You can bend a metal product in different ways, but without special tools the quality will be low. Using an edge bender you can solve many issues related to the preparation of parts from metal sheets.

Its features:

- possibility of bending to a specific length,

- no weld seams.

This makes it possible to prevent the formation of corrosion in the future and to produce elements of increased strength. The technique of working with the technical tool is simple. On its scale, it is enough to set the necessary bending parameters, insert a plane between the main and clamping parts and, moving, bend the edge.

This does not require significant effort or heating of the metal. Processing of products made of copper, aluminum, metal alloys and carbon steel is carried out by bending on machines or manually.

Device of manual edge benders

Edge bending machines are designed in such a way that the force acts simultaneously along the entire length of the edge or sheet blank. As a result, at the same time, the edge is deformed, but the metal does not warp, but lies in an even seam.

The designs of such equipment are divided into types:

- rotary,

- press,

- rotary.

The modern market provides the opportunity to purchase different designs of sheet bending devices, but you can make them yourself.

Edge bending tools are similar in appearance to sheet bending products, but the devices are structurally different from each other. The length of the flanging working area for manual edge benders can be small, because the parameters of the bead height and radius of curvature do not change.

If, with a large extent of edge formation, it is necessary to carry out the process simultaneously, the principle of operation of the edge bender is more similar to the sheet bending technology; the difference, in fact, is only in the method of pressing the workpiece.

Homemade hole punch

You can make a hole punch yourself, especially if you understand the principle of its operation and know how to connect the necessary parts together. Each craftsman comes up with his own design, but their basis is approximately the same:

- There must be a motor or several that puts the structure into action and runs from some kind of power source. Some people order motors separately, new and simple ones. Others take them from already unused household appliances, such as a sewing machine.

- You need needles to make holes. The main requirement for them is strength. And if you notice that even the needles of a hole punch purchased in a store quickly begin to bend, then you can safely replace them with self-tapping screws. The holes are made even better, it is easier to thread wire through them, and they will last much longer.

- For the base, you can take any boards or scraps from furniture, beehives and other wooden scraps that you have.

- Some attach a handle and fastenings for the planks to the structure, as on purchased models, while others do without them, simply holding the plank with their hands.

This is interesting Frameless beekeeping for beginners

The advantage of a homemade hole punch is that you can make the desired number of holes in the slats, place them at the distance you like, and the ability to experiment.

Let us describe a short instruction for one of the do-it-yourself hole punch options:

- You will need a motor, a movable table or furniture scraps for the base, diodes from old equipment, a limit switch, a toggle switch, furniture ball guides, screws, drills and screws for fastening.

- Make a base out of boards, attach screws to the motors and fasten them at the required distance from each other.

- Connect all the elements together according to the diagram.

You can make such a device in one evening and you have your own hole punch, which will save a lot of time.

Video: hole punch for frames - save time and labor costs.

Areas of application

Metal bending devices are used in various industries. They are used to create folds from roofing iron, make rectangular air ducts from tin or metal sheets, prepare the edges of products for welding, and parts of geometric shapes. Manual edge benders are actively used for construction and repair work. They are in demand during car repairs.

Among the advantages of this technology, in addition to the small thickness of the resulting edges and the low cost of rolled metal, one should add high resistance to wear.

Main varieties

Edge bending equipment is available in the form of mobile and stationary models. The designs of the machines are massive and practically cannot be disassembled.

They are mounted directly at the place of use, and are moved only with the help of technical means.

Models can be:

- manual,

- pneumatic,

- hydraulic.

A special place in the product line belongs to segmented manual devices intended for the manufacture of cases, boxes, i.e. products “closed” on all sides.” Due to the different configurations, the segments can be installed arbitrarily. Such equipment allows you to obtain any bending length that does not exceed the working length of the machine.

Tool models differ from each other not only in power, efficiency and thickness of the materials processed, but also in the type of metal.

Portable models of edge benders with gradual shaping consist of:

- two rubberized handles, one can be movable, the other cannot,

- lever system for applying force,

- working jaws with a profile corresponding to the edge parameters

- adjustable travel stop in the form of a slotted screw equipped with a thread.

Roller-type hand-held products have the simplest design. The whole process is carried out by a handle, and the main task of deforming the metal is performed by rollers. The bending width is regulated by a special limiter installed on the tool guides.

In a roller edge bender, friction during sliding of the jaws replaces rolling friction during rotation of the rollers. In this case, the forming force is significantly reduced, but the design of the tool is less universal, because it is impossible to change the edge formation parameters due to one pair of rollers. In addition, edge benders with rollers do not make it possible to carry out beading of small radii inside the product.

