Home / Welding technique

Back

Reading time: 3 min

0

861

The concept of “welding” refers not only to metal. It is also needed when working with materials such as polypropylene, polyethylenepropylene, polyethylene, that is, polymers.

This type of welding is called extrusion. Polymer parts are connected using a special filler material. The main thing is that their composition is the same. This will guarantee the quality of the seam.

The extrusion method comes in handy when you need to connect sheets of film, polypropylene and parts of any containers.

Less suitable for PVC products. And it is not suitable in the case of polyethylene and other plastic pipes under pressure. Its 80% strength in this case is catastrophically low.

- General information

- General rules

- Specifics

- Technology

- What types of extruders are there?

- Summary

General information

The extrusion method is specially designed to join thick-walled elements. Unlike the traditional one with a rod, where hot air is needed, here with a seam there is almost no pain.

Extrusion is fleeting, the welder’s participation is minimal, you don’t have to worry about observing the process regime, and it takes a long time to master the basics of “seammaking.”

Extrusion science is accessible even to a beginner. Craftsmen will be able to boast of a manual welding extruder by making it themselves.

Welding in manual and automatic modes is up to you. Among the extruders in the first case, Leister fusion 3c stands out. The advantages are a simple and rational body, it weighs modestly, and the performance is higher.

Yes, the rod is also safe in terms of “twisting”. A good range of accessories for welding can be found on the website of the Weldmax online store.

When welding, sometimes you need to walk through narrow places. Leister fusion 2 is suitable for just these purposes. It is easy to use, small in size, and resistant to mechanical stress. Fusion 2 will not upset the engine with cold starts.

It is impossible not to say a few words about the manual screw welding extruder from the line of the same company. None of the entire range of this manufacturer can compare with Leister weldplast s6 in terms of power. However, it is not very noisy, and you will be surprised at how many programs there are.

Features of the devices

There are many welding extruders on the market. The products are focused on specialized production and can be used to solve everyday problems.

The technology differs in a number of parameters.

Power

A key indicator when choosing an extruder. It displays the intensity of operation of the screw drive, heating element and air unit. Power has a direct impact on the performance of the extruder and the length of the formed seam.

Most products on the market have a power rating of 1600-3600 watts. More productive machines can be used to work with particularly thick pipes and polypropylene sheets.

Thickness of connected products

A parameter that reflects the thickness of workpieces that can be worked with. The characteristic is directly related to the power of the device. The minimum thickness of welded products is 1.5 mm (polymer films), the maximum value reaches 40.

Forming structures based on thick-walled plastic is a complex and responsible procedure. The operator needs to heat a significant layer of polymer, ensuring tight contact of the components along the entire length of the seam.

The thicker the parts being connected, the lower the strength of the assembly relative to the base material.

When carrying out welding work, rods or granules are used. Additives of the first type are most widespread. They are supplied in special coils and do not lose their performance properties if the packaging is damaged. The granulate is sold in bags. If the integrity of the container is damaged, the composition may be irretrievably lost.

Controls

Basic type extruders are equipped with one or two adjustment elements. As a rule, these are mechanical switches that allow you to change the heating temperature of the granules (wire) and the feed rate of the connecting compound.

Professional level equipment has richer functionality. It is equipped with electronic control systems, informative LCD displays and ergonomic keys. The most technologically advanced devices contain an external temperature sensor, which ensures optimal heating of the plastic before welding.

Performance

The productivity of most devices is at the level of 0.5–3 kg/h. The higher the value, the faster welding operations are performed.

Manufacturers

Extrusion welding equipment is not in mass demand. It is purchased by specialized organizations that install pipelines, storage tanks and special engineering systems. In this regard, there are not many companies producing extruders on the market.

- Munsch. A German manufacturer offering solutions of its own design. Products are assembled in Germany.

- Leister. The concern is registered in Switzerland. Its production facilities are located in China and Vietnam. Leister brand products are very popular in Russia.

- Stargun (Ritmo). An Italian manufacturer offering a wide range of devices. The technology has received recognition from international experts and is in demand in the EU.

- Weldy. Subsidiary, Chinese brand Leister. Such devices are suitable for organizations with a modest budget.

The listed manufacturers offer certified equipment adapted for intensive use. The equipment is suitable for critical and dangerous objects and allows you to obtain high-quality permanent connections.

General rules

When extrusion welding, all parts must fit together. This refers to the chemical composition, fluidity and density. In the case when you have parts with different indicators, the additive composition is selected as something between the parts that need to be connected.

The edges of parts must be cleaned with care. It is common for most types of thermoplastics to oxidize in the atmosphere. It is better to start cleaning 15-20 minutes before the start of the process.

It is not allowed to leave random debris on surfaces. The quality of work will suffer.

Did you fail to connect the prepared surfaces during this time? This means that the cleaning will have to start all over again. And further. Using a solvent for this is a bad idea!

Welding plastic using solvents

There is another type of welding for polymers, using solvents. To do this, a specialist will need to perform a certain series of actions: wetting the welded edges in a solvent, waiting for the material to swell under chemical action and become soft, using pressure to adhere and harden the weld. This type of welding is used in conjunction with amorphous polymers, which are well suited for this task. Materials that have a crystalline structure usually also have high resistance to solvents.

