Longitudinal and transverse cutting of galvanized, cold-rolled, galvanized with polymer-coated and stainless steel coils is carried out on a high-speed industrial line of imported production. Metalmos LLC provides services for rewinding coiled steel, and also offers the supply of coils of individual size/weight, which will significantly optimize the production process, minimize waste and, as a result, the cost of the finished product.

The client can order cutting of the following metals:

- Galvanized with or without polymer coating

- Cold rolled steel

- Stainless steel

The process uses high-speed industrial equipment from foreign manufacturers, which ensures high quality cuts. Our equipment allows you to rewind rolled steel. This allows the client to order rolls of individual weight or size. This service significantly optimizes production in the client's factories. In particular, the amount of waste is reduced and the price of finished products is reduced.

The production line has high precision. The error is only 0.1 mm, and surface defects are eliminated. The equipment can work with tape with a width of 15 mm, the thickness of which starts from 0.18 mm. The maximum processed thickness is 2.5 mm.

Specialists will perform longitudinal and transverse cutting of metal and steel of standard and custom sizes. The cutting accuracy is ±2 mm. Cutting into cards and strips is possible. The dimensions are determined by the customer. Thanks to the presence of modern production, the service is provided online.

The company works only with trusted suppliers, which allows us to guarantee the quality of raw materials and the durability of finished products. It has all the necessary certificates and meets the requirements of the standards. The company's extensive experience in providing this service allows us to guarantee its quality.

Strip (tape)

Specifications

| Sheet thickness: from 0.18 mm to 2.5 mm |

| Inner diameter of the original roll: from 500 to 700 mm |

| Inner diameter of finished strip: 600 mm |

| Roll width: up to 1270 mm |

| Roll weight: up to 9.5 tons |

| Minimum strip width: 15 mm |

| Cutting accuracy: +/- 0.1 mm |

| Cutting speed: up to 40 m/min |

Thanks to a high-precision industrial line, we produce strips with a cutting error of +/- 0.1 mm, without surface defects. The minimum width of the tape is 15 mm, sheet thickness from 0.18 mm to 2.5 mm. The output we get is tape, which is a common material in manufacturing and construction. The cost of services is affordable and profitable for the company’s clients, the quality meets European and Russian standards.

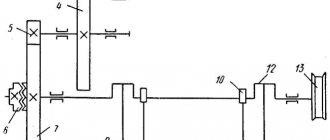

Slitting line for rolled and sheet metal

The cutting line is used in both large-scale and small-scale production. Such a system is characterized by high performance. With its help, sheet metal can be cut into blanks of various widths and lengths. As a result, such cutting systems are used for the production of dimensional blanks for stamping, for the pipe industry, semi-finished products (strips) and other products that are obtained from rolled sheets.

The cutting line for sheet metal or other material consists of the following mechanisms and components:

- A machine is a cutting unit used for longitudinal cutting of rolled metal. Moreover, a device is built into the cutting unit in high-speed lines that increases the plasticity of the metal due to heating by induction currents.

- Feeding ox systems - a conveyor, with the help of which the roll is unwinded and subsequently transported to the cutting zone of the sheet itself.

- A hopper where a roll of material to be cut is stored on a shaft.

- In addition, almost any line is equipped, in addition to a longitudinal cutting block, with a transverse mechanism, which is designed to separate the metal being processed.

- Moreover, high-speed processing forces the control system to build line operation based on numerical program control blocks.

And after the sheet cutting procedure is completed, the softened edges should be further processed with induction currents, removing residual stress in the metal structure.

The main advantage of such lines is the high processing speed and standard-size range of workpieces produced with their help. After all, with circular knives, the cutting unit can be adjusted to any width, and the transverse system can move at high speed, cutting rectangular or square workpieces from belts.

Rolled metal slitting unit

The units are fully automated cutting lines for rolled metal. Only in large-scale production are such devices used to produce large batches of similar products.

The unit for cutting rolled metal consists of the following blocks:

- Drum unloading systems, which remove a roll of the required width from the drum.

