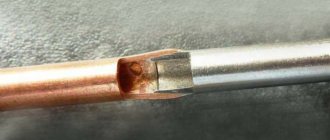

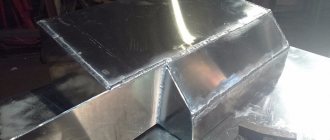

During critical repairs of aluminum parts and installation of profile frames, electrodes cannot be used to make reliable connections. When welding aluminum semi-automatically, the seams are of high quality. It is possible to weld light metal by electric arc welding in argon or carbon dioxide using special refractory electrodes and filler wire, but semi-automatic welding is the most effective and reliable method of processing aluminum alloys.

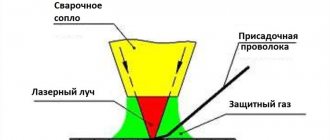

If aluminum is welded semi-automatically without gas, protective fluxes are used or a special multi-component flux-cored wire is used, which, when heated, creates a gas cloud that prevents oxidation.

Features of semi-automatic aluminum welding

Light metal is difficult to weld due to the oxide that forms on the surface when exposed to air. The oxide film must first be removed from the parts; depending on the alloy, it burns out at +2050 – +2200°C, and the melting point of aluminum is only +660°C.

Aluminum alloys have high thermal conductivity: parts quickly warm up when heated and immediately cool down as soon as the heat source disappears. During heat treatment, internal stresses arise in aluminum workpieces, causing cracks to appear in the seam.

When deciding how to weld aluminum semi-automatically, it is necessary to provide for preliminary heating of the workpieces with a gas burner to +150 - +190°C. Experts use linings that remove heat; they prevent the aluminum from getting too hot and cooling quickly. It is important to adhere to the welding mode so as not to burn through thin parts.

Types of wire

Wire for semi-automatic welding of aluminum is a filler material. During the welding process, it melts and becomes part of the seam. Therefore, the main requirement for its selection is that the chemical composition must be close to the chemical composition of the material that will be welded. Also, its melting temperature should be either the same as the elements being welded or slightly lower.

Aluminum welding wire for semi-automatic machines is produced by Russian and foreign manufacturers Ø 0.8 ÷ 3.2 mm. Welding of aluminum with wire is carried out with the grades indicated in the table.

| Brand according to international classification | Domestic analogue |

| OK Autrod 1070 (18.01) | St. - A85, St. - A97, St. - Amts |

| OK Autrod 1450 (11/18) | St. - 1201 |

| OK Autrod 4043 (18.04) | St. – AK5, St. – AK6 |

| OK Autrod 5183 (18.16) | St. – AMg5 |

| OK Autrod 5356 (18.15) | St. – AMg3 |

Wire for semi-automatic welding of aluminum according to another common classification EN ISO 18273 can be marked ER 4043, ER 5356. These are the most commonly used filler materials for welding cast alloys such as AD31, AD33 and AD35, if they do not require an anodizing operation. Supplied in coils or on cassettes of different weights.

Semi-automatic welding of aluminum without gas is carried out using flux-cored wire; it is also called self-shielding. It has a tubular structure inside which there is a powdery filler. It simultaneously performs several functions - deoxidizes, alloys, protects from harmful effects of air, forms a seam, etc.

The choice of diameter and brand of self-shielding wire depends on the thickness of the products that will be welded and the composition of the aluminum alloy.

Which semi-automatic machine is suitable for aluminum welding

Manufacturers offer a wide range of household and welding equipment. There are compact models that generate current of various parameters.

Functional

When choosing a semi-automatic welding machine for welding aluminum for a private workshop or car service, it is better to choose devices with the TIG function that generate high-frequency pulsed current. They are equipped with a “PULSE” mode. Working with them reduces the risk of burns and maintains a stable short arc. With TIG inverters without a pulse unit, the work is three times slower, but the connection quality will also be high.

Simple inverters with MIG/MAG functions are used for domestic purposes; argon and carbon dioxide can be connected to them. It is difficult to make a high-quality connection with such inverters; they are designed for low currents. There is no need to pay for additional features. The more complex the equipment, the greater the risk of failure.

Tasks of a welder at work

The welder will have to solve a number of problems simultaneously:

- pierce the oxide layer with a pulsed discharge;

- maintain the length of the electric arc within 12-15mm;

- take into account the high degree of expansion of aluminum when heated.

