Machining sheet or profile metal when preparing parts or creating a workpiece often requires the removal of some material. Cutting a sheet, obtaining a separate part, adjusting it to the installation site - all this is required when creating products, in construction and in the home.

Such an operation is also possible at home; complex equipment is not required. Every business person knows what tool is used to perform the metal cutting operation.

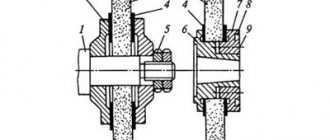

Device for chopping metal - guillotine

The equipment has a hydraulic drive.

The bed itself is very heavy and large. Using the device, you can only make straight cuts (without rounding) horizontally and vertically. If necessary, you can cut out the desired simple geometric shapes - squares, rectangles, rhombuses, etc. Usually the machine has a remote or computerized control. CNC allows you to preset shapes and cutting speed. Mathematical calculations are required to take into account the thickness of the workpiece and other parameters.

Sometimes the units are combined, that is, in addition to guillotine blades, they contain metal shears and a press. This speeds up work and allows for multifunctional operations. Features of the mechanized process:

- High speed.

- Accuracy of sawing.

- Possibility to cut off even the smallest edge.

- Fairly smooth edges.

- Working with metal products of large thickness (rebar, thick walls).

- The mechanic's actions consist only of setting up the machine and monitoring the process. Facilitating the physical labor of workers.

- High performance. Suitable for mass production.

The disadvantages include the high cost and weight of the equipment. Not every production can afford it.

Modern instrument

For metal cutting, hammers weighing 400, 500, 600 and 800 g are used. The hammers are mounted on handles made of hard and tough wood (birch, maple, oak, rowan). Handles should be oval in shape, with a smooth and clean surface, without knots or cracks. The length of the handle of a hammer weighing 400-600 g is 350 mm, and weighing 800 g is 380-450 mm. To prevent the hammer from jumping off during operation, the end of the handle on which the hammer is mounted is wedged with wooden or metal wedges 1-3 mm thick. The wedges are placed along the major axis of the handle section. Wooden wedges are placed on glue, and metal ones are roughed up so that they do not fall out.

The working part of the chisel and the crosspiece - (5, c, d) is hardened to a length of at least 30 mm, and the head is hardened weaker than the blade (to a length of about 15-25 mm) so that when hit with a hammer it does not crumble or crack.

The rest of the chisel and crosspiece should remain soft. Chisels and crosspieces should not have cracks, caps or other defects.

The most commonly used chisels are 175 and 200 mm long with blades 20 and 25 mm wide. To cut grooves in steel and cast iron, cross-cutting tools 150-175 mm long with a blade 5-10 mm wide are used. The heads of the chisel and crosspiece are forged to a cone, which ensures the correct direction of the hammer blow and reduces the possibility of a mushroom cap forming on the head.

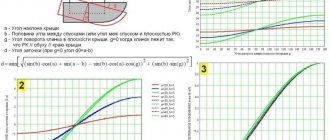

The sharpening angle of chisels and crossbars depends on the hardness of the metal being processed. For chopping cast iron, hard steel and hard bronze, the sharpening angle of the tool is 70°, for chopping medium and soft steel - 60°, for chopping brass, copper and zinc -45°, for chopping very soft metals (aluminum, lead) - 35- 45°.

Tools are sharpened on sharpening machines with abrasive wheels. During sharpening, the working part of the tool (blade) becomes very hot and may become loose. During tempering, the hardness of the hardening is lost and the tool becomes unsuitable for further work. To avoid this, the working part of the tool is cooled with water during sharpening. Figure 6 shows how to hold the chisel when sharpening and how to check that the angle is sharpened correctly.

Definition: what is metal cutting?

This is a plumbing operation during which a predetermined division of the workpiece occurs in various proportions. Before this, special markings are applied. The rupture can be carried out both along and across. This is a convenient method because it reduces the number of finishing procedures, and therefore the cost of the finished product. The only caveat is that the edges may turn out a little torn, which means sanding will be required.

This is a preparatory stage, it is not finishing, that is, the last. Tasks that are solved in the process:

- removing excess layer. scale, other defects after casting;

- removal of edges in which high edge stress remains after casting or stamping;

- dividing one product into small elements;

- breakdown of grooves or other functional recesses, grooves.

