For the construction of various types of structures, mechanical engineering, machine tool building and other areas, steel channels are often used as a reliable, inexpensive and durable element. In this case, most often the product is supplied in two types - hot-rolled metal and cold-rolled bent.

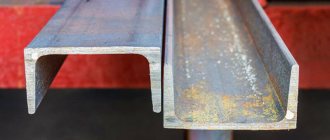

At first glance, the difference between them is small, but a specialist needs to know the nuances that will not only allow you to distinguish these two types of profiles by eye, but also choose exactly the type that will be most suitable for your work. After all, both have their own advantages and specifics.

Manufacturing method

You can guess the manufacturing method for both options based on their names. Hot rolled steel channel is produced using the hot rolling method on special machines. Under the influence of high temperature, the steel billet becomes plastic and takes the desired shape, that is, rolled steel with a U-shaped section.

To obtain a bent steel channel, a metal strip of the required size is used as a blank, which is bent using special equipment. This can be an automated line in a large production, where a profile bending machine will produce the desired profile according to the required dimensions. Much less often, bent channels of arbitrary size are produced in small batches using mechanical, non-automated equipment.

Directory of rolled metal products

ATTENTION!!! You are in the Help Section!

Here you can: download GOST and find out the main characteristics of the type of rolled metal you are interested in.

If you want to find out the prices of the main Suppliers of rolled metal products in your region, choose a Supplier with the minimum price or compare the prices of metal trading organizations, please follow the link “Bent equal flange channel price “

Bent channel is a product made by cold bending. This material has a cross-section resembling the letter “P” in shape. If we consider the visual distinctive points, it differs from hot-rolled by the presence of a rounded outer corner. To manufacture this type of channel, according to GOST 11474-76, rolled sheet blanks or strips are used. The price of a product largely depends on what steel it was made of.

The bent channel is manufactured according to established standards and requirements, which are regulated by GOST 11474-76. production is carried out on special roll forming machines using cold-rolled or hot-rolled steel. During manufacturing, such channels can be produced either equal-flanged or unequal-flanged. At the same time, the production of equal flanges is regulated by GOST 8278-83, and unequal flanges - 8281-80.

The channel number always corresponds strictly to its size, which is always indicated in mm. Let's consider an example: a channel 40x32x2.5 is available. What can be learned based on these parameters? So, 40 is the distance between the shelves, 32 is the width of the shelf, 2.5 is the wall thickness.

It is customary to distinguish between a bent equal-flange channel, which is manufactured in accordance with the established GOST 8278-83, and a bent non-equal-flange channel, which is manufactured in accordance with GOST 8281-80; it has its own specific purpose. Among some types of channels you can find models that have different shelf edges. Bent channel 160x80x5 and bent channel 120x50x3 are in great demand.

Steel channel is always valued in construction. It is highly durable and is often used as a load-bearing element. In most cases, the channel as a metal structure works primarily in bending. It is often used to construct a frame, as well as to erect partitions. When carrying out reconstruction work, a bent channel very often acts as an additional rib, which gives rigidity and stability to dilapidated buildings.

The equal-flange channel is installed on special roll forming mills. The material used is hot-rolled and cold-rolled steel, which is of average quality. In addition, carbon structural low-alloy steel is often used. The standard parameters are considered to be the following: the height of the product should be 50-400 mm, and the width of the shelves should be from 32 to 115 mm. If necessary, products can be manufactured not according to standards according to the individual order of the buyer. All standards and sizes are always indicated by GOST 8278-75.

Modern developed technologies make it possible to significantly expand the capabilities of the production process. Because of this, the variety of shapes produced is commonplace and hardly surprising. Due to the dynamically developing industry and human activity in general, the question arose about the manufacture of new types of channels.

Those products that are marked “U” are always manufactured with a slope. When the edges are parallel, the marking “P” is used; economical products with the edges parallel are marked “E”. If the planes are located parallel to each other, then the marking is “L”, special products are marked “C”. As for the maximum deviations, they should not exceed 4.5% of the total mass of the batch. The concept of mass deviation means the difference between the mass during delivery and the value that is calculated according to the developed tables.

