GOST 23518-79 Arc welding in shielding gases. Welded connections at acute and obtuse angles

GOST 23518 - 79

INTERSTATE STANDARD ARC WELDING IN PROTECTIVE GASES. WELDED JOINTS AT ACUTE AND OBTUDE ANGLES MAIN TYPES, STRUCTURAL ELEMENTS AND DIMENSIONS

| Moscow Standardinform 2011 |

INTERSTATE STANDARD

| ARC WELDING IN PROTECTIVE GASES. WELDED JOINTS AT ACUTE AND OBTUDE ANGLES Main types, structural elements and dimensions Cas - shielded arc welding. Welded joints. Main types, design elements and dimensions | GOST 23518 - 79 |

Reissue. February 2011

By Decree of the USSR State Committee for Standards dated 03/11/79 No. 870, the introduction date was set to 01/01/80 . The validity period was removed according to Protocol No. 4 - 93 of the Interstate Council for Standardization, Metrology and Certification (IUS 4 - 94) 1. This standard establishes the main types, structural elements and dimensions of welded joints made of steels, as well as alloys on iron-nickel and nickel bases, performed by arc welding in shielding gases. 2. The following designations for welding methods are accepted: IN - in inert gases with a non-consumable electrode without filler metal; INp - in inert gases with a non-consumable electrode with filler metal; IP - in inert gases and their mixtures with carbon dioxide and oxygen with a consumable electrode; UP - in carbon dioxide and its mixture with oxygen with a consumable electrode. 3. The main types of welded joints must correspond to those indicated in the table. 1. 4. Structural elements of welded joints, their dimensions and maximum deviations for them must correspond to those indicated in table. 2 - 20.

Table 1

| Connection type | Shape of prepared edges | The nature of the seam made | Cross-sectional shape of prepared edges and completed seam | Thickness of welded parts, mm, for welding methods | Connection angle of parts b, degrees | Connection symbol | |||

| IN | INp | IP | UP | ||||||

| Angular | No beveled edges | Single-sided with removable or steel remaining lining | 0,5 — 3,0 | 0,8 — 3,0 | 0,8 — 4,0 | 0,8 — 8,0 | 179 — 91 | U2 | |

| Unilateral | 0,5 — 4,0 | 0,8 — 6,0 | 0,8 — 6,0 | 0,8 — 6,0 | 179 — 91; 89 — 5 | U1 | |||

| — | — | 6,0 — 30,0 | 6,0 — 30,0 | 135 — 91; 89 — 5 | |||||

| Bilateral | 3 — 6 | 3 — 6 | 3 — 6 | 3 — 12 | 179 — 136 | U3 | |||

| — | 3 — 10 | 3 — 30 | 3 — 30 | 135 — 91; 89 — 45 | |||||

| — | — | — | 3 — 60 | 135 — 91 | |||||

| With one edge beveled | Unilateral | — | 3 — 10 | 3 — 10 | 5 — 40 | 179 — 136; 89 — 46 | U4 | ||

| Single-sided with removable or remaining lining | — | 3 — 10 | 3 — 10 | 5 — 40 | 179 — 136 | U7 | |||

| Bilateral | — | 3 — 10 | 3 — 10 | 5 — 40 | 179 — 136; 89 — 46 | U5 | |||

| With two bevels on one edge | Bilateral | — | 6 — 20 | 6 — 20 | 6 — 100 | 179 — 165; 80 — 75 | U6 | ||

| With two bevels on one edge and one bevel on the second edge | — | 6 — 20 | 6 — 20 | 6 — 120 | 179 — 36 | U8 | |||

| With two beveled edges | Unilateral | — | 3 — 10 | 3 — 10 3 — 20 | 179 — 122 89 — 61 | U9 | |||

| 3 — 20 | 3 — 60 | 179 — 142; 89 — 71 | |||||||

| Bilateral | — | 3 — 10 3 — 20 | 3 — 10 3 — 20 | 179 — 122 89 — 61 | U10 | ||||

| 3 — 60 | 179 — 142; 89 — 71 | ||||||||

| Tavrovoe | No beveled edges | Unilateral | — | 0,8 — 10,0 | 0,8 — 40,0 | 0,8 — 40,0 | 91 — 175 | T1 | |

