A drilling and milling machine, which uses both a milling cutter and a drill as a working tool, is a universal device. Due to this, such machines are used in various fields of activity.

One of the types of drilling and milling machine

A drilling and milling machine, used primarily for processing metal workpieces, can be additionally equipped with numerical control, which improves the quality of technological operations and the accuracy of the geometric parameters of the finished product. On drilling and milling machines, you can efficiently and accurately process parts with curved surfaces, regular and irregular shapes, carry out precise calibration, form holes, cut threads in them, make grooves with a smooth inner surface and ridges of even very small sizes. In addition, drilling and milling machines are successfully used for processing elements of spline and tongue joints.

Modern manufacturers producing such machines offer a wide variety of modifications. Models of drilling and milling machines equipped with CNC systems are considered high-tech. Such models, in addition to high accuracy and maximum productivity, are also convenient because the influence of the human factor on them is minimized during processing.

Very popular are machines that can be installed and fixed on a flat metal surface using a magnetic base. The sole allows you to fix the machine not only on the surface of a metal work table, but also directly on the workpiece being processed, if its surface area allows this.

How are they built?

Any metal drilling and milling machine, regardless of modification and configuration, has several standard components that determine its capabilities.

Base

The type of base depends on the drilling and milling machine itself. If this is a tabletop option, then the base is low and flat. If the drilling and milling machine is floor-mounted, the base is in the form of a cabinet. There may be stiffening ribs at the bottom of the base. The work table of such a machine is a three-dimensional structure with increased reliability parameters.

Column

The column moves along guides. They are mounted on a cast frame. The column of a drilling and milling machine consists of upper and lower parts, which are interconnected. The drilling head moves along the column itself. A support with a spindle is also located here.

Caliper

Due to the movement of the support along the column, the tool moves vertically; the spindle moves horizontally due to the support guides perpendicular to the table. Using a chuck, tools, cutters and drills are attached to the spindle.

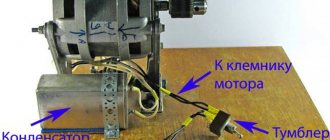

Electric motor

The drilling and milling machine can be equipped with one or two electric motors. They carry out vertical and horizontal movement of the spindle. The motor is combined with a ball screw drive using a coupling, usually split.

Rotation from the electric motor to the spindle is carried out through pulleys and a toothed belt. Depending on the type of equipment, engine power also increases. Industrial drilling and milling machines require more powerful electric motors than those used at home.

Transmission

The gearbox of a drilling and milling machine allows you to select the required rotation speed of the tool without any intermediate steps. The shift dial is turned using the speed indicator.

Control block

Depending on the model, the design of the control unit of the main components may vary, but for the most part all the main elements are the same:

- handle for switching vertical and transverse gears;

- switch for cooling system;

- stop and emergency stop buttons;

- spindle start button;

- manual movement of the trunk;

- flywheel for manual longitudinal movement of the table;

- swivel slide clamp.

Many modern broom drilling and milling machines are additionally equipped with numerical program control, which ensures higher equipment productivity and precision processing of parts.

Spindle unit

The spindle assembly is attached to the spindle head housing. The spindle rotates directly in the unit body on high-precision angular contact bearings. There are 2 keys located at the lower end of the bearing. They are necessary to transmit working torque to the tool. Directly inside the spindle there is a tool clamping mechanism, which consists of a rod with a set of disc springs.

Table

This is a three-dimensional structure that is made of metal by casting or pressing. Some models of metal drilling and milling machine include a magnetic base. This makes the equipment more mobile and compact. Also, the magnetic sole helps you work with the tool in different planes.

Drilling holes on a CNC machine, process features

“The general recommendation for a typical two-speed drill feed rate in many applications is 1.5-2% of the drill diameter. In these cases, switching to a three-flute drill makes it possible to increase the feed rate to 6% of the drill diameter, which will significantly reduce cycle time,” Matsumoto explained. “Another added benefit would be the extra flute and margin for better drilling stability and hole accuracy. These drills are typically best suited for high-volume production applications that will maximize cycle times.” Another way to reduce cycle time is to select the correct drill for each type of hole. No drill is universal and cannot make absolutely any hole.

