In this article we will tell you how to choose the right tungsten electrode for argon arc welding, what types of tungsten there are, their distinctive properties, and how the composition affects the quality of the weld.

But at the very beginning, we would like to draw your attention to the fact that tungsten electrodes of the WL-15, WL-20, WC-20, WY-20 and WZ-8 brands have appeared in the range of PTK branded products.

Our tungsten electrodes have undergone X-ray microanalysis of elemental composition at the National Research Institute. We conducted this paid study on our own initiative in order to demonstrate to dealers and consumers the highest quality of our products.

The analysis was carried out on a Tescan Vega II scanning electron microscope, which allows you to obtain SEM images and analyze the elemental composition in real time, which is necessary for quality control of products and materials.

You can familiarize yourself with the research protocols and the results of the elemental composition of tungsten electrodes produced by PTK in the reporting documents.

What is a tungsten electrode and where is it used?

A tungsten electrode is a round rod made of pure tungsten or tungsten with the addition of additives (alloying additives). Tungsten is used in TIG welding with a non-consumable electrode.

If you have a question, why “non-melting”, then the answer is very simple. Tungsten has the highest melting point among pure metals (3422°C). Therefore, argon arc welding is performed with straight polarity, because the temperature of the cathode spot (-) reaches 3000 °C, and the temperature of the anode spot (+) reaches 4000 °C. Because of this, the electrode is not consumed during welding, but burns out.

Electrodes can have a clean or polished surface. A distinctive feature of clean electrodes is that they are chemically cleaned, i.e. The workpieces are etched to remove oxides and contaminants from the surface.

This is the most labor-intensive and costly procedure, therefore it is used much less frequently in industrial production. The ground surface of the electrodes suggests that the electrodes may have been processed by forging, broaching, or centerless grinding. The latter method is the most popular; as a result of this manufacturing, the thermal conductivity of the electrodes improves.

The diameter and length of tungsten electrodes can vary. Standard electrodes have a length from 50 to 175 mm, and a nominal diameter from 0.5 to 10 mm. In Russia, electrodes are manufactured according to GOST 23949-80, TU 48-19-27-91, TU 48-19-39-85, 48-19-221-83 and TU 48-19-527-83 from pure tungsten and tungsten with activating alloying additives of rare earth metals.

Tungsten electrodes are used exclusively in TIG welding, due to the prevention of oxides on the surface of the connecting seam. Welding occurs in a shielding gas environment, which protects the welding zone from exposure to oxygen.

This type of welding uses a chemically inert gas (noble gas). These gases include helium, argon and special welding mixtures. A distinctive feature of these gases is that they have very low chemical reactivity, in other words, they do not interact with the metal of the weld. These gases are also colorless and odorless.

Criteria for selecting a tungsten electrode

When choosing tungsten rods, you need to focus on such parameters as:

- type, chemical composition and presence of alloying additives;

- diameter, which affects the thickness of the weld being formed;

- tip geometry, which determines many characteristics of the welding process;

- sharpening quality.

Naturally, the choice of a particular brand of electrode is significantly influenced by the characteristics of the parts being connected: dimensions, material composition, etc. When choosing tungsten rods, you can refer to reference tables or your own experience.

Basic criteria for selecting electrodes based on their properties

Alphanumeric marking of tungsten electrodes

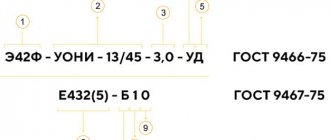

In Russia, 2 types of marking of tungsten electrodes can be used and applied - this is the classification according to GOST, TU and the international classification according to ISO 6848. Let us briefly consider these types of markings.

Marking of domestic electrodes according to GOST and TU

Products that are manufactured in Russia and comply with the established GOST and TU contain the letters “E” and “B” in their name; they come first in the name and mean “tungsten electrode.” Further, the name indicates the chemical composition of the additives and their mass fraction.

