49. Minimum radius R of bending sheet metal, mm

| Material | Line locations bending of rolled products in a condition | |||

| annealed or normalized | riveted | |||

| across fibers | along fibers | across fibers | along fibers | |

| Steel: | ||||

| St3 | 2S | |||

| 20 | 1.5S | |||

| 45 | 2.6S | |||

| corrosion resistant | 1S | 2S | 3S | 4S |

| Aluminum and its alloys: | ||||

| soft | 1S | 1.5S | 1.5S | 2.5S |

| hard | 2S | 3S | 3S | 4S |

| Copper | — | 1S | 1S | 2S |

| Brass: | ||||

| soft | — | 0.8S | 0.8S | 0.8S |

| hard | — | 4.5S | 4.5S | 4.5S |

The unfolded length of the curved section of a part made of sheet material when bending at an angle α is determined by the formula

A = π(α/180)(R+ KS),

where A is the length of the neutral line; R—internal bending radius; K is the coefficient that determines the position of the neutral layer during bending (Table 50); S—thickness of sheet material, mm

Note.

The minimum radii of cold bending of workpieces are set according to the maximum permissible deformations of the outermost fibers. They are used only in cases of structural necessity; in all other cases, increased bending radii are used.

K coefficient value

| Minimum bending radius R, mm | Rolled thickness S, mm | ||||||||||

| 0,5 | 1 | 1,5 | 2 | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | |

| 1 | 0,375 | 0,350 | — | — | — | — | — | — | — | — | — |

| 2 | 0,415 | 0,375 | 0,357 | 0.350 | — | — | — | — | — | — | — |

| 3 | 0,439 | 0,398 | 0,375 | 0,362 | 0,355 | 0,350 | — | — | — | — | — |

| 4 | 0,459 | 0,415 | 0,391 | 0,374 | 0,365 | 0,360 | 0,358 | — | — | — | — |

| 5 | 0,471 | 0,428 | 0,404 | 0,386 | 0,375 | 0,367 | 0,357 | 0,350 | — | — | — |

| 6 | 0,480 | 0,440 | 0,415 | 0,398 | 0,385 | 0,375 | 0,363 | 0,355 | 0,350 | — | — |

| 8 | — | 0,459 | 0,433 | 0,415 | 0,403 | 0,391 | 0,375 | 0,365 | 0,358 | 0,350 | — |

| 10 | 0,500 | 0,470 | 0,447 | 0,429 | 0,416 | 0,405 | 0,387 | 0,375 | 0,366 | 0,356 | 0,350 |

| 12 | — | 0,480 | 0,459 | 0,440 | 0,427 | 0,416 | 0,399 | 0,385 | 0,375 | 0,362 | 0,355 |

| 16 | 0,500 | — | 0,473 | 0,459 | 0,444 | 0,433 | 0,416 | 0,403 | 0,392 | 0,375 | 0,365 |

| 20 | — | 0,500 | — | 0,470 | 0,459 | 0,447 | 0,430 | 0,415 | 0,405 | 0,388 | 0,375 |

| 25 | — | — | 0,500 | — | 0,470 | 0,460 | 0,443 | 0,430 | 0,417 | 0,402 | 0,387 |

| 28 | — | — | — | 0,500 | 0,476 | 0,466 | 0,450 | 0,436 | 0,425 | 0,408 | 0,395 |

| 30 | — | — | — | — | 0,480 | 0,470 | 0,455 | 0,440 | 0,430 | 0,412 | 0,400 |

OST 1 00286-78 Bending radii of sheet materials made of steel

Buy OST 1 00286-78 - a paper document with a hologram and blue seals. more details

We have been distributing regulatory documents since 1999. We punch checks, pay taxes, accept all legal forms of payment without additional interest. Our clients are protected by law. LLC "CNTI Normocontrol"

Our prices are lower than other places because we work directly with document providers.

Delivery methods

- Express courier delivery (1-3 days)

- Courier delivery (7 days)

- Pickup from the Moscow office

- Russian Post

Establishes a calculation formula for determining the minimum bend radii of sheet materials made of deformable steel with a thickness of no more than 3 mm.