The channel shape has the following symbols:

U - the internal edges are sloped

P – parallel faces

E - economical with parallel edges

L – parallel edges of the light series

With special

As mentioned earlier, the maximum batch deviations should not exceed 4.5% and 6% for an individual product. The definition of weight deviation hides the concept of the difference between the actual weight during the delivery period and that calculated according to a special table.

The length of the bent equal-flange channel can be of several types:

- measured length

- measured length in combination with unmeasured length, but in an amount of no more than 5% of the total mass of the batch

- unmeasured length

- limited length within unmeasured limits.

Main types of channel:

The special channel is used primarily in the automotive industry. It is manufactured according to GOST 19425-74. To use the product in carriage building during production, they are guided by GOST 5267-90. Its standard length ranges from 4 to 13 meters. If necessary, it can be made in a larger size. These types of channels are always made using rolled steel on special pipe machines. In this case, the steel is of ordinary quality. Typically, the height of the product ranges from 50 to 400 mm, and the width ranges from 32 to 115 mm.

All steel bent unequal-flange channels are manufactured using roll forming machines, and the steel must be cold-rolled or hot-rolled. All requirements and requirements are regulated by GOST 8281-80. All channels are usually divided into numbers. They, in turn, indicate the distance between the shelves, which is always expressed in mm. Depending on the rolling precision used, bent channels are divided into:

— high accuracy with marking “A”

— increased accuracy with marking “B”

- normal accuracy marked “B”.

The highest category of bent unequal and equal flange channels is produced under the markings A and B.

Forms of bent channel:

Channel with parallel flange edges GOST 8240-97.

The characteristics and range of steel channels are established by the following standards:

· Hot rolled channel (GOST 8240-89);

· Bent equal flange channel (GOST 8278-75);

· Bent unequal flange channel (GOST 8281-80)

· Special channel (19425-74).

Any hot-rolled channel is always divided into a channel with a slope of the internal edges of the flanges and with a parallel arrangement of the edges of the flanges.

Channels belong to the category of long products. Manufactured according to technical specifications:

· GOST 535-88 – hot-rolled steel;

· GOST 11474-76 – bent steel;

· GOST 8278-83 – equal-flange bent steel;

· GOST 8281-80 – unequal bent steel;

· GOST 8240 – hot-rolled carbon and low-alloy steel;

· GOST 5267 – special for carriage building;

· GOST 5420 – special for tractors;

· GOST 19425-74 – special steel.

Channel GOST 8240-89 is divided into:

· channel with a slope of the internal edges of the shelves: No. 5, 6.5, 8, 10, 12, 14, 16, 16a, 18, 18a, 20, 22, 24, 27, 30, 33, 36, 40;

· channel with parallel edges of shelves P: No. 5P, 6.5P, 8P, 10P, 12P, 14P, 16P, 16aP, 18P, 18aP, 20P, 22P, 24P, 27P, 30P, 33P, 36P, 40P.

According to rolling accuracy, channel GOST 8240, GOST 19425, GOST 8278, GOST 8281 are manufactured:

· increased accuracy – B;

· ordinary accuracy – V.

An example of a channel designation: hot-rolled steel channel No. 10, steel grade St3, length 10 m GOST 8240-89 – channel No. 10 St3 GOST 8240-89.

The Taurus is a steel beam that is shaped like the letter “T”. Structural steel is used for its manufacture. Typically, the brand acts as a necessary element for load-bearing structures. Structural steel is used to make the beam. This product is an ideal solution for those who want to glaze balconies with high quality, as well as for installing glass garden greenhouses.

Rice. 1. Bent channel according to GOST 8278-83

Legend:

h – channel height;

S – flange thickness;

b – shelf width;

R – radius of internal curvature.

