Power transformers belong to the category of industrial equipment that provides adaptation of voltage values through step-by-step energy conversion. It can be used either as a stand-alone device or as part of a secondary power supply.

In the market for raw materials related to scrap processing, old products are highly valued, where the percentage of pure materials is highest. Steel, copper, and oil do not contain additives, which certainly increase performance, but significantly reduce the cost, since not all of them are also valuable.

Design of NOM-6 transformers

Transformer NOM-6 consists of an active part, a tank, a cover with LV and HV inputs. The active part consists of a magnetic core with a winding. The rod-type magnetic core is assembled from cold-rolled electrical steel. Multilayer cylindrical windings are wound from copper wire. The active part is rigidly connected to the transformer cover. LV and HV taps are made of copper wire.

The NOM-6 transformer tank is welded, has a round shape and is a structure consisting of an upper frame, a wall and a bottom. At the bottom of the tank there is a grounding clamp and an oil drain plug. The design of the plug allows you to take an oil sample when it is partially unscrewed. At the bottom of the tank there are 4 holes for attaching the transformer to the foundation or to the installation site. Mounted on the transformer cover are: HV and LV inputs, earrings for lifting the transformer.

To ensure sealing of the detachable parts of the NOM-6 transformer, oil-resistant rubber is used. The transformer is filled with transformer oil having a breakdown voltage of at least 40 kV. The lid-tank assembly and the oil drain plug are sealed.

Features of operation

For transformer TM 10/40, 320/10 and other varieties, the requirements for installation, commissioning and use are mandatory. Installation of structures is allowed inside and outside buildings and structures. The height above sea level is no more than 1 km. The ambient temperature ranges from +40 to -45ºС. Air humidity (relative) does not exceed 80%.

In conditions of increased vibrations, shaking, as well as in the close proximity of explosive and chemical substances, the presented equipment is not used.

Voltage transformers NOM-6 U3, NOM-10 U3, ZNOM-35 U1

Single-phase oil voltage transformers type NOM-6 U3, NOM-10 U3, ZNOM-35 U1 (hereinafter referred to as transformers) are designed for operation in conjunction with measuring instruments and in protection and signaling circuits in electrical systems with a rated voltage from 3 kV to 35 kV inclusive . Transformers are large-scale converters and are designed to generate a measurement information signal for electrical measuring instruments and protection and signaling circuits in networks with an isolated neutral.

General information

The TM transformer has two windings. Devices 27-2500 kVA fall into this category. Technical information on the operation of the transformer provides a rated voltage of 6-35 kV. The device is used for indoor and outdoor installation in public power supply networks.

The transformer of the presented type has 5 stages of regulation. The operating instructions indicate that the adjustment range is ±2×2.5%. Switching can only be carried out in a de-energized state.

Information on the State Register

| Basic data | |

| State Register number | 51200-12 |

| Name | Voltage transformers |

| Model | NOM-6 U3, NOM-10 U3, ZNOM-35 U1 |

| SI class | 34.01.02 |

| Year of registration | 2012 |

| Verification method / verification information | GOST 8.216-88 |

| Interverification interval / Verification frequency | 8 years |

| Manufacturer country | Kazakhstan |

| Certificate information | |

| Certificate validity period | 13.09.2017 |

| Certificate number | 48109 |

| Certificate type (C - series/E - batch) | C |

| Protocol date | Order 751 clause 42 of 09/13/2012 |

Manufacturer/Applicant

JSC "Kentau Transformer Plant", Kazakhstan, Kentau

Purpose

Single-phase oil voltage transformers type NOM-6 U3, NOM-10 U3, ZNOM-35 U1 (hereinafter referred to as transformers) are designed for operation in conjunction with measuring instruments and in protection and signaling circuits in electrical systems with a rated voltage from 3 kV to 35 kV inclusive .

Transformers are large-scale converters and are designed to generate a measurement information signal for electrical measuring instruments and protection and signaling circuits in networks with an isolated neutral.