Organizations:

For free

download this document in PDF format, support our site and click the button:

Minimum bending radius of metals of round and square sections, mm

| Diameter of a circle d or side of a square a | St3 | St5 | Steel 20 | Steel 45 | Steel12Х18Н10Т | L63 | M1, M2 | |||

| R1 | R2 | R1 | R1 | R2 | R1 | R2 | R1 | |||

| 5 | — | — | — | — | — | — | — | — | 2 | — |

| 6 | — | — | — | 2 | — | — | — | — | 2 | 2 |

| 8 | 3 | — | — | 3 | — | 5 | — | 7 | 2 | 2 |

| 10 | 8 | 10 | — | 8 | 10 | 10 | — | 8 | 6 | 6 |

| 12 | 10 | 12 | 13 | 10 | 12 | 13 | — | 10 | 6 | 6 |

| 14 | 10 | 14 | 14 | 10 | 14 | 16 | — | 11 | — | — |

| 16 | 13 | 16 | 16 | 13 | 16 | 16 | 16 | 13 | 10 | 10 |

| 18 | 16 | — | 18 | — | — | 18 | 14 | — | 10 | |

| 20 | 16 | 20 | 20 | 16 | 20 | 20 | 20 | 16 | 13 | 13 |

| 22 | 18 | — | 22 | 18 | — | 22 | 18 | — | 13 | |

| 25 | 20 | 25 | 25 | — | 25 | 25 | 25 | 20 | 16 | 16 |

| 28 | — | — | — | 22 | — | 30 | 22 | — | 16 | |

| 30 | 25 | 30 | 30 | 25 | 30 | 30 | 30 | 24 | 18 | 18 |

What affects the size of the bending radius of reinforcement

Bending of anchor rods is done using mechanical or manual machines, made by hand or in a factory. Mechanical machines are capable of bending reinforcing bars of almost any diameter. And manual machines allow you to bend reinforcement with a diameter of 12 millimeters or less. The bending radius of the reinforcement is determined by the class of reinforcement and the diameter of the rods. Standard standards for the diameter of the mandrel for bending reinforcement are listed in the Code of Rules 52-101-2003 on “Design of concrete structures and reinforced concrete structures without prestressing reinforcement.”

Important! Reinforcement bending to strengthen the foundation using a metal frame is carried out only mechanically, so that sharp corners do not form at the rounding point.

51a. Minimum bending radii R of equal flange steel, mm

Material - steel St3

The numerator shows the values of the bending radius of angle steel with the flange facing outwards, and the denominator – with the flange inwards.

| Pack thickness, mm | Profile number | |||||||||||||

| 2 | 2,5 | 3,2 | 3,6 | 4 | 4,5 | 5 | 5,6 | 6,3 | 7 | 7,5 | 8 | 9 | 10 | |

| 3 | 100/120 | 125/150 | — | — | — | — | — | — | — | — | — | — | — | — |

| 4 | — | 125/150 | 160/200 | 180/220 | 200/240 | 221/270 | 250/300 | 280/340 | 315/380 | — | — | — | — | — |

| 4,5 | — | — | — | — | — | — | — | — | — | 350/420 | — | — | — | — |

| 5 | — | — | — | — | — | — | 250/300 | 280/340 | 315/380 | 350/420 | 375/450 | — | ||

| 5,5 | — | — | — | — | — | — | — | — | — | — | — | 400/480 | — | — |

| 6 | — | — | — | — | — | — | — | — | 315/380 | 350/420 | 211/450 | 400/480 | 450/540 | — |

| 6,5 | — | — | — | — | — | — | — | — | — | — | — | — | 500/600 | |

| 7 | — | — | — | — | — | — | — | — | — | 420/350 | 450/375 | 480/400 | 540/450 | — |

| 8 | — | — | — | — | — | — | — | — | — | 480/400 | 540/450 | 600/500 | ||

| 9 | — | — | — | — | — | — | — | — | — | — | 450/375 | — | — | — |

| 10 | — | — | — | — | — | — | — | — | — | — | — | — | — | 600/500 |

| 12 | — | — | — | — | — | — | — | — | — | — | — | — | — | 600/500 |

Why bend sheet metal along a radius?

