The sandblasting gun, which is equipped with both industrial and domestic installations, is a universal device. With its help, you can effectively degrease various types of surfaces, clean them of dirt and old coatings, prepare them for subsequent finishing, and frost glass.

Pneumatic professional gun with sand intake from an external container

Design and diagram of a sandblasting gun

With your own hands, the sandblasting option under consideration can be made based on 2 variants of design schemes, which differ from one another in the process of supplying abrasive to the output channel. At the same time, their implementation will require almost the same set of components.

The design of such a device will have good performance and low price.

The scheme of its operation will be as follows: the abrasive, which is usually sifted fine sand, under the influence of air flows generated by the compressor, goes through a reinforced hose to the nozzle and enters through the hole in it onto the surface being treated. Due to the high air flow pressure, sand particles receive greater kinetic energy, which is the reason for the effectiveness of the actions taken.

The gun used for such processing does not function autonomously. Using special hoses, it must be connected to a compressor, where high air pressure is generated. In addition, there is a need to ensure sand supply to the gun from a separate container.

In order for such a homemade gun to work properly, a technical system must be created, the basis of which will be a compressor, dispensers and other elements.

Serious attention will also need to be paid to the quality of the sand, which must first be sifted using a sieve and cleaned of all excess. The sand must consist of fractions of specified sizes. If these requirements are not met, then with a high probability the gun nozzle will simply become clogged, so the device will not be able to work normally.

At the exit, such a sandblast should create a flow of air-abrasive mixture. At the same time, the pressure circuit is used to supply the abrasive using pressure into the outlet pipe, where it is mixed with the air flows created by the compressor. Household ejector sandblasting uses Bernoulli's principle to create a vacuum in the area where the abrasive is taken in. And the latter goes into the mixing container.

Sandblasting drawings and diagrams, which make it possible to create such a device yourself, can have a variety of options.

For this reason, the basic principles by which this type of device is created should be considered.

Nozzle for sandblasting machine. How to find the most durable one?

Typical nozzle design

The simplest nozzle for a sandblasting machine is a hollow tube with a threaded part at one end, which is designed to connect the part to the nozzle holder.

The main geometric characteristics of industrially produced replacement nozzles:

- The diameter of the connecting thread (depends on the technical characteristics of the sandblasting machine, but a 2" or 1¼" cylindrical pipe thread is usually used. It is also possible to connect the nozzle with the nozzle holder using a union nut and a sealing washer. Do-it-yourself nozzles are connected to the hose of the working unit using ordinary clamps.

- The length of the part, which varies in the range of 7…23 mm (shorter ones are used for cleaning less contaminated surfaces).

- The diameter of the internal hole at its minimum cross-section. Replacement tips are available with diameters of 6, 8, 10 and 12 mm.

- The inlet diameter of the nozzle, determined by the diameter of the connecting hose (it can be 25 or 32 mm).

The main parameter of the part under consideration is the profile of the internal hole, which determines the flow loss of the air-sand mixture, its speed at the inlet and outlet of the nozzle, as well as the value of the total hydraulic resistance, which ultimately determines the durability of the nozzle.

The simplest option (suitable for making it yourself) is a nozzle with a cylindrical internal hole of constant diameter. But to improve aerodynamic characteristics, two conical sections are sometimes made on such parts:

- Inlet confuser, the presence of which allows you to increase the energy of the flow of the mixture entering the nozzle;

- An output diffuser, the presence of which helps to increase the surface area processed simultaneously. In this case, the flow energy decreases, therefore, if higher-quality cleaning is necessary, a diffuser profile at the end of the nozzle is not always provided.

The most efficient internal orifice profile to ensure minimal flow loss is a Venturi profile sandblaster nozzle.

In this case, the hole consists of three interconnected sections, each of which performs certain functions:

- At the inlet of a nozzle with a Venturi profile there is a confuser expansion, the angle of which, however, is less than that of a confuser of a conventional nozzle (no more than 20...22º). The confuser part occupies up to 30% of the total length of the part.