To prevent the workpiece from becoming deformed and causing defects when cooling and shrinking, the weld must be started with a strong current that destroys the oxide layer, and finished with a gradually decreasing current, avoiding large temperature changes.

Setting up a semi-automatic welding machine

There are no universal settings for the operation of a semi-automatic machine for aluminum. Welders focus on the thickness of the workpiece. In everyday life, 2-mm aluminum is often welded; for this, the operating voltage is set to 15 V, the current, depending on the composition of the alloying additives, is regulated in the range from 100 to 150 amperes. The wire feed speed is adjusted based on personal welding experience. These are average settings, they are adjusted as work progresses. MIG welding of aluminum is carried out with reverse polarity: the negative terminal is connected to the workpiece, and the positive terminal is connected to the feed nozzle.

How to use?

The following parameters and characteristics should be provided:

Wire

When choosing aluminum wire for semi-automatic welding, you need to consider the following points:

- the chemical composition should be close to the composition of the workpiece material, this will ensure similar melting temperatures;

- diameter from 0.8 to 1.6 mm.

Thus, for alloys with a silicon content of less than 5%, grades ER4043 and ER5356 are used

Operating modes for alloys with low silicon content.

Burner

The hose must have a Teflon wire feed path and a length of no more than 3 meters.

The tip is selected with a margin of up to +0.4 mm relative to the wire diameter.

When operating at currents higher than 200A, a water cooling system for the torch will be required.

Wire feeder

To prevent soft aluminum wire from becoming kinked or stuck, a four-roll feed system should be used . The profile of the rollers should be U-shaped. The mechanism requires fine adjustment of the tension and pressure force after each change in wire diameter.

Gas burner position

When welding with argon using a semiautomatic welding machine, the torch should be tilted 10-20o. The gap between the nozzle and the workpiece must be maintained around 10-15 mm; if you move the burner further, the argon consumption will increase. Move the burner from right to left, or by moving your hand away from you, away from the bath. This allows you to clean the surface of the seam and reduce contamination with slag.

Driving speed

Aluminum should be welded with a fast torch movement, high-temperature electric arc . This allows you to avoid burn-through at high operating currents required to warm up the part.

Convex seams

The connection of aluminum workpieces is at risk of cracking due to the high coefficient of expansion of the material. If a crater has formed on the seam, it serves as a precise stress concentration and the beginning of cracks. The craters formed during welding must be welded until a bulge is formed that strengthens the seam. To do this, move the torch in the opposite direction without extinguishing the arc.

Precautionary measures

When performing work, the following safety precautions should be observed:

- use personal protective equipment against metal splashes and ultraviolet radiation from the welding arc: thick fireproof clothing and shoes, a welder’s mask with an adaptive light filter, and split leather leggings;

- protect the respiratory system with a respirator or individual breathing apparatus with a supply of clean air from a cylinder or from a main line;

- Before starting work, check the serviceability of the equipment, the absence of mechanical damage, insulation damage and gas leaks.

Possible difficulties

Difficulties that can be encountered when welding aluminum include:

- insufficient heating of thick-walled workpieces, leading to incomplete penetration of the edges;

- formation of an oxide layer due to poor quality or premature cleaning;

- the occurrence of cracks due to overheating of the workpiece and subsequent shrinkage;

- the difficulty of determining the temperature of the workpiece “by eye”, since aluminum does not change color when heated;

Experienced welders give one general piece of advice: strict adherence to welding modes and technological requirements will help avoid these problems.

Welding technology

At home, the workpieces are cooked using a household semiautomatic device with direct current of reverse polarity. You can make a pretty decent seam with your own hands if you follow the technology:

- First you need to prepare the equipment. Select a tip for a semi-automatic welding machine for aluminum welding. It should be a few mm larger than the wire size.

- The parts in the working area are cleaned to a shine using a grinding machine or a metal brush.

- Select the operating mode taking into account the thickness of the workpiece and alloy. You can use the tuning tables specified by GOST.

- The supply of shielding gas is turned on a few seconds before ignition of the arc so that a protective cloud of gas is formed.

- Light the arc, maintaining the distance between the melt pool and the nozzle no more than 15 mm, the minimum gap is 1 cm.