| Bilateral | — | 0,8 — 10,0 | 0,8 — 40,0 | 0,8 — 40,0 | 91 — 135; 89 — 45 | T2 | |||

| With one edge beveled | Unilateral | — | 0,8 — 10,0 | 0,8 — 40,0 | 0,8 — 40,0 | 89 — 45; 91 — 135 | T5 | ||

| Bilateral | — | 0,8 — 10,0 | 0,8 — 40,0 | 0,8 — 40,0 | 89 — 46; 91 — 135 | T6 | |||

| Unilateral | — | 4,0 — 10,0 | 4,0 — 10,0 | 4,0 — 40,0 | 91 — 134 | T3 | |||

| Bilateral | — | 4,0 — 10,0 | 4,0 — 10,0 | 4,0 — 40,0 | 91 — 134 | T4 | |||

| With two bevels on one edge | Bilateral | — | 6 — 20 | 6 — 60 | 6 — 20 | 91 — 100; 89 — 80 | T7 | ||

| With two asymmetrical bevels on one edge | — | — | 12 — 100 | 12 — 100 | 101 — 110; 79 — 70 | T8 | |||

| With two curved bevels on one edge | — | — | 18 — 100 | 18 — 100 | 91 — 105; 89 — 75 | T9 | |||

Table 2 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | yeah, no more | b | g | h, no less | |||||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | Nom. | Prev. off | ||||||

| 179 — 160 | 159 — 136 | 135 — 91 | ||||||||||

| U2 | IN | From 0.5 to 3.0 | S+5 | S+6 | 0 | +0,5 | 0 | ±0,5 | S | |||

| INp | From 0.8 to 1.0 | S+6 | 0,5 | |||||||||

| St. 1.0 to 2.0 | +1,0 | |||||||||||

| St. 2.0 to 3.0 | 1 | ±1,0 | 1,0 | |||||||||

| IP | From 0.8 to 1.0 | S+6 | 0 | 0,5 | ||||||||

| St. 1.0 to 2.0 | +1,5 | 1,0 | ||||||||||

| St. 2.0 to 4.0 | 1 | +1,0 | 1,5 | 3 | ||||||||

| UP | From 0.8 to 1.0 | 1,0 | ||||||||||

| St. 1.0 to 3.0 | ||||||||||||

| St. 3.0 to 4.0 | 1,5 | |||||||||||

| St. 4.0 to 6.0 | 2 | ±1,0 | 2,0 | ±1,0 | ||||||||

| St. 6.0 to 8.0 | ||||||||||||

Table 3 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | e, no more | b | g | ||||||||

| prepared edges of welded parts | weld | b, deg | ||||||||||||

| 179 — 160 | 159 — 136 | 135 — 81 | 89 — 61 | 60 — 46 | 45 — 5 | Nom. | Prev. off | Nom. | Prev. off | |||||

| U1 | IN | From 0.5 to 1.0 | S+5 | S+6 | S+6 | S+4 | 1.75S+b | 2S+b | 0 | +0,5 | 0,5 | +0,5 | ||

| St. 1.0 to 2.0 | +1,0 | 1,5 | ||||||||||||

| St. 2.0 to 4.0 | +1,5 | |||||||||||||

| INP IP UP | From 0.8 to 2.0 | S+5 | +0,5 | 1,0 | ||||||||||

| St. 2.0 to 4.0 | 1,5 | |||||||||||||

| St. 4.0 to 6.0 | +1,0 | |||||||||||||

| UP IP | St. 6.0 to 30.0 | — | — | 2 | +2,0 — 1,0 | 2,0 | +1,0 — 2,0 | |||||||

Table 4 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | yeah, no more | e1 | b | g | ||||||||||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | Nom. | Prev. off | |||||||||||