- Cylindrical part, no more than 15% long.

- A diffuser part with a fairly small expansion angle (7...15º), the length of which is determined by the size of the nozzle itself in plan.

In order to reduce the hydrodynamic resistance of the working mixture that moves in the nozzle channel, all transitions from one part to the next are made with radius curves, the value of which is taken within the range of r = (0.02...0.03) d, where d is the diameter of the middle, cylindrical part of the nozzle.

How to choose a nozzle for a sandblaster?

A nozzle with a Venturi profile allows you to increase the speed of movement of the sand-air mixture by 2.5...3 times compared to nozzles with a different internal hole configuration.

A modern nozzle for a sandblasting machine with a Venturi profile is capable of ensuring the movement of particles at the outlet up to 700...720 km/h.

At the same time, the cleaning performance at the same mixture flow rates and pressures increases approximately 2 times.

Approximately, the selection of nozzle parameters can be made according to the following criteria:

- In terms of performance. With the required installation productivity of up to 10...12 m3/h, the internal diameter of the nozzle does not exceed 8 mm, with 12...22 m3/h - 10 mm, with higher productivity values, the diameter of the internal channel should be 12 mm;

- According to the highest air pressure. If it does not exceed 5 at, then the channel diameter can be taken as 6...8 mm, at pressures up to 7 at - 8...10 mm, at higher pressures - 12 mm;

- Depending on the specific consumption of abrasive. If this parameter does not exceed 200...250 kg/h, then a nozzle with a diameter of 6 mm is suitable, at 350...400 kg/h - 8 mm, at 600...900 kg/h - 10 mm, in other cases - 12 mm.

Preparing tools

To obtain sandblasting, you will need to have the following components on hand:

- nozzle;

- compressor;

- a gas cylinder that will act as a container for abrasive.

In addition, depending on the characteristics of the structural type, the following elements may be needed:

- Ball Valves;

- rubber hose equipped with reinforced inserts 1.4 cm or more;

- air hose with a diameter of up to 1 cm;

- transition type coupling;

- fittings, which are hose fastenings or collet-type clamps;

- fum tape, which allows you to seal connections;

- glue gun or an analogue for polyurethane foam;

- hot glue;

- empty 0.5 liter plastic bottle;

- grinder or file;

- sandpaper with a block;

- drill with drills;

- Bulgarian;

- sharp knife;

- pliers.

Principle of operation

Guns that are used to perform sandblasting are now mass-produced and can be purchased by anyone. Meanwhile, such devices, if they are of high quality, are quite expensive, and those that can be bought at a low price are not of good quality and are not able to last a long time.

To make a pneumatic sandblasting gun inexpensive, you can make a homemade device.

The design of such a device is distinguished by the upper location of the tank and has a number of disadvantages, which are compensated by fairly high productivity and low cost. A homemade pneumatic gun, despite its simple design, allows you to effectively perform sandblasting operations on various surfaces, cleaning them from old coatings, traces of corrosion and various contaminants. Such a device can be used for frosting glass, as well as for degreasing surfaces.

A homemade device for sandblasting, like serial devices, works on the following principle. The abrasive material, which is mainly used as carefully sifted fine sand, under the influence of the air flow created by the compressor, is fed through a reinforced hose to the nozzle and flows through its hole to the surface being treated.

Due to the high pressure of the air flow moving the sand, significant kinetic energy is imparted to its particles, which contributes to the efficiency of the operation.

The gun used for sandblasting cannot work autonomously: using special hoses, it must be connected to a compressor, due to which a high air flow pressure will be created in them. It is also necessary to ensure the supply of sand to such a gun, which is located in a separate bunker.

In order for a homemade air gun to function normally, a technical system is formed, consisting of a compressor, hoses, containers, taps and dispensers. Particular attention should be paid to the quality of the sand used, which must be cleaned and sifted through a fine-mesh sieve.

If this requirement is neglected, contaminated or too coarse sand will certainly clog the gun nozzle and it will not be able to function normally.

