01/27/2021 Author: VT-METALL

Issues discussed in the material:

- Selection of drills for drilling metal

- Marking metal before drilling

- Methods for drilling metal

- Metal drilling devices

- Final Recommendations for Drilling in Metal

Methods for drilling metal are selected depending on the parameters of the workpiece itself and the type of hole that needs to be made. The choice of auxiliary devices and lubricants also depends on the specifics of the task. In general, the drilling technology is simple, but it requires knowledge of the nuances in order to obtain a high-quality product.

It is also important under what conditions the drilling occurs. For household operations, accuracy and speed may be of secondary importance, while in manufacturing these parameters come to the fore. In our article we will tell you what methods of drilling metal exist and how to prepare the workpiece for this operation.

Selection of drills for drilling metal

Drills are needed to make holes in metal. They are rods made from an alloy that must be harder than the workpiece material. Such devices are made from steel with the designation HSS - grades P18, P6M5, P9 (high-speed steel) or use hard alloys specially created for working with hard-alloy, hardened parts. Their brands are VK and T5K10.

Drills consist of three main parts:

- edges that are designed to penetrate holes and remove a thin layer of the material being processed;

- spiral cutting, designed for removing chips from the hole;

- shank used to secure the drill bit in the tool.

First, let's take a closer look at the cutting edges. They are bevels converging at the top, forming a jumper. The angle of convergence of the bevels, called the main one, varies and depends on the selected processing mode of the workpiece and its material.

The angle is standardized:

- for stainless and hard steel the angle should be from 135° to 140°;

- for structural steel – 135°;

- for aluminum, brass and bronze – from 115° to 120°;

- for copper – 100°;

- for cast iron - clearance angle is 120°, and the edge sharpening angle is 90°.

The drill has two edges, which are sharpened at an angle from 20° to 35°. They determine the sharpness of the instrument. The edge angle is called the back angle. The drill touches the workpiece surface in accordance with this parameter. At the same time, there will be free space behind it. This shape makes it easy to remove and throw away chips from the work site. The angle can be different, sometimes it is up to 90°. Increasing its value is necessary for processing fragile workpieces made of materials such as brass, cast iron, and bronze.

Spiral cutting is grooves that help remove chips. Each of them has its own edge. Their planes are always parallel to the axis of rotation of the drill. This edge is called “ribbon”. Its task is to clean the walls of the hole being made with the centering of the drill.

Marking metal before drilling

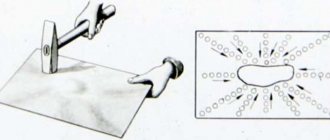

Before you start drilling metal using different methods, be sure to mark the hole. Using a punch, mark the place on the surface of the product where the slot will be made. In addition to the center punch, a marker can be used. However, this is less convenient, since you will have to constantly monitor the location of the drill at the selected point. The punch makes a small depression at the drilling site. To do this, it is hit with a hammer. The resulting outline will be convenient for further work.

VT-metall offers services:

Precision can be increased by pre-drilling. Notches are made on the surface of the workpiece with a chisel, designed to guide the tool towards the hole.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

If it is necessary to produce several holes in workpieces, a template is used. Thus, several sheets of metal are drilled at once, which are connected with a clamp.

A jig is used to make precise holes that must be angled. This is a small strip with templates for holes located on it. Such devices are used in various industries.

Currently, several types of conductors are used, for example:

- universal;

- fastened;

- turning;

- sliding;

- overhead.

Tools for marking and techniques for marking center holes

There are several ways to mark center holes using a marking compass, a center finder, or a device (bell).

Before marking, the ends are usually painted over with chalk and copper sulfate solution so that the marks that determine the position of the center holes are more noticeable. Then they mark it.

Marking using a marking compass

The legs of the compass are moved apart to a distance approximately equal to the radius of the part. A curved leg is applied to the circumference of the end of the part clamped in a vice, and an arc is drawn with a pointed leg near the center of the end.

Three more arcs are carried out in the same way, each time moving the curved leg of the compass by approximately 1/4 of the circumference of the end.

The drawn four arcs form a curvilinear quadrilateral.

The center of the hole should be in its middle. The center is marked by eye and then marked, as shown in the figure below.

Methods for drilling metal

1. Simple drilling.

A familiar technique for making holes in metal:

- Surface marking.

- Marking the location of the future hole with a center punch and hammer.

- Clamping the workpiece with a vice or clamp.

