Regardless of what guarantee the knife manufacturer gives that they will not require sharpening during use, sooner or later this question will still arise before the user. It doesn’t matter whether this applies to kitchen utensils or camping accessories, because... A sharp knife is the key to success in fishing and hunting, while traveling and when cooking. Devices for sharpening knives - types and rules of use, as well as how to make them yourself - this is the topic of today's review by the editors of HomeMyHome.ru.

The simplest device for sharpening a cutting tool is a block, and the device for its use is a clamp for the angle of the surface being sharpened

Introduction

No matter how wear-resistant and durable the steel on the knife is, sooner or later the sharpness will go away, damage will appear on the cutting edge, and the knife will have to be sharpened.

Under high magnification, the cutting edge is a series of teeth that, when working with a knife, grind the fibers of the material being cut. In the process of working with a knife, in collisions with hard materials, these teeth become jammed, chipped, and bent. As a result, the cutting aggression disappears and the knife becomes dull. During the sharpening process, the abrasive stone erases the metal layer, simultaneously forming a uniform series of teeth, thereby restoring the working structure of the cutting edge. The sharpening process begins with coarse grinding stones and ends with high-grit polishing stones. This is necessary in order to achieve the most uniform size of teeth on the cutting edge, and to remove rough scratches from roughing stones, which increases the durability of the edge and the duration of the cut.

Criteria for selecting a sharpening tool

Determine the intended purpose of the cutting edge. In everyday life, mechanical devices or low-power electrical appliances are used. For the production of professional food preparation facilities, you should choose powerful installations.

Pay attention to the design features of the sharpener: with or without the ability to change the angle of the blade, with or without a cutting edge lock. If you plan to use the product to increase the sharpness of knives and scissors, select a universal model.

Selection of sharpeners by type of blade material

The subtleties of sharpening different types of cutting edges are taken into account:

- For soft metal, use a medium-grit tool. After this, the material is additionally polished with a fine-grained bar.

- For hard steel alloys, a diamond-coated sharpener is suitable, since it is important that it be harder than the blade. Carbide and ceramics meet this requirement.

- For ceramic knives, only diamond-coated sharpeners are purchased.

Ceramic stones

The simplest, and at the same time most difficult way to sharpen a knife is to use full-size abrasive ceramic stones. Some require pre-soaking to work, and are accordingly called water stones, which require lubrication with special oil to work effectively, and accordingly are called oil stones. Lubrication with water or oil is required to ensure that pieces of metal and waste stone do not clog the pores of the abrasive, thereby reducing work efficiency.

The stone requires pre-soaking in cold, clean water for 10-15 minutes. After small bubbles stop rising, this will mean that the stone has drunk enough water, it can be moved to the workplace.

To sharpen, it is necessary to place the abrasive stone on a flat surface, on a base that will not allow the stone to slide during operation. Usually stones are sold complete with a stand on a rubber base.

Then, using the “Crutch” device, which is a hairpin with a rounded base, with a knife clamp attached to the hairpin, set the required sharpening angle. It should be especially noted that the purpose of the knife determines the sharpening angle. So for hunting or tourist knives that have to deal with heavy work, the sharpening angle is 40 degrees. In some cases, it is possible to perform a micro-approach to provide additional strength to the cutting edge. For kitchen knives that require an aggressive and high-quality cut, but do not require heavy loads on the cutting edge, an angle of about 30 degrees is optimal. For straight razors that only work when shaving hair, the angle can be 20 degrees.

You can set the angle either using a special device or simply by downloading an application to your smartphone. As a last resort, use a regular protractor. An important point: if we sharpen a hunting knife, then the full angle is 40 degrees, respectively, an angle of 20 degrees is set to the side.

Having held the knife in the clamp and determined the angle required for sharpening, without unnecessary effort we press the knife blade to the surface of the abrasive and begin sharpening with reciprocating movements. The main condition for effective sharpening is that you absolutely cannot apply any noticeable force to the knife. The abrasive itself will remove the required amount of metal. It’s not for nothing that the sharpening process is often compared to meditation.