Dimensions and weight of bent channels made of carbon boiling and semi-quiet steel

| h, mm | b, mm | S, mm | R, no more, mm | Weight 1 m, kg | h, mm | b, mm | S, mm | R, no more, mm | Weight 1 m, kg |

| 25 | 26 | 2 | 3 | 1,092 | 90 | 100 | 2,5 | 4 | 5,505 |

| 25 | 30 | 2 | 3 | 1,218 | 100 | 40 | 2,5 | 3 | 3,363 |

| 28 | 27 | 2,5 | 4 | 1,423 | 100 | 40 | 3 | 5 | 3,966 |

| 30 | 25 | 3 | 5 | 1,611 | 100 | 50 | 3 | 4 | 4,458 |

| 30 | 30 | 2 | 3 | 1,296 | 100 | 50 | 4 | 6 | 5,813 |

| 32 | 25 | 3 | 5 | 1,658 | 100 | 50 | 5 | 7 | 7,137 |

| 32 | 32 | 2 | 3 | 1,39 | 100 | 50 | 6 | 9 | 8,37 |

| 38 | 95 | 2,5 | 3 | 4,305 | 100 | 60 | 3 | 4 | 4,929 |

| 40 | 20 | 2 | 3 | 1,139 | 100 | 60 | 4 | 6 | 6,441 |

| 40 | 20 | 3 | 5 | 1,611 | 100 | 80 | 3 | 4 | 5,871 |

| 40 | 30 | 2 | 3 | 1,453 | 100 | 80 | 4 | 6 | 7,697 |

| 40 | 30 | 2,5 | 3 | 1,793 | 100 | 80 | 5 | 7 | 9,492 |

| 40 | 40 | 2 | 3 | 1,767 | 100 | 100 | 3 | 5 | 6,792 |

| 40 | 40 | 2,5 | 3 | 2,185 | 100 | 100 | 6 | 9 | 13,08 |

| 40 | 40 | 3 | 5 | 2,553 | 100 | 160 | 4 | 6 | 12,72 |

| 42 | 42 | 4 | 6 | 3,49 | 104 | 20 | 2 | 3 | 2,144 |

| 43 | 45 | 2 | 3 | 1,971 | 106 | 50 | 4 | 6 | 6,002 |

| 45 | 25 | 3 | 5 | 1,965 | 108 | 70 | 6 | 9 | 10,63 |

| 45 | 31 | 2 | 3 | 1,563 | 110 | 26 | 2,5 | 3 | 3,01 |

| 48 | 70 | 5 | 7 | 6,666 | 110 | 50 | 4 | 6 | 6,127 |

| 50 | 30 | 2 | 3 | 1,61 | 110 | 50 | 5 | 7 | 7,53 |

| 50 | 30 | 2,5 | 3 | 1,989 | 110 | 100 | 4 | 6 | 9,267 |

| 50 | 32 | 2,5 | 3 | 2,068 | 120 | 25 | 4 | 6 | 4,871 |

| 50 | 40 | 2 | 3 | 1,924 | 120 | 50 | 3 | 5 | 4,908 |

| 50 | 40 | 2,5 | 3 | 2,382 | 120 | 50 | 4 | 6 | 6,441 |

| 50 | 40 | 3 | 4 | 2,809 | 120 | 50 | 6 | 9 | 9,312 |

| 50 | 40 | 4 | 6 | 3,615 | 120 | 60 | 4 | 6 | 7,069 |

| 50 | 47 | 6 | 9 | 5,732 | 120 | 60 | 5 | 7 | 8,707 |

| 50 | 50 | 2,5 | 3 | 2,774 | 120 | 60 | 6 | 9 | 10,25 |

| 50 | 50 | 3 | 4 | 3,28 | 120 | 70 | 5 | 7 | 9,492 |

| 50 | 50 | 4 | 6 | 4,243 | 120 | 80 | 4 | 6 | 8,325 |

| 60 | 26 | 2,5 | 4 | 2,011 | 120 | 80 | 5 | 7 | 10,28 |

| 60 | 30 | 2,5 | 3 | 2,185 | 140 | 40 | 2,5 | 3 | 4,148 |

| 60 | 30 | 3 | 5 | 2,553 | 140 | 40 | 3 | 5 | 4,908 |