Varieties

Dimensions and weight of TM power transformers depend on the rated power. According to the technical specifications and operating instructions, oil units are produced in the following types:

| Name | power, kWt | Weight, kg | Dimensions, cm |

| TM-25 | 25 | 320 | 80x43x97 |

| TM-40 | 40 | 430 | 84x45x107.5 |

| TM-63 | 63 | 510 | 104.5x50x137.5 |

| TM-100 | 100 | 760 | 109x77x156 |

| TM-250 | 250 | 1500 | 156x93x167 |

| TM-400 | 400 | 1890 | 175x105x178 |

| TM-630 | 630 | 2105 | 193x118x191 |

| TM-1000 | 1000 | 3450 | 208x129x215 |

| TM-1250 | 1250 | 3850 | 213x129x225 |

TM-25 has the smallest size parameters among the devices (according to the passport information). Power devices weighing 4000 kg have a lot of weight. There are also heavier varieties.

Description

The principle of operation of voltage transformers is based on the conversion, through electromagnetic induction, of alternating current of one voltage into alternating current of another voltage at a constant frequency and without significant power losses. Voltage transformers belong to the class of measuring converters.

Transformers consist of an active part, a tank, a cover with LV and HV inputs. The active part consists of a magnetic core with windings. Transformers of the NOM series are single-winding. Transformers of the ZNOM series are two-winding. The rod-type magnetic core is assembled from cold-rolled electrical steel. Multilayer cylindrical windings are wound from copper wire. LV and HV taps are made of copper wire. The active part is rigidly connected to the transformer cover. The transformer tank is welded round (for the NOM type) or rectangular (for the ZNOM-35) shape, consisting of an upper frame, a wall and a bottom. At the bottom of the tank there is a grounding clamp and an oil drain plug. The design of the plug allows you to take an oil sample when it is partially unscrewed. At the bottom of the tank there are 4 holes for attaching the transformer to the foundation or to the installation site. Mounted on the transformer cover are: HV and LV inputs, earrings for lifting the transformer. To ensure sealing of the detachable parts of the transformer, oil-resistant rubber is used.

Transformers are filled with transformer oil having a breakdown voltage of at least 40 kV. The lid-tank assembly and the oil drain plug are sealed.

The general view of the ZNOM-35 U1 transformer is shown in Figure 1.

Table/calculator

High-voltage power oil transformers brand TM-2500

Dimensional and weight characteristics of TM-2500

| Rated power / voltage class, kVA/kV | Oil mass, kg | Total weight, kg | Length, mm | Width, mm | Total height, mm |

| 2500/10 | 2050 | 6300 | 2650 | 1450 | 2880 |

| 2500/35 | 2130 | 6380 | 2650 | 1450 | 3040 |

Table/calculator How much copper and aluminum is in a high-voltage power oil transformer TM-2500

How much copper and aluminum is in the high-voltage power oil transformer TM-2500

See page: Cop's reconnaissance of abandoned railways in Moscow.

Table of electric motor windings, how to figure it out? SEE HERE.

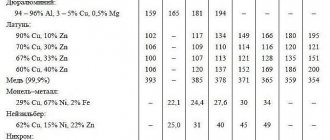

aluminum and copper alloys :

aluminum 80 kg.

aluminum 3rd - 350 kg.

copper alloys 30 kg..

Technical characteristics Rated higher voltage, kV 6; 10 Rated low voltage, kV 0.4 No-load losses, kW. 3.9 Short circuit losses, kW. 23.5 No-load current, % 1.0 Short circuit voltage, % 6.5 Scheme and group of winding connections U/D-11 Total weight, kg. 7200 Length, mm. 3250 Width, mm. 2200 Total height, mm. 3000

Transformer tag

TM - X/10 U(HL)1 T - three-phase transformer, M - oil cooling with natural circulation of air and oil, X - rated power, kVA, 10 - voltage class of the HV winding, kV. U(HL)1 - climatic version and placement category according to GOST 15150-69.

How much copper and aluminum is in the high-voltage power oil transformer TM-2500

Source

Transformer scrap or transformer scrap

Power transformers belong to the category of industrial equipment that provides adaptation of voltage values through step-by-step energy conversion. It can be used either as a stand-alone device or as part of a secondary power supply.

In the market for raw materials related to scrap processing, old products are highly valued, where the percentage of pure materials is highest. Steel, copper, and oil do not contain additives, which certainly increase performance, but significantly reduce the cost, since not all of them are also valuable.

