How to cut a large diameter hole in a metal plate?

We tell you how to make a homemade circular drill (ballerina) with your own hands for cutting round holes in sheet metal.

We spotted this interesting idea on the YouTube channel “Made in a Garage.”

Necessary materials:

- metal blank;

- round steel bar;

- square bar;

- metal drill;

- fastening hardware - screws.

note

: The circular ballerina drill can be easily adjusted to a specific diameter. To do this, you need to move the cutter holder to the left or right, increasing the distance between the cutter and the blank.

It is better to use a homemade drill on a drilling machine, and not in conjunction with an electric drill - this is the only way you will be able to achieve a high-quality result.

How to make a large diameter hole in metal

Any design, whether in your home or in production, involves working with metal.

Often, during the operation of this material, the question may arise: how to cut a circle in metal?

It deserves attention, since the labor intensity of the work process and the quality of its result directly depend on the choice of the right tool and technology.

Methods for cutting a circle from thin metal

Metal circles

How to cut an even circle from metal with a cutter is shown in the video:

How to drill a large hole in metal

Every person who makes repairs in their own home, sooner or later is faced with the need to drill metal. In today's article I want to look at ways to drill holes in various metal elements.

First of all, you need to follow safety precautions and wear safety glasses. Otherwise, if hot shavings get on the mucous membrane of the eye, you can get serious injury.

To make holes in metal products at home, use an electric or hand drill.

Tools that we will need in the process of drilling metal:

- drill (mostly electric)

- Carbon steel or carbide-tipped drill bits

- coolant (used oil can be used)

- protective glasses

- core

- scriber (a tool for marking the material being processed)

Before you begin directly drilling a hole of a given size, you need to apply markings. At the same time, if you need to drill several holes at a certain distance from each other, then you need to position the entire drawing.

Then the marked places must be punched using a core - knock out small depressions in the metal surface. This operation is carried out in order to avoid breakdowns of the drill, damage to the tool and material. Pre-made grooves also allow the drill to move in the correct direction.

To make holes in metal, drills with a spiral flute made of carbon steel are used. The cutting edges of the drill are sharpened depending on the material in which holes need to be drilled. The harder the material being processed, the greater the sharpening angle should be (usually the drill is sharpened at an angle of 85-90 degrees).

Having completed all the necessary preparatory work, you can begin the drilling process itself.

In order not to damage the drill during operation, when drilling metal, you should follow the specified direction and avoid strong pressure on the tool.

Also, if possible, coolant should be supplied to the drilling area to eliminate elevated temperatures. As you approach the desired result (if the hole is through), you need to loosen the pressure to prevent breakage of the drill.

If you do not have the opportunity to connect an electric drill, and you simply need to drill a hole in the metal, then you can use a manual version of the drill, but you should remember a few rules:

- For drilling metal, drills made of carbon steel U8, U10, U12 with a helical groove are used.

- When drilling a hole in metal by hand, you should start moving smoothly so that the drill does not break (if the diameter is small) or jump off.

- The center hole must be punched deeper to avoid failure.

- When drilling a hole of large diameter, it is recommended to use several drills, gradually increasing their size.

- It is advisable to place a wooden plank under the product in the drilling area in order to prevent a sharp exit of the drill.

- The thickness of the material being processed can be absolutely any (it all depends on the length of the drill), but the hardness of the metal should be lower than that of the drill.

Drill a hole in metal

17849 Section: Information

In this article, we will learn how to drill a hole in metal, in what way and what is the best way to drill a hole in a pipe, channel or sheet of metal. Let's find out whether it is difficult to drill a hole in metal. Let's find out how easy it is to drill a large hole in metal.

According to the already established tradition, before we begin to understand the topic of how to drill a hole in metal, I would like to introduce you to previous articles about drilling, namely: how to drill correctly *, this article contains partial information on how to drill metal in concrete and article: drilling and drilling without dust *, although it does not fit our topic today, it is also interesting.

How to drill a hole in metal.

To drill a hole in metal using hand tools, a drill or a screwdriver, in any: pipe, channel, metal plate, we need a set of metal drills.

To be more detailed, the smallest drill for drilling a hole in metal should be a two, a four, a six, and so on up to the size of the hole that we are going to drill. This number of metal drills will allow you to drill a hole in metal much faster.

If you skip at least one type of drill, you will have to drill a hole in the metal a little longer than usual.