| 60 | 32 | 2,5 | 3 | 2,264 | 140 | 60 | 3 | 5 | 5,85 |

| 60 | 32 | 3 | 4 | 2,668 | 140 | 60 | 5 | 7 | 9,492 |

| 60 | 32 | 4 | 6 | 3,427 | 140 | 60 | 6 | 9 | 11,2 |

| 60 | 40 | 2 | 3 | 2,081 | 140 | 70 | 5 | 7 | 10,28 |

| 60 | 40 | 3 | 4 | 3,045 | 140 | 80 | 4 | 6 | 8,953 |

| 60 | 50 | 3 | 5 | 3,495 | 140 | 80 | 5 | 7 | 11,06 |

| 60 | 60 | 3 | 4 | 3,987 | 145 | 65 | 3 | 5 | 6,204 |

| 60 | 60 | 4 | 6 | 5,185 | 148 | 25 | 4 | 6 | 5,75 |

| 60 | 80 | 3 | 5 | 4,908 | 160 | 40 | 2 | 3 | 3,651 |

| 60 | 90 | 5 | 7 | 8,707 | 160 | 40 | 3 | 5 | 5,379 |

| 63 | 21 | 2,2 | 3 | 1,677 | 160 | 40 | 5 | 7 | 8,707 |

| 65 | 75 | 4 | 6 | 6,284 | 160 | 50 | 2,5 | 4 | 4,916 |

| 68 | 27 | 1 | 2 | 0,9252 | 160 | 50 | 4 | 6 | 7,697 |

| 70 | 30 | 2 | 3 | 1,924 | 160 | 50 | 5 | 7 | 9,492 |

| 70 | 40 | 3 | 5 | 3,26 | 160 | 50 | 6 | 9 | 11,2 |

| 70 | 50 | 3 | 5 | 3,731 | 160 | 60 | 2,5 | 4 | 5,308 |

| 70 | 50 | 4 | 6 | 4,871 | 160 | 60 | 3 | 5 | 6,321 |

| 70 | 60 | 4 | 6 | 5,499 | 160 | 60 | 4 | 6 | 8,325 |

| 78 | 46 | 6 | 9 | 6,957 | 160 | 60 | 5 | 7 | 10,28 |

| 80 | 25 | 4 | 6 | 3,615 | 160 | 60 | 6 | 9 | 12,14 |

| 80 | 32 | 4 | 6 | 4,055 | 160 | 70 | 4 | 6 | 8,953 |

| 80 | 35 | 4 | 6 | 4,243 | 160 | 80 | 2,5 | 3 | 6,11 |

| 80 | 40 | 2,5 | 3 | 2,97 | 160 | 80 | 3 | 5 | 7,263 |

| 80 | 40 | 3 | 4 | 3,516 | 160 | 80 | 4 | 6 | 9,581 |

| 80 | 50 | 4 | 6 | 5,185 | 160 | 80 | 5 | 7 | 11,85 |

| 80 | 60 | 3 | 4 | 4,458 | 160 | 80 | 6 | 9 | 14,02 |

| 80 | 60 | 4 | 6 | 5,813 | 160 | 100 | 3 | 5 | 8,205 |

| 80 | 60 | 6 | 9 | 8,37 | 160 | 100 | 6 | 9 | 15,91 |

| 80 | 80 | 3 | 4 | 5,4 | 160 | 120 | 5 | 7 | 14,99 |

| 80 | 80 | 4 | 6 | 7,069 | 160 | 120 | 6 | 9 | 17,79 |

| 80 | 85 | 4 | 6 | 7,383 | 160 | 160 | 6 | 9 | 21,56 |

| 80 | 100 | 6 | 9 | 12,14 | 170 | 60 | 4 | 6 | 8,639 |

| 90 | 50 | 3,5 | 5 | 4,869 | 170 | 70 | 5 | 7 | 11,45 |

| 90 | 54 | 5 | 7 | 7,059 |

Dimensions and weight of bent channels made of carbon boiling and semi-quiet steel

| h, mm | b, mm | S, mm | R, no more, mm | Weight 1 m, kg | h, mm | b, mm | S, mm | R, no more, mm | Weight 1 m, kg |

