Due to the U-shaped profile, the channels have high strength characteristics with low metal consumption. Therefore, they are widely used for assembling load-bearing structures for various purposes. The welding technology is selected regardless of the manufacturing method (welded, hot-rolled, bent channels). The strength of the created structure depends on how reliably the channel is welded to other elements.

Welding methods

The welding method is chosen depending on the purpose of the structure being created. It is taken into account that in the weld zone the strength decreases to 10%.

Arc welding

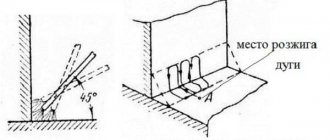

This welding technique is used more often than others, as it allows installation in hard-to-reach and inconvenient places. Small jumpers can be connected using conventional electrodes, but the UONI brand is used to assemble the node elements. However, due to their specific nature, experience is required to work. Therefore, it is useful for beginners to first practice on unnecessary trimmings.

Before starting work, the surfaces adjacent to the joint are cleaned of dirt and rust. The electrodes are dried, since the quality of the seam depends on the moisture content of the coating. The work is carried out with direct current of reverse polarity in a short arc. Electric arc welding is prohibited at temperatures below -40°C.

Gas welding

This method is practically not used for welding channels, as it is accompanied by heating of a large area near the joint. As a result, the zone with reduced strength on the welded beams increases. In addition, internal stresses arise in the metal, leading to deformation of the structure. A gas torch is used to eliminate defects, cut workpieces and prepare edges.

Welding channels without loss of joint strength

Any welded connection weakens the structure and its individual components. Therefore, in construction, to reduce welded joints under increased loads on the support beams of load-bearing structures, it is customary to use channel and I-rolled metal products. Welding a channel during installation of load-bearing parts of a structure is a particularly important stage, but it often causes difficulties and the inability to comply with strict welding rules (GOST).

General information about the channel

A steel channel is a metal product that has a U-shaped cross-section profile. This design makes it possible to obtain high structural characteristics with minimal consumption of material and metal. The methods of manufacturing channels (by bending on a special machine or by hot rolling) do not affect the choice of welding technique when connecting them, but only on the general strength characteristics.

The main advantages of the channel are aimed at strengthening individual structural units and are:

- Able to withstand large axial loads.

- High resistance to bending under central load.

- Possibility of connection without welding.

And also these same advantages are also disadvantages when welding channels.

Currently, five types of channels are produced:

- special;

- with shelves of different sizes;

- equal-flange;

- with a certain slope of the shelf edges;

- with parallel edges of the shelves.

The greatest joint strength can be achieved by welding equal-flange channels with parallel flange edges. They are the most in demand in the construction industry.

Difficulties in connecting channels

Channels have proven themselves well for prefabricated metal structures, but the smallest errors in their connection cause a critical violation of the strength of the entire structure. Each welded joint itself weakens the strength of the metal structure by 5-7%, despite the fact that the weld metal has higher strength characteristics than the metal of the main part.

The problem lies in the welding technique itself, in the correct preheating of the metal and in the experience of the welder. An inconvenient position when assembling some units, as well as incorrectly selected seams, leads to the fact that the heat-affected welding zone (zone of uneven melting) loses up to 20% of its strength. These are the most vulnerable joints and there are two of them for each weld, on both sides. GOST provides for the most common node connections, but not all.

Result:

- All recommended standards according to GOST cannot be neglected.

- Welding of channels according to GOST is much stronger, even with additional reinforcement of the structure.

- All additional linings after butt welding must be performed exclusively on the outside of the channels.

- Welding in the inner corners of the channel only weakens the overall structure, so welding in the inner corners, as well as inside the channel itself, is not advisable.

- You can weld not only according to GOST, as this is sometimes inconvenient, but also based on recommendations.

Arc welding

The peculiarities of using electrodes and the possibility of selecting them according to their main characteristics make electric arc welding the most preferable for connecting channels. The highest quality seam is obtained using UONI electrodes, but there are some peculiarities of their use.

Recommendations:

- It is advisable to make overlapped connections.

- Working with these electrodes requires experience.

- Before starting work, the electrode should be calcined in a special oven at a temperature of 250 0C for an hour.

- The metal must be carefully prepared in accordance with GOST.

- For welding it is necessary to use a short arc of medium power with reverse polarity.

- It is easier to weld with straight polarity, since the electrode burns more slowly, but then you need to monitor the weld pool. She must not overtake the arc.

- With such a connection, it is imperative to check for internal defects.

The welding mode itself and the speed of the seam depend on the selected type of connection, but the most optimal for manual welding is 20 m/h.

Gas welding

When connecting channels, the use of oxygen-gas welding is most often completely abandoned. The heating temperature and a large heating zone, and, accordingly, an even larger heat-affected weak heating zone, do not favor the choice of this joining method. Negative thermal effects, as well as overheating of the weld area, lead to unnecessary internal stress in the metal and severe deformation of the overall structure (beam).

