. And Tiberis store specialists are always ready to offer their assistance in choosing the most suitable welding equipment. Contact us - welding work is much easier and more efficient with us.

Welding methods

Welding work on stainless steel has gained wide interest due to the growing popularity of using this metal. Today, welding work on stainless steel is carried out in many ways:

- MMA (uses manual arc method);

- tig welding of stainless steel (using a tungsten electrode in an argon atmosphere);

- MIG/MAG (processing under inert atmosphere conditions).

However, in order to correctly answer the question of what type of welding to use to weld stainless steel, it is important to pay attention to the chemical and physical parameters of the metal. Features of stainless steel welding that can complicate the process include the following:

- Melting begins at a lower temperature

- Low thermal conductivity criterion

- Wide range of thermal expansion.

Before you start welding stainless steel at home or for industrial purposes, the material must be heated. The only material that does not require this procedure is an alloy with a carbon content of less than 0.2%. If the thickness is more than 30mm, the metal should still be heated to a temperature of 150 degrees. The welding current should be supplied with a reduced intensity of about 20%. This will help avoid burnout situations in the welding area.

Basic technologies for welding stainless steel pipes

The widespread use of stainless steel for the manufacture of various structures and parts has contributed to the development of technologies for welding such alloys. Welding of stainless pipes in accordance with GOST can be carried out in various ways: using manual MMA arc welding machines, a tungsten electrode in an argon TIG layer, semi-automatic devices in an inert gas - MIG/MAG, laser equipment.

Unlike the processes of welding parts made of carbon steel, to perform work with stainless steel it is necessary to use special technologies that take into account the physical characteristics and chemical composition of this material.

Argon welding process

tig welding of stainless steel implies the presence of a protective environment, which is created by argon. This is the best option if you plan to weld thin-sheet stainless steel. This method effectively protects the material from oxygen.

Using special equipment, an arc is produced that is located between the tungsten electrode and the workpiece. Under the influence of high temperatures, the edge begins to melt, resulting in the formation of a weld pool. The arc constantly contains a special wire for welding thin-sheet stainless steel. The entire process must occur at right angles. For all work to be carried out at the highest level, vibrations of the electrode should not occur.

This kind of work helps to make a high-quality seam without slag. It is necessary to pay attention to this, since such a seam will have the best characteristics: high strength and excellent aesthetic qualities.

Gas welding is carried out in many industries: automotive, chemical, thermal power and even aviation. However, this method also implies some disadvantages: a lot of time is spent, as well as the mandatory presence of a highly qualified worker.

As for equipment, to carry out the entire process, you will definitely need an inverter. Welding thin stainless steel with an inverter has quite a few advantages:

- it is easy to operate;

- stability of the arc;

- small specific gravity.

When using the tool, there is no doubt that the seams will be of high quality. In the question of how to weld stainless steel with an inverter, it is important to choose the right temperature. It is also worth noting that some device models do not work in open spaces in cold weather.

TIG welding of stainless steel also pays attention to power. In order to carry out the process correctly, before starting the procedure, all parts must be degreased. For welding, you need a cylinder containing argon. If the work will be carried out outdoors, then a device with a current of 160A will be suitable. The burner is attached to a special hose into which a tungsten electrode must be inserted. In the process of inverter welding of stainless steel, you will need a special wire made of the same material as the parts themselves.

Cost of welding stainless steel

Our services are available to everyone and are of high quality at a competitive price.

The minimum order requiring a site visit is 15,000 rubles. The cost of stainless steel welding depends on many factors:

- order volume;

- complexity of the project, drawings;

- location of work and its distance;

- the need to use additional equipment (including an electric generator).

The cost of the project is determined by specialists after assessing it and agreeing on the details. Discounts are provided upon receipt of an application for a large volume of work. Orders for stainless steel welding are accepted by phone in Moscow +7. In addition, you can write to us by email or make a request on the website in the “Contacts” section. We will review your project, calculate the price and offer optimal terms of cooperation.

Manual arc type welding

Welding stainless steel using manual arc welding is carried out using two types of electrode:

- the first type has a base coating that contains magnesium and calcium. As a rule, DC welding of stainless steel with reverse polarity is used. The electrode must be connected to the positive pole;

- the second type allows the use of alternating and direct current with reverse polarity. They are much more comfortable to use. However, the maximum effect is observed when working in the lower position.

Thus, it can be used for welding stainless steel pipes. Making a short seam using an electrode. Among the main advantages of stainless steel welding with alternating current are the following:

- Easy to use

- You can connect metals with different characteristics

- There is no need to include gas in the process, which means welding will cost much less

- Makes it possible to weld parts even in the most difficult to reach places.

However, there are also disadvantages to this technology:

- Slow process speed

- The seam will have to be additionally cleaned of slag.

As a rule, electrodes for welding stainless steel elements have a stable connection that resists corrosion. They can operate at high temperatures. The composition of such electrodes includes chromium and nickel. A wide variety of tungsten rods are used in the welding process.

Today there is a wide range of materials used to weld stainless steel:

- The green color of the rod means that it contains the maximum amount of tungsten content. Due to this composition, durability is of great importance.