| 179 — 160 | 159 — 136 | 135 — 91 | 89 — 61 | 60 — 45 | 179 — 91 | 89 — 45 | |||||||||||

| U3 | IN | From 3 to 4 | S+5 | S+6 | — | — | — | No more than 8 | 3 (informative) | 0 | +0,5 | 0 | +0,5 | ||||

| St. 4 to 6 | +1,0 | ||||||||||||||||

| INP IP | From 3 to 4 | S+8 | S+b | 1.75S+b | 1 | ±1,0 | |||||||||||

| St. 4 to 6 | |||||||||||||||||

| St. 6 to 10 | — | 2 | +2,0 — 1,0 | ||||||||||||||

| IP | St. 10 to 30 | ||||||||||||||||

| UP | From 3 to 4 | S+5 | S+5 | (S?4)+b | |||||||||||||

| St. 4 to 6 | S+7 | ||||||||||||||||

| St. 6 to 12 | S+8 | 2 | |||||||||||||||

| St. 12 to 14 | — | S+10 | |||||||||||||||

| St. 14 to 18 | |||||||||||||||||

| St. 18 to 30 | |||||||||||||||||

| St. 30 to 60 | S+12 | — | — | No more than 10 | |||||||||||||

Table 5 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | e, no more | a1, deg | b=c | g | a, deg, (limit deviation ±2°) | ||||||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | Nom. | Prev. off | ||||||||

| 179 — 136 | 89 — 46 | St. 90 | Up to 90 | |||||||||||

| U4 | INP IP | From 3 to 6 | 1.4S+4 | 1.5S+4 | a - (180 - b) | a - (90 - b) | 1 | ±1,0 | 1 | ±1,0 | 50 | |||

| St. 6 to 10 | 1.4S+4 | |||||||||||||

| UP | From 5 to 8 | 1.1S+4 | 2 | 45 | ||||||||||

| St. 8 to 10 | S+3 | |||||||||||||

| St. 10 to 30 | S+3 | 0.9S+4 | 2 | +1,0 — 2,0 | ||||||||||

| St. 30 to 40 | — | |||||||||||||

Table 6 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | yeah, no more | a1, deg | b | c | g | a, deg, (limit deviation ±2°) | ||||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | Nom. | Prev. off | Nom. | Prev. off | |||||

| 179 — 136 | |||||||||||||

| U7 | INP IP | From 3 to 6 | 1.4S+4 | a - (180 - b) | 0 | +3 | 1,0 | +1,0 | 1 | +0.5 — 1,0 | 50 | ||

| St. 6 to 10 | 1.4S+6 | 1,5 | ±1,0 | ||||||||||

| UP | From 5 to 8 | 1.1S+4 | 2 | ±1 | 0 | +3,0 | 45 | ||||||

| St. 8 to 10 | S+3 | ||||||||||||

| St. 10 to 30 | 3 | ±2 | 2 | +1,0 — 2,0 | |||||||||

| St. 30 to 40 | 4 | ||||||||||||

Table 7 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | yeah, no more | e1 | a1, deg | With | g = g1 | a, deg, (limit deviation ±2°) | ||||||

| Prepared edges of parts to be welded | weld | b, deg | |||||||||||||

| 179 — 136 | 89 — 46 | St. 90 | Up to 90 | St. 90 | Up to 90 | Nom. | Prev. off | Nom. | Prev. off | ||||||

| U5 | INP IP | From 3 to 6 | 1.4S+4 | 1.5S+4 | No more than 6 | 3 (informative) | a - (180 - b) | a - (90 - b) | 1,0 | +1,0 | 1,0 | +0,5 — 1,0 | 50 | ||

| St. 6 to 10 | 1.4S+6 | No more than 8 | 1,5 | ±1,0 | |||||||||||

| UP | From 5 to 8 | 1.1S+4 | 2,0 | +1,0 — 2,0 | 45 | ||||||||||

| St. 8 to 10 | S+3 | ||||||||||||||

| St. 10 to 30 | S+3 | 0.9S+4 | 2,0 | +1,0 — 2,0 | |||||||||||

| St. 30 to 40 | — | ||||||||||||||

Table 8 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | h | e = e1 | e | e1 | a1 | a2 | a1 | a2 | b | g = g1 | g | a, deg, (limit deviation ±2°) | With | |||||||||||||||