A significant disadvantage of portable models of hand tools is their lack of accuracy. As the device moves along the line of the future edge, the error gradually increases, which can reach more than a millimeter. This is unacceptable for work such as auto body repair, so the quality of the edges depends on the experience of the specialist. Because of these technical characteristics, it is advisable to use a roller edge bender only for solving simple problems.

A machine with a hydraulic drive is more functional. Thanks to its high power, it copes well with workpieces made of metal sheets, even of considerable thickness.

Preparation of materials and tools

To make a sheet metal bending machine, you cannot do without the following tools and consumables:

- electric drill and a set of drills of various diameters;

- grinder, as well as cutting and grinding discs for it;

- welding machine and set of electrodes;

- workbench vice, set of clamps;

- a set of hand tools (hammer, sledgehammer, pliers, punch, chisel file).

To connect the tool, if there is no outlet located in the yard near the work site, you will need a reel-to-reel extension cord of the required length.

As consumables you need:

- corner profile made of thick-walled steel;

- bolts, nuts and washers (you can use screw washers);

- channel (U-shaped profile with partially sharpened edges);

- rule (if it is this that is used as the trigger element);

- reinforcing rod (reinforcement with a smooth surface is acceptable);

- a set of ball bearings (if the mechanism provides for their use).

How to make a manual edge bender for auto repair

To save money, you can make a homemade edge bender for body repair. It will greatly facilitate the production of, for example, patches on the threshold or fender of a car.

In this case, the repair site will not protrude above the surface, which will reduce the time and costs of puttying and painting.

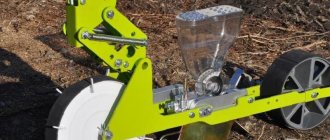

A roller model for bending sheet metal can be made from:

- pairs of bearings,

- bolt for an axle with a diameter equal to the inner diameter of the bearings,

- thick metal plate,

- handles from a grinder.

The process of making a roller model for bending sheet metal

- Cut two pieces of the same length from the bolt and place the bearings on them.

- Drill holes in the plate for welding.

- Install bearings into the plate with a distance of 1 mm from each other.

- Weld a nut for the handle from a grinder to the center of the plate on the side opposite to the bearings.

The most popular sheet bending design and its improvement

The design of a manual sheet bending machine, shown in drawing No. 1, can be easily improved. From the above drawing it can be seen that the device for bending sheet metal consists of the following elements:

Drawing No. 1: To build our sheet bending machine we will use this diagram

- pillow made of wood;

- support beam made of channel 100–120 mm;

- cheek, for the manufacture of which a sheet 6–8 mm thick is used;

- sheet of material to be processed;

- a pressure beam made of 60–80 mm corners connected by welding;

- an axis for rotating the traverse (made from a metal rod with a diameter of 10 mm);

- the traverse itself is a corner with dimensions of 80–100 mm;

- the handle of the device is made of a rod with a diameter of 10 mm.

The sheet bending traverse (item 7), which according to the original drawing is supposed to be made from a corner, is conventionally shown as a version made from a channel. Such modernization will significantly increase the endurance of the traverse, which, when using a corner, at a certain moment will inevitably bend in the middle and will no longer create a high-quality bend in the sheet in this place. Replacing with a channel will allow you to do not 200 bends without straightening or replacing this element (which is quite a bit for more or less active work), but more than 1300.

Drawing No. 2: Main elements of a sheet bending machine

Drawing No. 2 allows you to understand in more detail the design of a homemade sheet bender:

- a homemade clamp made from a suitable angle (40-60 millimeters) and a screw with a heel and a knob;

- cheek;

- channel acting as a support beam for the machine;

- a clamping beam bracket made from a 110 mm angle;

- the pressing beam of the sheet bender itself;

- axis of rotation of the traverse;

- the traverse itself.

Strengthening the pressure beam

Below we will look at the clamping bar reinforcement scheme. However, if you initially have a fairly massive corner as a clamp, and you do not plan to bend excessively thick sheets on your sheet bending machine, then it is quite possible to do without reinforcing the clamping bar in the described way.

Whether it is worth getting involved with increasing the clamping pressure depends on the operating conditions of the machine

To extend the service life of the pressure beam and make it comparable to the service life of the traverse, this structural element, which was originally made from an angle according to the drawing, should be supplemented with a base made of a metal strip with dimensions of 16x80 mm. The front edge of this base should be given an angle of 45 degrees in order to align its plane with the plane of the clamping angle itself, and the working edge of this element should be chamfered about 2 millimeters.