“Treat each drill as unique by optimizing cut settings and chip control on a drill-by-drill basis,” McEachern explained. “Providing good productivity and chip removal results in superior hole quality, longer tool life and lower cost per hole, all of which makes the company more profitable.”

However, if you're drilling holes of different sizes on a CNC machine , you need to find a fine balance between cycle time and the number of tools you're working with. “Some people think that going smaller is a rough job,” Hamil said. “You can CNC drill a smaller diameter and then put in a cutter and helical interpolate to get the size you need. This allows you to use one diameter drill and then in a second operation you can get the hole the size you need.”

He added that if metalworking companies operate at any production volume, reducing cycle time should be central to improving efficiency. Every time you change tools, it increases cycle time. Keep in mind that a drill produces a hole faster than anything else. But it is also important to note that CNC tool shops have their limitations.

For example, if your CNC drilling machine only has a capacity of 36 tools, and you suddenly get a job that requires a new tool, then given that the machine's magazine is full, the operator will need to make adjustments. One way to solve this problem is to use universal tools designed for drilling in several modes.

“Instead of using different tools to drill and ream or chamfer before installing them in the CNC tool magazine, you can choose a tool designed to drill and chamfer in one step,” McEachern explained. “This can often give the customer a quick return on investment in these tools by reducing cycle times and the number of tools used. If they can do two or three jobs on one hole with one tool, it's worth investing in a specially designed tool.”

What kind of metal work can be done

Drilling and milling machines for metal are capable of performing almost any drilling and milling operations. The high functionality of the unit is due to the high speed of the spindle with the tool. If a metal drilling and milling machine is equipped with CNC, the processing will be more accurate and the quality of the resulting product will be higher.

Drilling

On a metal drilling and milling machine, you can perform both blind and through drilling. The hole is obtained with an exact size only if the preparatory and main work is strictly carried out. When carrying out through drilling, it is necessary to switch the automatic transmission to manual at the moment the drill comes out of it. This will ease the pressure on the drill. During the process, it is necessary to periodically remove the drill from the hole and remove chips from there.

Milling

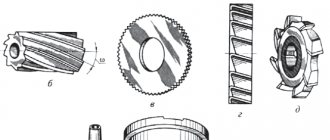

Depending on the operations performed on a metal drilling and milling machine, the equipment changes. For milling, various grinding wheels of conical and disk shapes are used. They allow grinding both along the plane and inside the holes. The accuracy of milling depends on the specific model. The configuration of metal parts that are made using copiers depends on the accuracy.

Boring

Boring is the process of increasing the diameter of a hole, as well as cleaning it. For through boring, through cutters are used; when boring blind holes, through stop cutters are used. Boring is less productive than drilling, but at the same time allows you to process parts with a large diameter.

Thread cutting

A tap is used to cut threads. It is used for internal metric threads. Taps can be of two types: for roughing and finishing work. We select the diameter of the drill depending on the diameter of the thread and its pitch. It is impossible to make a blind thread without the reverse function. A through one can also be done on a machine where there is no reverse, but in this case, the tap must be pulled out manually.

Grooving

A groove is a recess of metal in a part that is limited by shaped or flat surfaces. The groove can be:

- T-shaped;

- dovetail;

- shaped;

- end-to-end;

- open or closed.

Shaped, disk and end mills are used to cut grooves. When milling precise slots, the size of the disk cutter should be less than the width of the slot. To mill special profiles, for example, dovetails, it is necessary to use vertical or longitudinal milling machines in 3 or 2 transitions.

Spline milling

There are 3 types of spline connections:

- straight-sided;

- triangular;

- involute.

Splines are used to transmit rotational motion between shafts and bushings. Spline cutting occurs in several stages, which include roughing and finishing, slot milling, deburring, grinding and heat treatment.

Comb cutting

This is another operation that, along with cutting splines, is performed on a metal drilling and milling machine. The part is processed on three sides. To process long parts, a spindle and support mounted on a table are used.