| no more | hail | ||||||||||||||||||||||||||||||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | St. 90 | up to 90 | Nom. | Prev. off | |||||||||||||||||||||||

| 179 — 175 | 89 — 85 | 174 — 170 | 84 — 80 | 169 — 165 | 79 — 75 | 174 — 170 | 84 — 80 | 169 — 165 | 79 — 75 | St. 90 | up to 90 | Nom. | Prev. off | Nom. | Prev. off | ||||||||||||||||

| U6 | INP IP | From 6 to 20 | S+2 | 0.8S+1 | 0.8S+5 | 0.7S+5 | 0.9S+10 | 1.2S+8 | a - (180 - b) | a+(180 - b) | a - (90 - b) | a+(90 - b) | 1 | ±1 | 1 | ±1 | 1 | ±1 | 50 | 1 | ±1 | ||||||||||

| UP | From 6 to 20 | 0.8S | 2 | +1 — 2 | 45 | ||||||||||||||||||||||||||

| St.20 to 30 | 0.7S | 2 | +1 — 2 | 2 | +1 — 2 | ||||||||||||||||||||||||||

| From 30 to 70 | 0.6S | ||||||||||||||||||||||||||||||

| St. 70 to 100 | 0.5S | ||||||||||||||||||||||||||||||

Table 9 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | h = h1 | e = e1 no more | a1, deg | a2 = a3, deg | b | g = g1 | c | a, deg, (limit deviation ±2°) | ||||

| prepared edges of welded parts | weld | b, deg | Nomin | Prev. off | Nomin | Prev. off | Nom. | Prev. off | |||||||

| 179 — 136 | |||||||||||||||

| U8 | INP IP | From 6 to 20 | 0.8S+3 | 1 | ±1 | 1 | ±1 | 1 | ±1 | 60 | |||||

| UP | From 6 to 20 | 2 | +1 — 2 | 45 | |||||||||||

| St. 20 to 40 | 2 | +1 — 2 | |||||||||||||

| From 40 to 80 | 0.7S+2 | 2 | +1 — 2 | ||||||||||||

| St. 80 to 120 | 0.6S+4 | ||||||||||||||

Table 10 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | yeah, no more | a1 = a2 | b | c | g | a, deg, (limit deviation ±2°) | ||||||||

| b, deg | |||||||||||||||||

| prepared edges of welded parts | weld | 179 — 142 | 141 — 122 | 89 — 71 | 70 — 61 | St. 90 | Up to 90 | Nom. | Prev. off | Nom. | Prev. off | Nom. | Prev. off | ||||

| U9 | INP IP | From 3 to 10 | 0.8S+3 | S+5 | 1 | ±1 | 1 | ±1 | 1 | ±1 | 30 | ||||||

| St. 10 to 20 | — | ||||||||||||||||

| UP | From 3 to 8 | 0.8S+3 | — | 0.8S+3 | — | 20 | |||||||||||

| St. 8 to 22 | 2 | +1 — 2 | 2 | +1 — 2 | |||||||||||||

| St. 22 to 60 | 0.7S+2 | 2 | +1 — 2 | ||||||||||||||

Table 11 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | yeah, no more | a1 = a2 | e1, (limit deviation ±2°) | b | c | g | a, deg, (limit deviation ±2°) | ||||||||

| b, deg | ||||||||||||||||||

| prepared edges of welded parts | weld | 179 — 142 | 141 — 142 | 89 — 71 | 70 — 61 | St. 90 | Up to 90 | Nom. | Prev. off | Nom. | Prev. off | Nom. | Prev. off | |||||

| U10 | INP IP | From 3 to 10 | 0.8S+3 | S+5 | 6 | 1 | ±1 | 1 | ±1 | 1 | ±1 | 30 | ||||||