- EHF - “H” - pure (tungsten not less than 99.92%);

- EVL - “L” - lanthanum (mass fraction of lanthanum oxide from 1.1 to 1.4%);

- EVL-2 - “L” - lanthanum (mass fraction of lanthanum oxide from 1.4 to 1.6%)

- EVI-1 - “I” - yttrium (mass fraction of yttrium oxide from 1.5 to 2.3%)

- EVI-2 - “I” - yttrium (mass fraction of yttrium oxide from 2.0 to 3.0% and tantalum 0.1%)

- EVI-3 - “I” - yttrium (mass fraction of yttrium oxide from 2.5 to 3.5% and tantalum 0.1%);

- EVT-15 - “T” - thorium (mass fraction of thorium dioxide from 1.5 to 2.0%).

International marking according to ISO 6848 standards

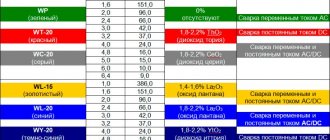

Most tungsten alloys have been standardized by the International Organization for Standardization in ISO 6848. The table below shows the alphanumeric designations and percentage composition of alloying additives.

| Letter designation | Color code | Mass fraction of alloying additives |

| W.P. | Green | – |

| WC-20 | Grey | ~2% |

| WL-10 | Black | ~1% La₂O₃ |

| WL-15 | Gold | ~1.5% La₂O₃ |

| WL-20 | Blue | ~2% La₂O₃ |

| WT-10 | Yellow | ~1% ThO₂ |

| WT-20 | Red | ~2% ThO₂ |

| WT-30 | Violet | ~3% ThO₂ |

| WT-40 | Orange | ~4% ThO₂ |

| WY-20 | Blue | ~2% Y₂O₃ |

| WZ-3 | Brown | ~0.3% ZrO₂ |

| WZ-8 | White | ~0.8% ZrO₂ |

What are alloying additives and rare earth metals?

We have looked at the alphanumeric designations of tungsten electrodes, now it’s time to talk about the rare earth metals (elements) that are part of the electrodes, or rather, alloying additives (additives).

Rare earth metals are a group of 17 elements that include scandium, yttrium, lanthanum and lanthanides. All these metals are silvery-white in color, similar in chemical and physical properties, and form refractory oxides that are practically insoluble in water.

These metals received the name “rare earth” due to the fact that they are rarely found in the earth’s crust, and these metals are also difficult to mine and industrially produce.

The most commonly used additives in tungsten welding electrodes are lanthanum, cerium, yttrium, zirconium and thorium.

Advantages and disadvantages

Welding using tungsten electrodes guarantees a slag-free weld. There are no pores in such a seam. Welding of this type makes it possible to connect most known alloys and metals with each other. In addition, the use of welding of this type allows you to create connections with walls of different thicknesses.

Welding with tungsten electrodes is performed without sparks or spatter. No slag is formed on the seam and no smoke is emitted, unlike coated electrodes. All these factors allow welding to be performed at high speed.

At the same time, welding with such a material implies that before performing the work it is necessary to thoroughly clean the surface of the parts. Otherwise, the resulting seam will have certain defects (lack of penetration, pores, etc.).

Properties of filler metals and their influence on the quality of the weld

Tungsten Electrode WP (Green)

Pure tungsten electrodes are classified as WP and have a green color code. The tungsten content in them is at least 99.5%.

- Features: Electrodes marked WP provide high arc stability, but have poor heat resistance and electronic emission. Due to this limited thermal load, the working end of the electrode must be sharpened into a round shape (ball).

- Current type: Designed for welding with sinusoidal current (AC) in argon or helium.

- Metal: This type of electrode is designed for welding aluminum, magnesium, nickel and their alloys.

Due to the fact that WP electrodes were used on transformer equipment, and now most welding equipment is inverter, the need for such electrodes has decreased significantly, so these electrodes are not in the PTK range.