During the sharpening process, a burr will form on the opposite side of the cutting edge; it can easily be felt with a fingernail. This is due to the fact that in the process of cutting material from one side, part flows onto the opposite side of the cutting edge, bending at the same time. After a burr has formed, you should turn the knife over to the other side and continue sharpening. During this process, regularly moisten the abrasive with water.

After the burr falls off, you can move to a higher grit. For rough grinding and rough shaping of the cutting edge, you can use stones with a grit of 120/300 units. For finishing the cutting edge, stones with a grit of 600-1000 units are used. For finishing, abrasives with a grit level of 2000-3000 units and higher are used.

In some cases, diamond polishing pastes are used to polish the leads. But it should be said that this is not always a good choice. You can roll up the cutting edge at the finish and get a so-called soap cut. That is, the knife will quickly shave hair on your arms, shred paper into noodles, but will slide over the skin of tomatoes. Therefore, I recommend finishing sharpening with ceramic high-grit abrasives.

As you gain skill, you can stop using the device and switch to sharpening by hand.

V-shape sharpeners

To be fair, such devices are used not so much for sharpening as for straightening a knife. That is, to quickly restore working acuity. It is extremely difficult to change the sharpening angle or remove damage to the cutting edge using such devices.

The most famous example of sharpening systems from this group is Triangle from Spiderco. The sharpening system is a plastic base with holes for abrasive stones. Triangle involves sharpening at the two most popular angles of 30 and 40 degrees.

Triangular-shaped abrasive stones are supplied with the sharpening system. Two brown stones, 600 grit. They are labeled as Medium and are intended for primary processing. And two white stones with a grit value of 1000 units. Marked as Fine and intended for finishing the cutting edge.

The sharpening process on Triangle is as follows. Brown stones are installed in the holes at a selected angle, with an acute angle inward. We take the knife at an angle of 90 degrees to the table surface, press it against the inclined abrasive, and with a little effort draw it down, on the left side of the knife, and then on the right. After completing 20-30 passes like this, we turn the stones over with the flat side inward and repeat the procedure. Then we install the white stones with a sharp downward angle and continue the editing process. Again we place the stones with the wide side inward and continue sharpening the knife.

The main advantage of Triangle is its simplicity and efficiency. In just 5-10 minutes, without extra effort and skill development, a knife can be sharpened into a razor. Separately, you can purchase polishing stones that are labeled as ExtraFine, or special diamond stones. Which are characterized by high productivity, and with their help it is quite possible to resharpen the knife to a different angle (30 or 40) and remove chips from the cutting edge. The disadvantage is the high cost of diamond abrasives; it exceeds the cost of the sharpening system itself.

The best electric models

Electric sharpeners greatly simplify the process of sharpening a knife. You don't need additional knowledge or sharpening skills. Compared to a mechanical sharpener, such a device is easier to use, the sharpness lasts longer, but it takes up more space and costs an order of magnitude more. Electric models are safe to use, and you don’t have to worry about hurting your hand.

Carefully! Some models of electric sharpeners grind down the surface of the knife excessively.

Swifty Sharp Tool and Knife Sharpener Editor's Choice

Price: 1780 rub. 890 rub.

The powerful universal knife sharpener Swifty Sharp Tool and Knife Sharpener copes not only with knives made of any alloy (except titanium), but also with scissors and other tools. Powered by 4 AA batteries and does not require replacement for a long time. Compactness and durability of artificial corundum are the 2 main qualities of this electric sharpener.

Advantages

- compact;

- artificial corundum lasts a long time;

- versatility - sharpens knives, scissors, pruners and other tools;

- low price, sometimes there are discounts;

- noiselessness;

- Ideal for hiking and country collections due to its compactness.

Flaws

- Doesn't sharpen titanium knives, but at this price it's useless to expect that from this sharpener.

