Principle of operation

Automatic darkening of the “chameleon” mask is ensured by the presence of light filters made on the basis of liquid crystals. The property of liquid crystals to orient themselves in space under the influence of electrical voltage determines the operating principle of the mask.

In the normal state, when there is no serious light exposure on the screen, the crystals are in a position that allows daylight to pass freely through the screen. When the welding arc is ignited, a sensor is triggered , transmitting a signal to the electronic unit . After processing the signal by the electronic device, a command is given to rearrange the position of the crystals . They change their structure, which makes the screen dark (light radiation is blocked by the screen).

The duration of the crystal restructuring process takes a period of time no more than ten thousandths of a second . Almost instantaneous darkening makes it possible to keep the mask on throughout the entire length of the intermittent weld. After completing the welding work, it is possible to set a delay on the mask for the end of the screen darkening . This provides eye protection from the bright light of a weld that has not yet cooled down.

In high-quality and therefore expensive “chameleon” masks, the light filter has a multi-layer structure . The more layers, the more evenly the shading is distributed across the surface of the screen. The filter includes a separate layer that protects against ultraviolet and infrared radiation.

How to check without welding

Important! You need to know that to check the functionality of the automatic mask filter without welding, you need to use a light source with unstable radiation.

- The filter reacts well to the spark of a flint lighter. Just for the spark, not for the burning flame.

- A conventional incandescent lamp operates on alternating current at a frequency of 50 Hz. A person does not notice this, but an automatic filter picks up the vibrations and darkens the screen.

- The TV control panel or the glowing smartphone screen covers only a small fraction of the spectrum perceived by the light filter. This is mainly infrared radiation, to which one of many layers reacts.

Some advanced chameleon masks have a “TEST” button , designed to test the quality of the filters. They are functional if, after pressing it for a certain time, the mask screen darkens.

Types of adjustments

The following basic parameters are subject to adjustment of the chameleon mask.

Adjusting the position of the mask on the head. Reliable fixation of the mask on the head is carried out using a handle located at the back of the head and a belt passing through the top of the head.

Selecting the optimal distance from the eyes to the filter. There are latches on the mask, by loosening which you can move the filter closer or further to the eyes . After choosing the optimal distance, you should not forget about securing the clamps.

Select the dimming level. By rotating the wheel located outside the mask, the darkening mode is selected . The scale indicates levels from 0 to 16 according to the European DIN standard , where the sixteenth will have the maximum darkness. Despite the existence of all kinds of tables, each welder approaches the choice of darkening intensity in his own way, as well as the choice of the electrode and welding current.

Adjusting sensitivity. This adjustment allows you to select the optimal filter threshold . During the welding process, you can rotate the wheel to select the on/off mode, not only taking into account the intensity of the welding arc radiation. The sensitivity of the filter is influenced by the radiation of the molten metal, glare from the welding of a neighbor - a welder, and other light sources.

Adjustment of delay time. Welding technologies leave behind seams with varying degrees of cooling rates. After welding with a high current, the deposited mass will cool for a long time, and a short weld made at a low current will cool very quickly. The opening of the filter in the first case will be with a greater time delay, in the second it will open almost immediately.

The best manufacturers of welding equipment

If welding is rarely done at home, and the duration of such work is short, then you can limit yourself to buying an inexpensive Chinese light filter, but you should not count on its high quality. It is better for professionals not to save money and purchase products from popular, reliable manufacturers:

- 3M is an American company that produces not only light filters, but also shields, masks, and plates. All products are of high quality, so the manufacturer occupies a leading position in the Russian and world markets.

- Svarog is a popular Russian company that produces protective equipment and welding equipment. The advantage of their products is their affordable price and high quality.

- FUBAG is a German manufacturer that produces equipment and protective equipment for various industries and construction. Offers a large selection of replacement light filters and welding helmets.

- Quattro Elementi is an Italian manufacturer. It produces modern models with fixed filters and those that can change the level of darkness in accordance with the strength of the light flux.

- BRIMA is another German company popular in Russia, offering protective equipment used for welding by both amateurs and professionals.

produces masks and light filters.

How to use

The rules for using the chameleon mask are indicated in the instructions supplied with it.

Before starting work with a new mask, remove the film from the protective plate . For used ones, check for visible damage.

Check the functionality of the light filters using one of the methods indicated in the section of this article “How to check without welding.”

Adjust the parameters specified in the “Types of adjustments” section of the article. The settings must be appropriate for the nature of the work being performed.

Welding work must be carried out at temperatures from 15°C to 55°C.

The use of the mask in plasma and gas welding is limited.

It is not recommended to leave the mask shield on heated surfaces.

Strong blows to the shield are contraindicated.

You cannot use spare parts for repairs that are not specified in the user manual.

If the mask does not perform the basic functions of darkening the screen, you should stop welding and look for the cause of the malfunction.

Avoid getting moisture on the filter. This may disable it.

The use of chemical detergents and solvents for cleaning is prohibited . It is recommended to wipe the filter elements with a soft, clean, lint-free cloth.

When the red light on the filter turns on, you need to replace the batteries . Replace it after switching to open screen mode.