Applications are in a wide range of areas - from small enterprises to large engineering plants. But the most primitive analogue of the procedure can be performed at home.

Rules and techniques for cutting metal and safety rules

The productivity and cleanliness of metal cutting depend on the correct working methods. When chopping, you need to stand steadily and straight, half-turned towards the vice. The hammer is supposed to be held by the handle at a distance of 15-20 mm from the end and applied strong blows to the center of the chisel head. You should look at the chisel blade, not at its head, otherwise the chisel blade will not go properly. The chisel should be kept at a distance of 20-25 mm from the head.

Basic safety rules include:

1. Carry out cutting only with safety glasses and a protective screen installed.

2. Securely secure the workpiece in a vice.

3. Use a working tool.

4. You cannot stand behind a working comrade.

5. When finishing work, reduce the impact force.

3. Tools and devices for cutting metal

Chopping is a metalworking operation in which, using a cutting tool (chisel), excess layers of metal are removed from a workpiece or part or the workpiece is cut into pieces.

With modern methods of processing material or workpieces, metal cutting is an auxiliary operation.

Laser metal processing

Laser cutting of products is a progressive technique. Its essence is the effect of a narrowly directed light beam on the rolled product, heating the part at the point of contact to high temperatures. Under the influence of the beam, the metal product melts, and the remaining melt is blown off its surface with a special gas.

With the laser method, there is no deformation of the metal product, and it is possible to obtain a highly accurate result without the need for additional processing of the edges.

Scheme and general view of the installation

Despite all the advantages, these types of cutting metal products have several disadvantages:

- use only for thin sheet material up to 20 mm thick;

- the impossibility of processing aluminum alloys and stainless steel metal products due to their high reflectivity of light rays.

What is called manual cutting of metal?

The process can be either horizontal or vertical, depending on the possibility of attaching the sample. First, it is clamped with a vice, if the thickness allows. Otherwise, it is placed on a special table (think about its strength in advance). To reduce the possibility of slipping, you can lay down rubberized pads, or even better, screw screws into the edges on all sides.

Then the tools are prepared. We will talk about them in more detail below, but now we’ll just outline the list of what’s needed – a crosspiece or chisel, hammers.

Next, think about the impact. Of course they vary in strength. But the most severe impact is not always beneficial. First you need to make a sufficient notch in place so that the blade does not move out. If you pound with all your might the first time, you can only achieve a deformed surface and damaged tools. However, the speed and cleanliness of the cut then depends on this.

Impacts can be of three types:

- carpal;

- elbow;

- brachial.

According to where the swing begins. They are presented in order of increasing strength. Also, this parameter increases depending on the length of the hammer handle and its weight.

Features of the manual procedure include:

- low productivity;

- high consumption of labor resources and time;

- low accuracy;

- bad, with obligatory further processing of the log house.

However, this option is advantageous for small-scale production and single products, as well as at home and in the absence of specialized machines.

Metal cutting tools

Metal cutting techniques depend on the tools used and the tasks assigned. The top layer is removed using a chisel and hammer. In this case, the steel grade of the chisel must be several times harder than the workpiece. These tools can also be used to make grooves on metal workpieces. Metal shears are used when it is necessary to cut thin sheets into pieces. They are also made of hard steel grades and undergo special sharpening.

For fine processing, when it is necessary to cut a part of an unusual shape from a sheet, metal chopping knives are used. They allow you to easily obtain a variety of patterns that serve as decorations. Knives come in different sizes: from huge to very miniature. This allows you to process parts of any complexity. Other tools used when chopping metal: an anvil or plate, which serves as a stand for work, a vice in which you can clamp the workpiece, a crossmeisel, which is a type of chisel and is used for cutting grooves and recesses. The set of tools is quite small and accessible to anyone.

Various manipulations with metal involve constant heavy loads, so components for work must have a high margin of safety. Tools for chopping metal must be purchased from trusted suppliers so that they last as long as possible and do not let the owner down at the most crucial moment. The process of manual processing of parts is associated with a high level of risk to human health. Therefore, it is necessary to carefully observe safety precautions when cutting metal. All working personnel must be dressed in protective clothing, their hands must be protected with mittens, and their eyes must be protected with goggles or a mask. This will minimize the risk of an accident or work-related injury. Compliance with established rules is the basis of working longevity.