In drawing No. 2, the resulting part is shown in section in the additional figure at the top right. These measures will allow the clamp metal to work not in bending (which is extremely undesirable), but in compression, thereby greatly increasing the service life without repair.

You should also take care of milling the lower plane of the pressure beam, which forms the bend. The unevenness of this plane, according to generally accepted rules, should not exceed half the thickness of the workpiece being bent. Otherwise, it will not be possible to bend the workpiece evenly, without a swollen fold line. It should be borne in mind that a beam should be submitted for milling only when it already has all the welds, since their implementation leads to a change in the geometric parameters of the structure.

We increase the reliability of machine mounts

There is another big drawback in the sheet bending machine - the way it is attached to the work table. The clamps provided in this device are a very unreliable fastening option, especially considering the rapid fatigue of welds. Such fasteners can be completely abandoned, which will also avoid the need to use welded joints and jaws. The following actions can solve this problem:

- making a support beam that will protrude beyond the desktop;

- making U-shaped eyes at the ends of the support beam;

- fastening the support beam to the work table using bolts (M10) and shaped nuts with claws.

If the improved sheet bending machine no longer has jaws, how can a crossbeam be attached to it? This issue can be solved quite simply: use butterfly door hinges, which are usually used for hanging heavy metal doors. Such hinges, which ensure fairly high accuracy, can be secured using countersunk screws. This is further illustrated in drawing No. 2 at the bottom right.

You can bend a lot of workpieces on a sheet bending machine with a traverse attached to butterfly hinges, since these hinges are very reliable.

Tinsmith's Tool

Such an edge bender is necessary during auto repair for a smooth transition of the metal patch to the base. After straightening, both planes must be coaxial with each other.

On a thin sheet of iron, it is impossible to guarantee the reliability of the butt weld joint. The device allows you to prepare an edge profile for overlap welding. It greatly simplifies the process of repairing a car body if you need to bend the metal at an angle of 90 degrees, i.e. make an edge or flange. Edge bending devices for auto repair are characterized by a simple design and low price, so making them yourself is not always impractical. Sometimes it is better to buy equipment for which there is an additional use in the household.

Video instructions on how to use a tinsmith's edge bender

Types of sheet benders

For various works with metal sheets, different types of sheet bending machines are used:

- with a rotating beam;

- roller;

- roller;

- mechanical and hydraulic presses.

They differ in their technical capabilities and scope of application. All varieties can be made both in mobile or manual, and in stationary versions.

- Pipe benders with a rotating beam are the most common and convenient for DIY production. They can work with large sheets, bending both edges a few centimeters high and a wall of 30–70 cm at an angle of up to 120 0. It is also easy to bend to create a seam connection.

- A manual roller bender is used for bending edges and low walls during body repairs, roofing work, installing window sills and joining large sheets of tin. By choosing a roller profile, you can make a rather complex profiled bend, forming, for example, a fender or a fragment of a car bumper or a decorative element for finishing a fence or balcony railing.

- A roller pipe bender is used for bending semicircular gutters or full-section pipes. It can be adjusted in radius by moving the rolls: the support rolls horizontally, and the pressure rollers vertically. Such a homemade roller bender can be easily equipped with an electric drive with a chain or gear drive.

- Presses will be needed for bending both thin, up to 1 mm, and thick, up to 2–3 mm metal. They are capable of not only bending metal at an angle of up to 90 0, but also perforating it or gluing it under pressure. To change the type of operation, you only need to change the punch and die.

How they work is shown in the figure:

All types of machines are not complicated; it is only important to decide on the upcoming tasks and choose an installation model that will help solve maximum metalworking problems. For example, when making boxes or roofing work, a roller machine will be of little help, but when installing drainage systems, it will become indispensable, while a rotary machine can only partially help

Pneumatic edge bender

Particularly popular among craftsmen are edge benders with pneumatic drive, which work as a “rotary beam”. The pneumatic drive contributes to significant pressure (up to 6.2 bar) on the workpiece. But such equipment can be used when working with sheet metal no thicker than 1.2 mm. In this case, the edge width will be no more than 12 mm.

If you want to make a pneumatic machine with your own hands, you must take into account that its operation requires an air flow of at least 113 l/min.

Pneumatic punch

This is a universal tool model. On one side, the structure is equipped with a mechanism for punching holes, on the other, with jaws for forming an edge.