Design features

The design of an air (pneumatic) gun intended for sandblasting includes the following main elements:

- a nozzle through the hole of which abrasive material is supplied to the surface being treated;

- a nozzle tip, which can be made of steel or ceramics;

- handle with a trigger, providing ease of manipulation of the device;

- fittings with which hoses for supplying compressed air and abrasive mixture are connected to the gun.

The effectiveness of a sandblasting gun largely depends on the quality of the nozzle used. Such an important design element of this device can be made independently, but in this case it will be difficult to achieve the required quality of workmanship.

That is why it is better to purchase serial nozzles for a sandblasting gun (and some of their models can even be equipped with a handle and trigger).

A homemade or serial nozzle, if it is purchased as a separate structural element, must be placed in a housing with a comfortable handle and fittings for connecting hoses. Those who want to make a sandblasting nozzle at minimal financial cost can find a video online demonstrating how an ordinary plastic bottle, standard fittings and tees can be used for these purposes.

If we talk about the design of a pneumatic sandblasting machine as a whole, its mandatory elements are:

- a compressor that provides the required air flow pressure;

- a pistol equipped with a nozzle, a steel or ceramic tip, and a trigger;

- a hose through which compressed air is supplied from the compressor to the apparatus system;

- a hose through which abrasive material is sucked from a special container;

- suction valve or intake pipe.

If you are going to make a device for pressure-type sandblasting, you should supplement its design with a special container from which sand or other abrasive material will be supplied under pressure. As the simplest version of such a container, you can use a metal barrel, the bottom of which is cut off and a metal cone with an outlet hole is installed instead.

In order for the abrasive material from such a barrel to be supplied under the required pressure, it must be located at a certain height.

In many cases, it is better to use a nozzle for sandblasting not in open space, but in special chambers, which allows not only to increase work efficiency, but also to significantly reduce the consumption of abrasive material. Such a chamber, which is a box welded from metal sheets, can be made independently if desired and has the appropriate experience.

Small parts are usually processed in special chambers. In the design of the sandblasting chamber, if you plan to make it yourself, you must provide the following elements:

- a viewing window with glass through which you can control the processing process;

- lighting of the interior of the chamber;

- two holes in the front of the camera with gloves attached to them, into which the operator’s hands will be inserted;

- a grate at the bottom of the chamber and a chute underneath it, through which the used abrasive material will be poured into a special container.

It is advisable to equip such a chamber with a ventilation system that will ensure the removal of dust generated during operation.

Which compressor to choose for a homemade sandblasting installation

The most important element of any sandblasting installation - both industrial and homemade - is the compressor, with the help of which the required air flow pressure is created. For the use of an air sandblasting unit in domestic conditions, a compressor operating from an electrical power supply with a voltage of 220 V is quite suitable. The main thing is that such a device can provide a productivity of 300 l/min and produce an air pressure of at least 6–7 atm.

If it is not possible to find a receiver for such a compressor, then you can do without it, since air intake will be carried out in a constant mode. However, it is better if there is a receiver: it will avoid pressure drops at those moments when the compressor switches to different operating modes. In addition, with its help, the air entering the device system will be freed from moisture and oil inclusions.

Double-piston compressor with forced cooling with a capacity of 500 l/min

When choosing a compressor for your homemade sandblasting machine, you should keep in mind that there are two main types of such equipment.

Pressure type

In such devices, abrasive material is fed into the system under the influence of not only compressed air, but also its own mass. This equipment, which is of a professional type, is used in cases where high productivity of sandblasting work is required. With the help of such devices, which are equipped with compressors with a capacity of at least 5000 l/min, the surfaces of large metal and concrete structures are treated - bridges, building facades, ship hulls, carriages, etc. Such devices can be manufactured for domestic use, but not always expedient.

Injection type

In such equipment, only the pressure created by the air flow is used to supply abrasive material from an open container. It is devices of this type that are most often used to perform sandblasting in domestic conditions.

How to make a blow gun?