Sheet metal cutting is carried out mainly using special equipment. This allows you to significantly increase labor productivity, improve processing quality and improve the safety conditions for working personnel. A machine for cutting metal will cost from several tens to several hundred thousand rubles. Everything will depend on the manufacturer and functional equipment.

Metal cutting

Chopping is often classified as a group of cutting jobs, but in fact, completely different tools are used here, and the possibilities they provide are much wider. Unlike the impact action exerted on the cutter in the previous case, pressure is used when cutting.

Manually

To work with various workpieces the following are used:

- for cutting wire - wire cutters,

- circle, square and hexagon are sawed with a hacksaw,

- sheet materials are cut with scissors.

The use of special equipment can expand the capabilities of metalworking several times.

In industry and mass production

Various types of machines are used in production:

- with hacksaw blades or circular saws,

- turning,

- milling,

- installations for plasma/laser/gas cutting.

The scope of application for these installations, like for hand tools, is quite different.

Hacksaws and circular saws are the simplest types of machines. Their only task is to save time when cutting long products. They can also handle thick workpieces with ease.

Lathes can be divided into models:

In the first case, using carbide cutters of various shapes, a worker manually grinds the required part from a horizontally fixed rotating cylindrical workpiece. In the second, all actions are performed automatically when executing a preloaded program.

The easiest way to understand the principle of use is in this video:

Milling machines perform approximately the same function, but can create products of absolutely arbitrary shape. A rectangular, square or cylindrical workpiece is fixed on a movable table, after which a head with a rotating cutter, following the program, begins to cut off the “extra” metal.

The process looks like this:

For thin and thick sheet metal, a separate group of CNC machines is used. The key difference between them is the technology used for cutting.

The blank sheet is placed on a stationary table, after which the cutting head, controlled by a computer, begins to cut parts according to a predetermined program.

The cutting head can be used for:

This technology ensures maximum accuracy and speed of production, which is highly valued in conditions of mass production.

Its main disadvantage is the likelihood of formation of molten metal deposits on the edges of parts and scale, especially when using workpieces of large thickness.

Techniques for cutting metal.

Cutting metal. When cutting metal, the chisel is set vertically and the cutting is carried out with a shoulder blow. Sheet metal up to 2 mm thick is cut with one blow, so a mild steel lining is placed under it. Sheet metal with a thickness of more than 2 mm or strip material is cut to approximately half the thickness on both sides, and then broken, bending it alternately in one direction and the other, or beaten.

Cutting a strip on an anvil.

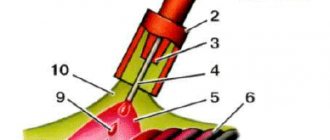

Beginning (a) and end (b) of installing a chisel when cutting sheet metal and scoring along the contour

Cutting blanks from sheet metal. After marking the contour of the part to be manufactured, the workpiece is placed on the plate and cutting is made (not along the marking line, but 2...3 mm away from it - allowance for filing) in the following sequence:

· install the chisel obliquely so that the blade is directed along the marking line;

· the chisel is given a vertical position and light blows are applied with a hammer, cutting along the contour;

· chop along the contour, delivering strong blows to the chisel; when moving the chisel, part of the blade is left in the cut groove, and the chisel is again moved from an inclined position to a vertical position and the next blow is applied; This is done continuously until the end (closure) of the marking line;

· turning the sheet over, they cut through the metal along the contour clearly marked on the opposite side;

· turn the sheet over again and finish cutting;

· if the sheet is relatively thin and sufficiently cut, the workpiece is knocked out with a hammer.

Cutting out a workpiece from sheet metal: a - cutting through the workpiece along the contour, b - knocking out the workpiece with a hammer.

When cutting with a chisel with a rounded blade, a smooth groove is formed, and when cutting with a chisel with a straight blade, a stepped groove is formed.

Sheet and strip metal is cut in a vice. Sheet material is usually cut at the level of the vise jaws. The workpiece (product) is firmly clamped in a vice so that the marking line coincides with the level of the jaws.

The chisel is installed to the edge of the workpiece so that the cutting edge lies on the surface of two jaws, and the middle of the cutting edge is in contact with the material being cut at 2/3 of its length. The angle of inclination of the chisel to the surface being processed should be 30...35º, and in relation to the axis of the vice jaws - 45°. In this case, the chisel blade goes obliquely relative to the jaws of the vice and the chips curl slightly. After removing the first layer of metal, the workpiece is moved above the jaws of the vice by 1.5...2 mm, the next layer is cut off, etc.