To wet two surfaces, as a rule, a regular sponge or other similar material is used. The amount of solvent should not be large so as not to cause leaks that are destructive to the material. Immediately after wetting and softening, both surfaces must be immediately attached to each other. Sometimes additional heat is also used to speed up the evaporation of the solvent. In general, solvent welding of plastics is simple and cheap, but due to the toxic fumes from the solvents themselves, it is rarely used, in fact, only in cases where other methods do not work.

Specifics

It is necessary to weld pipes and other configurations made of polyethylene using extrusion welding along the welding channels, the surfaces of the films that are overlapped, and the corners of the polypropylene sheet will also be a guide.

The working areas are preheated to t, at which the plasticization process should start. For this purpose, heated air is taken, which comes directly from the welding unit.

External sources such as thermal study, which is provided by a stationary extruder, will do.

Now the filler material that has been selected (you can also use a rod) is placed in a special chamber of the device in granular form, where it is heated.

When the mass reaches the stage of fluidity, then, using a screw, it is squeezed out using a welding shoe to where the intended seam is located. You can replace the screw, depending on what kind of extruder and disk you have.

Special equipment

Forethought is required when selecting equipment

It is important to consider the complexity of the work. To cope with large volumes of films, industrial equipment is used

Special devices are used to join polyethylene. Their prices vary. It is worth noting the budget model PP-40.

It allows you to get an even and durable seam on any contour: straight or complex. PP-40 is shaped like a soldering iron, but has a different tip.

They also use special attachments for electric irons. They are made from sheet metal, such as aluminum. The base of the nozzles is made flat and ribbed. This surface firmly fixes the film joint during welding.

The edges of the film are secured with ribs. Then move the strip along the area to be welded. This creates a double seam.

Large jobs require the use of more serious tools. To create a large-area film joint, you will need special welding equipment.

Such equipment is equipped with settings for the level of pressure, temperature, and the speed of movement of the heated element along the surface of the polyethylene. In household options for forming film seams, there are no such functions.

In addition to setting regulators, soldering machines are equipped with roller mechanisms. These are setting and tension elements that stabilize the speed of advance of the film sheets being welded.

This improves the quality of polyethylene soldering and increases the strength of the connection.

There are devices that use different heating methods: air and contact. Air heating is produced by exposing the material to hot air. Contact involves a heating element in contact with the material.

Technology

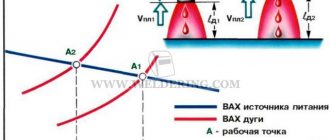

At the start of the extrusion welding process, the surfaces to be joined must be in a viscous state. Therefore, the air flow, which has been heated to the required t, is directed through the nozzle to the welding site.

Heating is possible using a hot air gun built into the extruder. Hot air will also be provided by a compressor and a pneumatic network available in the organization. At the same time, t in a hot air gun and from other sources can be adjusted.

What types of extruders are there?

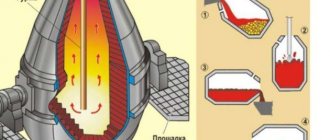

They are represented by screw and screwless samples. In the first extruders, the melting process takes place in a chamber. It is fed externally by a screw.

In those that do not have one, extrusion is carried out using a part of the rod that has not yet melted, which means it remains quite hard. Screwless extruders have a second name – plunger extruders. They are characterized by lower productivity.

They exclude the use of granular additives. But they will penetrate into the most inaccessible places. The tip of the welding shoe is equipped with a special hole. It provides control over the flow of additive to the welding site.

The extrusion method is used when work is to be done with Group I thermoplastics, including polypropylene and low-pressure polyethylene. They have their own specifics.

Acceptable melting is separated from irreversible thermal destruction by 50 degrees. That is, you should not be afraid of damage to the material if it overheats by only 30 or 40 degrees.

It’s a completely different matter if you have group II thermoplastics such as PVC or PVDF. With them, you need to carefully monitor the temperature during the heating process.

When working with thermoplastics of this group, a specially shaped screw is needed. It ensures optimal mixing of the additive, preventing overheating of the material and guaranteeing high-quality extrusion welding.

Using a soldering iron to weld film

Connecting sheets of polyethylene using a conventional soldering iron (40-60 W) allows you to obtain a strong seam, which will require minor modification of the tool. Using a soldering iron without special attachments will not give high-quality results. The joint will be uneven, and there may be places where the material will spread.

Film welding scheme.

To obtain a good result and weld joints of significant length, you will need to use additional devices. There are several options for modifying the soldering iron.

Take a regular soldering iron, then remove the end of the tip. A cut is created using a hacksaw. After this, a copper or aluminum plate is inserted into the cut and secured with a rivet. The surface of the plate is processed, its edges are rounded with a file. Welding is carried out by slightly pressing the soldering iron at an angle of 45° and moving it evenly.

Temperature and pressure are selected experimentally. When creating a joint, it is recommended to place a flat wooden or textolite substrate under the bottom layer of film, and center the soldering iron on a flat block. In some cases, thin paper will be placed between the plate and the film. This is relevant if thin film is being welded. After creating the seam, the paper is carefully separated.

An approximate sample of a nozzle is shown in Fig. 1 (1 – plate; 2 – soldering iron and its rod).

Ultrasonic welding diagram.

It is possible to install the disk in a separate tube-tip, and it, in turn, is put on the soldering iron tip. Welding pieces of film is carried out by rolling a heated soldering iron to the required distance. The amount of pressure is adjusted depending on the welding of the seam. This method allows you to carry out a significant amount of work.