Tungsten electrodes WL-10 (black), WL-15 (gold) and WL-20 (blue)

WL-10 is a lanthanum oxide (La₂O₃) electrode, color code black. The mass fraction of lanthanum oxide reaches up to 1%.

WL-15 is a lanthanum oxide (La₂O₃) electrode, gold color code. The mass fraction of lanthanum oxide varies from 1.4 to 1.6%.

WL-20 is an electrode containing lanthanum oxide (La₂O₃), the mass fraction of which reaches up to 2.2%. The electrode color code is blue.

- Features: These are universal electrodes that can withstand high current loads, improve arc stability and ease of starting while reducing burnout. Lanthanum electrodes are less likely to contaminate the seam with tungsten, which is especially important during finishing work. They also retain the sharpness of the working end for a long time.

- Current type: Electrodes can be used for direct and alternating current (AC/DC) welding.

- Metal: Used for welding carbon and alloy steels, aluminum, titanium, nickel, copper and magnesium alloys.

The range of PTK branded products includes tungsten electrodes WL-15 with a diameter from 1.6 to 4.0 mm and WL-20 with a diameter from 1.0 to 4.0 mm.

WY-20, dark blue

They are used in welding molybdenum, tantalum, copper, bronze, niobium, nickel, titanium. Universal by type of current (AC/DC).

The composition includes the addition of 2% cerium oxide, a non-radioactive element, which is safer for the welder to work with. Cerium facilitates easy initial start of the arc and allows increasing the welding current without harm to the equipment. The electrodes hold the arc perfectly at low currents when welding thin sheet steel. The most common application is orbital pipe welding.

Tungsten electrode PTK WL-15

Article: 007.100.117 Tungsten electrode PTK WL-15-175mm Ø 4.0

The WL-15 electrode containing lanthanum oxide is used in alternating and direct current for welding aluminum, carbon and stainless steels. Electrode diameter 4.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 699 RUR

Article: 007.100.116 Tungsten electrode PTK WL-15-175mm Ø 3.2

The WL-15 electrode containing lanthanum oxide is used in alternating and direct current for welding aluminum, carbon and stainless steels. Electrode diameter 3.2 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 519 RUR

Article: 007.100.115 Tungsten electrode PTK WL-15-175mm Ø 3.0

The WL-15 electrode containing lanthanum oxide is used in alternating and direct current for welding aluminum, carbon and stainless steels. Electrode diameter 3.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 402 RUR

Article: 007.100.114 Tungsten electrode PTK WL-15-175mm Ø 2.4

The WL-15 electrode containing lanthanum oxide is used in alternating and direct current for welding aluminum, carbon and stainless steels. Electrode diameter 2.4 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 298 RUR

Article: 007.100.113 Tungsten electrode PTK WL-15-175mm Ø 2.0

The WL-15 electrode containing lanthanum oxide is used in alternating and direct current for welding aluminum, carbon and stainless steels. Electrode diameter 2.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 203 RUR

Article: 007.100.112 Tungsten electrode PTK WL-15-175mm Ø 1.6

The WL-15 electrode containing lanthanum oxide is used in alternating and direct current for welding aluminum, carbon and stainless steels. Electrode diameter 1.6 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 130 RUR

Tungsten electrode PTK WL-20

Article: 007.100.127 Tungsten electrode PTK WL-20-175mm Ø 4.0

The WL-20 electrode with a lanthanum oxide content of up to 2.2% is used for welding aluminum, carbon and stainless steels at maximum currents. Suitable for alternating and direct current. Electrode diameter 4.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 846 RUR

Article: 007.100.126 Tungsten electrode PTK WL-20-175mm Ø 3.2

The WL-20 electrode with a lanthanum oxide content of up to 2.2% is used for welding aluminum, carbon and stainless steels at maximum currents. Suitable for alternating and direct current. Electrode diameter 3.2 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 535 RUR

