- Lever.

- Trigger.

- Nozzle for spraying air-sand mixture.

- Bushing for connecting a tank or sand supply hose.

- Sand reservoir.

- Bushing for connecting the air supply hose from the compressor.

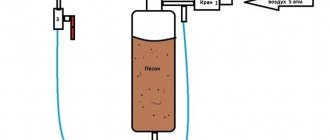

In many ways, a sandblasting gun resembles a spray gun, only the nozzle here is made of a different material and has a different diameter. The principle of its operation is as follows: compressed air from the compressor is supplied through the hose through the bushing ( 6 ). At this time, abrasive is sucked out of the reservoir ( 5 ), which is supplied to the nozzle ( 3 ) of the gun. And the abrasive is blown out of the nozzle under pressure onto the material being processed. Essentially, the gun has an injection method of operation, in which air and sand are supplied through different hoses. Because of this, the performance of conventional pistols is several times less than that of sandblasting machines, and they are much weaker than their larger-sized counterparts.

Sand supply method

The abrasive can be collected directly from the attached tank or from another tank using a hose. What is the best sandblasting gun, hose-fed or barrel-fed? It all depends on the amount of work being done. For example, if you need to clean 1 - 2 m2 of sheet metal, then a regular tank will be enough. But it needs to be constantly replenished, which means downtime. The advantage is its mobility, that is, you will have to drag fewer hoses. We can say that a pistol with a barrel is intended for small-scale work in the garage.

For larger jobs, it is better to choose a hose sand supply. In this case, the hose is lowered into a sand reservoir, such as a large barrel, and the sand is fed until it runs out. This method of supplying abrasive is convenient when you need to clean a large area, for example, a car body. However, due to the hose, some of the mobility that a device with a tank has is lost. In general, this is not critical if the sandblasting machine is in our garage and we perform all the work in one place. Also, hose sandblasters have a higher air consumption and require higher pressure. If for devices with a tank approximately 3 - 4 bar is enough, then for hose devices you need 5 - 8 bar.

How to choose the right model?

Before buying sandblasting machines, you need to familiarize yourself with a number of factors that affect the performance of the equipment:

- Sandblasting devices must be equipped with thick-walled hoses to withstand prolonged exposure to abrasive and pressure.

- The abrasive feed rate depends on the size of the hole on the nozzle.

- It is not recommended to buy models with plastic parts, as they will quickly fail.

- You need to evaluate the pen before purchasing so that it is convenient to work in the future.

If you need a model for your home, garage, or workshop, you need to buy a unit with a container for abrasive.

Material of manufacture and diameter of nozzles

When purchasing, it is important to pay attention to the material used to make the nozzles, as this is the main consumable material in the gun. As sand rubs against the inside of the nozzle, the material is gradually “eaten up.” Gradually, such a nozzle begins to wheeze and whistle like an ultrasonic plane, thereby indicating that it is time for it to retire. The best materials for nozzles remain ceramics and tungsten carbide. The easiest way to find ceramic nozzles on sale.

- Home Appliances

Pumping air in liters: the best oil compressors 2020

Also select the size of the nozzle, taking into account the pressure it needs to operate properly and the performance of the compressor. And if the compressor usually does not have problems with pressure (most are capable of freely delivering up to 8 bar), then you need to pay close attention to performance. Below is an approximate dependence of the nozzle outlet diameter on the compressor performance:

- 2 mm – 0.2 – 0.3 m3/min.

- 3 mm – 0.3 – 0.6 m3/min.

- 4 mm – 0.6 – 1.2 m3/min.

- 6 mm – 0.9 – 1.8 m3/min.

Based on the fact that in most cases we first buy a compressor, and only then choose a sandblasting gun, pay attention to the performance of your compressor to select the optimal nozzle diameter.

What parts are useful as components for making sandblasting with your own hands?

Before sandblasting, you should make sure you have the necessary parts, most of which can always be found in your garage, storage room or workshop. You should look for missing items at flea markets or hardware stores. One of the important components is the container from which abrasive sand will be supplied to the main line. Most craftsmen prefer to use an old gas cylinder for this purpose.

