Machining sheet or profile metal when preparing parts or creating a workpiece often requires the removal of some material. Cutting a sheet, obtaining a separate part, adjusting it to the installation site - all this is required when creating products, in construction and in the home.

Such an operation is also possible at home; complex equipment is not required. Every business person knows what tool is used to perform the metal cutting operation.

Metal cutting - what is it?

Cutting consists of the planned and controlled formation of the required shape of a sheet metal part. The process is included in the list of standard plumbing operations, the level of complexity is low.

The bottom line: remove excess material according to the intended shape and size using just a couple of tools.

Metal cutting

Markings are applied to the blank sheet, and processing of blanks according to the established template is practiced.

Then, with a slight deviation from the line, the material is separated by striking the chisel with a hammer.

With careful actions, the quality of the part will be quite high.

The only need is subsequent processing of the edges: due to the impact method, the edges will look torn.

What is this operation used for?

- removing allowances and edges on the finished product;

- receipt of finished products and sheet blanks;

- removal of scale and other marketable defects;

- obtaining recesses (grooves, grooves, etc.).

Who needs this operation?

- workers of machine-building and repair organizations, foundries, in automobile repair shops - where work with metal takes place;

- in construction and repair (interior and exterior work);

- specialists involved in equipment repair;

- to ordinary people for household and household needs.

Equipment and tools used

This list depends on the method of work. Manual cutting is carried out using:

- cutting tools (chisels, crosspieces, etc.);

- a plumber's hammer (chosen by weight and handle length);

- vice;

- metal substrate;

- marking tool.

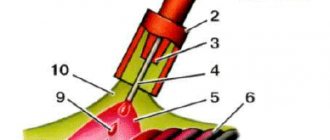

A metalworking chisel structurally consists of three main parts: impact, middle (holder) and cutting (working). The shape of the cutting part is different for each and depends on the task being solved. A chisel is used to perform a standard chopping operation. Kreuzmeisel has a narrower cutting edge. The groover is designed for cutting grooves, so its cutting part is made in the shape of a semicircle. The beard is made from a round metal rod, and has a working part in the shape of a circle sharpened around the perimeter. It is used to cut holes in sheet metal. All percussion instruments are made from durable tool steel.

The main parameters of these tools are geometric dimensions and sharpening angles of the cutting part. A plumber's hammer is used to strike the upper (impact) part of the chisel. They differ in the shape of the striker (round or square), the method of attaching the handle, and the total weight.

Cutting out small parts, holes, and individual parts is done using fastening equipment or on steel substrates. To ensure secure fastening, this operation is performed in a vice.

Various metalwork rulers, squares, marking calipers, and small markers are used as marking tools. To make marks, the following are used: cores (of various modifications), scribers with different tip shapes, and pencils. The tools used are manufactured according to developed standards

In industrial enterprises, the tools for cutting metal are special machines. These include:

- guillotines;

- presses (hydraulic and mechanical);

- press shears;

- angle cutting machines.

They have high productivity and allow you to cut even very thick metal.

The hydraulic guillotine is controlled by an electronic unit. With its help, the parameters of the future operation are set. Set the type of metal, the cutting angle, the amount of pressure on the knife, and the cutting speed. In addition to the guillotine, so-called combined units are used to solve these problems. These include cutting machines (press shears) and highly specialized ones (angle notching machines, presses and dies). Press shears are used for cutting sheets and strips of metal, shaped and long products. They work well with profile metal, for example, channel, I-roll, square. With their help, smooth holes and grooves of various shapes are obtained.

Angle notching machines allow angular cutting of metal products of almost any thickness. High precision cutting is achieved thanks to the presence of a scale that allows you to accurately lower the tool to the required place and a correctly sharpened set of chisels.

Presses and stamps solve similar problems. They use mechanical, hydraulic, pneumatic and electric drives.

What operations are performed when cutting metal?

When performing felling, you should remember the mandatory operations. All techniques used directly affect the productivity and quality of the result.

Metal transportation

Transportation of metal intended for processing is carried out manually or using mechanization. Trolley, stretcher, lifting and transport equipment up to a beam crane - depending on the weight and size characteristics.

Marking is carried out in sufficient lighting.

During the cutting process, it will not be superfluous to periodically check it if erasable products (pencil or chalk) were used.

All hand work is accompanied by body position and leg stance.

Sitting during the process is ineffective, as the impact force is reduced. By making small changes in body position, it is possible to vary the angle of impact and select the most effective position.

The exception is machine work. The Safety Instructions and Procedure contain the full scope of recommended actions. The regulations usually contain all the requirements and recommendations.

It is necessary to stand half a turn in relation to the place where the hand cut is performed.

The distance between the table and the body is approximately half the body or as convenient at a particular moment.