- Installing a drill of the selected diameter into the tool.

- Tool centering.

- Drilling a hole (blind or through).

2. Reaming.

Reaming a workpiece is a technology for increasing the diameter of a hole that was previously made using drills of a larger diameter.

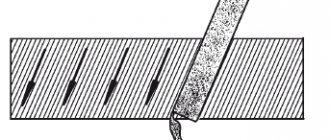

When working in small-scale production or at home, stage-by-stage drilling is used. It occurs by a gradual increase in the diameter of the tool. The reason lies in the tool used, which cannot immediately make a hole significantly different from the existing one in a thick product. With step-by-step drilling, the axial pressure on the tool (drill) is significantly reduced, which reduces the possibility of breakage.

3. Reducing the diameter at the depth of the hole.

The technology consists of several stages. First, a thick drill is used, and then a smaller diameter.

4. Technology of deep drilling of workpieces.

According to technology, holes are considered deep if their diameter is 25 or more times less than its length. The work is complicated by the need to stop drilling and remove chips from the hole, as well as lubricate it with coolant. It is used to cool the drill and helps prevent its deformation (or breakage).

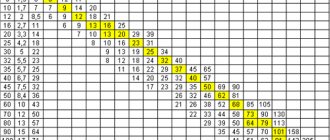

Deep drilling involves the use of various types of cutting fluids. The most effective of them are the following:

| Product material | coolant |

| Heat-resistant and stainless alloys | The composition includes sulfofresol and oleic acid in a proportion of 80x20%. Instead of sulforesol, you can use a mixture of sulfurized oil (50%) and kerosene (30%) |

| Aluminum and its alloys | Various mixed oils, emulsion, kerosene are used. Drilling can take place without cooling |

| Nickel | Emulsions |

| Copper | Mixed oils and emulsions are used. Drilling can take place without cooling |

| Brass | 3–5% emulsion. Drilling can take place without cooling |

| Zinc | Emulsions |

| Bronze | Blended oils. Drilling can take place without cooling |

| Iron casting | 3–5% emulsion and kerosene. Drilling can take place without cooling |

| Malleable iron | 3–5% emulsion |

| Alloy steel | Mixed oils |

| Tool steel | Mixed oils |

| Structural steel | Kerosene and sulfurized oil |

| Carbon steel | Emulsion and sulfurized oil |

Deep drilling occurs using special metal drills (core, spiral). Cooling fluids are supplied automatically. Machines for making deep holes are equipped with special automatic feeding systems.

Deep drilling should be done slowly, with stops, removing the drill from the hole, and clearing it of chips. Drilling using twist drills occurs in several stages, with the tool changing from a small diameter to a larger one.

5. Technology for processing thick sheets of metal.

Sheets of thick metal are drilled using core or cone drills. Their choice depends on the required hole diameter. If it is less than 30 mm, then use conical ones. If more, then use core drills. They are installed in high-power drills or in special drilling machines, which must operate at the lowest speeds.

The most effective technology for making holes using core drills is recognized. The reason is low energy costs. In addition, the holes are precise with smooth walls.

6. Technology for making holes in thin sheets of metal.

Thin sheets of metal are drilled, as a rule, with conical drills, gradually increasing their diameter. In this way, deformation of the workpieces is avoided.

If there are stepped cone drills, then they are used. Using marked steps makes it much easier to make multiple holes of different diameters (or just one) on a sheet of thin metal.

7. Features of manufacturing through holes in metal blanks.

An important step in through drilling is to protect the working surface from damage by the drill when it exits from the back side of the workpiece. There are several ways to prevent furniture damage:

- Drilling is carried out on workbenches equipped with holes.

- A wooden block or a metal device with holes for the passage of the drill is placed under the workpiece.

- Significantly reduce the processing speed at the end of drilling.

8. Features of manufacturing blind holes in metal blanks.

Holes of a certain depth are called blind. There are a number of methods for installing it:

- a special ruler with which the machine is equipped;

- using sleeve stops for drills;

- limiting the drilling depth with chucks on which the stop is adjusted.

Feeding systems on modern equipment are automated, which greatly simplifies the production of blind holes in metal. To do this, work parameters are set.

Important! The technology for producing long blind holes in parts made of thick sheets of metal involves stopping and removing chips from the hole.

