A turning tool is necessary for working on a lathe. A high-quality tool is very expensive, so one chisel costs from 3 thousand rubles, and the cost of some can reach 20 thousand rubles. Not everyone is ready to shell out that kind of money for turning chisels , given the fact that for work you need to have 3 or 4 cutters of different configurations.

In this article I will talk about the types of turning cutters , their purpose and methods of making them yourself from blade to handle.

I won’t drag it out and start talking about what kind of incisors there are and what they are needed for.

Centers for lathes

The design of lathes requires the use of certain equipment. Only if you have the necessary equipment can you make a part with the required accuracy parameters. In this case, you need to purchase special equipment or make a homemade version. It is worth noting that you cannot create everything for precision turning with your own hands.

Algorithm for carrying out the work

The production of any cutting devices is carried out according to a standard algorithm:

- Using drawings and photos, the required shape of the future chisel is cut from the blanks using metalworking machines.

- Primary turning of the product is carried out.

- When the workpiece is processed, the metal needs to be hardened to give the homemade product strength. This way he can process wood of different hardnesses. To do this, the metal tool is heated to maximum temperature and dipped in machine oil until it cools.

Another hardening option is natural cooling at normal ambient temperature. - Final sharpening of cutters for a lathe.

- Wooden handle attachment.

Fixing workpieces

Turning on a lathe occurs by mounting it in a jaw chuck, which transmits rotation and at the same time holds it in place. Such a device is effective when turning cylindrical bodies. In this case, the cutter is fed perpendicularly, which allows the metal to be machined to the desired diameter.

When considering a metal lathe, keep in mind that many homemade and commercial versions have a structure at the back to support the workpiece and perform other tasks. A homemade type of metal lathe also has a headstock version, which requires special equipment.

Thus, when fixed on two opposite sides on the lathe, the tailstock and the headstock, the workpiece will be in the specified position during even heavy loads.

When considering the tailstock, the following features should be noted:

- The device in question is intended only for attaching special equipment. The types of equipment used on a lathe determine the purpose of the tailstock: it can serve both for fixing a cylindrical body and for processing.

- You can make the center yourself or purchase it at a specialized store. When making it yourself, you need to take into account that the workpiece must be solid solid metal with an increased strength index. This is due to the fastening method: the quill presses the part against the spindle at the end and throughout the entire time the tip is in contact with it, slight friction occurs.

- The position of the lathe quill is adjustable only in the longitudinal direction. Given this feature, it is worth remembering that the position of the center must coincide with the axis of rotation of the spindle. Otherwise, rotations will occur with beating.

To ensure that the workpiece does not change its position at the time of strong feed or at high speeds, the center is used, which determines the purpose of the tailstock.

The device in question can also be used for drilling end holes and solving other technological problems.

Mounting at two ends

Fixation at two ends occurs in the following cases:

- An industrial-type metal lathe has adjustable speed. The high rotation speed that is transmitted to the part leads to “wobble” of the part. With precision processing, according to GOST, this phenomenon leads to a fairly large error.

- The large length and weight of the workpiece also determines the need to use a tailstock. Under its own weight, the cylindrical body can be deformed and the cutter will “hit” the metal while feeding the cutter.

- Depending on the turning mode and spindle speed, excessive cross feed may occur. When processing a part in such a situation, it is quite difficult to make it with high accuracy.

In such cases, fixation should be carried out at both ends.

What is a copy sleeve used for?

It helps to confidently guide the cutting elements of the router along a complex trajectory, maintaining the distance between the cutter blade and the edge of the template. As a rule, it is used in conjunction with various templates and rules that should be followed along the edge of the part. The outer edges of this instrument necessarily extend beyond the sole of the instrument.

Types of turning centers

You can fix the necessary tool in the quill yourself. This job will take a few minutes to complete, and you can do it yourself. According to GOST, the following types can be distinguished:

- persistent. GOST determines that the tip and shank have almost the same diameter. The device of this design determines that the tip is made of hardened steel or hard alloy in accordance with GOST 13214-79.

- the fungal version is somewhat different from the previous one. According to GOST 8742-75, the fungal tip has a larger diameter with a truncated working cone. According to GOST 8742-75, there are two types of tips that the fungal center has: with a centered roller or with an attachment for it. The mushroom tip allows the device in question to be used for fastening rotating bodies with hollow end holes during processing.

