The peculiarities of aluminum welding cause certain difficulties when joining this metal. The developed technologies, to one degree or another, make it possible to combat this and achieve positive results. The quality of aluminum welding using an inverter cannot be compared with argon arc welding or other Al joining technologies.

However, in domestic conditions it is unlikely that suitable equipment will be found. The master may have at most a home welding machine at his disposal, be it an inverter or a DC transformer. Reasonable questions arise: is it possible to weld aluminum with an inverter at home, how to do it correctly and what materials are required for this?

Is it possible to weld aluminum with an inverter?

When welding products made of aluminum and its alloys with an inverter, you have to deal with a number of certain difficulties caused by its physical and chemical properties, namely:

- the oxide film on the surface of aluminum parts, which is formed by a completely natural interaction with atmospheric oxygen, has a melting point of 2000⁰ C, and aluminum itself melts at a temperature of only 660⁰ C;

- the refractory oxide film from the surface of the welding site must be removed by mechanical removal or chemical action, and the metal must be welded immediately after this to avoid re-oxidation;

- with large temperature differences during electric welding, the strength properties of aluminum are significantly reduced;

- due to the high temperature of the electric arc, aluminum intensively melts and begins to flow out of the welding zone;

- when heated during welding, aluminum practically does not change its color, which makes it quite difficult to control the size of the weld;

- a low value of the modulus of elasticity of aluminum products can cause deformation of the structure being welded, and upon cooling, the formation of microcracks in the area of the weld pool.

Therefore, knowing all the nuances and observing certain conditions, you can weld aluminum with an inverter even at home. Moreover, if there are no special requirements for the inverter welding machine, then paramount importance is given to consumables and the methodology for carrying out the welding work itself. From here we will try to formulate answers to the question: how to properly cook aluminum with an inverter.

What is duralumin

Duralumin consists of the following elements: aluminum - 93.5%, copper - 4.5%, magnesium - 1.5%, manganese - 0.5%. This composition determines the performance characteristics of the alloy. The main component affects the chemical activity of duralumin, so it quickly oxidizes in open air, resulting in the formation of a durable oxide film on the surface.

The given alloy composition is not constant, it can change. Not only the ratio of metals is important, but also the technology of heat treatment of duralumin.

Aluminum welding rules

When welding aluminum, the following requirements must be observed:

- welding of products made of aluminum and its alloys is possible only under the protection of inert gases such as argon or a mixture of argon and helium, therefore the inverter apparatus must have special gas-cylinder equipment for argon-arc welding;

- It is best to weld using non-consumable tungsten electrodes, which must be periodically cleaned of accumulated oxides, otherwise the quality of the weld will deteriorate;

- It is recommended to preheat aluminum parts before welding to reduce the effects of temperature deformations in the weld area;

- aluminum is mainly welded using alternating electric current, and the value of the welding current is set for working with aluminum slightly higher than for welding similar steel products;

- Before use, aluminum filler electrodes must be heated in a muffle furnace.

Aluminum welding can be done with almost all inverter-type welding machines with any productivity and degree of automation of work processes.

Aluminum and its alloys for home welding

Features of welding aluminum at home

In welding, it is customary to separate metals and alloys depending on their performance characteristics. For example, aluminum is a difficult metal to weld.

Welding seam on aluminum

For this reason, we can say about welding aluminum with an inverter at home that it has a specific combination of features. It is worth taking a closer look at them in advance so that unforeseen difficulties do not arise during the work process.

By and large, there are no fundamental differences when welding at home - the requirements for safety precautions, equipment and technical process are the same as in industrial conditions.

The main thing you should pay attention to in order to ensure safety is the toxic gases that are formed when working with standard electrodes. Care should be taken to neutralize them effectively.

The vagaries of aluminum when welding at home

Inverter for aluminum welding

Working with aluminum requires fairly high qualifications, which, although it comes with experience, must be accompanied by certain skills.

This applies to even the simplest welding manipulations - everything requires a good theoretical basis and practical experience. Melting, the formation of through holes, and other unpleasant effects are the main pitfalls that need to be prevented. This requires not only increased attention, but also an understanding of the processes of thermal expansion, knowledge of the properties and characteristics of the metal, as well as the ability to correctly select electrodes.

List of the most important parameters

Aluminum is a very common metal in various fields of human activity. Its alloys are also actively used. This is due to the set of its physical properties and chemical characteristics.

Aluminum is one of the most common metals

What are the main difficulties encountered during welding work involving this metal? The reasons are easy to understand if you understand the main properties.

Significant level of turnover

When exposed to high temperatures, aluminum sharply loses strength, which leads to the destruction of already molten metal by unmolten metal. It often happens that molten metal flows out through the seam. The difficulty of controlling the welding process at home is compounded by the fact that aluminum does not change color when heated. To maintain the shape of the weld pool, experienced welders use special ceramic (or made of another metal) pads.