- A drum onto which the finished strips are wound to the required width.

- A loop compensator, its task is to slow down the speed of movement of the cut strips.

- A longitudinal cutting unit in which the sheet is divided into strips of the required parameters using circular knives.

- A pre-treatment complex that heats up the sheet and cuts the edges before entering the cutting zone. Moreover, cutting waste is wound onto separate coils.

- A trolley with a hopper is a conveyor that is mounted on rails. The trolley moves along the rails in the direction opposite to the direction of sheet metal supply; the sheet is unwound and loaded into the transport pressure rollers. Rollers hold the sheet from winding into a roll and then roll the material. This scheme makes it possible to increase the feed rate of material into the cutting zone. In addition, in this case the trolley acts as the engine, and the transport sheets only simply position the sheet.

Of course, these units are only automatically controlled. And thus, the resulting cut rolls of strips can be further moved to less productive machines and lines for subsequent transverse or longitudinal cutting.

Smooth sheet

Specifications

| Standard galvanized sheet | |

| Length: 2,500 mm | |

| Width: 1,250 mm | |

| Thickness: 0.4mm to 2.5mm | |

| Length: 2,000 mm | |

| Width: 1,000 mm | |

| Thickness: 0.4mm to 0.7mm | |

| Custom Galvanized Sheet | |

| Length according to customer dimensions: from 500 mm to 6,000 mm | |

| Cutting accuracy: +/-2 mm | |

| Thickness: 0.4mm to 1.0mm | |

| Maps and stripes | |

| Length and width: according to customer sizes | |

| Cutting accuracy: +/-1 mm | |

| Thickness: 0.3mm to 2.5mm | |

Cross-cutting of rolled steel into sheets is carried out in standard sizes: width - 1250 mm, length - 2500 mm, thickness from 0.4 mm to 2.5 mm; width - 1000 mm, length - 2000 mm, thickness from 0.4 mm to 0.7 mm. And non-standard sizes: length from 500 mm to 6000 mm, thickness from 0.4 mm to 1.0 mm, cutting accuracy +/- 2 mm. Cutting into cards and strips is possible: width and length according to customer dimensions, thickness from 0.3 mm to 2.5 mm, cutting accuracy +/- 1 mm.

Slitting Equipment

It is possible to implement the above methods on lines oriented towards large-scale production, small machines and high-performance units.

Each type of equipment is oriented toward a specific cutting pattern and has its own disadvantages and advantages. Moreover, the choice of a specific unit or a specific cutting model is associated with a set of tasks that can be solved with their help.

Metal slitting machine

This machine is a type of cutting equipment and is used for transverse or longitudinal cutting of metal measuring sheets. That is, it is not the roll that is loaded into the feed rollers of the machine, but a sheet prepared in advance, which is then transported to the cutting zone.

Disc shears, which are used in machine tools and intended for such a procedure as longitudinal cutting of metal , can easily separate structural polymers, thick cardboard, sheet aluminum, copper, and sheet steel into strips of the required thickness.

Moreover, the cutting tool is fixed to the pressure shaft using screws. The width of the stripes can be adjusted either manually or automatically. More advanced models are not limited to longitudinal cutting only - such units have a head with cutting rollers mounted on screw shafts, which perfectly ensures transverse cutting of metal.

In addition, in addition to cutting, such machines can be equipped with a block for applying a protective film, which is glued to the sheet before the material is divided into strips.

Features of working with Metalmos

Longitudinal-transverse cutting is performed on modern machines, which guarantees quality. The company makes every effort to ensure that the result of the work meets the client's expectations. To arrange a cutting service, just call the company’s office or leave a request on the website.

To ensure high quality and durability of products, we purchase raw materials from the largest manufacturers of rolled steel in Russia: OJSC Novolipetsk Iron and Steel Works, OJSC Severstal, PJSC Magnitogorsk Iron and Steel Works. All products are certified and comply with GOST standards.

Each client is provided with an individual specialist with whom you can discuss all the nuances of the order. To calculate the cost, send a request by email or use the form below. We are waiting for your call by phone number 8-495-118-36-88!