Shearing of sheet metal in a vice: a, b - inclination of the chisel, respectively, to the surface being processed and to the axis of the jaws.

Felling along marking marks is the most difficult operation. Scores are first applied to the workpiece at a distance of 1.5...2 mm from one another, and bevels (chamfers) are made at the ends at an angle of 45º, which facilitate the installation of the chisel and prevent chipping of the edge when cutting fragile materials. The workpiece is clamped in a vice so that the marking marks are visible. They cut strictly according to marking marks. The first blow is applied with the chisel in a horizontal position, further cutting is carried out with the chisel tilted by 25...30º. The thickness of the last finishing layer should be no more than 0.5...0.7 mm.

Felling according to marking marks.

Chopping wide surfaces is a labor-intensive and low-productivity operation, used when it is impossible to remove a layer of metal on a planer or milling machine.

The work is carried out in three steps. First, a little metal is cut off at two opposite ends of the workpiece, making chamfers (bevels) at an angle of 30...45°, and marks are applied at two opposite side ends, marking the depth of each working stroke. Then parallel marks are made on the wide surface of the workpiece, the distance between which is equal to the width of the cutting edge of the crossmeissel, and the workpiece is clamped in a vice.

After this, narrow grooves are first cut with a crosspiece (Fig. 75, a), and then the protrusions remaining between the grooves are cut off with a chisel. After cutting down the protrusions, final processing is performed. This method (pre-cutting grooves on wide parts) greatly facilitates and speeds up cutting. On workpieces made of cast iron, bronze and other brittle metals, in order to avoid chipping of the edges, chamfers are made at a distance of 0.5 mm from the marking line.

When chopping non-ferrous alloys, it is recommended to slightly moisten the cutting part of the chisel with soapy water or wipe it with an oiled rag, and when chopping aluminum - with turpentine. This helps to increase the durability of the cutting part of the chisel until the next sharpening.

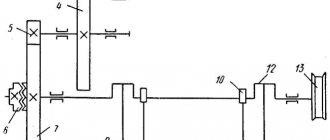

§ 5. Mechanization of the cutting process

Manual cutting is a labor-intensive and low-productivity operation. It should be used when machine processing (planing, milling, etc.) cannot be used.

To mechanize the cutting process, pneumatic or electric chipping hammers are used; special tools and devices; special machines on which the cutting operation is performed 8-10 times faster than manually.

When chopping, the pneumatic hammer is held with two hands: with the right hand by the handle, and with the left hand by the end of the barrel, guiding the chisel along the chopping line (Fig. 100). The hammer should be put into operation after the cutting edge of the tool is pressed onto the surface being processed.

Rice. 100. Chopping with a pneumatic hammer

Special chisels are used as a tool for chopping with a pneumatic hammer. Cutting productivity when using mechanized tools increases 4-5 times.

In electric hammers, the rotation of the electric motor shaft mounted in the housing is converted into a reciprocating movement of the striker, at the end of which a chisel or other tool is attached.

Our industry produces various types of pneumatic chipping hammers. The MP-4 hammer is designed for light chopping: the number of blows per minute is 3500, power is 0.54 kW, striker stroke is 41 mm. MP-5 is used for medium cutting: the number of blows per minute is 2200, power is 0.43 kW, striker stroke is 71 mm. MP-6 is used for heavy cutting: with a number of blows of 1600, striker stroke - 106 mm, power - 0.42 kW.

Safety regulations

When cutting metal, the following safety precautions should be followed.

- the hammer handle must be well secured and free from cracks;

- when cutting with a chisel and cross-cutting tool, the mechanic must use safety glasses;

- When cutting hard and brittle metal, be sure to use a fence: mesh, shield;

- To protect your hands from damage (during uncomfortable work, as well as during training), you should put a safety rubber washer on the chisel, and a safety visor on your hand.

Self-test questions

- How are a chisel and a cross-cutting tool sharpened for cutting various materials?

- List the safety rules when cutting.

- How does the point angle, back and front angles affect the cutting process?

- What mechanized cutting tools are used in your workshop?