To give the workpiece the required shape, taking into account its relief modification (including corners and roundings), it is customary to use radius bending of sheet metal. This is an orderly process, so when multiple bends are required, each element is processed sequentially until the desired configuration is achieved.

This technology is used to shape:

- sheet profiles;

- street cornices and canopies;

- suspended elements of building facades;

- metal furniture components;

- decorative interior elements, etc.

Spherical, cylindrical and cone-shaped parts made of bent sheet metal or metal profiles are in great demand in the boiler industry.

Radial bending may be required in domestic construction and repair work, for example, when laying pipes. You should not try to perform such an operation at home - you need a special machine for this. Thanks to modern technologies, it is possible to select optimal parameters for working with workpieces of different sheet metal composition, thickness and shape. The bending radius is accurate and of high quality, and the material does not lose its strength characteristics.

We recommend articles on metalworking

Of course, there are other ways to give sheets the desired radius configuration: welding, riveting or cutting. But bending has a number of advantages over them:

- no seams or joints, which guarantees the natural strength of the metal;

- resistance to oxidation, corrosion, etc. due to the integral structure of the sheet blank;

- efficiency and absence of production waste;

- preserving the aesthetics of the source.

There are several types of radius bending of sheet metal, which are selected individually in each case (depending on the technical characteristics of the source material and the characteristics of the desired result). Let's take a closer look at each of them.

51c. Minimum bending radius R of unequal angle steel with the large flange facing outwards, mm

Material - steel St3

| Shelf thickness, mm | Profile number | |||||||

| 3,2/2 | 4,5/2,8 | 5/3,2 | 6,3/4 | 7,5/5 | 8/5 | 9/5,6 | 10/6,3 | |

| 4 | 160 | 225 | 250 | — | — | — | — | — |

| 5 | — | — | — | — | 375 | — | — | — |

| 5,5 | — | — | — | — | — | — | 450 | — |

| 6 | — | — | — | 315 | 375 | 400 | — | 500 |

| 7 | — | — | — | — | — | — | — | 500 |

| 8 | — | — | — | 315 | — | — | 450 | 500 |

| 10 | — | — | — | — | — | — | — | 500 |

Standardization, processing parameters

There are no state standards directly regulating the bending of sheet material, but recommendations are given in reference books. They are based on the practice of factories and research institutes. Since the 1930s, data have been presented in industry documents (OST), mechanical engineering standards (MN), and enterprise standards (STP). GOST standards for bent profiles (angle, channel, etc.) contain requirements for radius sizes.

The classic designer's handbook, edited by Anuriev, contains information on the minimum internal bending radii (R) of sheet metal. For mild steels, the value is equal to twice the sheet thickness: R = 2S. Deformation of the cold-worked metal or across the grain requires an approximately doubling of the radius.

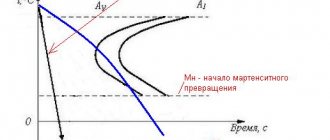

The outer and inner fibers are maximally stretched and compressed, respectively, and the resulting stresses can lead to cracks under cyclic loads. The negative effect is weakened by increasing bending radii and performing recrystallization annealing. During hot working, the required force is less due to increased ductility. The optimal temperature range eliminates grain growth during overheating, oxidation along crystallite boundaries - irreparable defects - burnout of the metal. The deformation rate and equipment features are also taken into account.

51 Minimum bending radius R of unequal-flange steel with the smaller flange inward, mm

Material - steel St3

| Shelf thickness, mm | Profile number | |||||||

| 3,2/2 | 4,5/2,8 | 5/3,2 | 6,3/4 | 7.5/5 | 8/5 | 9/5,6 | 10/6,3 | |

| 4 | 120 | 170 | 195 | — | — | — | — | — |

| 5 | — | — | — | — | 300 | — | — | — |

| 5,5 | — | — | — | — | — | — | 340 | — |

| 6 | — | — | — | 240 | 300 | 300 | — | 380 |

| 7 | — | — | — | — | — | — | — | 380 |

| 8 | — | — | — | 240 | — | — | 340 | 380 |

| 10 | — | — | — | — | — | — | — | 380 |

Advantages of bending, essence of the process

A large proportion of parts and blanks in metalworking are elements obtained by bending. The method is economical, allows you to avoid welding, use a wide range of rolled sheets, provides high productivity, and is used for all types of serial production.