Drilling according to markings

Rice. 1. Drilling holes according to the markings:

a – marking and punching the center of the hole; b – marking and punching of the control circle; c – moving the drill away from the center of the hole; d – correction of the drill direction; 1 – mark from the center punch; 2 – groove from a pre-drilled hole; 3 – machined hole

This type of processing of workpieces is carried out in several stages:

When pre-drilling, drill a small hole (0.25d). Next, the spindle with the drill is retracted to check the prepared hole with the original markings.

If the result of preliminary drilling is satisfactory (Fig. 1, b), final processing is carried out, for which work continues until the cutting tool leaves the part.

If a bevel occurs and the hole being drilled goes away (Fig. 1, c), an adjustment is made using a cross-section tool - grooves are cut in the direction where the hole needs to be moved (Fig. 1, d).

Thanks to the guides for the drill, the direction is set in the desired direction to correct the bevel.

Cutting a circle in thick metal

Cutting a circle with a grinder

In order to outline the exact contours of the figure that will be cut out of metal, you should use a ruler, a marking compass and a marker.

First, using a ruler, set the required width of the compass connector so that it matches the required diameter of the circle.

Then the center point of the circle is determined on the metal plane.

Contours are drawn from it using a compass.

So that they are clearly visible during the work, they should be drawn with a marker.

Application of cutting torch

A circle in medium-thick metal can be cut using a gas cutter. The work takes place in several stages:

- The outline of the circle is outlined.

- The instrument burner lights up.

- The combustion torch is adjustable.

- The torch is carefully and slowly drawn according to the drawn drawing.

Using this method, you can cut a hole in metal that is about four or five millimeters wide.

How to properly drill holes in metal

When working with metal, you cannot do without drilling holes. Working with metal is a complex operation. This is due to the fact that metal parts have high strength, for the processing of which special equipment and technologies must be used.

You may need to drill holes in any field and when performing work in the country, at home or in the garage. Even when repairing a car, you have to drill holes in the metal. If you are going to do the work away from the workplace, you will need an electric drill or hammer drill with an adapter chuck for the drill, as well as a core or tap to center the hole.

If you need to make holes in small parts, it is better to use a drill press. On it you will be sure of the correct direction of the drill and the drilling speed.

Which drill to choose for drilling metal

One of the first questions that inexperienced craftsmen ask is which drill to drill into metal? In fact, answering correctly is not so easy. For metal processing, you need to use special drills made of high-speed tool steel. The cutting part in them is made with the addition of titanium nitride.

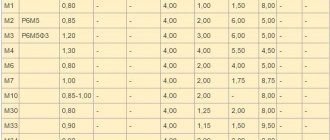

When choosing drills for drilling metals, the main and running ones are drills made of high-speed tool steel; they can be found in the store by the HSS .

When working with cast iron, stainless steel and other metals that are difficult to machine, you should use carbide drills. Their disadvantage is their very high price, which makes the work expensive.

If you choose drills with one of the best cutting properties, it will be a tool with the addition of cobalt, marked P6M5K5. This is the best value for money.

Is it possible to drill metal with a concrete drill?

There may be an urgent need to make a hole in metal, and only a concrete drill is at hand. On such a drill, the tip is made of pobedite, which makes it possible to drill concrete and brick with a hammer.

You cannot use such a drill to drill a hole in metal. You may lick off the tip of the drill bit, especially if you try to use a large diameter drill bit or drill through thick metal.

To sum it up, you won’t be able to drill through metal with a Pobedit drill.

However, if you sharpen it at the right angle, it is possible to drill into metal.

Power and speed when working with metal

An important factor is the choice of tool, namely a hammer drill, drill or screwdriver, which will be used to make holes in the metal. If you use a drill with a power of up to 700W, you will not be able to make a large hole right away. A hand drill with a power of up to 700W is best used for drilling holes with a diameter of up to 10-13mm.

It is important to choose the correct speed of the drill or screwdriver. After all, at high speeds, your drill will simply burn out. This way you will ruin it.

You need to drill metal at low or medium speeds, not exceeding 500-1000 revolutions.

The larger the diameter of the drill you are working with, the lower the speed you need to choose.

How to drill metal products correctly

One of the most important parameters when drilling a hole is the sharpness of the drill. If you purchased one of the cheapest drills, it may turn out to be dull and made of soft metal, which will not allow you to make even a couple of holes.