Thanks to this, you can simultaneously bend the edge and make holes in the metal for fasteners. That is why the tool is often called a pneumatic punch. Its working part is made of high-speed steel. The rubberized handles of the product are equipped with springs. They help reduce pressure on the palm, which facilitates the process of punching and processing.

Any model of hole punch-edge bender works much faster and more efficiently than its manual counterparts, which is why it is intensively used at service stations and car repair shops.

How to choose

The WUKO tool line includes several models of various manual sheet benders, suitable for different requirements. The principle of their operation is the same: the roller mechanism bends the edge when the tool is pulled along the sheet manually. The company's engineers in the design of the sheet bender have originally implemented the process of flanging a metal sheet: roller guides simultaneously serve as a tool handle and a metric scale, allowing you to set the required distance for bending. The video demonstrates how the tool works.

Wuko Mini Bender. The simplest model of a manual sheet bender, the Wuko Mini Bender, has one pair of rollers. Model 2022 allows you to bend from 5 to 20 mm. There are options with the possibility of obtaining a higher side: 2030 and 2050.

WUKO DUO BENDER. For higher productivity, models with two pairs of rollers are available. They also differ in the amount of bend - from 200 mm (model 3200) to 350 (model 3350). There is also a version of WUKO DUO Bender 3350 PLUS, equipped with an additional removable handle and a support bar. Models with two rows of rollers are designed to work on straight sections.

- WUKO Uni Bender. To work on curved sections, especially when constructing dome structures, it is advisable to use special manual roller benders. They have an additional support roller, which simplifies the movement of the tool along the radius.

- DISC-O-BENDER. This tool is designed for forming a recumbent seam when making horizontal seams, joining valleys, and other works.

The range of manual roller bending tools is designed for professional roofers and tinsmiths performing various tasks in the installation of seam roofing and other sheet metal products. Manual sheet benders are used as additional convenient tools for sheet bending and seam-forming machines, but if necessary, you can use a manual roller sheet bender to produce a small volume of paintings when installing the roof yourself. If you decide to use a manual roller bender to create paintings for the roof, do not forget that the formation of each bend occurs in several steps: the tool beads the edge gradually, in several passes, so the production of the entire required volume of paintings, even for a relatively small roof of a country house, will take quite a long time time.

Self-production

The design of the hand bender is simple and elegant. On the Internet you can find drawings that allow you, if you have access to lathes and milling machines and the ability to use them, to reproduce the tool yourself. However, it must be taken into account that the factory-made tool has a special coating of the rollers - the most loaded part.

A variety of products made from tin and sheet metal, obtained by bending, are popular and in demand both in professional construction and mechanical engineering, as well as for minor household repairs and household needs. A fully functional do-it-yourself sheet bender for sheets up to 1.2 mm thick from ferrous, galvanized or non-ferrous metal can be made in a home workshop or a small metalworking shop.

How does an edge bending machine work?

Structurally, a metal bending machine consists of several parts:

- supporting surface,

- working base,

- clamping element

- crimping punch,

- levers-handles.

Some models are equipped with a hole punch and a knife for trimming edges. In the standard design, the supporting plane measuring 1m x 1.5m is a table made of wood or metal with powerful legs. The horizontal fastening of the base is made from channel No. 8 or 6.5. Metal structures are connected by welding, and wooden structures are connected by bolts.

Clamp

To clamp the surface when bending the edges, the device is equipped with a pressure bar - an angle with a shelf of 0.05 m. It presses against the punch at a given angle. Holes for bolts are drilled on both sides of the clamping mechanism. Also for clamping, “lambs” with pins welded to the base are used. More complex clamping parts are equipped with springs.

Punch

To make a punch, a square section of pipe is often used. The design of a part involves its horizontal rotation around an axis. In this case, the upper edge in front of the base exactly coincides with the punch.

For this purpose, the ends are equipped with loops. The clamp is located exactly vertically so that there are no distortions when bending metal. The punch is adjacent to the edge of the base without gaps so that the fold line is accurate. When not in use, the top edge of the punch is located in the same plane as the table plane. If the design has deviations, the fixture will work, but with an increased bend radius, which leads to a rounded straight line.

Drive unit

A manual drive made from a pair of pipe sections is connected by welding to the front or side of the punch. It can be in the form of a bracket or a telescopic lever. The length of the lever is firmly fixed for specific positions using pins connecting through the holes in increments of 0.1 m. This handle helps to distribute the load evenly, adjusting the force on the surface depending on its thickness. For example, the telescopic shape of the lever during body work allows you to increase the effort by more than 2 times.