Article: 007.100.125 Tungsten electrode PTK WL-20-175mm Ø 3.0

The WL-20 electrode with a lanthanum oxide content of up to 2.2% is used for welding aluminum, carbon and stainless steels at maximum currents. Suitable for alternating and direct current. Electrode diameter 3.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 472 RUR

Article: 007.100.124 Tungsten electrode PTK WL-20-175mm Ø 2.4

The WL-20 electrode with a lanthanum oxide content of up to 2.2% is used for welding aluminum, carbon and stainless steels at maximum currents. Suitable for alternating and direct current. Electrode diameter 2.4 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 309 RUR

Article: 007.100.123 Tungsten electrode PTK WL-20-175mm Ø 2.0

The WL-20 electrode with a lanthanum oxide content of up to 2.2% is used for welding aluminum, carbon and stainless steels at maximum currents. Suitable for alternating and direct current. Electrode diameter 2.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 211 RUR

Article: 007.100.122 Tungsten electrode PTK WL-20-175mm Ø 1.6

The WL-20 electrode with a lanthanum oxide content of up to 2.2% is used for welding aluminum, carbon and stainless steels at maximum currents. Suitable for alternating and direct current. Electrode diameter 1.6 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 134 RUR

Article: 007.100.121 Tungsten electrode PTK WL-20-175mm Ø 1.0

The WL-20 electrode with a lanthanum oxide content of up to 2.2% is used for welding aluminum, carbon and stainless steels at maximum currents. Suitable for alternating and direct current. Electrode diameter 1.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 67 RUR

Tungsten electrodes WC-10 (pink) and WC-20 (gray)

WC-10 is a cerium oxide (CeO₂) electrode, pink color code. The mass fraction of cerium oxide reaches up to 1%.

WC-20 is an electrode containing cerium oxide (CeO₂), the mass fraction of which varies from 1.8 to 2.2%. Has a gray color code.

- Features: Cerium as an alloying element improves arc stability and ease of starting while reducing burnout. Tungsten grade WC-10/20 is recommended for use in short welding cycles at low current values.

- Current type: Cerium electrodes are designed for welding with direct and alternating current (AC/DC).

- Metal: Electrodes are designed for welding aluminum, all types of steels and their alloys, especially thin sheets.

Only branded tungsten electrodes PTK WC-20 with a diameter of 1.6 to 3.2 mm are on sale.

Article: 007.100.134 Tungsten electrode PTK WS-20-175mm Ø 3.2

WC-20 electrode containing cerium oxide is used for welding aluminum, carbon and stainless steels. It is used for welding on alternating and direct current. Electrode diameter 3.2 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 435 RUR

Article: 007.100.133 Tungsten electrode PTK WC-20-175mm Ø 2.4

WC-20 electrode containing cerium oxide is used for welding aluminum, carbon and stainless steels. It is used for welding on alternating and direct current. Electrode diameter 2.4 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 247 RUR

Article: 007.100.132 Tungsten electrode PTK WC-20-175mm Ø 2.0

WC-20 electrode containing cerium oxide is used for welding aluminum, carbon and stainless steels. It is used for welding on alternating and direct current. Electrode diameter 2.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 211 RUR

Article: 007.100.131 Tungsten electrode PTK WC-20-175mm Ø 1.6

WC-20 electrode containing cerium oxide is used for welding aluminum, carbon and stainless steels. It is used for welding on alternating and direct current. Electrode diameter 1.6 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 134 RUR

Tungsten electrode WY-20 (blue)

This is a tungsten electrode containing yttrium oxide (Y₂O₃), which is color coded blue. The mass fraction of the alloying additive varies from 1.8 to 2.2%.

- Features: Yttrium tungsten electrodes can withstand high currents and, subject to welding technology, provide a high-quality and reliable seam, therefore they are especially suitable for welding particularly critical structures.

- Current type: Designed for direct current (DC) welding only.

- Metal: This type of electrode is suitable for welding all types of steels, titanium, copper and their alloys.

The range of WY-20 electrodes is presented in diameters of 1.6 / 2.0 / 2.4 and 3.2 mm.