How quickly the drill tip will shear and dull depends on the drilling speed, the hardness of the metal, the force applied to the drill, and cooling.

- When drilling large holes, you must first make holes of a smaller diameter. This way the process will be much faster, and the drills will not become dull so quickly.

- To accurately center the hole, you need to use a core punch and punch the center of the hole before drilling.

- To cool the working part of the drill, you need to use machine oil. Simply lower the working part of the drill into a container of oil. Repeat this operation periodically. You can use soapy water for cooling (by reducing friction).

- When drilling deep holes, periodically remove the drill and clear it of chips.

How to drill sheet metal

When working with sheet metal, there should not be any particular difficulties, even when drilling large-diameter holes. The only thing is that you need to place a wooden block under the drilling site, it will help remove the chips. When you feel like you've almost drilled through the metal sheet, reducing the pressure on the drill will also help reduce the likelihood of burrs.

How to make holes in pipes correctly

The main problem when drilling holes in round pipes is the difficulty of perpendicular drilling. This means that the hole from which drilling began does not correspond to the exit hole. To solve this problem, you need to use a drilling machine, or special guides, which you can make yourself or purchase ready-made.

How to drill aluminum

Anyone who has worked with aluminum parts knows that it is a soft metal. The main problem when drilling aluminum is excessive shavings wrapping around the drill bit. Because of this, the drill stops drilling and gets stuck in the metal. To avoid this, you need to remove the drill from the hole more often and remove the chips.

How to drill stainless steel (stainless steel)

Stainless steel is an alloy steel, which is not an easy task to drill. To make drilling comfortable, it is advisable to choose drills with a cobalt tip.

You need to drill stainless steel at minimum speed, namely 100-200 rpm. Such speeds provide the required cutting speed for stainless steel and good quality.

If your tool does not have a rotation speed control, you should press the button periodically for a second or two, which will prevent the drill from accelerating quickly.

If you need to make a hole of a large diameter, you need to use metal crowns, which make it possible to drill only along the outer diameter of the hole.

How to drill large diameter holes

When you need to make large diameter holes in metal, you need to use a tool suitable for this purpose.

- First you need to make a hole of a smaller diameter. You can use several drills, gradually increasing the diameter of the hole. In this way, it will be easier for drills to pass through metal, especially thick metal.

- Using a step drill. Such drills can be called conical drills.

- The use of special crowns for metal. Drilling large diameter holes with hole saws is very easy due to drilling only the outer diameter of the hole. The crown consists of a centering drill, which first drills through the metal in the center and then guides the crown. Drilling with a crown must be done at very low speeds.

One of the best ways is to use metal crowns. The disadvantage of this method is the non-adjustable diameter of the crown (adjustable crowns are also sold, but we do not recommend buying these because of their poor quality). For each hole diameter you need to have different crowns.

How to avoid dulling a metal drill?

While drilling, you can easily burn (blunt) the working part of the drill. This occurs due to high speeds, due to which the drill heats up and melts. This can be avoided by keeping the speed low or lubricating the drill with a cooling lubricant.

If there is no special cooling lubricant for drills, you can use machine oil, which will reduce the friction force.

How to drill with a drill?

To figure out how to properly drill metal with a drill, you need to derive a number of basic rules from which it is not advisable to deviate:

- You will need a drill or screwdriver, a core with a hammer, protective equipment - glasses and a means for cooling the drill (most often machine oil).

- Before starting work, you need to mark the center of the hole

- Wear protective equipment. The chips can easily bounce into your eyes. After which it will be difficult to get out of there without specialized medical care.

- Punch the center of the hole.

- Start drilling at low speed

- Periodically remove the drill from the hole, clearing it of chips and cooling it in oil.

By following the above rules and sequence, you can make holes of any diameter without any problems. When performed, the shelf life of the drill will be maximum due to maintaining low speeds and cooling it in oil.

On a large number of drills, you can install a depth limiter, which allows you to adjust the drilling depth. You may need it when drilling blind holes.

Technology and equipment for drilling large cross-section holes

Cone drills

They are a tool made in the form of a set of cylindrical sections gradually decreasing towards the tip, the ratio of diameters between which is taken in such a way as to reduce the force when moving from a smaller diameter to a larger one. Drills are usually made double-threaded, since they are not intended for use in thick sheet metal: the recommended thickness of the workpiece at the drilling site does not exceed 2-5 mm, and the latter applies to plastics.