Where to start making a sheet bending machine

To make a machine for bending sheet metal, you will need a drawing of such a device or its detailed photos. In addition, a number of important factors should be taken into account, such as the force that will need to be applied to use the sheet bending machine, its weight and dimensions (on which mobility depends), cost and availability of components. As a result, we obtain the following initial parameters.

- The maximum width of the sheet that will need to be bent is 1 m.

- Maximum thickness of sheet material: galvanized – 0.6 mm, aluminum – 0.7 mm, copper – 1 mm.

- The number of operating cycles that will be carried out without readjustment or repair is 1200.

- The maximum bend angle of a metal profile, obtained without manual finishing, is 120 degrees.

- It is highly undesirable to use workpieces made of special steels (for example, stainless steel).

- In the design of a sheet bending machine, welded joints that do not withstand alternating loads should be avoided.

- You should limit as much as possible the number of sheet bending machine parts that you will need to order externally, using turners or millers.

It is very difficult to find a drawing of a device that would satisfy all these requirements, but the most successful one can be modified.

Self-production

Following the drawings, you can make your own manual edge bender for processing metal of small thickness during car repair.

It is enough for him:

- corner,

- metal beams,

- hinges with bolts,

- clamps,

- handles,

- table,

- welding machine.

Preparatory stage

- Make a base from an I-beam profile.

- Bolt the corner to the top of the beam.

- Weld three hinges under the corner.

- Provide tight metal clamping with two clamps.

To make it easier to turn the machine while bending a sheet of metal, attach handles on both sides. Using clamps, attach the machine to the table.

For processing, the product is placed between the profile and the corner. The gap for it is formed after unscrewing the corner. The metal sheet is aligned along the edge and bent by turning the device by the handles.

Long straight edge bending machine

Making your own manual edge bender for long straight edges should begin with studying the drawings, as well as selecting the equipment and necessary materials:

- pairs of channel sections for the base and punch,

- corners with straight edges.

- welding machine,

- steel sheet,

- steel axles - rods with a cross-section of 10 mm,

- brushes with steel bristles,

- handle brackets.

4 main details:

- base,

- clamp,

- punch,

- pen.

First, you need to chamfer the edge of the crimping punch and weld the axles to it. The axes of the bar itself must coincide with the edge of the angle. Samples are made at the ends of the working part of the clamp.

For assembly, the base with the punch is clamped in a vice. In this case, the walls of the first and second shelves must be in the same plane. The gap between the parts will be created by a cardboard spacer. After this, the elements are firmly fixed in a vice.

Brushes with metal bristles are placed on the punch axis. These components are attached to the base using a clamp - a frame with a movable clamp.

Then the brushes are welded to the channel, and holes are drilled in the base into which the clamping bolts are screwed. Screw nuts onto hardware studs. Then they are welded to the channel.

After unscrewing, the bolts are inserted into the clamping holes and the limiting nuts are screwed onto them.

The handle-bracket is welded to the corner. The final stage of assembling the structure is installation in a vice.

DOMOSTROYPlumbing and construction

- Category: Construction

- Link to post

- https://firmmy.ru/

Butt welding is notoriously difficult to do on thin iron material. Thanks to the tool that is presented in this video of the “car resuscitator” channel, the work of car repair is greatly facilitated. Now you can mask a seam that is overlapped, resulting in a complete illusion of butt welding. Externally it looks very impressive and beautiful. First, look at how the master works with this tool of his, the design of the edge bender. In the second video you can see product drawings.

The master shows how, using a hand-made homemade edge bender, it is possible to make an even connection between two parts during auto repair. One of the parts has a uniform, flat surface. 2 parts have an edge with a recess. Millimeter deep groove. Two elements are applied to each other. A weld is made along the groove at the junction. Next it is sanded and leveled. We get an even, neat and flat connection of two elements; after coating with paint, it looks like one whole. The effect of butt welding, but in reality there is an overlap.

Let's look at the design of a manual edge bender in more detail. Small vice for stability. Support point. The length of the levers is 0.5 meters. 25 tube. Two pieces of tire are welded to it. Two holes. The result is a U-shaped part. Bolts 12. Let's try to disassemble the tool. When will it be possible to show all the components in more detail. The protrusion on this part is not formative. 2 parts have a counterpart. A lever is made to make work easier.