Channel welding options

Depending on the requirements and installation conditions, the channels are connected end-to-end, inward, with overlays, or offset.

Butt welding

This option is used to create seams that do not have increased strength requirements. Butt welding of channels is performed on both sides. If a one-sided suture is applied, its root must be welded. With a shelf thickness of 6 - 12 mm, the edges are cut at an angle of 30°. On thicker metal, the angle is made obtuse with a V or X-shaped profile.

To weld channels together, they are installed horizontally with a gap of no more than 3 mm. For precise alignment, a centralizer is used, then fixed with tacks in increments of 4 cm. Butt welding of the channel is carried out from the middle to the edges. However, such a connection is unreliable. Therefore, when the extension of the beam is completed, it must be reinforced with overlays.

Types of joining channels

The choice of connection is directly proportional to the size of the structure and the forces acting on it.

The following options for the relative arrangement of channels are distinguished:

- the channel shelves are facing inward;

- the channel flanges face outward (forms an I-beam);

- mixed arrangement of shelves;

- the channel flanges are perpendicular to the plane of the frame;

- diagonal placement (standing or lying down).

The choice of a particular option is associated with:

- suture conditions;

- the length of the welding site and the number of workers involved to apply it;

- type of forces and places of their influence;

- type and overall dimensions of the channel;

- the required design stability and full load on the structure.

Requirements for channel welding

To create a durable structure, welded joints must be made in accordance with the following requirements:

- first the shelves are welded, then the thinner elements;

- It is unacceptable to weld the internal corners of the profile, as this reduces the strength of the beam;

- there should be a gap of 2 - 3 mm between the ends so that you do not have to clean off the “slide” from the seam, which leads to a decrease in its reliability;

- lightweight structures that are not subject to significant loads during operation can be assembled by double-sided butt welding;

- The appearance of horizontal and vertical fractures at the joints is unacceptable.

Regardless of the connection method, the sequence of work must comply with GOST. If it is indicated there that edge cutting is carried out after cleaning, this must be strictly followed. In addition, the document specifies the requirements for channel material, which are necessary when calculating the structure.

Metal structures or any welded parts come in various shapes. These are pipes of all possible diameters, channels, profile pipes, I-beams, etc.

When welding parts such as pipes and channels, it is more advisable to use reinforcing gusset plates. These plates are used for rigid connection between the parts to be welded. Welding of these parts is carried out in the following way. If the pipes are connected to each other crosswise, then squares measuring approximately 150x150 mm are welded to the places of the intended connections with the pipes. or 200x200 mm. Next, spacers are welded to these plates, for which a corner with a size of at least 65 or 73 is used. Also, a plate is welded at the crosshairs between the spacers and a weld is made at each junction of the plate with the corners.

Types of welding used

Arc welding

A huge selection of types of electrodes according to their nominal characteristics and the features of their operation provide an undeniable advantage over other types of welding and make it preferable for this task. We will get the best seam if we use UONI electrodes. When working with these electrodes, you should take into account their features and recommendations:

- Where possible, connections should be overlapped.

- To use this electrode, prior experience with it is required.

- Before use, the electrode must be calcined in a special. oven for an hour. Calcination temperature 250 C.

- The joints of products must be cleaned of dirt, rust and prepared in accordance with GOST 5264-80.

- The welder must work with a short arc of medium power, direct current and reverse polarity.

- Metal structures welded with this electrode should not be used at temperatures below – 40 C.

We recommend! Why do electrodes stick when welding?

Gas welding

This type is often not used when welding channels due to the huge area and heating temperature. These factors are a source of internal stresses in the metal structure and general deformations that negatively affect the entire metal structure. Nevertheless, gas welding is often used to eliminate flaws in finished structures or to cut workpieces and then remove edges.

How to properly butt weld channels using overlays?

If it is necessary to obtain a seam whose strength is not inferior to the strength of the rolled profile body, overlays are used, the thickness of which depends on the thickness of the workpiece walls. One of the regulatory documents regulating the quality of the resulting connection is GOST 15164.

- The ends of the workpieces are prepared and welded to each other.

- The inside of the seam is cleaned to a smooth surface.

- A steel strip of the same grade and thickness as the base metal is welded inside the workpiece. Experienced welders advise welding not a strip to the seam, but a hexagon, which is scalded on all sides.

- A hexagonal overlay is also welded on the outside, but its size should be larger than the inside.

The linings must be welded along the entire contour, otherwise moisture may get into the gaps, causing corrosion of the steel. If it is impossible to fulfill this condition, an anti-corrosion compound is poured into the gaps. The connected elements must fit in a line without fractures in the horizontal and vertical planes.