Now let's look at how to make such a pistol from various devices. The first will be instructions for creating a version of the device from a blow gun. You will need to have:

- blow gun;

- drill according to the diameter of the nozzle.

First, you should cut off the strip on the neck of the bottle, which is located under the cork. A hole is made where the strip was. Now you need to try on the nozzle by inserting it into the drilled hole. We use a marker to mark the groove for the technological type opening in the pistol nozzle, and then file this place. Now you need to insert the nozzle into the hole.

After this, all that remains is to seal the joint and then secure it with hot glue. All that remains is to pour sand into the bottle, connect the device to the compressor and you can begin work on cleaning the tool from rust.

However, when working with a sandblasting machine, it is necessary to comply with safety standards and use the necessary personal protective equipment: goggles, closed clothing, a respirator, mittens or gloves.

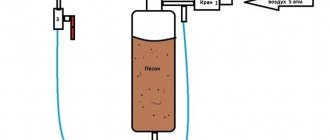

Assembling the apparatus from a gas cylinder

The next option for creating such a device is from a gas cylinder. You will need to have:

- gas cylinder;

- ball valves – 2 pcs.;

- a piece of pipe that will become the basis of a funnel for filling the container with sand;

- brake tees – 2 pcs.;

- hoses with a nominal bore of 10 and 14 mm - they are needed to connect to the compressor and remove the mixture;

- clamps for securing the sleeves;

- fum tape.

The algorithm of actions will be as follows.

- Preparing the balloon. You will need to remove the remaining gas from it and clean the inside of the surface using non-abrasive detergents and wait until the surface is dry.

- Making holes in the container. The hole at the top will be used to pour sand. It should be the same size as the prepared pipe. The hole at the bottom is for the compressor, or more precisely, for connecting a tap.

- Crane installation. It can be welded or simply screwed using an adapter pipe.

- Now all that remains is to mount the brake tee and the mixer block. To make the threaded connection as tight as possible, you can use fum tape.

- A tap is mounted on the balloon valve, after which a tee is located.

- Next, you need to decide to make the device as mobile as possible. To do this, you can weld the handles and wheels for ease of transportation. To make the device stable, you need to weld supports from a corner or parts of reinforcement.

It remains to connect the parts of the supply and delivery channels of the composition:

- the fittings must be mounted on the tee and the balloon valve;

- a sleeve with a 14mm passage should be placed between the tee and the mixer area;

- a pressure-type installation should be connected to the tee branch, which is free and equipped with a fitting;

- a hose for supplying the finished composition is connected to the last free outlet from the tee.

To create a tight structure, a screw-type cap can be mounted on the pipe for filling the cylinder with sand.

Making from a spray gun

Sandblasting can also be done using a spray gun. The following components should be prepared:

- gun with mixing valve;

- handle with air supply device;

- a plastic bottle that will act as a container for abrasive;

- tee;

- a ball valve with which you can control the supply of sand.

The assembly of such a device will be carried out according to the following algorithm:

- the gun should be bored out so that the diameter of the inlet nozzle increases;

- the mixing tee should be connected to the gun;

- Next, it is necessary to install and secure the supply and circulation hoses;

- Now you need to press the trigger so that the abrasive is released. If everything works fine, then the device from the painting console is ready for use.

It should be added that a small plastic container will be enough to clean surfaces within half an hour.

Other options

A sandblasting gun is also made from other devices. The most common options include upgrading your pressure washer. We are talking, for example, about the K?rcher mini-wash. Such a sink generates very high water pressure with low water consumption, and therefore is an ideal solution for obtaining a sandblasting machine. Here it will be especially important to use fine (calibrated) sand of uniform dispersion.

Another advantage is that there is no need to disassemble the mini-wash itself. It will only be necessary to make a nozzle for the outlet tube of the device.

To do this you will need to purchase:

- ceramic nozzle;

- hoses with reinforcement;

- mixing block in the form of a tee of suitable diameter;

- cylindrical dispenser.