- white rods (WZ8) have an alloyed coating containing zirconium

- red color indicates the presence of thorium oxide. The most common type of rods, which is used to perform various works, since the durability criterion is the highest.

Other types of rods coated with lanthanum and cerium may also be found.

Laser welding

For modern industry, this method is one of the most popular and in demand. It is practically not used at home. The main advantage of this method is the preservation of all the positive characteristics of the material. The strength criterion remains untouched. If the material has previously been heat-treated and hardened, then you also don’t have to worry about the appearance of cracks in the part.

The laser method is also popular because after welding the seam cools much faster. The grain is smaller in size. The suture or point method can be used. Since the reaction rate is much faster, the oxide film does not have time to form. This is another plus, thanks to which the strength of the metal remains at its best.

When using a laser, the entire procedure is carried out end-to-end to avoid a negative impact on the quality of the structure and its strength. It is worth noting that in the absence of welding electrodes, there is not even a minimal probability of foreign particles getting into the welding seams. In some cases, it is even used in jewelry production.

However, there is a serious drawback with this innovative approach. The cost of such welding is much more expensive, which means that not every enterprise can afford its use.

MIG/MAG

This method involves the use of a semi-automatic welding method. The atmosphere assumes a content of 98% Ar, CO - 2%. As an alternative, oxygen is sometimes used to replace carbon dioxide. The percentage ratio remains the same. It is also worth noting the quality of the seam. When using MIG/MAG, the seam strength is high as well as the precision.

Typically, the following methods are used:

- Pulse. The most relevant method for those who want to control the process. Metal enters the bath drop by drop, due to which the average current decreases, which means the thermal energy also decreases. This method can be successfully used when working with metals with low thermal conductivity. There is minimal chance of splashing, which increases accuracy. When making a decorative element or making special containers, this approach is most relevant.

- Jet transfer. Relevant when working with large materials.

- Short arc. Most often, this method is used when working with low-density metal, for example, welding thin stainless steel.

Preparatory stage

In order to obtain a quality result, it is important to carry out the preparatory stage in accordance with all the rules. The most important thing is to carefully and efficiently process the area in which welding work will take place. First of all, you need to degrease it and get rid of dirt and dust. You can first wash it with gasoline and acentone and then dry it. Using a brush, we clean all the edges and edges to create a shine.

Before welding at home, it is important to remember the features of the process. There is a high probability of thermal expansion, which can lead to cold cracks. Therefore, under no circumstances should the part be moved closely. You should always leave at least a small gap. As a rule, to determine the optimal width size, it is enough to use a special reference book, or use the services of a qualified specialist.

Final stage

When all the work has been successful, do not forget about the final stage. It consists of complete and competent cleaning of the seam. When the procedure is carried out correctly, first of all, the service life increases and the seam visually looks aesthetically pleasing.

If this is not done, metal corrosion may occur as a side effect. First you need to start the mechanical cleaning stage. If sandblasting is used, then in the future the joint will look more presentable.

After the procedure, the seam must be sanded. To avoid the occurrence and further spread of corrosion, it is strongly recommended not to use corundum abrasives. It is important to understand that such procedures help improve the aesthetic appearance. To maintain the proper condition and appearance of the seam, you can use etching or passivation.

The first method is the process of treating a metal surface with special synthetic substances or chemicals that destroy scale. The second method uses a special substance where the parts were connected by welding. As a result of a chemical reaction, a special film is formed from chromium oxide.

Before proceeding with cleaning the seam, it is first necessary to visually assess the quality of the work done, whether cracks or deformation have appeared after completion of the work. If stainless steel was welded at home, then flaw detection equipment will not be needed.

However, in the industrial field, carrying out such work is a prerequisite. Treatment with hydrochloric and sulfuric acid occurs throughout the final stage. After the process is completed, it is imperative to rinse the affected area with ordinary running water. At home, this method is used quite rarely, especially since without professional training it can be hazardous to health. Therefore, it is best to protect yourself when using it mechanically.

Other common technologies

There are other welding methods that are most often used in certain situations, so they cannot act as universal methods. Examples of how to weld stainless steel include the following:

- Organization of cold welding with high pressure. As the name suggests, using this technology does not require exposure to high temperatures. The joining process occurs at the level of crystal lattices. Depending on how the process is organized, pressure may be applied to one or both parts

- Contact welding process. In this case, a roller system is used. It is relevant for joining thin sheets no more than 2 mm thick. As a rule, the same equipment is used.

Welding stainless steel sheets is characterized as one of the most complex processes. This is due to the fact that the metal itself is quite difficult to carry out the necessary manipulations. The presence of an electrode when welding stainless steel with an inverter with your own hands is considered a prerequisite, and it must consist of the same material as the part.

To improve the result when welding at home, it is recommended to use flux and constantly monitor it at each stage. It is important to note that the electrode should not lose its original state so that the seam is of high quality and corrosion does not form in the future.

Some experts note that one of the complex processes is ceiling welding. This is due to the fact that the material spreads greatly, which means there is always a chance that it will simply fall down. It is equally important to control the final stage so that there is no deformation of the metal and a decrease in the physical characteristics of the metal itself.