| St. 10 to 20 | — | 8 | ||||||||||||||||

| UP | From 3 to 8 | 0.8S+3 | — | 0.8S+3 | — | 6 | 20 | |||||||||||

| St. 8 to 22 | 8 | 2 | +1 — 2 | 2 | +1 — 2 | |||||||||||||

| St. 22 to 60 | 0.7S+2 | 10 | 2 | +1 2 | ||||||||||||||

Table 12 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | yeah, no more | g, no less | b | ||||||||||

| b, deg | ||||||||||||||||

| prepared edges of welded parts | weld | 91 — 100 | 101 — 110 | 111 — 120 | 121 — 135 | 136 — 175 | 175 — 136 | 135 — 91 | Nom. | Prev. off | ||||||

| T1 | INP IP UP | From 0.8 to 2.5 | 4 | 5 | l.5±1.0 | 3 | 0 | +1,0 | ||||||||

| See 2.5 to 4.5 | 7 | |||||||||||||||

| St. 4.5 to 6.0 | 5 | 8 | ||||||||||||||

| St. 6.0 to 10.0 | 6 | 0.4S+5 | 0.6S+5 | 0.9S+5 | 1.1S+5 | |||||||||||

| IP UP | St. 10.0 to 16.0 | 8 | +1,5 | |||||||||||||

| St. 16.0 to 20.0 | 9 | 5 | ||||||||||||||

| St. 20.0 to 4i0.0 | 0.5S | 0.3S | ||||||||||||||

Table 13 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | e, no more | e1, no less | b | g | ||||||||||||

| b, deg | |||||||||||||||||||

| prepared edges of welded parts | weld | 90 — 100 | 89 — 80 | 101 — 110 | 79 — 70 | 111 — 120 | 69 — 60 | 121 — 134 | 59 — 46 | 135 | 45 | Nom. | Prev. off | Nom. | Prev. off | ||||

| T2 | INP IP UP | From 0.8 to 2.5 | 4 | 0.4S+5 | 0.6S+5 | 0.9S+5 | 1.1S+5 | 4 | 0 | +0,5 | 3 | ±2 | |||||||

| St. 2.5 to 6.0 | 5 | 5 | +1,0 | 4 | |||||||||||||||

| St. 6.0 to 10.0 | |||||||||||||||||||

| IP UP | St. 10.0 to 16.0 | 6 | 6 | +2,0 | 5 | ||||||||||||||

| St. 16.0. up to 20.0 | 8 | 8 | 6 | ||||||||||||||||

| St. 20.0 to 24.0 | 0.5S | 10 | 7 | ||||||||||||||||

| St. 24.0 to 30.0. | 8 | ||||||||||||||||||

| St. 30.0 to 40.0 | 9 | ||||||||||||||||||

Table 14

Dimensions, mm

| Connection designation | Structural elements | Welding method | S | e = g | a1, deg | b | |||||||

| Nom. | prev off | ||||||||||||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | |||||||||

| 89 — 45 | 91 — 135 | 89 — 45 | 91 — 135 | St. 90 | Up to 90 | ||||||||

| T5 | INP IP UP | From 0.8 to 2.5 | 2 | 3 | +1 | b - 90 | 90 - b | 0 | +0,5 | ||||

| St. 2.5 to 4.0 | 3 | 4 | +2 | +1,0 | |||||||||

| St. 4.0 to 6.0 | 4 | 6 | +2 — 1 | ||||||||||

| St. 6.0 to 10.0 | 5 | 7 | |||||||||||

| IP UP | St. 10.0 to 15.0 | 6 | 8 | ±2 | +1,5 | ||||||||

| St. 15.0 to 21.0. | 7 | 9 | +2,0 | ||||||||||

| St. 21.0 to 30.0 | 8 | 10 | |||||||||||

| St. 30.0 to 40.0 | 9 | 12 | |||||||||||

Table 15 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | e = g | a1, deg. | b | |||||||

| Nom. | Prev. off | ||||||||||||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | |||||||||