Two levers are connected to each other through a fulcrum. The pipe is 25, the tire is the same size. Shoulder length 100 millimeters. The distance between the bolts is 25 millimeters. The inner tube is 20 x 20. A millimeter plate is welded to it. The plate compensates for the difference in external and internal diameters. To simplify the design, a thread is cut into the cheek. The master did not use any drawings in the process of making this hand-held device; everything was done on a whim. The entire structure was drawn on paper.

If you want to replicate this design for your auto repair shop, then the following video will be valuable to you. Here you can see all the necessary drawings of this tool, which is called an edge bender. A very convenient device for working in the auto repair process.

A manual edge bender for auto repair, made by yourself, is easy to use and is popular among tinsmiths. There are a number of modern offerings of this device available at retail, although it is not difficult to manufacture.

Manual edge bender for flanging

Beading is a method of bending an edge on cylindrical or oval products. During operation, the material stretches. Its value depends on the properties and thickness of the material, the inclination of the flanging angle, and the parameters of the edge.

Flanging is performed on a machine or using a manual edge bender with your own hands. This processing technology is necessary in preparation for soldering, welding, and in the manufacture of any flange.

Drawing up technical specifications

Thanks to the capabilities of the Internet, you can quickly find the required set of drawings, and on the YouTube channel you can even watch advertising and informational videos about the device and operating principle of the required unit. However, all these materials are strictly individual, and therefore were intended by their authors for specific sheet-bending operations. Therefore, before building a sheet bending machine with your own hands, you need to make the right choice of its future technical characteristics. The main ones should be the following:

- maximum width of bent metal, mm;

- maximum thickness of the workpiece, mm;

- desired range of bending angles;

- overall dimensions of the mechanism (length, width, height);

- required bending accuracy.

The direct choice of the limit values of the listed parameters depends on the conditions of use of the machine that will bend sheet metal products. In particular, when constructing a roof, you will most likely have to deal with galvanized sheet or steel with a thickness of no more than 1 mm. When processing copper, an even thinner sheet or strip is often used, and when making fences and railings with your own hands, on the contrary, the thickness of the metal can be 2 - 3 mm.

When choosing the optimal width of a workpiece - sheet or strip - you should proceed from the fact that the width of the part will rarely exceed 1000 mm (in extreme cases, adjacent workpieces can then be joined into a fold using the same machine).

Drawing of a homemade sheet bending machine

The most difficult point in the technical specifications is considered to be the choice of the optimal range of metal bending angles. If everything is clear with the upper limit - 180°, then the lower value should be chosen very wisely. A natural consequence of bending most sheet metals in a cold state is springback - a spontaneous decrease in the actual bending angle due to the elastic properties of the deformed metal. Springing depends on:

- Plasticity of the material: for example, for low-carbon steel the maximum spring angle is 5 - 7°, and for high-carbon steel - up to 10 - 12°. Alloy steels and alloys are even more springy. In particular, for aluminum alloy AMg6, the maximum springback can be 12 - 15°;

- Thickness of the bent part: with decreasing metal thickness, springing decreases;

- Bending angle: as this angle decreases, the springback of almost all metals increases. In particular, at relatively small bending angles (up to 15 - 20°), it is generally impossible to bend a workpiece made of most types of sheet metals and alloys to a given amount in the usual way: it is necessary to use units with simultaneous longitudinal stretching of the sheet. It is impossible to make such machines with your own hands: you will need to install and debug a special hydraulic drive. Therefore, in such cases, it is easier to bend the part with the usual blows of a mallet on, for example, a wooden matrix.

Do-it-yourself manual edge bending - saving the family budget

Many people are interested in how to make an edge bender themselves, and how difficult it is. Making a simple design will take several evenings and save several thousand rubles. Another argument may be the urgency of use.

For example, for auto repair, using a hand-made edge bender will save time and nerves. But such equipment may be inferior to factory products in terms of accuracy and manufacturability.

Video - how to make an edge bender yourself

Recommendations for assembling the edge bender

It is very difficult to make roofing, ventilation, drainage systems from sheet metal, various boxes, bottoms and other products without edge bending equipment. Traditional pliers and mallets can solve the problem, but the work will be slow and with a low level of precision. Sooner or later the question will arise - how to make an edge bender with your own hands?

Modern tool factories offer edge bending equipment of any level of complexity - from household manual to professional pneumatic, electromechanical or hydraulic. These are very productive machines, but they have one common negative feature - they are very expensive. Moreover, they are expensive not only for a home craftsman, but also for a small workshop or construction team of roofers.