As mentioned above, a feature of this device is that water, rather than air, will be responsible for the supply of sand here. Liquid under pressure will flow through the mixing compartment, forming a vacuum in the hose, which is responsible for supplying the abrasive. Thanks to this, sand will be ejected with great force, which will allow cleaning, grinding and matting the surface.

Another interesting option is to make an anti-gravel device from a regular fire extinguisher.

To do this, you will need to find a fire extinguisher and then create a plug using a lathe to seal the top area. You will need to put a rubber sealing ring on the plug and then screw it into the neck of the device. This hole will be used to fill sand inside.

After this, you will need to drill holes for the housing in the upper part, as well as at the bottom. First you need to clean these areas of the old paint coating. In addition, legs made of fittings or pipes can be welded to the bottom using welding. After installing the tees and supply and output hoses, the sandblaster will be ready for its intended use.

As you can see, there are a large number of options for creating a sandblasting gun: from a sandblasting gun, a spray gun, a fire extinguisher and other devices or improvised means. In principle, this is not difficult, but you should clearly understand what exactly you are doing, and also have the necessary components on hand.

When creating sandblasting with your own hands, you must strictly comply with safety requirements, and all work must be carried out only with special protective equipment and devices.

Initial conditions

The principle of abrasive blasting is that abrasive particles are introduced into a strong stream of air or a water-air suspension (see below). In the jet they both accelerate to speeds of several hundred km/h and spin. If you direct such a jet at a part, the impact of the abrasive on its surface will be comparable in strength to that of a hard abrasive tool, but much “softer”; the abrasive jet spreads over the surface being treated and processing occurs virtually without disturbing its configuration. Matting of hard materials using the abrasive blasting method is possible using abrasives of equal or even slightly less hardness than the material being processed. Have you ever wondered how diamonds are sawed, cut and polished? Diamond powder. But in both cases, a large amount of abrasive dust is formed, which has a detrimental effect on literally everything, living and inanimate, natural and man-made. Therefore, a DIY sandblasting machine is not enough; in the end it's not that difficult, see below. However, first you need to firstly become familiar with the basic safety rules for abrasive blasting. Secondly, decide for what purposes you need sandblasting and whether the additional equipment necessary to start it is available - an air compressor or a car or household washer. Thirdly, remember whether you have a garage or workshop, either already equipped for sandblasting, or suitable for such conversion. It is not difficult, but without it, using sandblasting means ruining yourself. And finally, if you plan to carry out air sandblasting, then see if there is space in the garage/workshop for installing a sandblasting chamber, see below.

Recommendations for making your own sandblasting gun

How to choose a sandblasting gun, how to make it yourself, how to properly assemble and adjust all the elements of the device? These and many other questions are of interest to those who independently clean various surfaces, prepare them for painting, degrease them, make the glass surface matte, etc.

After you have purchased or made your own air gun, it is very important to correctly connect all the structural elements. First of all, you need to connect the gun to the compressor, for which you use a fitting on its body and a special hose. A hose must be connected to the second fitting on the gun body, through which abrasive material, sucked from a separate container, will be supplied to the nozzle. Naturally, the second end of this hose should be placed in this container.

To ensure effective suction of sand from the container, the length of such a hose should be made as short as possible. The diameter of the hose through which abrasive material will be sucked into the system should be selected within 20 mm.

So that sand, which is not a flowing material, can be sucked into the hose, it is necessary to make a special nozzle that will provide air suction. Making such a device is not at all difficult. To do this, take a metal pipe with a diameter corresponding to the diameter of the hose. A slot is made at the end of the pipe, which will be inserted into a container with sand; its clearance is adjusted using a rubber ring, also cut from a hose. By moving such a ring along the end of a metal pipe and blocking the slot on it to varying degrees, you can regulate the flow of abrasive material supplied to the apparatus system.

To start working with the sandblasting machine, you need to open the valve on the gun or press a special trigger, which will lead to the supply of compressed air to the system. Air passing through the hose under high pressure will cause a vacuum in the intake hose, due to which abrasive material will begin to be sucked out of the container through it. Once in the main hose, the sand will mix with air and begin to flow to the nozzle of the device, and through it to the surface being treated.