The appearance of an oxide film

Oxygen has a very characteristic effect on aluminum - it very quickly covers it with a specific oxide film, as a result of which the metal surface acquires a much higher level of refractoriness and density. In addition, the oxide interferes with the transformation of the metal into a monolithic seam.

Argon welding prevents air ingress

How to prevent the appearance of an oxide film? The welding area must be protected from contact with air. This is achieved using argon welding. Alternatively, the oxide can be removed by cathode sputtering.

Another distinctive feature of aluminum is that, having a very high coefficient of linear expansion, it has a fairly low elastic modulus. Because of this, deformation of the structure that needs to be welded often occurs. How to reduce the likelihood of deformation? For this, various technological methods are used, i.e. electric welding in optimal mode, or heating.

When welding aluminum at home (and not only at home), porosity appears in the alloys containing this metal. Why does this happen? The answer is simple: various metal compounds contain hydrogen, which is released through pores formed during the heating process. In addition, if the composition contains a significant silicon content, then there is a high probability of the appearance of crystallization cracks, which, although small in size, can significantly weaken the weld.

Another feature of aluminum is its high thermal conductivity. That is why the welding process cannot do without powerful current sources.

An additional danger that awaits those who weld aluminum at home is the formation of hot cracks. They appear as a result of specific processes that occur inside the hot metal when it begins to solidify. How to minimize the risk of cracks? It is necessary to use special modifiers added directly to the weld. Another safety precaution is to not place the seams too close together.

How to weld aluminum with an inverter at home?

In practice, a situation often arises when it is necessary to perform welding work on aluminum alloys, the brand of which is unknown. Is this possible without special auxiliary materials and special welding modes? If you prepare properly, it can be done.

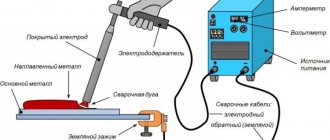

Welding equipment

First, you need to choose the right welding equipment. An inverter apparatus is best suited for aluminum and its alloys: it provides a stable arc, fast ignition, a high level of weld accuracy, as well as stable currents.

Which inverter is most suitable for this type of work? There is no fundamental difference - any will do. It is worth considering another factor: the result is influenced to a much greater extent by the competent choice of electrodes.

To weld aluminum with an inverter at home, you must have the following:

- special electrodes that are well suited for aluminum (they are marked OZR, OZR-2, or OZANA, OZANA-1, OZA, OZA-1);

- a furnace in which the electrodes can be calcined - this is done before using them.

Key welding rules when working with aluminum and its alloys

Cleaning the aluminum surface before welding

Treat the metal surface

It is recommended to remove dirt from the metal surface and then degrease it with acetone, aviation gasoline or white spirit. To destroy the oxide film, you can use a file, sandpaper or abrasive.

Edge cutting

When the metal thickness is 4 mm or more, edges are cut. When using coated electrodes, it is allowed to process metal up to 20 mm thick without cutting edges.

overheat protection

To prevent metal deformation, you can use an inverter-type welding machine attachment.

Using an inverter when welding aluminum at home

The argon environment helps protect against oxygen exposure. A mixture of argon and helium can also be used. This mixture helps thick layers of metal.

Welding using an argon arc can only be done with alternating current. In this case, inert gas is supplied through the burner, and the consumable material is filler wire.

Electrodes for aluminum have a special coating

When the gas leaves the nozzle and envelops the electrode, the molten metal forms a weld pool with liquid aluminum. Then the filler wire gets there. It is recommended to select wire of the same grade as the main part that needs to be welded (for example, with an aluminum diameter of 2 to 5 mm, it is better to take wire of the AO, AK or AD grade).

The seam is applied gradually and slowly, the part is welded quite deeply. Do not stop the supply of inert gas immediately after completing the seam - it is recommended to wait a few seconds so that the seam does not deform or crack.

The filler rod and electrode should not move crosswise - the filler rod should go in front of the torch. You can warm up the part both before and after welding.

Video: Tig welding of aluminum

Similar articles

promtu.ru

Consumables for aluminum welding

For welding various products made of aluminum and its alloys using non-consumable tungsten electrodes on TIG inverter machines, it is recommended to use filler wire from 2 to 5 mm in diameter marked AO, AK and AD with a high content of magnesium alloy additives.

You can also use special aluminum electrodes of the OZA, OZR and OZANA brands made in Russia or their higher quality imported analogues - OK 96.20, OK 96.40 and Kobatek-213, but only at a slightly higher cost. Photo

For semi-automatic inverter welding machines, a special aluminum wire with a diameter of 0.8-1.0 mm is produced, wound on standard spools weighing 0.5 kg. As a rule, the welding wire most often used is a cast alloy of aluminum with silicon (Al-Si 5) grades ER 4043 and ER 5356, less often a similar wire, but made from aluminum-magnesium alloys deformable grades Sv-AK 5 and Sv- AMG 5. Photo

The main component of the price of a meter of seam when welding on aluminum is the cost of consumables, namely inert argon gas and special aluminum electrodes.