Manual method of cutting metal

Metalworking techniques determine the sequence of actions:

- securing the workpiece in a vice; if this is not possible, place it on an anvil;

- the chisel is placed at the beginning of the marking line;

- first, preliminary gentle blows are applied with a hammer to highlight the contour of the intended cutting line;

- then a cutting tool is moved along this line and struck with strong blows;

- after completion, the half-cut workpiece is turned over;

- on the reverse side, repeat these steps until complete cutting off.

When working with strip metal, use the horizontal method. The rules of work are as follows:

- When sharpening, the cutting edge of the chisel is given a certain curvature;

- begin to carry out the operation from the far edge gradually approaching the front mark;

- When cutting out blanks according to the established template, an allowance should be provided.

During manual operation, there is a high probability of damage to the workpiece or the appearance of various defects. To avoid this, you must:

- ensure strong fixation of the workpiece;

- observe the angle of the chisel (it should be 30 degrees);

- carefully mark the cutting line;

- It is recommended to chamfer the workpiece before starting work;

- The frequency of blows applied must be uniform with the same force.

These recommendations must be observed especially when cutting metals from the PZO profile.

What is the essence of metal cutting?

Regardless of the equipment used, the entire cutting process comes down to the following.

The workpiece must be marked - apply the shape of the element to be cut, taking into account the dimensions and tolerances for the thickness of the cut. The latter is often forgotten - meanwhile, for cutting metal, you should plan a cut from one thickness of the workpiece.

When marking, it is important to use the maximum usable area - for this, preliminary planning of placement is optimal. This is especially true for products with complex shapes, and the trajectory of their cutting may be limited in direction and angles.

When cutting metal, the first task is to secure the material. This is done using a vice or other clamping device. An ordinary anvil or just a massive piece of metal is popular for this.

Metal cutting

If the work is carried out by mechanization, further operations are reduced to moving the workpiece relative to the lowering knife. When manually cutting, cutting will require at least 2 steps:

- Initially, weak blows are made along the intended line - this is required to establish the cutting contour;

- When the entire line or a separate part of it is ready (if the trajectory is complex), cutting is carried out - powerful blows are applied to the cutting tool.

As a result of this, the cutting edge passes exactly along the desired line of cutting off the excess. Without preliminary marking, the movement of the tip will be difficult, and there is a risk of it reaching the body of the future part.

When the work is done on one side, the sheet is turned over, the process is repeated for the reverse side. With a material thickness of more than 2-3 mm, this is almost guaranteed to be required. If you cut the entire thickness at once, the quality of the edge will be unsatisfactory.

Metal cutting

As a result of the described sequences, metal is gradually removed around the perimeter, and the shape of the part is revealed. In this case, safety is of great importance: individual pieces of material can fly off at high speed.

To prevent injury you must:

- put on locksmith glasses and gloves before starting work;

- try to knock the metal in such a direction that its parts do not fall on people;

- organize the absence of strangers in the work area, for which the use of screens is allowed;

- blows with a hammer - apply without excessive force, try not to hit the vice.

All working tools must be kept intact and in order.

If the work is done without a vice (“horizontal” method), the essence does not change:

- the workpiece is laid flat, it can be pressed so that the cutting line is free (with a heavy object, a clamp);

- the chisel is pre-sharpened until the required degree of sharpness and curvature is obtained;

- felling is carried out in 2 stages (preparatory-basting and power), with a continuous line in one direction;

- When bending the workpiece, if this interferes, its flatness is periodically restored (with hammer blows).

Possible defects

During this operation, certain defects always appear. The main defects include:

- the cut edge is not straight;

- The parallelism of both edges of the part is not maintained;

- the edge of the part turns out torn with burrs and great roughness.

Each of the defects that appear has its own individual causes. The first defect always appears with weak fixation of the workpiece. This defect is especially evident if the cutting process is carried out on a metal frame without fixing the part. The manifestation of these defects is caused by the following reasons:

- the part is not secured securely enough;

- the applied marking has shifted;

- the process was carried out with blows exceeding the necessary force;

To eliminate them, you need to follow simple rules:

- Check the strength of the workpiece;

- Maintain the accuracy of the location of the part relative to the applied marking;

- Check the sharpening parameters of the tool.