| 89 — 45 | 91 — 135 | 89 — 45 | 91 — 135 | St. 90 | Up to 90 | ||||||||

| T6 | INP IP UP | From 0.8 to 2.5 | 2 | 3 | +1 | b - 90 | 90 - b | 0 | +0,5 | ||||

| St. 2.5 to 4.0 | 3 | 4 | +2 | +1,0 | |||||||||

| St. 4.0 to 6.0 | 4 | 5 | +2 — 1 | ||||||||||

| St. 6.0 to 10.0 | 5 | 6 | +1,5 | ||||||||||

| IP UP | St. 10.0 to 15.0 | 6 | 7 | ||||||||||

| St. 15.0 to 21.0 | 7 | 9 | +2 | +2,0 | |||||||||

| St. 21.0 to 30.0 | 8 | 10 | |||||||||||

| St. 30.0 to 40.0 | 12 | 15 | |||||||||||

Table 16 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | yeah, no more | b | c | g | a1, deg | a, deg, (limit deviation ±2°) | |||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | Nom. | Prev. off | ||||||

| 91 — 134 | ||||||||||||

| T3 | INP IP | From 4 to 6 | 1.4S+2 | 0 | +1 | 1,5 | +1,0 | 0.15S - 0.5S | a - (b - 90) | 55 | ||

| St. 6 to 10 | 1.3S+5 | +2 | ||||||||||

| UP | From 4 to 6 | 1.4S+4 | 45 | |||||||||

| St. 6 to 10 | 1.3S+2 | 2,0 | +1,0 — 2,0 | |||||||||

| St. 10 to 14 | ||||||||||||

| St. 14 to 18 | ||||||||||||

| St. 18 to 22 | ||||||||||||

| St. 22 to 40 | 1.2S+2 | |||||||||||

Table 17 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | yeah, no more | a1, deg | e1 | b | g | c | a, deg, (limit deviation ±2°) | |||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | Nom. | Prev. off | |||||||

| 91 — 134 | |||||||||||||

| T4 | INP IP | From 4 to 6 | 1.4S+2 | a - (b - 90) | 3 (informative) | 1 | +1 | 0.15S - 0.5S | 1,5 | +1,0 | 55 | ||

| St. 6 to 10 | 1.3S+5 | ||||||||||||

| UP | From 4 to 6 | 1.4S+2 | 3 | +2 — 1 | 45 | ||||||||

| St. 6 to 10 | 1.3S+2 | 2,0 | +1,0 — 1,0 | ||||||||||

| St. 10 to 14 | |||||||||||||

| St. 14 to 18 | |||||||||||||

| St. 18 to 22 | |||||||||||||

| St. 22 to 40 | 1.2S+2 | ||||||||||||

Table 18 Dimensions, mm

| Connection designation | Structural elements | Assembly method | S | h | e = e1 | e | e1 | a1 | a2 | a1 | a2 | b | g = g1 | a, deg, (limit deviation ±2°) | |||||||

| No more | hail | ||||||||||||||||||||

| prepared edges of welded parts | weld | b, deg | Nom. | Prev. off | |||||||||||||||||

| 91 — 95 | 89 — 85 | 96 — 100 | 84 — 80 | 96 — 100 | 84 — 80 | St. 90 | Up to 90 | ||||||||||||||

| T7 | INP IP | From 6 to 8 | 0.7S+2 | 0.7S+4 | S+6 | a - (b - 90) | a + (b - 90) | a - (90 - b) | a + (90 - b) | 3 | +2 — 1 | 0.08S - 0.25S | 55 | ||||||||

| St. 8 to 12 | 0.7S+4 | ||||||||||||||||||||

| St. 12 to 20 | |||||||||||||||||||||

| UP | From 6 to 8 | 0.8S+4 | 0.8S+6 | S+8 | 45 | ||||||||||||||||

| St. 8 to 12 | |||||||||||||||||||||

| St. 12 to 18 | 0.7S+2 | 0.7S+5 | S+4 | ||||||||||||||||||

| St. 18 to 24 | |||||||||||||||||||||

| St. 24 to 30 | 0.6S+3 | ||||||||||||||||||||

| St. 30 to 48 | |||||||||||||||||||||

| St. 48 to 60 | 0.6S | ||||||||||||||||||||

Table 19 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | h | e | e1 | a1 | a2 | a1 | a2 | b | g = g1 | a, deg, (limit deviation ±2°) | |||||||||||

