Wire bending, performed either manually or using various tools and special equipment, allows products made from this material to be given different configurations. During the bending process, the inner layer of the wire is subjected to compression, and the outer layer is subjected to tension. Wire bending machines, which today are presented in a wide variety of models, are very popular, since bent wire products are actively used to solve various industrial and household problems.

The simplest device for bending wire

To perform bending operations at home without any problems, it is best to choose wire made from soft materials. Simple bending of stiffer wires, if necessary, can be carried out using ordinary plumbing tools:

- pliers (with the help of such a tool, which every home craftsman has, you can form a simple bend in the wire, as well as securely fix its segment for further processing);

- pliers (using this tool, which is one of the types of pliers, you can perform bending of varying degrees of complexity);

- wire cutters or needle nose pliers (using such a tool, the wire can be cut into pieces of the required length).

Simple techniques for manual wire bending

If you need to make a product of complex configuration from wire using the bending method, it is better to first draw it on paper and periodically check the sketch. To form the simplest figures, such a sketch does not need to be used. For example, if you need to create a bent product of a rectangular shape, you can do this as follows:

- The wire at the place of its future bend is clamped in a bench vice.

- The upper (not clamped) part of the wire is bent using ordinary pliers or a hammer.

As a result of this simple procedure, a bend at a right angle is formed on the surface of the wire.

To produce a large number of similar wire parts, templates and homemade devices are used.

Bending machines: purpose and principle of operation

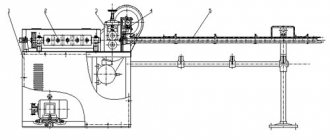

Bending machines are used to cold form products of the desired shape from wire, reinforcement, strip or sheet metal and are a device equipped with a feeding unit, a bending console and a cutting mechanism.

How does a wire bending machine work?

Depending on the type of machine, a wire coil or pre-cut rods can be used as a raw material for the manufacture of wire products. In the first case, bending machines are equipped with an unwinder and a straightening block; the wire from the unwinder is pulled through straightening rollers (most often located in two perpendicular planes) and then into the bending unit, where, in accordance with a given program, bending and cutting of the finished product is performed.

Machines for bending wire and fittings, the raw materials for which are already cut rods, have a simpler design: the rods are immediately fed into the bending unit. Such machines are cheaper and have lower productivity, but in some cases their use is much more efficient, for example, when it is necessary to perform some operations before bending (thread rolling, sharpening, etc.). Modern automatic bending machines for rebar or wire are machines equipped with computer numerical control (CNC). On such machines bending is carried out with the greatest efficiency. Reconfiguring equipment to produce products of a different shape is simple and comes down to selecting the desired program.

Types of bending machines

Bending machines are distinguished by the type of raw materials used.

Sheet metal bending machines

Used to give metal sheets different shapes. They are widely used in the manufacture of body parts, roofing elements, window structures, ridges, canopies, and ebbs.

All metal bending machines have the same design and differ only in the drive. The most widespread are hydraulic bending machines, electromechanical and manual.

The first ones are the most powerful and allow you to work with sheet metals with a thickness of more than 3.5 mm. Electric bending machines combine high performance, a wide range of functions and low price. This is the cheapest equipment among industrial sheet benders. The main advantage of the latter is compactness, mobility, and independence from the power grid. The price of manual bending machines is very low, which allows them to be used for domestic needs, in small workshops and on construction sites.

Machines for bending reinforcement

Machines for working with reinforcement, based on the type of raw material used, are divided into machines that work with rods and coils, and according to the degree of automation, they are divided into manual, electromechanical and CNC machines.

The operating principle of all bending machines for reinforcement is the same: a part of the reinforcement is placed between the bending pin and stops, the bending pin is set in motion and bends to the required angle.

Manual bending machines for reinforcement use a lever system that allows the force required for bending to be reduced several times. Such machines are compact, simple, reliable and are in great demand on construction sites.

Electromechanical machines differ from manual machines only in that bending is carried out not by the physical strength of the operator, but by an electric motor. These machines allow you to bend reinforcement with a diameter of up to 40-50 mm.

CNC bending machines for reinforcement allow automatic bending. The reinforcement from the unwinder passes through straightening rollers and enters the bending zone, where, using a rotating disk with stops and bending fingers, it is bent in accordance with the established program. Such machines are highly productive and do not require operator intervention in the work process, but they have restrictions on the diameter of the fittings, as a rule, no more than 16 mm.

Pipe bending machines

Pipe bending is necessary for the manufacture of air and gas lines, refrigerator radiators, heat exchanger elements, and in the production of POS products.

Pipe bending machines are divided into manual and hydraulic based on the type of drive.

Manual pipe cutters are typically used to cut small diameter pipes made from soft materials. In other cases, hydraulic pipe benders are used, the most widely used of which are three-roll bending machines.

In mass production of more complex products, such as refrigerator radiators, automatic CNC pipe bending machines are often used. The principle of their operation is similar to the operation of machines for bending reinforcement.