General information: design, application, dismantling

Most often, devices are required to reduce the voltage supplied to the consumer. But there is a category of transformers that increases these values. The main distinguishing characteristics of both types of power plants remain the following parameters:

- number of phases;

- number of windings, methods of their connection;

- location (street or under the roof);

- cooling method;

- calculation of maximum power (universal, specialized equipment).

Structurally, all types of transformers have similar circuits, which include:

- A magnetic circuit consisting of active and inactive parts.

- Rods with insulated windings.

- Bushings consisting of a current-carrying rod or cable, a metal flange, an insulator (for example, porcelain).

- Expander for oil inlets (where necessary).

- Cooling system.

- Voltage regulator.

For the manufacture of parts/elements of power equipment, electrical steel , copper, and insulator are used. Therefore, if renovation is necessary, they try to find collection points for transformers for scrap , where they provide dismantling services and carry out removal, based on the principles of efficiency. The disassembly process for professionals does not take much time; it allows you to simultaneously determine the condition of the components:

- consider the winding and the difficulty of removing it;

- carry out the necessary labeling and sorting;

- check the radiator for leaks;

- give an approximate estimated cost.

However, knowing the model of the transformer and having the technical passport in hand, both parties can agree on the price even before the start of work, regardless of the wear and tear of the internal parts.

It is IMPORTANT to remember fire safety before dismantling the transformer!

Commissioning

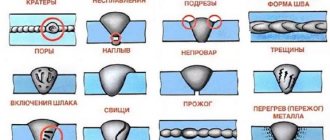

The equipment can only be put into operation after preliminary preparation. First, a visual inspection of the unit is performed. There should be no defects on it. The design elements must correspond to the factory configuration.

A visual assessment of oil sealing materials and fasteners is carried out. If necessary, they should be tightened. Oil leaks are unacceptable. You also need to pay attention to the oil level in the tank. The indicator is at the level established by the manufacturer. If necessary, excess will need to be drained. If the coolant level is insufficient, you need to add liquid to the tank.

The insulators are wiped with a dry cloth and gasoline. You need to pour special oil into the thermometer sleeve body. Next you need to mount the measuring device.

If the indicator silica gel is wet, it must be replaced. It is located in the dehumidifier design. The equipment must be connected to ground. This also needs to be checked before starting.

The oil from the cooling system will need to be analyzed. It must meet the established requirements. After this, the plug is isolated. If the oil fluid does not meet the specified requirements, it must be completely drained. A new coolant of appropriate quality is poured into the system.

The resistance of the windings is measured. The switch must be set to the operating position. After this, the equipment can be connected to the network.

Main components interesting for sale:

Transformer copper

Transformer copper is often called busbar and is accepted with great enthusiasm at specialized collection points for non-ferrous scrap. There is one important reason for this: the quality of the material obtained through electrolysis .

Transformer copper - part of the transformer bus

These are almost pure samples of copper, the conductive properties of which are in second place after silver:

- resistivity - 0.0175 μOhm-m at 20°C;

- density 8.96 g/cm 3 at the same temperature.

Winding wires are made from round or rectangular grades. The quality of the material is further divided into the following types:

Rods from the structural part of transformers, in addition to conducting properties, have mechanical strength and rigidity. Semi-soft copper is used for their manufacture.

Insulators are used in different parts of the product: cable or telephone paper, cotton thread, fiberglass with various impregnations, and the already mentioned porcelain. For a transformer scrap collection point, the price of such copper will depend on the expected costs of cleaning it, or more precisely, the blockage, as well as the labor intensity of the process of disassembling the device. Some of them require a little more attention, time, and special equipment.

Sometimes aluminum is used to assemble the power plant. It is similarly sorted into pure metal and those containing impurities. Costs and provision of services for equipment dismantling are taken into account. However, the material clearly retains the highest rating in its category.

Elements with an insulating shell are sent for preliminary mechanical processing - grinding. After which the entire volume is melted and separated from impurities using magnets, then subjected to electrolysis and other similar purification methods. Thanks to powder metallurgy, copper gets a second life.

Electrical steel or transformer steel

Electrical steel also becomes recyclable when equipment is dismantled or disassembled. In some sources this type of material is listed as charge . In other words, this is a transformer core made of electrical steel. Also, the cores in different designs of transformers can be made of permalloy, ferrodielectrics, and ferrites.