When cutting grooves, in addition to the listed defects, others may appear. These include:

- torn groove edges;

- the depth of the groove varies along the length;

- chips at the end of the groove;

To prevent the occurrence of the listed defects, it is necessary to follow the procedures established by the instructions for use of specific equipment and accepted standards. Before the operation, preparation is made for cutting the workpiece itself, the cutting tool and the machine used.

If you follow the rules for preparing and carrying out cutting and cutting operations, you get a smooth edge, without defects or chips.

What are the methods for cutting metal?

Methods of achieving a goal can be classified according to a number of characteristics.

Goal:

- edge or surface cleaning;

- dividing the workpiece into parts of a simple shape (rectangles, triangles) or a little more complex (polyhedrons, rounded silhouettes);

- cutting down a complex configuration, which will require changing the cutting direction and a certain amount of time;

- removing a volume of metal to a specified depth and width.

Locksmith tool

- manual type: hammers, chisels and other tools;

- mechanized type: a group of machines and structures with the help of which separation along the line is carried out with less labor and time.

Vector of movement of the working tool (affects the required force and the overall organization of work):

- vertical cutting (the cutting edge acts from above);

- horizontal (cutting is performed at an angle to the horizontal, the workpiece is fixed vertically).

Need for fixation:

not required - just adjust by hand;

- minimal pressure - a heavy object will be required;

- reliable fixation - in a vice, clamps or clamps;

- when working on equipment - using integrated press beds.

The quality of the result directly depends on the means used. The type and condition of the tool (machine), the mechanical properties of the material and its thickness, the speed of work and the experience of the person - these factors are of great importance.

Types of hand tools by purpose

During the repair process, a craftsman may need various metal work: bending, chopping, drilling, filing, threading. Solving the listed problems is possible using specialized plumbing tools, which are always at hand. Based on its purpose, it can be divided into several main groups. Below we will look at where each device is used.

Impact and marking tools:

- Machinist's hammers and blacksmith's sledgehammers are used in many technological operations: chopping, bending, straightening.

- Punch punches are used to mark metallic as well as non-metallic materials.

- Chisels are used to cut metal.

- Crosspieces allow you to cut out keyways and grooves. They differ from chisels in having a narrower cutting edge.

- Using scribers and compasses, precise marking work is carried out.

- The bits are designed for punching holes in sheet metal.

In the process of performing plumbing and assembly operations, various pliers are used. This includes pliers, pliers, round nose pliers, tongs, and pliers. A bench vice is used to fix parts for subsequent processing.

Thread cutting tool:

External threads are cut with dies, internal threads with taps. Die holders and wrenches are devices for rotating hand-held thread-cutting tools.

Devices for cutting and machining metal:

Files and needle files are used for filing parts and workpieces. Hacksaws are used to cut sheet and profile metal, and also perform other types of work. Hand shears are designed for cutting sheet metal. Thin layers of material are removed from parts using scrapers. As a result of scraping the mating surfaces, their tight fit and tightness are ensured.

Hole making tool:

- Holes in the workpieces are made using drills. They are made from alloyed carbon steels.

- Reamers allow high-precision machining of cylindrical and conical holes.

- Countersinks are used to process recesses and chamfers of drilled holes for the heads of screws, bolts, and rivets. Using counterbores, the end surfaces are cleaned.

- Countersinks are used to increase the diameters of drilled holes, improve their accuracy and quality.

Tool for assembling threaded connections:

- Spanners. By design, they can be horn or cap, end, hinged, adjustable, ratchet. Choosing the right version ensures ease of work in hard-to-reach places.

- Torque wrenches allow you to adjust the tightening force of fasteners.

- Plumber's screwdrivers for screws and screws with straight or Phillips slots are indispensable in production, construction, and repair.

Measuring devices include:

- Rulers, roulettes.

- Vernier tool. This includes calipers, height gauges and depth gauges.

- Micrometric instruments, bore gauges.

- Length measures: plane-parallel end, angular prismatic, line.

- Test plates, probes, straight edges, squares.

- Radius and thread templates.

- Instruments for measuring angles: protractors, levels, sine rulers.

- Indicating devices.

Thus, hand tools allow you to solve most problems when working with metal.

Equipment and tools used

This list depends on the method of work. Manual cutting is carried out using:

- cutting tools (chisels, crosspieces, etc.);

- a plumber's hammer (chosen by weight and handle length);

- vice;

- metal substrate;

- marking tool.