Metal bending is a forming operation without separating the material, based on plastic deformation of the bending zone. Grains (crystallites) are oriented and stretched along the applied load. When the maximum elongation is reached, destruction begins, so it is important to correctly set the technological parameters.

51d. Minimum bending radius R of unequal-flange corner steel with the larger flange inward, mm

Material - steel St3

| Shelf thickness, mm | Profile number | |||||||

| 3,2/2 | 4,5/2,8 | 5/3,2 | 6,3/4 | 7,5/5 | 8/5 | 9/5,6 | 10/6,3 | |

| 4 | 195 | 270 | 300 | — | — | — | — | — |

| 5 | — | — | — | — | 450 | — | — | — |

| 5,5 | — | — | — | — | — | — | 545 | — |

| 6 | — | — | — | 380 | 450 | 480 | — | 600 |

| 7 | — | — | — | — | — | — | — | 600 |

| 8 | — | — | — | 380 | — | — | 545 | 600 |

| 10 | — | — | — | — | — | — | — | 600 |

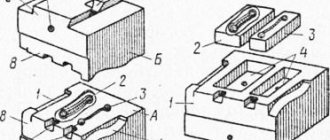

Selection of equipment and workpieces

Selecting a press includes calculating the force and checking whether the working area matches the dimensions of the sheet blank. Evaluate productivity and economic efficiency, depending on the rational choice of length and width of the sheet. offers a wide range of sheet steel assortments that meet the requirements of minimizing waste and increasing CMM.

The popularity of hydraulic sheet benders for processing open and closed profiles is due to the versatility provided by prefabricated dies. Shells of cylindrical and conical shape are produced on rollers. An electric welded steel pipe is an example of bending on a specialized pipe rolling mill.

51e. Minimum bending radius of I-beam, mm

(material - VSt3 steel)

| Profile number | 10 | 12 | 14 | 16 | 18 | 20 |

| Minimum bending radius R, mm | 250 | 300 | 350 | 400 | 450 | 500 |

Sheet metal bending technology: features and classification

Bending technology, depending on the required modification of sheet metal, includes the following types:

- Single-angle (V-shaped) - considered the simplest. Under the influence of the bending force, the upper surface of the workpiece is compressed, and the lower surface is adjacent to the walls of the mechanism and stretched. This way the desired radius is achieved.

- Double-angled (U-shaped) - performed in a similar way except for the number of processing steps.

- Multi-angle bending.

- Radial bending of sheet metal (rolling) – allows you to obtain a smooth bend. Used to create hinges, clamps, etc.

This technology for processing workpieces does not require enormous effort, so preheating the material is not required.

Hot bending along a radius is used only for thick sheet blanks (12–16 mm), as well as low-plasticity metals. The latter include duralumin, high-carbon steels and their alloys.

This method of processing sheet material is often used in combination with other operations, for example, cutting, cutting or punching. The result is complex three-dimensional metal products. To make them, they resort to stamps that can be used in several transitions.

From the point of view of spatial positioning, there are two ways to bend along a radius:

- Longitudinal - in this case, cold work technology is used, which does not allow processing thick sheet blanks.

- Transverse - includes several stages: first of all, the edges of the metal part are bent, then it is heated. Afterwards, the actual production operations begin: bending, upsetting and drawing.

For radius bending of sheet metal, a specialized manual or industrial machine is required. Its design is modified depending on the required shape of the product.

Working in cold technology requires maintaining an optimal ratio of bending radius, metal thickness and the size of the sheet itself. Deviation from the limit value is fraught with loss of strength characteristics of the workpiece and the possibility of damage.

Giving a radius shape to a workpiece under the influence of high temperatures can change the structure of the material. Thus, during cooling after heating, the bonds between the molecules in a sheet of metal become closer and more ordered, which helps to increase its hardness, strength and elasticity. In addition, the elongation at break decreases at this point. The plasticity of the material changes little.