In order for the operator of such an installation to regulate the flow of air and abrasive material during processing, the gun is additionally equipped with a dispenser and a tap.

The functions of the sandblasting nozzle and the homemade apparatus for performing processing with its help are not limited to the above-mentioned possibilities. With their help, in particular, you can engrave glass, applying decorative patterns and designs to its surface.

Manufacturers

Experts recommend nozzles from the following companies:

- Contracor - Russia;

- CLEMCO - Germany;

- VMZ - Velikoluksky Mechanical Plant.

German products are known for their reliable performance and long service life. Nozzles from CLEMCO are considered the best. The company produces mainly ceramic and tungsten carbide inserts.

Sandblasting nozzles from the Russian company Contracor are not inferior to them in quality. The main products are boron carbide, tungsten and ceramic inserts are available.

VSW produces conventional nozzles at a budget price. Hobbyists can purchase a variety of attachments - metal, ceramic and cast iron for one-time repairs.

How to install sandblasting on a Karcher and other alternative manufacturing options

Inventors who like to assemble their own tools from scrap materials or other devices suggest using a variety of materials in their work. Thus, they manage to produce devices of different types, for example, a sandblasting gun with a bag for collecting sand, which allows the use of abrasive several times in a row, or a variety of recirculation-type devices. At the same time, the work often uses devices intended for completely different purposes.

- One good example is a homemade sandblaster made from a pressure washer. Most often, equipment is taken for work. The result is a dust-free sandblasting machine that can effectively clean even complex contaminants.

- The washing process creates high water pressure during operation, but it is important that the liquid consumption is minimal. In order to get an efficiently operating dust-free installation, you will need to assemble a sandblasting nozzle onto the outlet pipe.

In addition, you will need other components:

- homemade or ceramic nozzle;

- high-quality reinforced hose;

- mixing unit, you can use an ordinary tee, the main thing is to choose the part you need in diameter;

- feed control unit, which is a cylindrical dispenser;

- a pipe for sand intake, supplemented by an air supply path into a closed container with abrasive.

The finished water-type sandblaster from the sink will work using an ejector system. In this case, high-pressure water, as it quickly passes through the mixing unit, creates a vacuum in the abrasive material supply unit. After this, the sand along with water is thrown out under high pressure.

Among the features of using such a device, the following point can be highlighted: despite the low water consumption, the abrasive is supplied very intensively. This allows you not only to clean surfaces, but also to frost the glass.

Helpful advice! In order for a device made from a high-pressure washer to consistently supply abrasive, you need to use fine sand of uniform dispersion. For household work, fine, sifted river sand is suitable.

By following the instructions, you can create a powerful sandblaster for large-scale work or make a simpler device. In this case, it all depends on the skills and parts that are available. Before choosing a specific design, it is better to immediately decide on the scope of work that is planned to be solved using the device.

Overview of species

Types of functional devices can be divided into:

- pressure (designed for a large area that needs to be treated);

- injection (ideal for non-industrial work).

In turn, injection systems are divided into:

- suction;

- vacuum (the abrasive does not remain on the surface, but is sucked back by the vacuum);

- pneumatic – optimal for carrying out work over a large area.

The nozzle for a sandblasting machine can be:

- different diameters (both outlet and in the holes on the nozzle);

- round or oval cross-section;

- made of different materials - ceramic, steel and cast iron, boron carbide, fluorine (up to 1 thousand hours of operation) or tungsten.

In the description, you should definitely look at the performance of the compressor (this is one of the factors in the correct selection of the tip).

The Venturi nozzle stands separately, it has a complex design and is not cheap, but if the direct-flow nozzle gives an abrasive flow rate of no more than 340 km, it provides an indicator almost twice as high. When creating it, the principle of the Laval nozzle was taken into account, which in many cases determines the optimization of operation and regulation of the direction of the emitted jet.