A metalworking chisel structurally consists of three main parts: impact, middle (holder) and cutting (working). The shape of the cutting part is different for each and depends on the task being solved. A chisel is used to perform a standard chopping operation. Kreuzmeisel has a narrower cutting edge. The groover is designed for cutting grooves, so its cutting part is made in the shape of a semicircle. The beard is made from a round metal rod, and has a working part in the shape of a circle sharpened around the perimeter. It is used to cut holes in sheet metal. All percussion instruments are made from durable tool steel.

The main parameters of these tools are geometric dimensions and sharpening angles of the cutting part. A plumber's hammer is used to strike the upper (impact) part of the chisel. They differ in the shape of the striker (round or square), the method of attaching the handle, and the total weight.

Cutting out small parts, holes, and individual parts is done using fastening equipment or on steel substrates. To ensure secure fastening, this operation is performed in a vice.

Various metalwork rulers, squares, marking calipers, and small markers are used as marking tools. To make marks, the following are used: cores (of various modifications), scribers with different tip shapes, and pencils. The tools used are manufactured according to developed standards

In industrial enterprises, the tools for cutting metal are special machines. These include:

- guillotines;

- presses (hydraulic and mechanical);

- press shears;

- angle cutting machines.

They have high productivity and allow you to cut even very thick metal.

The hydraulic guillotine is controlled by an electronic unit. With its help, the parameters of the future operation are set. Set the type of metal, the cutting angle, the amount of pressure on the knife, and the cutting speed. In addition to the guillotine, so-called combined units are used to solve these problems. These include cutting machines (press shears) and highly specialized ones (angle notching machines, presses and dies). Press shears are used for cutting sheets and strips of metal, shaped and long products. They work well with profile metal, for example, channel, I-roll, square. With their help, smooth holes and grooves of various shapes are obtained.

Angle notching machines allow angular cutting of metal products of almost any thickness. High precision cutting is achieved thanks to the presence of a scale that allows you to accurately lower the tool to the required place and a correctly sharpened set of chisels.

Presses and stamps solve similar problems. They use mechanical, hydraulic, pneumatic and electric drives.

Cutting metal with a guillotine

Metalworking, engineering firms, and large workshops use mechanized metal cutting. The most common is considered to be cutting using a variety of guillotines. Mechanization of cutting makes it possible to increase the quality of the chopped edge, cut very thick metal, and increase the speed of obtaining the finished workpiece.

Guillotines are used for cutting sheet metal of different thicknesses. The cutting technique is very simple. The guillotine has a specialized knife, which, under pressure, is lowered onto a metal sheet, cutting it according to the applied markings. To create the required force, mechanical, hydraulic or electromechanical systems are used. In this case, the steel strip is exposed to the action of a knife, which implements the vertical cutting method. In this case, a specialized device—a roller table—feeds the steel billet to a given length. The fixing device captures and holds the workpiece in the required position. A knife is lowered to the cutting site under pressure and performs this operation exactly along the marking line.

Creating the necessary short-term pressure on a metal sheet makes it possible to make precise cutting along the mark made and ensure high quality of the result. Guillotine cutting has the following advantages:

- get a smooth edge on the cut;

- there are no nicks or burrs;

- there are no crescent-shaped slopes along the entire length of the edge;

- There are no uneven bevels.

In addition to its technical positive qualities, the use of a guillotine makes it possible to reduce the selling price of each part and increase labor productivity in this procedure.

It is considered very important that with such cutting it is possible to increase the safety of the operation.

Based on this, you can select the grade of metal, the required cutting angle, and the parameters of the operation (power, speed, frequency).

General terminology

At the everyday level, many people use some words with the wrong meaning. The process of cutting metal is often mistakenly called cutting or punching, which leads to terminological confusion. Cutting, chopping and punching are three processing methods that differ in a number of parameters. The main differences between these processes:

- Cutting. With this processing method, one part of a metal part or sheet is separated from another part. For cutting, knives, scissors or automatic saws are most often used.

- Felling (the outdated name “felling” is also found). A series of similar metalworking operations in which a recess or groove is either created in a part, or metal is cut (with or without the removal of the top part), or one part of an object is separated from the others.

- Punching. With this processing method, one or more holes are created in the thickness of the metal sheet. Electric drills or similar equipment are usually used for punching.