Working with us, you can be confident in the quality and efficiency of cutting.

Purpose and types of slitting

Sheet metal with a thickness of up to 12 mm comes from manufacturing plants, packaged in rolls. To produce finished steel-based products, in a number of cases, the coil must be unraveled lengthwise into strips. For this purpose, longitudinal technology for separating steel is used, implemented using special machines and equipment, often operating in one line with devices for the production of final finished products. The latter can be rolled pipes, corrugated sheets, metal tiles and other types of products.

The equipment allows you to automate the production process and eliminate the human factor. As a rule, the equipment is represented by separate modules controlled by an automatic system. Using longitudinal cutting equipment, rolled sheets are cut into blanks with the required overall dimensions.

How to avoid cutting problems

Problems encountered with strip slitting include poor edge quality, edge burrs, waviness, crescent, bowing, knife marks, and not meeting specifications.

The first thing to pay attention to is the edge.

How is a good edge determined? It's not that difficult. Examine the edge visually! At most thicknesses used, 30x magnification is quite sufficient for this. The edge usually has a shiny zone and a faded zone. If they are separated by a smooth border and both zones have a smooth surface, the edge is considered good (see Fig. 1 ). If the line is uneven or the break is rough, then it is a bad edge.

Sometimes defects are associated with low quality metal, but more often their cause should be sought in the technological parameters that are set and adjusted during the cutting process.

Slitting has a large number of parameters, and most of them can be adjusted. To achieve good cutting results, they must be adjusted optimally.

If previously slitting was talked about as an “art,” then recently it has tended to be viewed more as a science. Indeed, thanks to the improvement of equipment, tools and software, many parameters can now be precisely adjusted. And this, in turn, makes it possible to improve the quality of longitudinal cutting to a level previously unattainable.

- A good cutting tool and its proper use will produce a good edge.

- Picture 1

- Figure 2 The horizontal gap between the knives is the most important adjustable parameter affecting the quality of the cut.

Adjustable Parameters

Knife gap.

Of all the adjustable parameters, the horizontal gap between the knives plays the most important role (see Fig. 2 ). In the “good old days,” the gap between the knives was almost always set to 10% of the metal thickness. Let's say a 0.008-inch gap was used when cutting 0.080-inch thick metal. For many thicknesses and types of metal, the “10% of thickness” rule actually gives good results; however, 10% is not ideal for any type.

It is clear that with a small metal thickness it is very difficult to “catch” the required gap. But even on thicker metal, the old rules are of little help today. The fact is that new types of metals are created for very specific needs, so their mechanical qualities differ from each other much more than those of previous, less “technological” metals. And this has to be taken into account no matter what you cut: steel, aluminum, copper, bronze, alloys, any of the modern brands of metal. Each material has its own optimal clearance, and even the same metal from a different manufacturer or thickness can (and usually does) require a different blade clearance.

Excessive vertical clearance, or overlap, causes many strip defects, including waviness, bowing, crescent, and knife marks. It can also cause damage to the tool, knives and piston rings, and even cause wear on the slitter itself.

What gap would be “correct”? Very simple: the one that gives the best result. This may seem like a truism, but longitudinal and transverse cutting is a very complex process. There are no formulas that have been derived that will always work without error - or at least work for most cases. Therefore, the most important method is to carefully analyze the result and adjust the gap accordingly in search of the “golden mean”.

Tool.

If we talk about a “formula for success,” then the tool is a very important variable in it. It is the tool that is often the cause of both good and bad results. If a tool is well made and maintained, it will not only produce a good edge, but will also last longer. If it is in poor condition, does not fully meet the required parameters and/or plastic spacers are used, then it is difficult, if not impossible, to achieve good edge quality.

Operators, of course, achieve real art in making even such a tool “work.” But the same operator will acquire much more valuable production skills if the equipment does not require “rework” and does not need to be “made to work.” But, from practice, a lot of time is spent on these things!... It is much less expensive and more effective not to skimp from the beginning and purchase high-quality equipment with suitable characteristics.