The protection plate should be changed regularly. Droplets from molten metal cause pitting, cracks, and ultimately clouding of the screen.

Rules for choosing filters

Before purchasing masks or glasses, you should understand the optical characteristics of light filters and the specifics of using the products.

Recommendations for choosing filters for welding

- If you regularly carry out welding work, you should choose the “Chameleon” mask.

- The size of the filter determines visibility and comfort during welding activities.

- The filter response time can vary from 0.03 to 0.0001 s.

- You should choose models with continuously adjustable dimming levels, which are more comfortable than stepped ones.

- It is recommended to use universal filters that have a shade of 9-13 DIN.

- The optical class of the filter determines the clarity and visibility of the image through glass (the best option has an indicator of 1).

Additional features

Additionally, you need to pay attention to: dispersion, homogeneity and angular dependence of the filters, what type of welding will be used, current indicators, risk of mechanical stress

When choosing protective devices, it is important to decide how the work will be carried out: indoors or outdoors

When choosing protective devices, it is important to decide how the work will be carried out: indoors or outdoors. The type of work carried out is indicated by markings: E – electric welding, G – gas welding,

The type of work carried out is indicated by markings: E – electric welding, G – gas welding,

B – auxiliary work, C – marking for “Chameleon” type filters.

Marking of different types of welding

To ensure uninterrupted operation of the filter, you should pay attention to:

- an adjustment unit, which can be accessed on the front side of the mask, which allows for correction without stopping work;

- on/off system that increases the longevity of the power supply and filter;

- availability of changing power sources;

- the number of sensors that determine the response time;

- possibility of adjusting parameters.

When choosing a model, it is recommended to choose filters marked 1/1/1/2, which determines the relationship to the optical class, uniformity and light dispersion.

When purchasing, it is important to study the product certificate, warranty period, and location of service centers. Explanation of the symbols on the welding mask

Explanation of the symbols on the welding mask

How to adjust the mask, auto darkening degree

The author of the following video, a practicing welder and at the same time a talented teacher, shows in an accessible form how to adjust the parameters of the chameleon mask. An inexpensive Chinese-made mask is used as a sample.

A specific example shows how to choose the optimal darkening. It is emphasized that with proper adjustment, a small area of the heat-affected zone should be visible. The advantage of the video is that it contains a table of correspondence between the dimming parameters and the current strength of the welding operation being performed. The values in the table are recommended; the author draws attention to the effect of dimming the vision of the welder on the setting.

Briefly, but very clearly, the process of selecting the delay time for opening the screen window after welding is described.

Setting the sensitivity or response threshold of a light filter causes difficulties for novice welders, because depends on external conditions. The author clearly explained why, due to incorrect sensitivity settings, you can “catch a bunny” (see the arc not through a darkened screen). The author's fundamental rule for adjusting sensitivity

A small drawback of the video is the lack of description of how to adjust the mask for convenient fixation on the welder’s head. Perhaps the author wanted to leave more time for summing up the results of the competition.

Which one to choose?

In order to buy a model for home and production, special attention should be paid to the following factors

Level of reliability of eye protection. Reflects the darkening parameters of the mask display, calculated in DIN and varies in the corridor from 3 to 15 units.

Additional options mode. After the metal hardens, the darkening should be removed, and the glass of the shield should become as transparent as possible. This allows you to continue the work process without removing PPE from your head. At the same time, the practicality and parameters of retinal protection directly depend on the speed of activation of the sensor. The optimal parameter is considered to be 0.1 s.

Ventilation. Welders are often forced to perform work in poorly ventilated areas, so it is best to choose “chameleon” PPE that provides the possibility of forced ventilation

This will allow workers to protect themselves from toxic fumes of hot metal and smoke generated when the electrodes burn.

The weight of the helmet plays an important role. When adjusted correctly, the headband of the product should not put too much pressure on the worker’s head.

At the same time, lightweight models made from synthetic materials are not able to protect the welder from accidental impacts resulting from falling objects.

Particular attention should be paid to the availability of all documents and certificates confirming the quality of the products. All data must be kept in the public domain and provided upon request

Consumers should be able to review the manufacturer's contact information and warranty terms. If at least one of these points is not met, then the safety of the helmet will be very difficult to confirm.

Obviously, the correct choice of any chameleon welding PPE implies increased safety. For the user, the main factor is to focus on the presence of a diagnostic option and the ability to display all information on the display, so that the worker can check all the design settings.

Why doesn’t it dim, doesn’t dim well and other faults

Chameleon protective masks, like any other welding equipment, do not last forever; they can break for various reasons. most frequently .

- There is no darkening of the filter screen for radiation from the welding arc . The main reason is a broken power supply. Dead batteries should be replaced; the batteries can be recharged from the mains. Some designs use solar panels to power the electronic unit. To replenish energy, they need to be sent directly to a light source for a certain time.

- Dirty protective glass causes the filter to flicker when reacting to the welding arc. It needs to be washed periodically. In case of severe mechanical damage, glass replacement is required.