| 170 | 70 | 6 | 9 | 13,55 | 200 | 180 | 6 | 9 | 25,33 |

| 180 | 40 | 3 | 5 | 5,85 | 205 | 38 | 2,5 | 3 | 5,345 |

| 180 | 40 | 4 | 6 | 7,697 | 210 | 57 | 4 | 6 | 9,707 |

| 180 | 50 | 4 | 6 | 8,325 | 250 | 35 | 3 | 5 | 7,263 |

| 180 | 70 | 6 | 9 | 14,02 | 250 | 60 | 3 | 5 | 8,441 |

| 180 | 80 | 4 | 6 | 10,21 | 250 | 60 | 4 | 6 | 11,15 |

| 180 | 80 | 5 | 7 | 12,63 | 250 | 60 | 5 | 7 | 13,81 |

| 180 | 80 | 6 | 9 | 14,96 | 250 | 60 | 6 | 9 | 16,38 |

| 180 | 100 | 5 | 7 | 14,2 | 250 | 125 | 6 | 9 | 22,5 |

| 180 | 100 | 6 | 9 | 16,85 | 270 | 100 | 7 | 10 | 24,42 |

| 180 | 130 | 8 | 12 | 25,76 | 280 | 60 | 3,9 | 6 | 11,8 |

| 185 | 100 | 3 | 5 | 8,794 | 280 | 140 | 5 | 7 | 21,27 |

| 200 | 50 | 3 | 5 | 6,792 | 300 | 80 | 6 | 9 | 20,62 |

| 200 | 50 | 4 | 6 | 8,953 | 300 | 100 | 8 | 12 | 29,53 |

| 200 | 80 | 4 | 6 | 10,84 | 310 | 100 | 6 | 9 | 22,97 |

| 200 | 80 | 5 | 7 | 13,42 | 380 | 65 | 6 | 9 | 22,97 |

| 200 | 80 | 6 | 9 | 15,91 | 400 | 95 | 8 | 12 | 35,18 |

| 200 | 100 | 3 | 5 | 9,147 | 410 | 65 | 6 | 9 | 24,38 |

| 200 | 100 | 6 | 9 | 17,79 |

Note: The weight of 1 m of profile is calculated based on the nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

Dimensions and weight of bent channels made of carbon mild and low-alloy steel

| h, mm | b, mm | s, mm | R, no more, mm | Weight 1 m, kg | h, mm | b, mm | S, mm | R, no more, mm | Weight 1 m, kg |