Article: 007.100.144 Tungsten electrode PTK WY-20-175mm Ø 3.2

The WY-20 electrode containing yttrium oxide is used for welding structures made of carbon, low-alloy and stainless steels. Used when operating on direct current. Electrode diameter 3.2 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 452 RUR

Article: 007.100.143 Tungsten electrode PTK WY-20-175mm Ø 2.4

The WY-20 electrode containing yttrium oxide is used for welding structures made of carbon, low-alloy and stainless steels. Used when operating on direct current. Electrode diameter 2.4 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 292 RUR

Article: 007.100.142 Tungsten electrode PTK WY-20-175mm Ø 2.0

The WY-20 electrode containing yttrium oxide is used for welding structures made of carbon, low-alloy and stainless steels. Used when operating on direct current. Electrode diameter 2.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 177 RUR

Article: 007.100.141 Tungsten electrode PTK WY-20-175mm Ø 1.6

The WY-20 electrode containing yttrium oxide is used for welding structures made of carbon, low-alloy and stainless steels. Used when operating on direct current. Electrode diameter 1.6 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 126 RUR

Tungsten electrodes WZ-3 (brown) and WZ-8 (white)

WZ-3 is a zirconium oxide (ZrO₂) electrode, color code brown. The mass fraction of cerium oxide reaches up to 0.3%.

WZ-8 is an electrode containing zirconium oxide (ZrO₂), the mass fraction of which varies from 0.7 to 0.9%. Has a white color code.

- Features: This type of electrodes can be used when welding at high currents. They have poor arc stability and are very demanding on the cleanliness of the weld pool. It is recommended to sharpen the working end of these electrodes in the shape of a hemisphere.

- Current type: Designed for welding on alternating current (AC) only.

- Metal: Electrodes are designed for welding aluminum, magnesium, nickel, bronze and their alloys.

Only branded tungsten electrodes PTK WZ-8 with diameters of 1.6 / 2.0 / 2.4 and 3.2 mm are on sale.

Article: 007.100.154 Tungsten electrode PTK WZ-8-175mm Ø 3.2

The WZ-8 electrode containing zirconium oxide is used when operating on alternating current for welding aluminum, bronze, nickel and their alloys. Electrode diameter 3.2 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 535 RUR

Article: 007.100.153 Tungsten electrode PTK WZ-8-175mm Ø 2.4

The WZ-8 electrode containing zirconium oxide is used when operating on alternating current for welding aluminum, bronze, nickel and their alloys. Electrode diameter 2.4 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 303 RUR

Article: 007.100.152 Tungsten electrode PTK WZ-8-175mm Ø 2.0

The WZ-8 electrode containing zirconium oxide is used when operating on alternating current for welding aluminum, bronze, nickel and their alloys. Electrode diameter 2.0 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 211 RUR

Article: 007.100.151 Tungsten electrode PTK WZ-8-175mm Ø 1.6

The WZ-8 electrode containing zirconium oxide is used when operating on alternating current for welding aluminum, bronze, nickel and their alloys. Electrode diameter 1.6 mm, length – 175 mm. Supplied in a plastic pack of 10 pieces.

Price: 134 RUR

Tungsten electrodes WT

WT brand electrodes are doped with thorium oxide (ThO₂) and include the following varieties:

- WT-10 - yellow color code, thorium dioxide content up to 1%;

- WT-20 - red color code, thorium dioxide content up to 2%;

- WT-30 - purple color code, thorium dioxide content up to 3%;

- WT-40 - orange color code, thorium dioxide content up to 4%.

Tungsten electrodes made of thorium oxide alloy are used in direct current (DC) welding of stainless steel, copper, nickel, titanium and their alloys.

An important and distinctive feature of thorium is its radioactivity. Thorium is considered a radioactive metal, making inhalation of fumes and dust a health risk to the welder and disposal an environmental risk. Based on these considerations, there are no WT thorium tungsten electrodes in the range of PTK branded products.