| no more | hail | |||||||||||||||||||||||

| prepared edges of welded parts | weld | b, deg | ||||||||||||||||||||||

| 101 — 105 | 79 — 75 | 106 — 110 | 74 — 70 | 101 — 105 | 79 — 75 | 106 — 110 | 74 — 70 | St. 90 | Up to 90 | Nom. | Prev. off | Nom. | Prev. off | |||||||||||

| T8 | IP UP | From 12 to 22 | 0.8S+5 | 0.6S+6 | S+8 | 1.2S+5 | a - (b - 90) | a + (b - 90) | a - (90 - b) | a + (90 - b) | 2 | ±2 | 4 | ±2 | 45 | |||||||||

| St. 22 to 34 | 1.3S+6 | 6 | ||||||||||||||||||||||

| St. 34 to 46 | 8 | |||||||||||||||||||||||

| St. 46 to 58 | 10 | |||||||||||||||||||||||

| St. 58 to 76 | 12 | |||||||||||||||||||||||

| St. 76 to 100 | 14 | |||||||||||||||||||||||

Table 20 Dimensions, mm

| Connection designation | Structural elements | Welding method | S | e = e1 (limit deviation ±2) | a1 | a2 | a1 | a2 | b | g = g1 | a, deg, (limit deviation ±2°) | ||||

| prepared edges of welded parts | weld | hail | |||||||||||||

| b, deg | Nom. | Prev. off | Nom. | Prev. off | |||||||||||

| 91 — 105 | 89 — 75 | St. 90 | Up to 90 | ||||||||||||

| T9 | IP UP | From 18 to 40 | 0.7S | (20 ± 2) - (b - 90) | (20 ± 2) + (b - 90) | (20 ± 2) - (90 - b) | (20 ± 2) + (90 - b) | 0 | +1 | 6 | 2 | 45 | |||

| Over 40 to 50 | 0.6S | 7 | |||||||||||||

| St. 50 to 100 | 8 | ||||||||||||||

5. For welded joints U7, U5, U6, U8, T7, T8, T9, performed by welding in carbon dioxide, a bluntness of C = 5 ± 2 mm is allowed. 6. Welding parts of unequal thickness if the difference in thickness does not exceed the values specified in the table. 21, should be made in the same way as for parts of the same thickness; the structural elements of the prepared edges and the dimensions of the weld should be selected according to their greater thickness.

Table 21 mm

| Thickness of thin part | Part thickness difference |

| 2 — 3 | 1 |

| 4 — 30 | 2 |

| 32 — 40 | 4 |

| Over 40 | 6 |

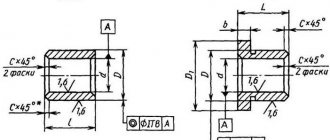

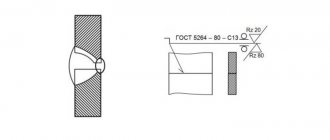

If the difference in the thickness of the parts being welded exceeds the values indicated in the table. 21 on a part with a large thickness S1, a bevel should be made on one or both sides to the thickness of the thin part at an angle of 15°, as indicated in Fig. 1 and 2.

Crap. 1

Crap. 2

7. The dimensions of the seams made in the overlap area for closed connections, as well as in places corrected by welding, may differ from those established by this standard. In this case, they must comply with regulatory and technical documentation. 8. With a variable mating angle b of the parts, the seam is divided into sections. Each section of mating elements is made in accordance with the requirements of this standard. 9. When welding in carbon dioxide with wire with a diameter of 0.8 - 1.4 mm, it is allowed to use the main types of welded joints and their structural elements in accordance with GOST 11534 - 75.