Note! If you use a gas cylinder for work, you should carefully check that there are no signs of rust, dents or other damage. In addition to using the cylinder as a container for abrasive, it can be useful for making a receiver for a compressor, however, during disassembly, maximum safety precautions must be observed.

Without all the necessary parts, it will not be possible to assemble a sandblasting machine.

In order for the container to be freely filled with abrasive, it is necessary to weld a piece of pipe to the container. For convenience, a neck should be fixed in the upper part, which will act as a funnel for pouring sand.

You will also need other equipment for sandblasting:

- Ball Valves. It is better to choose the most reliable and durable materials from trusted manufacturers with a good reputation.

- Reinforced rubber hose. The best option is a sleeve with a diameter of 14 mm, which is designed for high pressure and constant friction of abrasive sand.

- Gas hose. The diameter of the product must be at least 1 cm. It is through this hose that compressed air will be supplied to the system, which has not yet mixed with the abrasive material.

- Collet-type fittings and clamps. Needed to secure hoses to other elements of the system.

- Fum tape or other sealant. All connections require reliable sealing, because sandblasting works under constant high pressure.

Most of the parts you need can be found in your garage.

Connection of nozzles and air hoses to the gun body

The important elements in a sandblasting gun are the connecting fasteners. The nozzles can be attached to the gun using a union nut or a grub screw. During operation, vibration can cause the nut to often loosen, which is why it will have to be constantly tightened. The threaded pin in this case is much more reliable and does not unscrew due to vibration.

The air supply hose can be connected to the gun body using a tightening coupling or a rapid-type quick-release coupling. If the coupling is not tightened properly, the pressure hose may break off. But this will not happen with a quick-release connection, so we recommend purchasing a device with this air hose design. For example, you can take a Matrix 57328 with a rapid mount.

Compressor unit design

When choosing a compressor, it is recommended to decide which engine will be used for the drive. Typically used:

- Electric motors, they operate on 220 or 380 V.

- Gasoline engines consume A-92 gasoline as fuel (usually four-stroke devices are installed, but some manufacturers also install two-stroke engines).

- Diesel power plants. Solar oil is used as fuel.

Types of drives for household and industrial compressors:

Compressor equipped with diesel engine. Power is 12 kW, equipped with a 350 l receiver:

Heat engines allow compressors to operate autonomously. Such installations are operated when performing work at a distance from power sources. They are used to work on remote construction sites:

- During the repair and construction of bridges and overpasses. There it is necessary to clean the reinforcement from various impurities before subsequent pouring with concrete.

- In case of destruction of objects taken out of service. The country is undergoing an extensive renovation of the housing stock. We have to demolish buildings that are unfit for habitation. They contain significant volumes of metal frames. To remove construction waste, you need to remove the reinforcement. Sandblasting units assist in cleaning.

- If it is necessary to use high-performance equipment, compressors based on diesel or gasoline engines can produce tens of cubic meters per minute.

A household compressor uses a single-cylinder device. The drive is carried out by a V-belt. It is these installations that have become widespread in small car repair shops:

- Electrical equipment with power supply up to 3.0...3.5 kW is usually operated from a 220 V network. They are connected with ordinary plugs. In this case, the current consumption does not exceed 15 A. Such installations are used in small industries or by individual entrepreneurs engaged in car repairs.

- If it is necessary to use more productive units, a 380 V network is used for power supply. It is capable of connecting compressors that consume up to 90...100 kW of electricity. Such installations can produce up to 5...10 m³/min. Such devices are installed in industrial enterprises.

- In factories or workshops, they try to locate power equipment in a separate room. Then the sound from operating devices will tire the ears of workers less. Compressed air is supplied from compressors through pipes.

- Modern enterprises widely use polypropylene pipes. They are easy to weld together, and it is not difficult to organize branching and distribution to different consumers.

- To evenly load the network with compressed air, receivers are installed near consumers. They smooth out pressure pulsations. The available reserve allows the operation of technological equipment in optimal modes.

- To operate sandblasting, they try to place a 500...800 liter receiver near the object. Then, during operation, a productivity reserve will be provided. The work will be carried out in a stable mode.