9. Technologies for making complex holes in metal products.

Complex holes are considered, for example, half holes, which are made at the edge of the part. They do this as follows:

- use a vice to clamp parts or workpieces with a tightly pressed lining;

- center the drill at the joint of the workpieces;

- make a hole.

The process of drilling holes in cylindrical workpieces is more complicated. It is divided into two stages:

- a platform is placed perpendicular to the hole using a countersink or milling;

- the hole itself is made.

Angled holes are made as follows:

- a platform is being made;

- the lining is installed at the required angle;

- a hole is drilled.

Wood blocks are placed under the hollow parts before drilling. The production of holes with ledges occurs using the technology described earlier (drilling, reducing the diameter of the hole).

Metal drilling devices

Various methods of drilling metal involve the use of cutting fluids. In most cases, they are used to reduce friction and equalize the temperature of the surface being processed and the tool. Good quality coolant will not cause corrosion, it is completely safe to use, it has no odor, and fully performs its function.

As a lubricant for drilling metal workpieces at home, you can take:

- Technical Vaseline - used primarily for drilling soft materials.

- Soap solution - used for aluminum parts.

- Turpentine with alcohol is used for silumin.

- A mixture of various oils is applied for processing steels (tool or alloy).

Sometimes a fairly universal lubricant composition is used, which is made from a mixture of laundry soap (200 g) and motor oil (20 g), followed by boiling to an emulsion.

There are industrial coolants. Their use makes it possible to increase the speed of work with different types of metal. Working with stainless steel is 30% faster. With cast iron the growth is even higher – 40%.

How to drill with a drill?

Drilling metal with a drill requires following some recommendations:

- To make a hole you will need an electric drill, a core punch, a hammer, machine oil and safety glasses.

- Initially make markings.

- Wear safety glasses.

- When the pressure on the drill is low, you need to select the low speed position and start working.

- Don’t forget to water the area being treated with coolant.

If you follow the technology and use high-quality tools, you can make holes of different diameters and depths. To drill straight holes or accurately select the depth, you can use a device called a “depth stop.” It is attached to an electric drill and adjusted to the desired depth.

Drilling metal with a drill

Final Recommendations for Drilling in Metal

In conclusion, it is important to note the need to comply with safety regulations, as well as to prevent defects and accelerated wear of tools. Let's give some useful tips:

- Before starting drilling, always check that all parts of the tool and workpiece are secure.

- Clothing should be comfortable and not have parts that could get caught in the rotating parts of the machine. The use of safety glasses is mandatory.

- Contact with the workpiece should only occur when the drill is rotating. Otherwise, it will quickly become dull.

- The reverse movement of the drill when removing it from the hole should occur with the drill turned on at low speed.

Advice from the experts

When carrying out work, I advise professionals to pay attention to the following features. They are divided into three categories:

- preliminary (preparatory) stage;

- stage of work;

- compliance with safety regulations.

At the first stage you need:

- select the necessary equipment (machine, electric or hand drill), depending on existing capabilities;

- based on standards and reference literature, determine cutting modes and acceptable types of drills for future operations;

- choose a marking tool (if this is not available, make it yourself);

- select a drill fixation device.

The preliminary stage should end with checking the reliability of the fastening of the drill and the workpiece. If a drill lock is used, its reliability should be checked.

Work on drilling holes must be carried out in strict sequence with the drawn up technological map or technical process. Particular attention should be paid to:

- the drill must be brought to the location of the future hole only after it has reached the specified rotation speed;

- The drill should be removed only while it is rotating (preferably at minimum speed if it is possible to change the rotation speed);

- monitor the cutting process (for example, if the cutting edge does not perform a drilling operation, therefore, the drill material is softer than the workpiece material);

- for drilling non-through holes, it is necessary to provide a clamp or mark that allows you to determine the depth of the passage in the material;

- When working on CNC-equipped machines, it is necessary to control the sequence of operations performed.

An important element when carrying out drilling work is compliance with safety regulations. It requires compliance with the following rules:

- ensuring reliable fastening of all structural elements;

- organizing conditions for removing the resulting chips;

- compliance with the temperature regime (preventing overheating of the drill and workpiece);

- use of special clothing and protective equipment (hands, eyes, open areas of the body);

- there should be no loose elements hanging on the clothing;

- long hair should be tucked into a headdress (this will prevent it from getting wrapped around the rotating elements of the machine).

Using professional advice will allow you to perform the drilling operation efficiently and obtain holes with a high degree of accuracy in the places specified in the design documentation.