To apply sufficient force to the edge of the part to deform and cut it, it is optimal to hold it with a vice. The product should protrude from the jaws a couple of millimeters from the marking line - otherwise the required dimensions will not be met.

Holding the instrument is confident, all movements are precise and without undue haste.

For safety reasons and at the same time creating the most powerful blow, you need to hold the handle 1-2 cm from the end, and not near the head. Hold the chisel with 2-3 cm between your hand and the striking part.

Metal cutting operations

It is recommended to strike the chisel with a hammer in the center of the striking part. To maintain the greatest accuracy, when striking, you need to concentrate your gaze on the connection between the tip and the material. If you look at the striking part, there is a high risk of the cutting edge moving out of place.

Thick metal is processed in several approaches. It is recommended to alternate between deepening and removing metal from the groove. After this, subsequent cutting down along the resulting small thickness.

Cutting of closed profiles (round, square, rectangular or other pipe) is carried out with their uniform rotation. A blow is made with a cut of a certain length, the tube is rotated, and the cut is repeated. Only a small residual strip may be broken off, not the entire tube.

Possible defects

During this operation, certain defects always appear. The main defects include:

- the cut edge is not straight;

- The parallelism of both edges of the part is not maintained;

- the edge of the part turns out torn with burrs and great roughness.

Each of the defects that appear has its own individual causes. The first defect always appears with weak fixation of the workpiece. This defect is especially evident if the cutting process is carried out on a metal frame without fixing the part. The manifestation of these defects is caused by the following reasons:

- the part is not secured securely enough;

- the applied marking has shifted;

- the process was carried out with blows exceeding the necessary force;

To eliminate them, you need to follow simple rules:

- Check the strength of the workpiece;

- Maintain the accuracy of the location of the part relative to the applied marking;

- Check the sharpening parameters of the tool.

When cutting grooves, in addition to the listed defects, others may appear. These include:

- torn groove edges;

- the depth of the groove varies along the length;

- chips at the end of the groove;

To prevent the occurrence of the listed defects, it is necessary to follow the procedures established by the instructions for use of specific equipment and accepted standards. Before the operation, preparation is made for cutting the workpiece itself, the cutting tool and the machine used.

If you follow the rules for preparing and carrying out cutting and cutting operations, you get a smooth edge, without defects or chips.

What are the methods for cutting metal?

Methods of achieving a goal can be classified according to a number of characteristics.

Goal:

- edge or surface cleaning;

- dividing the workpiece into parts of a simple shape (rectangles, triangles) or a little more complex (polyhedrons, rounded silhouettes);

- cutting down a complex configuration, which will require changing the cutting direction and a certain amount of time;

- removing a volume of metal to a specified depth and width.

Locksmith tools:

- manual type: hammers, chisels and other tools;

- mechanized type: a group of machines and structures with the help of which separation along the line is carried out with less labor and time.

Vector of movement of the working tool (affects the required force and the overall organization of work):

- vertical cutting (the cutting edge acts from above);

- horizontal (cutting is performed at an angle to the horizontal, the workpiece is fixed vertically).

Need for fixation:

- not required - just adjust by hand;

- minimal pressure - a heavy object will be required;

- reliable fixation - in a vice, clamps or clamps;

- when working on equipment - using integrated press beds.

The quality of the result directly depends on the means used. The type and condition of the tool (machine), the mechanical properties of the material and its thickness, the speed of work and the experience of the person - these factors are of great importance.

What is called manual cutting of metal?

This plumbing business is not highly complex. It is advisable to pre-clamp the semi-finished product - this will ensure the stability of the part and eliminate vibrations. To do this, you will need a powerful base: a metal table, cabinet or frame with a vice. Ordinary furniture or improvised items will not work.

To create force and transfer it to the cut, you need a tool. The chopping technique is to provide a small indentation to ensure the installation of the tip and perform the main chopping blow.

The basic movement is called the “swing.” It depends on the required impact force and is performed with a movement based around one of the following joints:

- wrist - for light blows and precise manipulations;

- elbow – the main option, suitable for impact during steady-state operation with small and medium thicknesses;

- shoulder - for the most powerful blow when working with large thicknesses or serious scale.

Chopping metal

The impact increases as the weight of the hammer and the length of its handle increase. The heavier the impact tool, the greater the impact on the cutting edge. This way you can get an accurate and fairly clean cut.

With a strong impact, there is immediately a very high probability of the cutting edge coming off and damaging the material. There are frequent cases of instrument damage and even injury. Therefore, haste and inattention are not welcome.

The manual cutting method is optimal for single production and home conditions. It is good for its versatility, but has a number of disadvantages:

- not the highest performance;

- need for time reserve;

- the result in most cases will require modification of the edge (removal of a thin layer, grinding).

Semi-automatic

Perhaps this name is not entirely correct, but the essence of the method is that various mechanical machines are used to cut the workpiece - guillotines, which speed up and simplify the process and provide a much more accurate cut.