WT-20, red

Used for welding: copper, bronze, nickel, alloy steel, titanium, metals with a high melting point (tantalum, molybdenum).

A mixture of tungsten and thorium oxide. Thorium is a radioactive material, so sharpening the rod must be carried out in protective equipment, otherwise the dust will affect the health of the welder. For irregular welding, the normal process with natural ventilation is allowed. For continuous work with red tungsten electrodes, forced ventilation is required, and when welding in containers, masks with turbo blocks are required.

The required special form of sharpening is in the form of a platform with protrusions. It is better to cook with direct current. Due to the addition of thorium, the rods can withstand elevated temperatures without deformation, therefore they are used for welding thick metals.

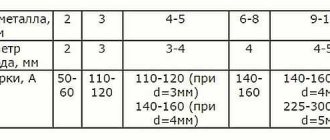

Recommendations for selecting electrode diameter and welding current

The quality of the weld directly depends on the correctly selected diameter of the welding electrode and the set current. Therefore, we have prepared special recommendations for you that will help you achieve the highest quality results in the welding process.

| Electrode diameter, mm | Recommended current for welding in argon (AC), A | Recommended current for welding in helium (AC), A | Recommended current for welding in argon (DC), A | Recommended current when welding in helium (DC), A |

| 1,0 | up to 60 | up to 50 | up to 70 | up to 50 |

| 1,6 | 60–120 | 50–110 | 70–120 | 50–100 |

| 2,0 | 70–130 | 60–120 | 90–150 | 70–130 |

| 2,4 | 100–180 | 90–160 | 110–180 | 90–150 |

| 3,0 | 140–230 | 120–200 | 150–220 | 120–200 |

| 3,2 | 160–250 | 150–220 | 180–270 | 160–250 |

| 4,0 | 200–320 | 180–300 | 200–350 | 180–320 |

WC-20, gray

Used for welding: copper, bronze, nickel, alloy steel, titanium, metals with a high melting point (tantalum, molybdenum).

A mixture of tungsten and thorium oxide. Thorium is a radioactive material, so sharpening the rod must be carried out in protective equipment, otherwise the dust will affect the health of the welder. For irregular welding, the normal process with natural ventilation is allowed. For continuous work with red tungsten electrodes, forced ventilation is required, and when welding in containers, masks with turbo blocks are required.

Welding calculator for TIG welding

We remind you that we have developed a specialized TIG welding calculator that will be useful to dealers and welders who are just learning the basics of argon arc welding. The calculator will “give” recommendations for welding work with aluminum, steel and stainless steel, possibly with the choice of torches and components. The choice of thickness of the welded metal is from 1 to 12 mm. Also, the calculator will tell you which areas need to be welded, depending on the type of connection.

Follow the link and use the TIG calculator.

Welding equipment

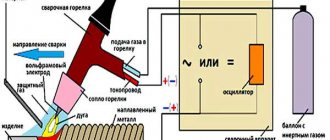

If a tungsten electrode is used for argon welding, a special set of equipment is required. It includes:

- source of direct or alternating current;

- burners with a non-consumable electrode installed on it;

- containers into which inert gas is pumped;

- sleeves (hoses) for supplying gas to the workspace.

Electrodes are made of tungsten or its compounds. Its melting point is 3,380 degrees Celsius, which allows it to be used to work with almost all metals. It does not melt during operation; the only thing required is to sharpen it in accordance with certain requirements. The electrode is installed in the burner, and the part of the electrode that does not take part in the work is protected by a cap. This is necessary to prevent it from shorting to ground.

The burner has a button that supplies gas and voltage. A ceramic nozzle is installed at the end of the burner. The tip of the electrode comes out of it. Hoses through which gas is supplied are connected to the burner handle.

After the welder presses the button, the supply of gas and electricity begins. The gas coming from the nozzle isolates the weld pool from the effects of gases contained in the atmosphere.