Conical drills

The range of conical drills is limited to the range of 6-30 mm, since when this size is reduced, the tip quickly becomes dull, and processing larger holes leads to a sharp increase in loads on the drive (for a machine) or on the hands of the worker (if hand-held power tools are used).

The design feature of conical drills is that they are available with two shank designs - round and hexagonal. The latter option is more preferable, since with constantly increasing forces, a tool with a round shank can slip in the chuck. This increases the risk of breakdown and reduces the productivity of the operation. At the same time, such drills also have a number of advantages:

- You can make a hole gradually, without the formation of burrs and sharp edges.

- The presence of cylindrical pads allows you to produce several holes of different diameters using only one drill: it is enough to control the amount of axial feed. This is more difficult to do for a hand-held power tool, therefore, when using this method, it is worth stocking up on movement limiters for the tool head or chuck.

- When drilling with conical stepped equipment, the cutting force increases gradually, so the durability is not significantly reduced. The use of smooth conical drills is a different matter: although they are simpler in design, they require (when fed manually) significant effort.

- The tool is suitable not only for drilling a large hole in metal, but also for performing operations such as drilling, boring or countersinking.

- Since the side surfaces of conical drills have grooves, they can be used to produce through cuts in metal workpieces.

When using the tool, it is necessary to use reduced spindle speeds and first check the head runout. The first warning is associated with an increase in drilling force, and the second is associated with the appearance of bending stresses that are dangerous for the tool.

Core drills

They are classified as universal-purpose equipment, because a regular drill or screwdriver is suitable for installing such a drill. The core drill consists of the following parts:

- An end centering attachment that pre-drills a hole. Relying on it, the crown begins its action.

- Shank.

- Actually the crowns.

- Mounting bolts.

Due to their prefabricated design, core drills can be used to produce holes of different diameters: it is enough to remove one crown and install another. It is important that the final value of torque and axial force does not exceed the limits for which the tooling and equipment are designed.

Core drills are not only characterized by high productivity, but also increased durability. They are quite rigid, there are no stress concentrators in them (no spiral grooves), and the load is distributed only along the circular metal cutting line.

The sequence of making a hole using a core drill is that you first need to make a center hole, and then the main one. Therefore, the spindle stroke increases slightly.

The special tool described has a high price, and the equipment produced by the Bosch brand enjoys the greatest confidence among users. It is highly not recommended to chase Chinese handicrafts, which are attractive due to their lower cost.

Drill a hole in metal

Drilling through holes in metal workpieces is done with various tools using special techniques. Many specialists, when performing engineering work, have to drill holes in metal structures quite often. These objects have high elasticity, which forces the use of special cutting devices when drilling.

Types of drills and devices for drilling in metal

The necessary equipment for drilling metal products are electric and hand drills, as well as drilling machines. The working part of such devices is a drill of different shapes:

- spiral;

- screw;

- crown-shaped;

- conical;

- flat;

- cannon;

- rifle;

- centering;

- stepped.

Each drill is individually marked, where the tip indicates the cross-sectional diameter and the type of alloy from which it is made. To drill a hole of the required diameter, you need a drill a few tenths of a millimeter narrower.

Drills are also classified by length:

- short;

- elongated;

- long.

Drilling in some materials may require a specially sharpened diamond-tipped drill bit. Twist drills may not be able to handle products made from thin sheet alloys.

In some cases, to drill deep holes, the product must be fixed in a vice, stops, jigs, or corners with fasteners.

This is done for safety reasons and to obtain high quality holes.

Modes for drilling holes in metal products

For drilling through holes in metal products, preliminary preparation for the process is extremely important. The drill must be correctly secured and guided in the tool.

You need to adjust the rotation speed and other parameters. For products that are too strong, a low drill speed is recommended.

An indicator of correct drilling should be uniform, long chips.

Types of holes and methods for drilling them

Some manufacturing jobs often require the following types of holes in metal workpieces:

- Through. They completely pierce metal workpieces. It is important to protect the surface of the machine from accidental exit of the drill beyond the product to avoid damage to the drill and the occurrence of burrs on the blank. Workbenches with holes, where it is possible to place a wooden spacer under the workpiece, are ideal for such types of work. Holes in thin blanks are drilled with flat drills, because a twist drill can noticeably destroy the edges of the product.