Video: compressor for sandblasting.

Rating of sandblasting guns 2022

Sturm AU-1720-03

Sandblasting gun made in China for working with sand and other abrasive materials. This device has an abrasive supply from a tank. The tank is made of stainless steel and has a volume of 1 liter. A pressure of 4 bar is sufficient for this gun. The kit includes connecting fasteners for the air supply hose of the bayonet type. This is a type of quick release fastener in which one part of the coupling is rotated and secured to another part of the coupling.

Air consumption is 164 l/min, but users note that a compressor with a capacity of at least 200 l/min is needed. The diameter of the air hose connection sleeve is ¼ inch. The kit comes with a fairly thin 2.5 mm nozzle. This gun is certainly not for large volumes of work, but it is quite suitable for household tasks.

Fubag SBG 142/3.5

This is a fairly popular sandblasting gun that has proven itself well in cleaning bodies of old paint and rust. A stainless steel tank with a capacity of 0.8 liters, as well as a nozzle with a diameter of 6 mm, are standardly installed here. Thanks to this nozzle, you can remove paint from a large area. However, the tank will be used up quite quickly, so be prepared to refill it with abrasive often.

The diameter of the air hose connection sleeve, like the previous model, is ¼ inch. The gun consumes about 142 l/min, and it requires a compressor with a tank capacity of at least 70 l and a capacity of at least 260 l/min. It operates with a pressure of 3.5 bar. The model is distinguished by high-quality assembly and reliable operation. The manufacturer provides a 2-year warranty on it.

Matrix 57326

This is a more powerful sandblasting gun, and it is intended for more serious work. Operates with a pressure of 4 bar, flows up to 230 l/min. To work with it, we recommend using a compressor with a capacity of at least 300 l/min.

The gun uses a 6mm diameter nozzle. The manufacturer recommends using abrasive material with a grain size of 1.6 mm or less to work with it. However, from experience we can say that the device copes quite well with sand with a grain size of up to 2 mm. The pistol is not as popular as the Fubag SBG 142/3.5, but is not inferior to it in terms of reliability and performance.

Metabo SSP 1000

The Metabo company produces not only high-quality power tools, but also good equipment for auto repair shops, of which the Metabo SSP 1000 professional sandblasting gun is clear proof. To operate it, you will need a compressor capable of delivering a pressure of 7 bar and an air flow of about 400 l/min. The gun itself consumes up to 300 l/min.

The manufacturer included 3 ¼-inch bushings (nipple) for connecting the air hose: EURO, ISO and ARO/Orion. The connection of the bushing to the gun body is made using quick-release rapid fasteners. This model has a good quality vacuum tank and nozzle. If you need a gun for regular and not one-time work, feel free to take this device from Metabo.

Another tool for the auto repair shop:

- Let's tighten everything: how to choose a reliable wrench?

- Ready for anything: 7 powerful cordless screwdrivers

Application of technology

A sandblasting gun is a device for carrying out abrasive processing of various materials, surfaces, and objects. As an independent device or in conjunction with a sandblasting chamber, it is used in construction and repair, metallurgy, instrument making, the automotive industry, and a number of other industries.

The device is in demand for different types of work:

- removing rust before applying anti-corrosion compounds, other protective agents or to extend the service life of products;

- grinding wood, metal, plastic, stone, ceramics (objects, blanks, individual components) before decorating;

- cleaning from dirt and old paintwork;

- frosting glass to give an opaque effect (dishes, showers, windows);

- degreasing metal before coating with varnish or paint;

- applying drawings to glass and other materials;

- cleaning parts of complex shapes;

- restoration of art objects;

- imparting roughness to materials in order to enhance adhesion with various coatings;

- artificial aging of wood - furniture, decor, interior elements;

- cleaning the car body from dirt and old coatings before painting.

A sandblasting gun is indispensable for cleaning various curved parts: you can spend a lot of time on this process manually, and the quality of preparation of the product will not be the best. When using sandblasting, even hard-to-reach areas will become perfectly clean and sanded in a short period of time.