| 25 | 26 | 2 | 5 | 1,065 | 50 | 40 | 2,5 | 6 | 2,331 |

| 25 | 30 | 2 | 5 | 1,191 | 50 | 40 | 3 | 7 | 2,748 |

| 30 | 25 | 3 | 7 | 1,571 | 50 | 50 | 2,5 | 6 | 2,723 |

| 30 | 30 | 2 | 5 | 1,269 | 50 | 50 | 3 | 7 | 3,219 |

| 38 | 95 | 2,5 | 6 | 4,254 | 50 | 50 | 4 | 10 | 4,135 |

| 40 | 20 | 2 | 5 | 1,112 | 50 | 60 | 4 | 10 | 4,763 |

| 40 | 30 | 2 | 5 | 1,426 | 60 | 30 | 2,5 | 6 | 2,135 |

| 40 | 30 | 2,5 | 6 | 1,742 | 60 | 30 | 3 | 7 | 2,513 |

| 40 | 40 | 2 | 5 | 1,74 | 60 | 32 | 2,5 | 6 | 2,213 |

| 40 | 40 | 2,5 | 6 | 2,135 | 60 | 32 | 3 | 7 | 2,607 |

| 40 | 40 | 3 | 7 | 2,513 | 60 | 40 | 2 | 5 | 2,054 |

| 48 | 70 | 5 | 12 | 6,498 | 60 | 40 | 3 | 7 | 2,984 |

| 50 | 30 | 2 | 5 | 1,583 | 60 | 50 | 3 | 7 | 3,455 |

| 50 | 30 | 2,5 | 6 | 1,938 | 60 | 60 | 3 | 7 | 3,926 |

| 50 | 40 | 2 | 5 | 1,897 | 60 | 60 | 4 | 10 | 5,077 |

| 60 | 90 | 5 | 12 | 8,539 | 120 | 105 | 8 | 20 | 18,43 |

| 65 | 40 | 4 | 10 | 3,978 | 130 | 135 | 8 | 20 | 22,82 |

| 65 | 75 | 4 | 10 | 6,176 | 140 | 40 | 2,5 | 6 | 4,097 |

| 70 | 40 | 3 | 7 | 3,219 | 140 | 60 | 4 | 10 | 7,589 |

| 70 | 60 | 4 | 10 | 5,391 | 140 | 60 | 5 | 12 | 9,324 |

| 70 | 65 | 4 | 10 | 5,705 | 140 | 60 | 6 | 14 | 10,99 |

| 78 | 46 | 6 | 14 | 6,754 | 140 | 70 | 5 | 12 | 10,11 |

| 80 | 32 | 4 | 10 | 3,947 | 140 | 80 | 4 | 10 | 8,845 |

| 80 | 35 | 4 | 10 | 4,135 | 140 | 80 | 5 | 12 | 10,89 |

| 80 | 40 | 2,5 | 6 | 2,92 | 145 | 65 | 3 | 7 | 6,163 |

| 80 | 40 | 3 | 7 | 3,455 | 145 | 75 | 5 | 12 | 10,7 |

| 80 | 50 | 4 | 10 | 5,077 | 160 | 40 | 3 | 7 | 5,339 |

| 80 | 60 | 3 | 7 | 4,397 | 160 | 40 | 5 | 12 | 8,539 |

| 80 | 60 | 4 | 10 | 5,705 | 160 | 50 | 4 | 10 | 7,589 |

| 80 | 60 | 6 | 14 | 8,167 | 160 | 50 | 5 | 12 | 9,324 |

| 80 | 80 | 3 | 7 | 5,339 | 160 | 60 | 3 | 7 | 6,281 |

| 80 | 80 | 4 | 10 | 6,961 | 160 | 60 | 4 | 10 | 8,217 |

| 80 | 85 | 4 | 10 | 7,275 | 160 | 60 | 5 | 10 | 10,18 |

| 90 | 54 | 5 | 12 | 6,89 | 160 | 60 | 6 | 14 | 11,94 |

| 90 | 115 | 5 | 12 | 11,68 | 160 | 75 | 8 | 20 | 17,17 |

| 100 | 40 | 2,5 | 6 | 3,312 | 160 | 80 | 2,5 | 6 | 6,06 |

| 100 | 40 | 3 | 7 | 3,926 | 160 | 80 | 4 | 10 | 9,473 |

| 100 | 50 | 3 | 7 | 4,397 | 160 | 80 | 5 | 12 | 11,68 |

| 100 | 50 | 4 | 10 | 5,705 | 160 | 120 | 6 | 14 | 17,59 |

| 100 | 50 | 5 | 12 | 6,969 | 160 | 160 | 6 | 14 | 21,36 |

| 100 | 50 | 7 | 18 | 9,207 | 170 | 70 | 5 | 12 | 11,29 |

| 100 | 60 | 3 | 7 | 4,868 | 170 | 70 | 6 | 14 | 13,35 |

| 100 | 60 | 4 | 10 | 6,333 | 180 | 50 | 4 | 10 | 8,217 |

| 100 | 80 | 3 | 7 | 5,81 | 180 | 70 | 5 | 12 | 11,68 |

| 100 | 80 | 4 | 10 | 7,589 | 180 | 70 | 6 | 14 | 13,82 |

| 100 | 80 | 5 | 12 | 9,324 | 180 | 70 | 7 | 18 | 15,8 |

| 100 | 120 | 8 | 20 | 19,05 | 180 | 80 | 4 | 10 | 10,1 |

| 100 | 160 | 4 | 10 | 12,61 | 180 | 80 | 5 | 12 | 12,46 |

| 110 | 26 | 2,5 | 6 | 2,959 | 180 | 80 | 6 | 14 | 14,76 |

| 110 | 50 | 4 | 10 | 6,019 | 180 | 80 | 8 | 20 | 19,05 |

| 110 | 50 | 5 | 12 | 7,361 | 180 | 100 | 5 | 12 | 14,03 |

| 120 | 25 | 4 | 10 | 4,763 | 180 | 100 | 6 | 14 | 16,65 |

| 120 | 50 | 3 | 7 | 4,868 | 180 | 130 | 8 | 20 | 25,33 |

| 120 | 60 | 4 | 10 | 6,961 | 200 | 60 | 4 | 10 | 9,473 |

| 120 | 60 | 5 | 12 | 8,539 | 200 | 80 | 4 | 10 | 10,73 |

| 120 | 60 | 6 | 14 | 10,051 | 200 | 80 | 5 | 12 | 13,25 |

| 120 | 75 | 4 | 10 | 7,903 | 200 | 80 | 6 | 14 | 15,7 |

| 120 | 80 | 4 | 10 | 8,217 | 200 | 100 | 5 | 12 | 14,82 |

| 120 | 80 | 5 | 12 | 10,11 | 200 | 100 | 6 | 14 | 17,59 |

| 120 | 90 | 7 | 18 | 14,7 | 200 | 160 | 8 | 20 | 30,36 |

Continued Dimensions and weight of bent channels made of carbon mild and low-alloy steel

| h, mm | b, mm | s, mm | R, no more, mm | Weight 1 m, kg |

| 205 | 38 | 2,5 | 6 | 5,294 |

| 206 | 75 | 6 | 14 | 15,52 |

| 210 | 57 | 4 | 10 | 9,599 |

| 250 | 25 | 3 | 7 | 6,752 |

| 250 | 60 | 4 | 10 | 11,04 |

| 250 | 60 | 5 | 12 | 13,64 |