Purpose of drilling and milling machines

On a milling and drilling machine, a part is processed from one installation, drilling and milling operations are carried out along a plane. The equipment is intended for the production of spare parts that are in demand when repairing machines and various mechanisms, and for the independent creation of original devices. In private workshops it is possible to produce small batches of parts. At enterprises with mass production of products, combined models such as drilling and milling equipment are not used, or floor-mounted CNC units are installed.

The following operations are performed on milling and boring machines:

- drilling;

- milling;

- boring;

- countersinking;

- thread cutting;

- selection of grooves;

- spline milling;

- cutting combs.

The use of conical and disk-shaped flap wheels allows grinding along the plane and inside holes on drilling and milling equipment. Circles designed for grinders and routers are installed.

To perform operations, the tool changes, depending on the type of processing. FS 1, a tabletop drilling and milling machine, is popular in repair shops and private entrepreneurs. It is designed for processing workpieces up to 200 mm high and 450 mm long. It is used for drilling, tapping and milling along planes, including ends. FS 1 has manual control. Rotation from the motor to the spindle is transmitted by belts.

The following types of parts are manufactured using drilling and milling equipment:

- slabs;

- crackers;

- dowels;

- levers;

- shoes;

- housings.

The precision of milling and the cleanliness of processing allow us to make templates of various configurations for processing metal and wooden parts using copiers. The following grooves are made using shaped cutters:

- rectangular;

- T-shaped;

- dovetail.

When connected to a CNC machine, splines are cut on the shafts, gear racks and fastening bolts with figured heads are made for the grooves on the plates.

Drilling and milling machines can process gypsum, stone, and wood in addition to metal. They are used in construction when laying communication routes. The equipment is suitable for cutting ventilation holes, tapping threads in fittings, and making recesses in bricks.

Capabilities of CNC models

More and more models of modern metal drilling and milling machines are being used using CNC. This expands production capabilities. Program control has several obvious advantages:

- it is enough to use one operator who can operate several machines in parallel;

- the accuracy and quality of part processing increases;

- productivity increases by an order of magnitude;

- Such machines have advanced functionality.

In fact, the drilling and milling machine works independently according to the program established by the operator.

Milling

Milling is the processing of metal using a cutter. It is performed on various types of milling machines and consists of milling splines, various planes, grooves, as well as external contours of cylindrical products. The cutting teeth of a milling machine can be located both on a cylindrical surface and on the end surface. But the turning method allows you to process parts such as couplings, gear wheels, gears, pulleys, nuts, bushings, shafts and other similar products. Milling allows you to trim products, thread cutting, diameter boring, surface turning, and grooving.

What criteria should you rely on when choosing?

First of all, it is important to consider for what work the equipment is purchased. For use in a small workshop, you should not buy an overly powerful drilling and milling machine. It is necessary to evaluate the dimensions of the equipment, as well as the table on which it will be located.

It is necessary to choose a specific model based on its functionality, since they may differ. It is not necessary to pay attention to expensive equipment, since it may not justify itself.

General characteristics

Drilling and milling equipment (both manually controlled and equipped with a CNC system) is not only highly functional, it is reliable and safe to operate. The versatility and capabilities of such a machine are ensured both by its design features and by the fact that it can perform processing using various tools. Thus, cutters, drills, taps, reamers, countersinks and other tools can be installed in the spindle of a drilling and milling machine.

Processing of workpieces made of metal or other material on such a device is carried out due to the rotation and translational movement of a working tool fixed in the spindle. An electric motor is responsible for rotation, transmitting it through a system of drive mechanisms. In drilling and milling machines that are equipped with a CNC system, all operating modes are set by special commands transmitted to the controls.

Cantilever drilling and milling machine from DEKA

When carrying out drilling and milling work, the workpiece and all equipment components absorb significant loads, so the machine must have very high rigidity. If you neglect this requirement, then you may not only fail to obtain the required quality and accuracy of the finished product, but also encounter the fact that the workpiece will move from side to side during processing. Modern manufacturers producing drilling and milling machines carefully develop their design to ensure high rigidity.

The convenience and high efficiency of working with such equipment is also ensured by the fact that the tool in its spindle head is replaced very quickly, without any complex manipulations. At the same time, the reliability of tool fastening is at a high level.