Go to the store. Buy at a discount!

Hatamoto EDS-H198

Rating

10.0

Price: 7500 rub.

The sharpener operates from a wall outlet and has a power of 60 W. The device can be called universal, because it is equally suitable for steel, ceramic, and Japanese knives. This is largely facilitated by the sharpening angle specified by the manufacturer - 15 degrees.

It sharpens and polishes the cutting surface well. For these purposes, there are two types of abrasives - coarse and fine. Abrasive material: diamond-coated steel.

The knife must be dry and clean when sharpening. It will take 1 minute to give the blade primary sharpness. And the metal shavings that appear during processing are collected in a special compartment.

Advantages

- universal – suitable for steel and ceramic knives;

- there is a tray for chips;

- acute sharpening angle;

- high-quality assembly.

Flaws

- scissors and serrated blades cannot be sharpened;

- high price.

Zigmund & Shtain ZKS-911

Rating

8.0

Price: 3990 rub.

The electric knife is designed for double-sided symmetrical sharpening of metal and ceramic knives. It has three stages of operation. The first stage is for coarse sharpening and forming the correct angle of the blade, the second is fine, to give maximum sharpness, the final stage is finishing and polishing the blade.

Has a high disk rotation speed of up to 2800 rpm. The time stated by the manufacturer to give an ideal sharpness to the blade is from 10 seconds to 2 minutes. The sharpening angle is set automatically and is 15-20 degrees.

The abrasive material is the natural mineral corundum. It has three types of coating - coarse, medium and fine grain. The reliability and service life of the engine is increased due to the presence of a fan for cooling.

Advantages

- housing made of high quality ABS plastic;

- built-in engine cooling fan;

- compact size;

- high power 60 W;

- symmetrical blade sharpening;

- there are containers for collecting metal dust;

- anti-slip base.

Flaws

- not suitable for scissors and serrated blades;

- vibration of the device during operation;

- The angle adjustment is not fixed rigidly.

KitchenIQ 50387

Rating

8.0

Price: 7100 rub.

American-made two-stage electric sharpener. Suitable for sharpening European and American knives with straight and serrated blades.

The guide system is set at 20 degrees. The device not only sharpens the cutting surface, but also polishes it on both sides during the finishing stage. First, rough sharpening occurs using diamond discs, and ceramic rods are built in for finishing and polishing.

The abrasive coating has coarse and ultra-fine grains. To sharpen the blade, it will take from 1 to 10 minutes; for polishing, 10 seconds is enough.

Attention! Sharpen only dry, clean, not heavily damaged knives.

Advantages

- suitable for knives with straight and serrated blades;

- anti-slip base;

- high quality plastic case with soft coating;

- compact size and weight only 1.2 kg.

Flaws

- not suitable for sharpening Asian, ceramic knives and scissors;

- high price;

- low power 28 W.

Apex similar sharpening systems

The APEX EDGE PRO sharpening system was developed in the 90s of the last century, and gave rise to a whole class of sharpening devices. It is one of the best samples for professional and amateur knife sharpening.

It is a plastic frame with a pressure table, on which you can use a pressure screw and a stop to adjust the position of the knife for sharpening. In the original system, the knife must be held by hand; numerous replicas began to use powerful neodymium magnets, which makes the sharpening process more comfortable.

There is a rotating unit on the rod, to which an abrasive holder is attached. The sharpening angle varies over a wide range with high accuracy, using a protractor or an application on a smartphone. The kit usually uses high-quality abrasive stones from Boride. A set that allows you to form a cutting line from scratch and polish the leads to a mirror finish.

The only drawback of the system is the rather high cost. Which, in fact, first gave rise to numerous Chinese counterfeits, and then to a whole range of sharpening systems of varying costs and quality levels.