- The additive supply rate is adjusted gradually, do not immediately set to maximum, make sure that the metal is well boiled.

- The arc is conducted evenly, forming a uniform surfacing bead.

- At the end of the work, the arc is first smoothly pulled to the side, only after that the current is turned off. The supply of protective gas is not stopped for 10-20 seconds while the work area cools down. It protects the molten metal from exposure to oxygen.

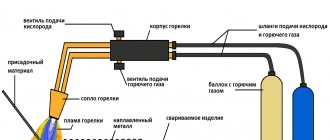

Soldering silumin

Decorative parts and those that do not experience stress can be soldered with a gas torch, the metal is heated to 200°C. Soldering silumin with thin walls is done with a soldering iron with a powerful tip. Metal linings are used to protect against oxidation. Only the work area is left uncovered.

- ER4043 – additive for cast aluminum alloyed with silicon and magnesium grades AD31, AD33, AD35,

- Harris52 – solder for aluminum with flux additives,

- HTS2000 is a Chinese analogue of Harris52.

Useful tips

To weld metal with a high-quality semi-automatic machine, you should listen to the professionals:

- To clean aluminum, it is not advisable to use metal brushes that have been used to clean other metals; it is better to knit a new one, without foreign inclusions. It is better to use chemical treatment of the metal with acid followed by washing.

- When welding aluminum semi-automatically in argon using a four-cycle pulsed current, the metal warms up faster, creating a high temperature in the melt zone. The likelihood of a residual oxide layer getting into the seam is reduced.

- Internal linear voltages can be reduced by reducing the current towards the final stage of welding. They begin work, on the contrary, at maximum mode in order to break through the oxidized layer.

- When working semi-automatically in a carbon dioxide environment, do not make sudden movements; the nozzle should melt evenly.

- When a protective atmosphere is used, the work area is protected from drafts so that gusts of wind do not blow the gas cloud away.

- When working, it is necessary to observe safety precautions, use special clothing, personal protective equipment, including for the respiratory system; some alloying additives have a toxic effect on the body.

Semi-automatic welding of aluminum at home requires certain skills. Beginners can weld metal poorly, then it will warp and the seam will crack. Before you take on important connections, you need to “get your teeth into it,” learn how to maintain the optimal distance, and develop a speed limit.

Special properties

The main feature of the metal is the appearance on its surface of a layer of oxide, which has a high melting point, three times higher than that of the metal itself . If this layer is not removed by mechanical or chemical cleaning, it will be impossible to weld the workpieces.

The oxide layer forms in the form of a film on the surface of the melt, so the weld pool must be protected from contact with air.

Another feature of aluminum is its high thermal conductivity . For full penetration it is necessary to use high welding currents, this increases the risk of burn-through. Before welding thick-walled workpieces, they should be heated.

Advantages and disadvantages of argon arc

Argon arc welding is the only method today to obtain a joint of silumin parts that is not inferior in strength to the base metal.

Its other advantages include:

- speed;

- possibility of adjustment and adjustment to any type of alloy;

- reliability and ease of preventing the formation of aluminum oxide.

There are two serious disadvantages:

- the price of devices with the help of which successful silumin welding is achieved starts from 40-45 thousand rubles;

- high qualification requirements for the welder.

In addition, the process itself is not cheap, so it makes sense to use it to repair unique products.

Primary requirements

For silumin welding, A1F type electrodes are used, or the A1 coating contains lithium . Since such electrodes are hygroscopic, it is recommended to dry them for at least 2 hours at a temperature of 150-180oC before starting work.

Fluxes for gas welding of silumin parts, no matter whether it is carbon dioxide or an inert gas, must ensure the dissolution of the oxide and withstand temperatures of at least 600 degrees.

Regardless of the welding method used, before starting work, the seam area up to 10 mm wide in both directions is degreased with acetone, gasoline, white spirit, etc.

To remove the oxide film that interferes with welding the metal, the surface of the part, as well as the filler wire (rods), is etched .

To do this, use an aqueous solution of sodium hydroxide and sodium fluoride. At the end of the treatment, the surface is treated with nitric acid and washed in running water. The filler material is prepared using similar methods. You can replace etching by cleaning the welded area with a steel brush, or (which is better) by sandblasting.

Regardless of the cleaning method, it should be performed no more than 2-2.5 hours before welding.