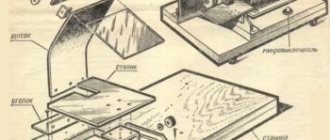

Do-it-yourself copying bushings for a router

In some cases, the manufacturer does not equip the milling machine with such an important tool. To make this necessary device yourself, you will need a washer made of duralumin or sheet metal, and a plumbing extension made of metal with a thread. The manufacturing process is as follows:

- A nut that matches the threads of your extension is selected and cut so that a ring is formed in the process.

- Then it should be sharpened.

- A round platform is cut from a metal sheet or aluminum 2 mm thick. It is necessary to cut off a certain amount of material from the sides, doing this on a sharpening machine, and place it on the sole.

- We install your tool vertically and mark the places for fixation through the holes in the sole.

- The holes are drilled using a small diameter drill, and then with a drill that matches the diameter of the mounting bolt.

- We put on the washer and tighten the nut. We clamp the part in a vice and cut millimeters of thread with an angle grinder so that it is flush with the nut.

- We clamp the part with a vice and shorten it.

- After this, we align the part on the grinding wheel, insert it and secure it in the tool base.

In this article, we tried to briefly highlight the key points regarding bushings, talked about the method of their manufacture, and talked a little about such a useful tool as a copying ring.

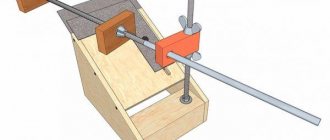

How to make a ROTATING CENTER for a lathe

Show Control Panel

- It is shown in detail how to make a rotating center for a lathe with your own hands. Rotating centers with a Morse cone km1 have been made: both classic and a center with a reverse Morse cone. Two angular contact bearings are installed in the center. A special feature of the design is the presence of a through central hole in the cone for pressing out the rotating part and two holes in the housing for pressing out the bearings. The km1 cones are machined with the upper slide aligned according to the indicator. You can see how this is done here: ru-clip.com/video/1-6naGgrVUs/video.html Thus, you can quite easily make a rotating center yourself. You can see how to reduce cone runout here: ru-clip.com/video/rpREM7K7HLs/video.html You might be interested in watching a playlist that contains videos about repairs, adjustments, modifications, and modernization of T-65 turning and milling machines , MN-80, JMD-1 and DUPLEX-58: ru-clip.com/p/PLmP5IFA2la2GMeKIcvDp9swc9hIYG637V I advise you to watch the playlist “Unusual work on machines”: ru-clip.com/p/PLmP5IFA2la2HYjP34zP3EZtg1bLXql242 I invite you to my channel: ru-clip. com/user/my_videos?o=U

Comments • 46

This is how I make the center of any shape ru-clip.com/video/C9-JP68dHsw/video.html subscribe.

I am not at home at the moment. Everything is the same: two drills, turning the upper slide. Nothing new or interesting. I can shoot a video for you. Remind me after April 2.

@Anatoly Sandimiro excellent. curious to see for experience..

The inner center can also be sanded with a small stone. Available with a diameter of 2 mm. I even have 1.5 mm.

@Anatoly Sandimirov yes, your method is simpler. But I think it will be difficult to make an illt to fix any special center such as an internal one.

Good way. I correct the center differently: ru-clip.com/video/rpREM7K7HLs/video.html

Thank you! Subscribed. I recently bought a TV-4. In the spring I will connect the power (small problems with switching) and start studying using your videos.

I'll be glad if it's useful.

What bearings do you use? GOST or international marking. radial contact small sizes are difficult to find. The Chinese have E5 or E6.

I used regular #18.

I would like to purchase such a center from you, is this possible?

Sorry. I don't work on orders.

Soooo. Here's how to make a rotating center without a lathe? This is something to look at and grasp. And with a lathe.

Sorry, I didn’t understand you right away. What is the cone in ZB? Is it not possible to purchase a ready-made one? Or are there some subtleties there? I have never worked on woodworking machines.

@Anatoly Sandimirov Why did you decide that there is no machine? Yes, but on wood. 3 jokes. There is also a rear headstock and a rotating stop, albeit on one bearing. And it was made without lathe. Shit, damn it, but I carved it out with a grinder. Yesterday I completed the last, so to speak special one, installed a motor from a washing machine with controls, turned out the first smoking pipe on it, a test of the pen. We need to make the cutters now. I raised the motor 15 cm from the frame (a piece of channel), the stop moves, you can sharpen the plates. And you can also get cuckolded. Although I limited the speed - the upper limit. How bad it is to live, damn it, without a jig boring machine. or at least a lathe. . )))

Why do you need a rotating center if you don’t have a lathe?