Strip bending machines

Our company offers machines for bending metal strips. Such machines produce clamps, staples, clamps, wheel rims, etc. There is also a specialized machine for making letters from aluminum and steel strip for signs.

bending>

There are 2D and 3D bending machines. The former are used for the manufacture of simple flat products: hooks, hangers, wire frames, etc. 3D wire machines are universal bending machines suitable for the production of almost any wire product: trays, brackets, baskets, etc. Three-dimensional bending is made possible thanks to the presence of a rotary console. Spring winding machines should be included in a separate group. Their use allows you to make springs of various diameters and with different numbers of turns in a matter of seconds.

Manual bending rules

If you are going to manually bend the wire, you must adhere to a number of recommendations that will allow you to complete this procedure without harm to your own health.

- All bending procedures should be carried out only with gloves made of thick fabric.

- The wire that is being bent must be secured in a vice as securely as possible so that it does not jump out during operation.

- All tools and equipment that you are going to use for work must be in good working order and perform their assigned functions efficiently.

- Heavy tools and equipment that you use when bending should not be placed on the edge of the workbench, so as not to accidentally hit them and drop them on your feet.

- When carrying out all manipulations with the wire bending tool with one hand, the other should be kept as far as possible from the future bend. Pliers or any other tool can break off and injure a hand located close to the bending area.

Wire bending using improvised means is possible only in small quantities, since such a procedure is quite labor-intensive. In addition, this operation can only be used to create products of the simplest configuration.

A specialized wire bending machine allows you to produce various products in large volumes, including those with complex shapes.

Bending machines for wire and fittings: device, design

The CNC bending machine has the following main design elements.

Unwinder

Included in the package of machines capable of working with wire or reinforcement from coils. It is necessary for unwinding and feeding the wire into the correct machine unit. Either a mechanical or motorized unwinder can be used.

Correct knot

Rollers are used as the correct mechanism. The use of this straightening method is due to the fact that the wire is fed into the bending unit in jerks, and the use of the correct drum involves continuous pulling of the wire.

Bending unit

The bending mechanism consists of a stop and several bending fingers that perform bending under the control of a CNC system, as well as guide rollers. 3D wire bending machines are also equipped with a rotating console.

Bending machine: diagram of the bending mechanism

Cutting device

After completing the bending program, the CNC system sends a control signal to the cutting mechanism, which is a guillotine-type knife; it lowers, cutting the finished product.

Options for devices for bending wire materials with your own hands

For bending, sometimes it is enough to use improvised tools. Much depends on the thickness of the material used.

For bending products with your own hands with a diameter of up to 3 mm, the following are suitable:

- bench vice;

- pliers;

- round nose pliers.

The material is cut with side cutters or ordinary nippers.

Products with a large diameter will require the use of a home-made device. The assembly of the machine is carried out in stages:

- a steel corner 19 cm long is screwed to the table with bolts;

- a frame is made from a metal plate, holes are drilled in it;

- a frame with guide rollers and handles is screwed to the corner;

- a metal block is selected to the frame groove;

- several through and blind holes are made in the block;

- a handle and a corrugated roller are bolted to the block;

- plates are welded at the bottom of the frame;

- the block is inserted into the frame groove so that it slides in it and does not fall out;

- guide rollers are screwed in;

- the bar structure is screwed to the corner.

A self-made mechanism will allow you to make products of more complex configurations.

Types of bending machines

There are 2D and 3D bending machines. The former are used for the manufacture of simple flat products: hooks, hangers, wire frames, etc. 3D wire machines are universal bending machines suitable for the production of almost any wire product: trays, brackets, baskets, etc. Three-dimensional bending is made possible thanks to the presence of a rotary console. Spring winding machines should be included in a separate group. Their use allows you to make springs of various diameters and with different numbers of turns in a matter of seconds. Based on the type of raw materials used, there are:

- sheet metal bending machines;

- machines for bending reinforcement;

- bending machines for profile pipes;

- tape bending machines;

- wire bending machines.

Our website presents machines for working with metal strip, pipe, wire and fittings, as well as a specialized machine for making letters from aluminum strip for signs.

Bending wire at home

To give simple shapes to not very stiff wire, use metalworking tools, available in almost every home workshop:

- Pliers . With their help, you can bend or securely fix the end of the product.

- Pliers . A type of pliers.

- Wire cutters . With their help, metal products are cut into measured pieces.

To create complex shapes, templates are used, which are checked against during the bending process. To bend a rectangular clamp, the end of the wire is clamped in a vice, and bending is carried out with pliers or hammer blows.

Safety rules for manual bending:

- work must be carried out wearing thick fabric gloves;

- it is necessary to ensure tight fixation of the material being processed;

- There should be no heavy objects on the table on which work is carried out that could fall to the floor.

Buy a bending machine with maximum benefit in

In addition to supplying equipment to our customers, we provide quality service:

- consulting support on operation and maintenance of the machine during the warranty period and after;

- supply of components and spare parts for the bending machine in the shortest possible time;

- free installation and commissioning of equipment supplied by us;

- Warranty and post-warranty repair of the bending machine if necessary.

All machines are delivered according to the agreed configuration and within the specified time frame with all accompanying documentation: instructions for connecting the bending machine and operating it in Russian, electrical diagram, drawings.

Didn't find the right model? Contact our specialists and explain your tasks. We can select a bending machine, the price and technical characteristics of which will suit even the most demanding customers.