When using them, the processed edge is smooth, there are no nicks and burrs on it, which are common when working with a chisel, and the geometry of the product itself is not disturbed. The absence of unevenness on the resulting edge significantly saves time, since there is no need for further processing.

To use the guillotine, simply place a metal sheet on it and lower the handle. A cutter reinforced with hydraulics, mechanics or pneumatics will easily cut through the entire width of the workpiece.

Such mechanized devices are popular in small industries, but electromechanical guillotines are considered truly productive.

Device for chopping metal - guillotine

Cutting steels and softer alloys may be required constantly and in large quantities. In production conditions, home workshops and small private workshops, machines and devices with varying degrees of mechanization are used:

- manual guillotine - a frame-type structure based on a long carbide knife;

- press shears - a guillotine driven by an electric or pneumatic drive;

- press - a more detailed unit, manufactured in the form of full-fledged equipment;

- die-cutting machine - allows you to process a sheet of metal and obtain holes in it of the required shape and density.

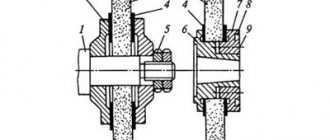

The guillotine is designed relatively simply. A supporting frame is installed on the foundation, on which the remaining components are mounted. The housing, knives, drive, pipelines (cable routes) and controls create the technical ability to cut sheet metal and other rolled products, for example, a channel or angle. The unit is completed with protective fences and alarm systems.

Manual guillotine

The guillotine is interesting due to its range of adjustable parameters:

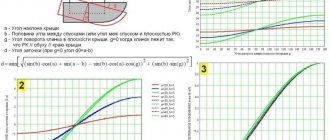

- type of metal and its mechanical characteristics (processing of aluminum alloy and alloy steel will require different forces);

- optimal angle α, “alpha” (characteristic of the relative position of the rear edge of the tool and the surface being cut);

Guillotine diagram

- knife feed speed;

- working pressure created by the knife.

The adjustment is carried out by mechanical or electronic components.

Press shears

The main advantage of mechanized equipment is high efficiency and the ability to work with large thicknesses. Mechanized industrial equipment is characterized by both flexibility in use and high specialization:

- cutting sheet metal of any thickness depending on the capacity of the installation;

- creating unique corner cuts;

- development of openings in long and shaped steel;

- obtaining highly specialized objects (for example, grooves in bearing liners and bushings - in addition to cutting, chopping is also involved here).

What is the essence of metal cutting?

Regardless of the equipment used, the entire cutting process comes down to the following.

The workpiece must be marked - apply the shape of the element to be cut, taking into account the dimensions and tolerances for the thickness of the cut. The latter is often forgotten - meanwhile, for cutting metal, you should plan a cut from one thickness of the workpiece.

When marking, it is important to use the maximum usable area - for this, preliminary planning of placement is optimal. This is especially true for products with complex shapes, and the trajectory of their cutting may be limited in direction and angles.

When cutting metal, the first task is to secure the material. This is done using a vice or other clamping device. An ordinary anvil or just a massive piece of metal is popular for this.

Metal cutting

If the work is carried out by mechanization, further operations are reduced to moving the workpiece relative to the lowering knife. When manually cutting, cutting will require at least 2 steps:

- Initially, weak blows are made along the intended line - this is required to establish the cutting contour;

- When the entire line or a separate part of it is ready (if the trajectory is complex), cutting is carried out - powerful blows are applied to the cutting tool.

As a result of this, the cutting edge passes exactly along the desired line of cutting off the excess. Without preliminary marking, the movement of the tip will be difficult, and there is a risk of it reaching the body of the future part.

When the work is done on one side, the sheet is turned over, the process is repeated for the reverse side. With a material thickness of more than 2-3 mm, this is almost guaranteed to be required. If you cut the entire thickness at once, the quality of the edge will be unsatisfactory.

Metal cutting

As a result of the described sequences, metal is gradually removed around the perimeter, and the shape of the part is revealed. In this case, safety is of great importance: individual pieces of material can fly off at high speed.

To prevent injury you must:

- put on locksmith glasses and gloves before starting work;

- try to knock the metal in such a direction that its parts do not fall on people;

- organize the absence of strangers in the work area, for which the use of screens is allowed;

- blows with a hammer - apply without excessive force, try not to hit the vice.

All working tools must be kept intact and in order.

If the work is done without a vice (“horizontal” method), the essence does not change:

- the workpiece is laid flat, it can be pressed so that the cutting line is free (with a heavy object, a clamp);

- the chisel is pre-sharpened until the required degree of sharpness and curvature is obtained;

- felling is carried out in 2 stages (preparatory-basting and power), with a continuous line in one direction;

- When bending the workpiece, if this interferes, its flatness is periodically restored (with hammer blows).