DMT/Lansky sharpening systems

Diamond Machining Technology is a lightweight, mobile and highly efficient version of the sharpening system. It consists of a plastic, screw-adjustable knife clamp, with holes made in the symmetrical protrusions to accommodate the abrasive stone holder at a fixed angle. You can set the following angles: 16, 20, 24, 28, 32, 36, 40. The sharpening system is equipped with diamond sharpening stones, which ensures high efficiency and speed of sharpening knives made from the hardest steels. The grit of diamond stones is 120, 220, 325, 600, 1200, 8000 units, which allows for a full cycle of sharpening work, from shaping the cutting edge and removing chips to polishing it.

The advantages include low weight, so this sharpener can be easily used on the go. Small in size, it will not take up much space in your backpack. Large selection of diamond stones. Ability to sharpen knives with a spine thickness of up to 8.0 mm. The disadvantages include the fact that sharpening is carried out by hand, which affects the quality. In addition, diamond stones work quickly but roughly. Sharpening with ceramic abrasives provides a more durable result.

Lansky is a sharpening system very similar in design to the DMT. Only the knife clamp is made of aluminum. Lansky is characterized by a huge variety of delivery options, from sets with 1-2 stones to a rich set of abrasives, including those designed for sharpening serrated blades. Moreover, there are both diamond and ceramic stones. On the sharpening system, you can set 4 angles - 17, 20, 25 and 30, which, in principle, is enough for most cases.

Making a machine for sharpening knives with your own hands

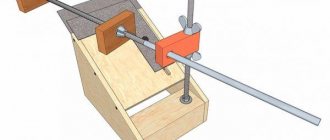

Although nowadays you can easily buy the necessary tools and equipment designed for sharpening knives and other cutting tools, nevertheless, handicraft citizens continue to make knifes with their own hands in their free time. When making a knife sharpener with your own hands, you need to decide on its type (manual or electric) and the type of abrasive materials used (block, wheel, sanding belt), as well as the available materials that will be used to make the body of the assembled device and its frame. Let's consider the option of a manual sharpener using an abrasive stone and plywood as a structure frame. The appearance of the assembled device is shown in the following figure.

Manual sharpening machine made from scrap materials

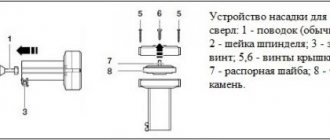

To make such a machine you will need the following materials and tools:

- sheet plywood 10–12 mm thick or chipboard, can be from old cabinet furniture;

- metal pin with a diameter of 10–12 mm;

- sheet steel 1 mm thick;

- fastening screws or nuts with washer corresponding to the diameter of the stud used;

- a block 25–30 mm thick - for making stops for the abrasive stone;

- profile metal pipe with a cross-section corresponding to the dimensions of the bar;

- abrasive block;

- hacksaw for metal and wood or their electric analogues (jigsaw, grinder);

- electric drill or screwdriver.

Manufacturing work is carried out as follows.

| Illustration | Description of action |

| Making the machine base and tool rests | |

| The base of the machine is made from plywood or chipboard. | |

| Holes are drilled in the base for attaching the adjusting pin. | |

| Hand rests are made from sheet steel. | |

| The adjustment pin and hand rests are installed on the base of the machine. | |

| Manufacturing of fixing and tilt angle controlling devices. | |

| A fixing device is being manufactured. | |

| The fixing device is installed on the prepared base. | |

| A device that regulates the angle of inclination is manufactured and installed. | |

| Manufacturing of the carriage and base for replacement bars. | |

| A carriage for abrasive bars is made from another metal pin and wooden blocks. | |

| The base for placing the bars is cut out of a profile metal pipe, and the final assembly of the machine is performed. | |

The market for goods intended for sharpening knives and other cutting tools offers a wide selection of models that differ in design and purpose, type of use and equipment, which allows you to select a device in accordance with the selection criteria and financial capabilities of the user. When choosing a specific device or model of sharpening equipment, assistance will be provided by sales consultants in trade organizations, and how to use it correctly can be found on the Internet.

You can learn how to properly sharpen knives with a whetstone by watching the video below.