So, to get straight edges you need to have a good tool, keep it in good shape and use it correctly. If the spacers and discs are damaged, they will not sit straight. This means that the horizontal gap of the knives cannot be set with the required accuracy. In addition, the blades will wobble, the gap will fluctuate, and the edge will be of poor or uneven quality.

- Figure 3 A damaged tool causes the knives to beat, which causes chips or nicks on the working surface of the knife. This has a detrimental effect on the quality of the strip edge

If the tool is damaged, the knives may interlock, resulting in nicks and gouges on the cutting edge of the knife (see Fig. 3). A tool whose specifications and tolerances do not meet the needs of your production will behave in the same way as a defective or low-quality tool. The so-called “spacerless” tool, as the name suggests, does not require the use of spacer rings and elements for normal operation. But if you still have to use spacer rings, then something is wrong. Well, spacerless tools have been produced for more than 20 years... over these years, you must admit, some things could have worn out.

By the way, spacer rings made of lighter materials are more convenient to use; workers will be less tired and... make fewer mistakes (see Fig. 4).

High-quality tools provide good working conditions, a high degree of edge quality control, and long service life of the knives. If problems arise during the slitting process and you suspect the cause is a bad tool, check the tool for defects, or have someone with extensive manufacturing experience and a good professional reputation do it.

- Figure 4

What to look for

Equipment

However, a good tool alone will not solve ALL problems. If the machine is not properly maintained, the bearings are loose or the flanges are damaged, the quality of the product will be poor. For questions about equipment care, consult technical support; It is also useful to learn from the experience of great specialists in this field of production.

Burrs

A defect such as a burr along the edge of a strip may appear during the slitting process. The first cause of a burr may be improper horizontal clearance of the blades - too much or too little. And an incorrect gap automatically results in a bad edge. A burr is, in fact, one of the indicators of a “bad” edge.

If the gap is too large, the metal will stretch under the knife and then tear.

If the gap is too narrow, the cutting process will require much more force. Well, the only way to provide more force is to lower the knife vertically, which, in turn, produces a burr.

A dull knife also produces a burr as the metal is pulled against the dull edge and then breaks. Therefore, it is very important to use a knife that is suitable for your operations. A knife that dulls too quickly will cause a burr. On the other hand, if the knife crumbles easily, then you will have to readjust everything too often and you will lose valuable time. It is advisable to use the most wear-resistant knife, whose cutting edge retains its sharpness for as long as possible. The fewer opportunities there are to somehow affect other operating parameters of your equipment, the more wear-resistant your knives should be.

Too large a vertical gap (overlap of knives) will also produce a burr.

wavy edge

Although a wavy edge can be caused by stresses within the metal, most of it is caused by errors in the slitting process. Excessive vertical gap (overlap) can create a wavy edge. Another reason could be improper use of spacer rings. If the outer diameter of the spacer rings is too small, you will be constantly lowering the blades to avoid slipping. If the rings are too large, the metal will stretch around the edges. The lack of parallelism also produces a wavy edge.

Knife marks

Knife marks are almost always caused by improper use of the push rings. In the past, all push rings were the same size and hardness. Even today, some manufacturers wrap electrical tape around the non-functional edge of the knife to prevent it from leaving marks on the metal. If you're doing this, you better stop! First of all, wrapping duct tape around knives is dangerous; In addition, this leads to poor edge quality, burrs and waves. It would be correct to use male-female pushing rings of different colors, sizes and hardness. Ring sizes and hardness may vary from machine to machine. The size will depend on the hardness and thickness of the (working) metal.

Sickling

Sickling can occur due to stresses within the bobbin. If the crescent always goes in the same direction, it is very easy to check whether the material itself is the source of the crescent - try cutting the roll upside down. If the crescent shape goes in the opposite direction, then the reason was the stress inside the roll. Otherwise, the crescent shape appeared during the slitting process.

This type of crescent shape is obtained if the strip is cut into narrow strips and the horizontal gap differs from edge to edge. The edges of such a strip will differ from each other. For example, on one side the edge may be of good quality, but on the other side it may be too stretched.