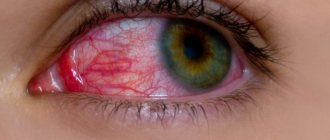

- Budget options from some “manufacturers” suffer from poor dimming . Low technological discipline contributes to the ingress of dust particles onto the liquid crystal layers. Such crystals can no longer close completely over the entire working surface of the screen. Ineffective darkening will cause eye inflammation after intensive work with such a mask.

- Uneven darkening may cause a deviation in the horizontal position of the filter relative to the face. Eliminated by leveling the casing.

- The use of masks in cold winter conditions is not intended . The filter will darken slowly, making it impossible to provide effective eye protection.

- A common reason for poor visibility of the weld seam during operation arises from forgetting to remove the film from the protective glass .

- Water may get into the electronic unit . A mask with such a defect should be sent to professionals for repair.

- The weak point of some mask models is the contacts from the control unit to the light filter . They often break and the mask screen stops working. An example of the defect is described in the following video. The author claims that he eliminated the defect by soldering with a regular soldering iron in road conditions. Not overheating the filter during such a repair is a great success. The actual process of restoring contact is not shown in the video.

Operating the Welding Chameleon

The main requirement for caring for the mask: the light filter must be taken care of: it is easily scratched. Therefore, you cannot put the mask face down. It should only be wiped with a completely clean and soft cloth. If necessary, you can moisten the cloth with clean water. DO NOT wipe with alcohol or any solvents: the filter is covered with a protective film that dissolves in these liquids.

There is one more feature of any welding chameleons: they begin to “slow down” at low temperatures. That is, they operate with a delay, and in both directions - both for darkening and for brightening. This feature is very unpleasant, so you won’t be able to work normally in them in winter, even if the operating temperature is specified as -10°C, as on the TECMEN DF-715S 9-13 TM8. Already at -5° everything cannot darken in time. So in this regard, OTOS turned out to be more honest, indicating the starting operating temperature from -5°C.

Finally, watch the video on how to choose a chameleon mask for welding.

Work order, necessary tools

If the light filter of the chameleon mask does not work, it completely eliminates its protective functions. There are two options left: throw the mask in a landfill or try to repair it. Self-repair can be carried out by familiarizing yourself with the procedure for performing the work and the tools used and materials from the video.

The most common reason for the lack of dimming is the failure of the power supply . The author immediately determined that his round factory battery had run out. Still, it is better to make sure that there is no voltage on the contacts using, for example, a multimeter.

Contacting the service center

Additional options make repairs more difficult and increase the risk of mask failure. If the degree of darkening has decreased significantly, it is necessary to inspect the structure.

Some components cannot be repaired and require mandatory replacement. If you cannot do this yourself, you need to contact a service center. The guarantee is valid only for complete masks. If you managed to delve into it, you will have to pay for the service.

There is no point in undertaking repairs to the system board: this is a matter for professionals. It is better to contact the service center immediately. Unsuccessful DIY repairs can result in additional costs.

Carrying out maintenance

Compliance with maintenance schedules will have a beneficial effect on the trouble-free operation of chameleon protective masks. While the filter is operating, dust and dirt collect . They must be removed at intervals of at least one month . When working in dusty conditions, for example, in enclosed areas of metallurgical plants, the filter must be cleaned every week .

Cleaning the light filter requires compliance with certain regulations . Only cotton, lint-free soft fabric is used as material . The detergent composition must be neutral and comply with the manufacturer’s recommendations. The use of abrasive and oil-containing products in cleaning technology is excluded. Dirt and dust should be washed off carefully, avoiding pressing hard on the surface of the filter.

Safety precautions

It is impossible to carry out welding work without a protective mask. In addition to visual impairment, you can burn your face and neck with ultraviolet rays, and damage your respiratory organs with hot harmful gases. A chameleon mask protects your eyes much better than a permanently darkened mask. Novice welders can “catch a bunny” using a regular mask without any problems while igniting the arc.

To further reduce the likelihood of eye injury when working with a chameleon mask, the following safety precautions should be followed:

- check mask settings;

- position of operating mode switches;

- availability of battery charge;

- check the darkening of the filter using the “TEST” button, a light bulb or a silicon lighter.

If before starting work it turns out that the mask is faulty, you should refuse to carry out welding work with it. It is better to throw all your efforts into fixing the breakdown. You should first think about health, and then about the quality of the weld.

Important! To maintain the functionality of the chameleon masks, light filters and solar panels should be stored in shaded places, in the absence of influence of light fluxes on them.

Solar panels, battery life

Some chameleon welding helmets are designed with a built-in, non-replaceable battery that is charged via a solar auxiliary panel. These helmets often require a charging period in direct sunlight before first use, and a similar charging period if they are stored for a long time, which can be a real problem when you want to start welding work as quickly as possible. The disadvantage of this type of mask is the fact that as soon as the battery wears out, the light filter does not work. It is better to buy a welding helmet in which the filter is powered by a replaceable battery and a solar panel, which allows you to start welding right away. Choose a filter with AAA batteries due to their low replacement cost and worldwide availability. Choose lithium batteries for longer life, but note that lithium batteries are more expensive than regular batteries. The service life of a regular AAA battery is about 2000 hours for MIG/MAG, MMA and other types of welding.