- Deaf. They are carried out to the required depth without penetrating the product right through. In this case, an important point is measuring the depth, which can be conveniently done by limiting the length of the drill by the stop of the sleeve or the drill chuck with a locking stop. Professional machines are equipped with automatic feeding systems for a given depth of penetration, which allows you to fix the depth of the drill.

- Deep. This type of hole includes those drills whose length is five times the diameter. When drilling deep holes, it is necessary to periodically remove the resulting chips using additional lubricants. Often it is necessary to enforce measures to cool the drill and the workpiece itself, the temperature of which rapidly rises to too high levels as a result of friction. This applies to workpieces made of high-strength alloys. For deep holes, twist drills are used.

- Wide diameter. Drilling large-diameter holes in products of large proportions is a very responsible and labor-intensive process. For such holes, conical, crown-shaped or stepped drills are used. Specialists carry out drilling at low tool speeds, trying to ensure the safety of the edges of the workpiece.

- Complex shape. Sometimes it is necessary to drill through or blind holes in workpieces of different densities for internal threads. The technology has to be divided into two actions: preliminary preparation of the site and the drilling itself.

- Half-hearted. Half blanks are drilled, filling the cavities with wood. Stepped holes can be obtained using one of two techniques: reaming (passing a drill of a smaller diameter to the entire depth of the workpiece, followed by drilling with drills of a larger diameter) and reducing the diameter (drilling a hole of a larger diameter to the required depth, followed by replacing a drill with a smaller diameter). As a result, the hole is clearly centered.

Safety when drilling holes in metal workpieces

When drilling holes in metal workpieces, you should be very careful to avoid rapid destruction of the drill. Following simple rules when drilling will ensure safety and guarantee a high-quality product upon completion of the work:

- On the eve of drilling, you must carefully check the fixation of all fastening devices on the machine.

- You can start work in special clothing to prevent any elements from getting under the moving parts of the machine. Protect your eyes from metal shavings with special glasses.

- When the drill tip enters a metal workpiece, it should already be rotating at low speeds to avoid dulling.

- The drill should be pulled out of the drilled hole gradually, reducing the speed, but not stopping completely.

- When the drill tip does not penetrate into the workpiece, you will have to check the strength of the metal. When running a file over the surface, it is possible to determine the degree of strength. If there is no roughness left on the alloy, you need to choose a drill with a diamond tip or from a harder material, and drill at low speeds.

- Drills of small diameter, which are difficult to fix in the chuck, are recommended to be wrapped with brass wire on the tail to increase the diameter of the girth.

- If you are working with a polished workpiece, you can put a felt washer on the base of the drill to avoid damage when it comes into contact with the drill chuck.

- To fix metal workpieces made of polished or chrome-plated steel, fabric or leather spacers are used.

- When drilling deep holes, a small piece of compressed foam placed on the drill will ensure that small metal shavings are blown away. Also, foam plastic will make it possible to deepen the drill to the required level when producing blind holes.

The power of electric drills must be taken into account when drilling holes in metal workpieces of varying hardness. Manufacturers of electric tools mark devices by indicating technical characteristics on their housing. For drills of different power, drills of the appropriate diameter are required.

https://www.youtube.com/watch?v=ZjueKzIhTVs

You can entrust any metalworking work, including drilling, to the specialists of the Proflazermet company. We ourselves will determine the required hole diameter and select the appropriate tool, of which we have a large selection. As a result, you will get the perfect solution in a short time.

| [td]» Articles » Professionally about metalworking » Drilling machines |

We recommend purchasing:

Installations for automatic welding of longitudinal seams of shells - in stock!

High performance, convenience, ease of operation and reliability in operation.

Welding screens and protective curtains are in stock!

Radiation protection when welding and cutting. Big choice. Delivery throughout Russia!