Transformer charge or electrical steel

The chemical structure of electrical steel scrap is an alloy of iron and carbon supplemented with silicon. Due to its presence, soft ferromagnetic iron is obtained, used in alternating fields.

Electrical steel in the transformer core

For electrical steel scrap , the following parameters are of greater importance:

- method of obtaining the material (cold rolled, hot rolled);

- thickness of sheets, wire, other shapes (ranges from 0.05 mm to 2 mm);

- presence of holes, soldering;

- Sometimes the year of manufacture of the equipment is important.

Before delivery to the final receiving point, the charge must be cleaned of insulating paint and varnish coatings and traces of formed rust. The presence of both unwanted layers reduces the scrap value of the transformer slightly.

Today, cold-rolled steel is increasingly being made from recycled materials, producing sheets for magnetic circuits with a thickness of 0.28-0.5 mm. The following physical requirements are imposed on this type of material:

- low watt losses;

- metal anisotropy;

- bending strength.

Electrical steel on small transformers

Therefore, to produce new electrical steel, iron alloys with a low carbon content of up to hundredths of percent are used, and in some cases manganese, aluminum or nickel are added. However, these substances, along with improving qualities, give various side effects: they impair flexibility and electrical properties. Adding silicon in an amount of 0.5-3.5% has become the optimal solution; with its help it is possible to change the following characteristics:

- increase the electrical resistivity value;

- reduce losses due to eddy flows;

- increase magnetic permeability;

- reduce hysteresis losses;

- improve strength, reduce ductility.

Anisotropic and dynamic steel are the most highly valued at scrap collection points; their cost is tens of times higher than the price of an also unusual and high-strength tool alloy.

Transformer oil

The next important component present in the design is transformer oil. It is obtained by distilling oil, so the product is considered natural and is characterized by the following qualities/properties:

- maintaining optimal viscosity, which changes with operating conditions (cooling, heating);

- freezing does not occur until the temperature drops to -45 0 C;

- the content of water-soluble acids and alkalis varies in hundredths of a percent;

- absence of impurities;

- dielectric loss tangent not more than 7%;

- the presence of breakdown voltage, determined experimentally.

For comparison, spindle oil, also obtained from petroleum distillation, is more mobile, but has a number of undesirable impurities. Therefore, it is used as a lubricant, and as a transformer for cooling equipment during operation. In addition, the latter type of oil has insulating and arc-extinguishing properties.

Dry transformer - there is no oil in such transformers

Taking into account the variability of viscosity at different temperature conditions, the quality of the product is controlled by a graph of the dependence of these values; it should have the most flat appearance.

The acid number is of great importance, which increases as the device is used. An important criterion for maintaining low acidity is the correct installation of equipment and the implementation of degassing measures before adding liquid. However, transformers that have served for 20, sometimes more, years inevitably contain oil with a relatively high oxidation number. Therefore, the product, although it remains at the same price, requires repeated processing: filtration, purification from formed impurities, testing for various properties. When changing product oils or filling new units, use only fresh oil that has not been used.

Today, a number of complexes (know-how of companies) for the introduction of antioxidant additives have been developed. This allows us to talk about the long-term use of transformers with a new generation of oils.

Oil transformer radiators

Scrap collection points are also interested in receiving oil radiators, which act as reservoirs that ensure convection of liquids in the transformer. There are several basic types: internal and external. The first is to assemble the equipment directly at the factory, deliver it and install it along with it. The role of the second can be played by hanging steel pipes (oval or round), specially attached to the tank; during installation, various sealing methods are used, as well as rubber plugs similar to them.

Such radiators are ideal for cutting pipes for further sale.

The greater the power of the transformer, the more likely it is to use a mounted oil radiator, called straight-tube, equipped with an external fan as necessary. Radiator taps are also used, made of stainless steel and having a specific attachment to the transformer pipes.

However, in the case of the delivery of scrap electrical steel, an interesting fact is the condition of the pipes:

- the outside is covered with protective layers that prevent corrosion (varnish, paint, zinc);

- inside, thanks to the use of transformer oil, they are clean, free of scale and rust;

- When carefully dismantled, they retain their dimensions (length).

Pipes from a transformer - cut into 2.5 meter lengths for sale

If this radiator pipe is cut to size, for example 2.5-3 meters, they can easily be sold as a post, used intake pipe of excellent quality, in good condition.