Convexity

Like crescent, convexity can appear both due to defects in the strip and during the cutting process. Typically, bowing is caused by excessive vertical play or incorrectly sized push rings. If the male rings are too large or the female rings are too small, bulging may occur.

Cutting width

The width can be precisely adjusted. Some of the reasons why the cut strip width may not be within the specified parameters include incorrectly set gap, improper or worn tooling, poor machine maintenance, or incorrect use of push rings. Different metals react differently to the horizontal cutting process.

In general, if you are going to cut 12 inches wide, you will want to space the blades a little more than 12 inches apart. Exactly how much wider will depend on the thickness of the metal itself, the cutting width, the type of metal and its physical characteristics. The extra width will be more noticeable on thicker metals and less noticeable on thinner ones. In addition to this, axle deflection, knife deflection, accuracy of settings, correct use of spacers, general condition of the machine are all taken into account when calculating the exact distance between the knives. In our age, the requirements for accuracy are so high that permissible errors of the order of 0.001 inches are quite common.

Finally, each machine, metal and tool has its own rules. Therefore, careful records of the results of each operation should be kept and quality consistently improved based on such monitoring.

The more the tool maker knows about your work, the easier it will be for them to help you choose the right blade metal and advise you on clearance sizes. If you do not understand the principles of proper use of push rings, then setting up the machine correctly will be difficult. Because there are literally hundreds of recipes for using push rings effectively, you should consult your equipment manufacturer. It will be very helpful to have training and practice in slitting, as the same scenario may not work for two different equipment configurations.

Posted by Al Zelt March 7, 2006

Process technology

Slitting is a technological process that is carried out in several stages, one after another. Carrying out work in automatic mode:

- The sheets are fed to the equipment desktop. They are cut into strips.

- Electric current is applied to the finished strips. The metal is heated. The current increases depending on the thickness of the strips.

- To reduce the resistance of the cutting material, local heating is performed. Due to heating, the mechanical properties of the metal are reduced.

- The last stage is longitudinal cutting of the workpieces.

Do-it-yourself work is done on hand-held machines. All the technician needs to do is place a sheet of metal, start the engine of the equipment, and control the work process. It is important to remember to check the sharpness of the cutting scissors so as not to damage the metal sheets during cutting.

Longitudinal cutting of metal is considered a popular technological process, on par with transverse cuts. To carry it out, you need to select equipment and become familiar with the features of its use. Next, all that remains is to perform the work in a certain sequence to obtain stripes and tapes.

Metal cutting methods

There are the following methods for cutting metal sheets:

- Cut the sheet with a guillotine.

The advantages of this method include the low cost of work, as well as the absence of thermal effects on the material. But there are some peculiarities: when cutting with a guillotine, the cut is often uneven, and mechanical damage also remains on the metal.

- Gas cutting of sheets.

The strengths of this method of cutting metal sheets include low cost and a large selection of cutting widths. But during the cutting process, due to the influence of gas, a rather wide cut is formed, which is not economical enough. In addition, a large area of steel sheet or sheet of other material is exposed to thermal effects.

- Plasma cutting.

Plasma cutting does not deform the metal. This type of cutting is also good because it allows you to obtain workpiece shapes of varying complexity. However, the method is only applicable to electrically conductive materials.

The advantages of plasma cutting include:

- high rates;

- increased accuracy;

- the ability to cut large complex shapes;

- highest cutting quality;

- material savings: virtually no waste is generated during the cutting process;

- the ability to cut both the hardest and easily deformable metals.

The high-quality equipment that our company uses is a guarantee that the cutting of sheet metal will be carried out in the best possible way.

- Laser cutting of metal.

The advantages of this method are high speed, especially when cutting thin materials, and in addition, high accuracy, which is especially important when cutting small parts, where it is necessary to accurately fit the size. Another advantage is the small width of the cut, which saves material. The peculiarities of laser cutting include the difficulty of cutting materials with high reflective abilities, limitations on the thickness of the material, and high cost.