Depending on the required quality and number of workpieces to be processed, holes are drilled using markings or a jig. During the work process, the following basic rules must be observed:

- when drilling through holes in workpieces, it is necessary to pay attention to the method of securing them; if the workpiece is mounted on a table, then you need to place it on a support to ensure free exit for the drill after processing is completed;

- the drill should be brought to the workpiece only after turning on the spindle rotation so that when it touches the surface of the workpiece, the load on it is small, otherwise the cutting edges of the drill may be damaged;

- Do not stop spindle rotation while the drill is in the hole being machined. First you need to remove the drill, and then stop rotating the spindle or stop the machine, otherwise the drill may be damaged;

- if a grinding noise or vibrations occur during drilling resulting from jamming, misalignment or wear of the drill, you should immediately remove it from the workpiece and then stop the machine;

- When drilling deep holes (l>5d, where l is the depth of the hole, mm; d is the diameter of the hole, mm), it is necessary to periodically remove the drill from the hole being machined to remove chips, as well as to lubricate the drill. This significantly reduces the likelihood of drill breakage and premature dulling;

- a hole with a diameter of more than 25 mm in solid metal is recommended to be drilled in two transitions (with reaming or countersinking);

- drilling should be performed only according to the modes specified in the technological maps or in the tables of reference books, as well as according to the recommendations of the foreman (technologist);

- When drilling holes in workpieces made of steel or viscous materials, it is imperative to use coolant to protect the cutting tool from premature wear and increased cutting conditions.

Drilling by marking is used in single and small-scale production, when the manufacture of jigs is not economically justified due to the small number of processed parts. In this case, the driller receives marked blanks with control circles marked on them and the center of the future hole (Fig. 6.21, a). In some cases, the marking is made by a driller.

Drilling according to the markings is carried out in two stages: first, preliminary drilling, and then final. Pre-drilling is carried out with manual feed, drilling a small hole (0.25d). After this, the spindle and drill are retracted, the chips are removed, and the alignment of the circle of the overdrilled hole with the marking circle is checked.

If the preliminary hole is drilled correctly (Fig. 6.21, b), drilling should be continued and completed, and if the hole has gone to the side (Fig. 6.

21, c), then make the appropriate adjustment: cut two or three grooves 2 with a narrow chisel (crossmeisel) on the side of the center where you want to move the drill (Fig. 6.21, d).

The grooves guide the drill to the location designated by the center punch. After correcting the offset, continue drilling to the end.

Drilling on the jig

To guide the cutting tool and fix the workpiece according to the requirements of the technological process, various jigs are used.

Constant mounting bases of the device and jig bushings that provide direction to the drill increase the accuracy of processing.

When drilling along a jig, the driller performs several simple techniques (installs the jig, the workpiece and removes them, turns the spindle feed on and off).

Drilling through and blind holes. There are mainly two types of holes in workpieces: through holes, passing through the entire thickness of the part, and blind holes, drilled only to a certain depth.

The process of drilling through holes is different from the process of drilling blind holes. When drilling through holes, when the drill comes out of the hole, the resistance of the workpiece material decreases abruptly. If you do not reduce the feed speed of the drill at this time, it may become jammed and break.

This happens especially often when drilling holes in thin workpieces, through intermittent holes and holes located at right angles to one another. Therefore, drilling a through hole is carried out with a high mechanical feed speed of the spindle.

At the end of drilling, you need to turn off the feed speed and drill the hole manually at a speed lower than mechanical.

When drilling with manual tool feed, the feed speed before the drill leaves the hole should also be reduced somewhat, drilling should be done smoothly.

There are three main methods of drilling blind holes.

If the machine on which a blind hole is drilled has any device for automatically turning off the spindle feed speed when the drill reaches a given depth (reading rulers, dials, hard stops, automatic stops, etc.), then when setting up to perform this operation it is necessary to adjust to the specified drilling depth.

If the machine does not have such devices, then to determine the achieved drilling depth, you can use a special chuck (Fig. 6.22, a) with an adjustable stop.

The thrust sleeve 2 of the chuck can be moved and installed relative to the body 1 with the drill at a given processing depth.

The machine spindle moves down until the end of the bushing 2 stops at the end of the jig bushing 3 (when drilling along the jig) or into the surface of the workpiece. This chuck ensures hole depth accuracy within 0.1...0.5 mm.

If greater accuracy of drilling depth is not required and there is no specified chuck, then you can use a stop in the form of a sleeve attached to the drill (Fig. 6.22, b), or mark the depth of the hole on the drill with chalk. In the latter case, the spindle is fed until the drill goes deep into the workpiece to the mark.

The drilling depth of a blind hole is periodically checked with a depth gauge, but this method requires additional time, since you have to remove the drill from the hole, remove the chips and, after measuring, reinsert it into the hole.