Properties and weldability of duralumin

The difficulties of the welding process of duralumin are largely explained by its refractoriness. Compared to the main component, this composition is more dense, so it is less soft and flexible. During welding, electrodes are quickly consumed, and the fluidity of the alloy increases. You need to prepare for this before starting welding. Preliminary hardening of duralumin parts helps to eliminate this problem; it is performed at a temperature of +500°C.

Basic properties:

- density – 2.5-2.8 tons/m³;

- melting point – +650°C;

- Max fluidity – 250 MPa.

This material has high strength and relatively low weight, which makes it possible to make parts, mechanisms and structures from it that are used in various industries, the national economy and in everyday life.

Due to its high tendency to oxidize, duralumin is cooked at temperatures within +300°C, using a protective atmosphere of inert gases or flux.

This material is very refractory.

Step-by-step welding instructions

If you understand the basic requirements for how to properly weld aluminum with an inverter, then you can proceed directly to welding work, while observing the following sequence:

- We configure the inverter welding machine for this:

- We switch the AC/DC toggle switch to AC mode;

- We set the polarity balance from the 50/50 position, shifting it to the negative side when working with pure aluminum, and for various alloys we use the positive part of the adjustment range;

- we set the welding current based on the thickness of the material itself and the diameter of the electrode, so for a two-millimeter aluminum sheet and 3 mm of filler wire it is enough to set the welding current to 60 amperes;

- we adjust the slowdown of the attenuation process of the electric arc to fill the crater at the end of the weld pool, which also depends on the thickness of the workpiece and at 2 mm it is necessary to set the time to about 3 seconds;

- we set the time and intensity of purging with inert gas necessary to cool the welding seam.

- We prepare aluminum parts for welding by:

- carrying out mechanical cleaning of the oxide film from the future welding site using a metal brush or sandpaper, bringing the surface to a perfect white shine;

- degreasing the surface by treating it with chemical reagents - various solvents or special soldering acid;

- mandatory heating of workpieces immediately before welding to a temperature of 400⁰ C.

- After completing all the preparatory work, we proceed to finishing welding, while observing the main rule, which requires welding aluminum slowly to ensure uniform heating of the material of the parts being welded.

- The filler wire or aluminum welding electrode must be fed to the beginning of the weld pool at an angle of 15 degrees, using light touches so that the weld is uniform and slightly ribbed.

You should not start finishing welding work without having the proper experience in welding aluminum products. Practice first and gain the necessary skills and experience. To do this, you can watch a video that clearly shows how to properly weld aluminum using an inverter:

If you have your own specific experience in this topic, then share it in the comments block.

What parameters are set depending on the thickness of the metal being welded?

When setting up the welding machine, you must perform the following manipulations:

- adjust the AC balance (plus or minus) . Typically, when welding aluminum, reverse polarity is used, that is, “-“;

- adjust the welding current depending on the thickness of the elements being connected . The pulse current increases with increasing thickness of the parts being welded. So, for aluminum with a thickness of 1 mm, a current of 23 to 27 Amperes is used, and for welding aluminum with a thickness of 5 mm - 150-180 Amperes;

- adjust arc attenuation, which also depends on the thickness of the parts : the thicker, the longer. For example, to connect aluminum with a thickness of 2 mm, it is enough to set this parameter for 3 seconds;

- set up gas purging for cooling (if such a function is available).

Advantages and disadvantages

Among the advantages of this alloy, the following are noted:

- light weight, but duralumin parts can withstand high loads;

- welding work is performed using different technologies, their choice depends on the work conditions and other factors;

- preparing products does not require much labor and time;

- the necessary electrodes can always be purchased in specialized stores.

We recommend reading: How to weld aluminum yourself

This process also has a number of disadvantages:

- the weld seam has low resistance to corrosion;

- after creating such a connection, the characteristics of the alloy deteriorate;

- To carry out work, you must have high qualifications, be careful and perform everything with high precision;

- to select electrodes, you need to know exactly the grade of the alloy;

- the high fluidity of duralumin creates difficulties when forming a welding bead;

- to perform the work efficiently, you have to use flux or shielding gas;

- the cost of consumables is high;

- When performing high-speed welding, it is difficult to organize quality control of the seam.

The seam may be subject to corrosion.

Requirements for welding

When welding parts made of duralumin, you must adhere to the following requirements:

- Flux is preliminarily applied to the joint and evenly distributed, this allows to improve the welding process;

- heating of the parts to be joined is carried out evenly, otherwise they may become deformed under the influence of temperature;

- after completion of the work, the created seam is heated for some time, do this until the metal cools down;

- After welding and cooling of the seam, it is cleaned of slag and checked for cracks, cavities, and damage.