| 250 | 60 | 6 | 14 | 16,17 |

| 250 | 90 | 8 | 20 | 24,71 |

| 250 | 125 | 6 | 14 | 22,3 |

| 270 | 100 | 7 | 18 | 24,04 |

| 280 | 60 | 3,9 | 10 | 11,69 |

| 280 | 60 | 6 | 14 | 17,59 |

| 300 | 80 | 6 | 14 | 20,41 |

| 310 | 100 | 6 | 14 | 22,77 |

Note: The weight of 1 m of profile is calculated based on the nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

Differences

The main external difference that shows the difference between the two types of U-shaped profiles is the outer corner. In the cold-rolled version it is more rounded, while in the hot-rolled version you can notice a slight thickening at the corner, which gives it special strength.

The second important difference is weight. The bent version is much lighter than hot-rolled, so it can be used to create lightweight structures.

The third difference is durability. The hot-rolled version is more durable, since its bending point is more reliable and is not subject to mechanical deformation. In addition, the strength can be additionally recognized by the batch marking, where the letter B indicates standard strength, B - increased, and A - the highest.

Finally, the last difference is the choice of sizes and options. Hot-rolled profiles are produced on standard machines, so their dimensions are clearly limited by standards. Cold-rolled channel, which is sometimes called lightweight, has many more manufacturing options, because a strip of any size can be bent into a U-shaped profile. Moreover, the accuracy of the finished steel product will be even higher than that of the “hot” version.

Bent and hot-rolled channel: what to choose?

We have already given different versions of answers to the question about the difference between a cold-rolled channel and a hot-rolled analogue. The most significant difference between these types of rolled products is that products with the same wall height have different strength and, accordingly, load-bearing capacity. This indicator is a determining factor in the selection of rolled products, which are intended for the manufacture of load-bearing structures in construction and industrial production.

Bent and hot-rolled channel in construction

In construction, bent and hot-rolled channels are usually used for building floors, bridge spans, loading and unloading overpasses and other structures where structures must have high load-bearing capacity with relatively low weight. Both types of rental are completely equal in the construction industry. The main condition is that their strength characteristics meet the requirements of the construction project or technical documentation for the production of a particular industrial product.

Which channel to choose - bent or hot rolled?

The main criterion for choosing channels is their strength. If bent and hot-rolled products of suitable size meet the design requirements for the moment of resistance to vertical load, bent products are preferable. It is lighter and cheaper. However, when it comes to extreme loads, hot-rolled channels have no alternative.

For example, the moment of resistance for the walls of hot-rolled channels of the maximum standard size (No. 40P) is 763 units. For bent products with a wall height of 400 mm, it is only 458.99 units.

Choice

Based on the properties and characteristics, experts recommend making the following choice. For those structures where strength, stability and reliability are especially important, for example, for frames, it is better to purchase a hot-rolled channel. If the weight of the finished structure is especially important to you and you would like to lighten it, and also if you need high-precision rolled products or you intend to use a U-shaped profile for the manufacture of machines or machines, then a bent metal channel is more suitable.