Active thermal impact on metal is not recommended. If the temperature is close to the melting point of the sheet material, then its physical properties deteriorate sharply - burnout occurs. It is accompanied by oxidation and decarbonization of the surface. Prolonged overheating causes the formation of a coarse-grained structure of the material.

From the outside, the process of bending a metal profile along a radius seems simple, but this does not mean that it has an insignificant effect on the structure of the material. During exposure, tension arises in it. At first it is elastic, and then acquires a plastic character. It is important to determine the balance of these tensions and changes; this can often be difficult.

When bending a sheet along the radius, the deformation occurs unevenly. So, it is more noticeable in the corners themselves and is almost imperceptible at the edge of the plate. A peculiarity of working with thin metal sheets is that their upper part is compressed under the influence of bending, and the lower part is stretched.

The space between them is usually called the neutral layer. Accurate determination of this gap is one of the necessary conditions for performing a high-quality radius bend.

For qualified seaming, it is important to know some features of the procedure:

- The structure of the metal plate contains directed fibers. To ensure that the integrity of the material is not compromised during processing, the sheet must be positioned across the fibers or at an angle of 45° to them.

- For each sheet metal, the yield strength must first be determined. Its violation is fraught with ruptures.

- At the point of bending, a number of deformations of the plate occur: the neutral layer, located in the middle of the sheet or at its center of gravity, shifts towards a smaller radius; there is a change in cross section; the thickness of the material decreases.

Working with small-sized workpieces requires great skill. It is important to consider that:

- the smaller the bending radius of sheet metal, the larger the area of its deformation;

- with a large radius, the changes do not affect the entire plate.

It is important to take into account the peculiarities of this type of work when organizing the process of stamping blanks.

We give examples of calculations for manual and semi-automatic bending

The length of the workpiece is determined by the formula:

where Y1 and X1 are the length of straight sections of the sheet profile; φ – external angle; r – bending radius; K – neutral line position coefficient (determined from technical tables) S – metal thickness.

To determine the length of a workpiece with several bend angles, the amounts in parentheses for each additional angle are added to the above formula. The workpiece is calculated using the sweep method by summing the length of all straight flanges Yn, Xn and adding the curvature radius.

The force of the press on the workpiece when bending sheet metal is determined by the formula:

where S is the thickness of the metal sheet profile; L – workpiece length size; ∂ʋ – tensile strength (reference value); V – matrix scan (technical parameter of the machine).

In practice, experts use ready-made templates and tables depending on the type and size of the metal profile. The exact parameters of the workpiece are selected from the tables and the maximum permissible press forces with deformation angles are selected.

Calculations using formulas are used only when working with non-standard workpieces and single orders, where it is important to maintain dimensions exactly to 0.1 mm.

FROM STEEL

regarding steels Tested in 1984

By Order of the Ministry of August 3, 1978 Ns 087-16

the introduction date is set to July 1, 1979.

1. This standard establishes a calculation formula for determining the minimum bending radii of sheet materials made of deformable steel with a thickness of no more than 3 mm.

2# Minimum bend radii (R) are determined by the formula:

where L is the bending coefficient, depending on the properties of the material and the angle oi;

3. The application of letter designations on the bend elements is indicated in the drawing.

4. The bending coefficient 0 when the material edge roughness parameter is no more than Rz40 should be selected according to the table; for materials not included in the table, it should be determined according to the nomogram.

Bend factor 1 for OS corner

15X18N12S4TYu (EI654) KhN38VT (EI703) KhN28VMAB (EP126)

Quenched and tempered t = 600°; 3 hours

to determine the coefficient O at a value of -a- = 2. 8

Inv. Original No.__3690 Rev. No. 8581 9147

Notes: 1. Between two values of uniform relative elongation on the nomogram (curves = 0.05...0.4), its value along the ordinate axis changes uniformly.

2. The bending coefficient 0 according to the nomogram should be determined as shown by the arrows.

3. The values of the relative elongation ^ (final) and Sg (uniform) and the relative narrowing of the neck y should be determined from reference materials.

4. The final relative elongation ^ is determined by the formula: r ——,

For example, for magnitude = 3.4, °g = 0.3 and angle " = 90, the bend coefficient 0 will be 1.3.