Even for an expensive knife, the warranty for factory sharpening rarely exceeds a year, so the issue of restoring the sharpness of the blade always remains relevant. Not every knife sharpening device can properly straighten the blade of a tableware, travel or kitchen utensil. Let's figure out what auxiliary devices exist, how to choose the right tool and how to make it yourself.

Even the highest quality tools need sharpening Source remontkit.ru

Sharpening theory: profile and type

The blade profile (geometry) refers to the contour formed by sharpening. The profile outlines the part of the blade that will be in contact with the material while using the knife. Different tools have different blades and their own characteristic profile.

Its shape is related to the properties of the material used and the purpose of the tool. Using blade processing, the following types of profiles are formed:

- A simple blunt wedge. The blade is durable, but rough. It creates significant cutting resistance, and cutting rather viscous materials leaves a ragged mark.

- Sharp wedge. It is poorly suited for cutting, quickly becomes dull, and may chip. When cutting tough or fibrous materials, the result may be worse than with a dull blade due to high friction and cutting resistance.

- Ogival (bullet-shaped). The slopes (the sides of the cut line) have a characteristic convex shape. Such a blade is expensive and difficult to make even in production conditions. Tools with a bullet-shaped sharpening are made for special equipment (for example, medical equipment, when studying the thinnest tissue sections).

Model of a desktop sharpener with the ability to change the sharpening angle Source ytimg.com

- Faceted. Faceted geometry is used for disposable safety razor blades. The cutting part ends with edges (straight segments). Hex sharpening is considered universal. A profile with 3-4 edges is suitable for coarse hair, with eight – for the finest hair.

The most common is traditional double-sided sharpening; its variety is lens sharpening. It has high cutting efficiency and is considered the best choice of blade options. However, it is quite difficult to implement, which increases the cost of finished products, regardless of whether it is a kitchen tool, hunting, folding or tourist. There are knives with other, more specific blade shapes that determine the functionality and ease of use of the tool.

Types of knives and their purpose

Modern classification divides knives into the following categories:

- Combat. They are bladed weapons and are in service with the army as an addition to firearms. They are not intended for free sale and use.

- Tourist. Available for purchase, not prohibited from wearing, the handle and sheath are usually made of synthetic materials.

- Hunting. They have a varied form and purpose of use: work on cutting up hunted game, skinning, arranging a hunting area. Some types require permission to purchase and carry.

- Foldable or collapsible. A very common type, loved by all age categories of people. As the name suggests, the blade folds and the cutting edge fits into the handle. Some types are equipped with clips for attaching to a belt or pocket.

- Multitool A folding multifunctional knife with a set of tools - indispensable for travel and repairs. The standard sample includes: a small and large blade, pliers, screwdrivers, wrenches, a ruler, a hook, and scissors.

- Special purpose. A tool used in certain branches of human activity: medicine (scalpel), diving, Ministry of Emergency Situations, gardening.

- Campers or bivouacs. They are quite large in size and weight. Designed for setting up a tourist camp and clearing the area of the recreation area from bushes and small trees. An example is a machete or kukri. In practice, they easily replace an ax, but at the same time, they remain knives.

- Mark or sports knife for throwing. It is all-metal, without a cutting edge, and is designed to hit a target with a hand throw.

- Kitchen. Used for cooking, they come in a variety of shapes, sizes, thicknesses and blade configurations.

- Dining rooms. They have a certain shape with a rounded tip of the blade, the main purpose is to make eating easier.

- For survival. Positioned as assistants in extreme conditions. They have a number of features: the presence of a compass, a hollow handle that can accommodate a survival kit (a lighter, a fishing line with a sinker and a hook, a thread and a needle, an antiseptic, an antibiotic).

Sharpening theory: angle

Each specific blade has its own area of application, even if it is kitchen appliances. During manufacturing, they are sharpened at different angles, which is especially noticeable on new tools (after manual sharpening of knives, the differences often disappear).

Blade parameters affecting its functionality Source klinok.zlatoff.ru

The sharpening angle is a fundamental characteristic. It is always indicated in half, since many products are sharpened on one side (for example, a bayonet). The purpose of the knives can be determined by the following angle parameters:

- 10-15°. Straight razors, medical scalpels, and tools for artistic carving are taken to the sharpest corner. This sharpening makes it easy to cut hairs, but quickly becomes dull when trying to cut unsuitable material.

- 15-20°. This is how food tools, vegetable and pastry (cake) knives are sharpened.

- 20-25°. The angle is typical for bread and fillet knives (although on fillet varieties the angle is often adjusted to 15°).

- 25-30° (sometimes up to 40°). The corner is torn out for a hiking and hunting tool. The edge is sharp enough to cut through wood, open a tin can, or chop a bone.

- 30-35°. Meaning inherent in general purpose household products.

- 35-40°. Sharpening is performed on specialized (carpentry) tools, axes, shoe knives.

Full and half sharpening angle Source 2proraba.com

- 30-50°. This angle is typical for a special-purpose tool, such as a machete. You won’t be able to cut bread evenly with its help, but it can deal with thick undergrowth and vines just fine.

There are blades with different types of sharpening in different parts of the blade. Such a tool becomes more versatile in use, but it is much more difficult to manufacture. The angle of sharpening determines how convenient and useful the knife will be. It becomes clear that the correct device for sharpening knives should allow you to set the required sharpening angle. This is the main difficulty in its manufacture.

How to sharpen a knife in extreme conditions

It happens that you urgently need to sharpen a knife. But there is no sharpening stone at hand. The following tips will help you:

- the blade can be sharpened on the corner of a concrete step in the entrance, you just need to rinse it;

- find a stone on the street that looks more or less smooth;

- The knife can be sharpened on the edge of a ceramic plate or cup from the reverse side.

Here are three useful tips. They really work, of course you can’t achieve razor sharpness using these methods, but they really work.

Optimal one-and-a-half sharpening

Almost all (except special) knives are sharpened with a one-and-a-half profile during the manufacturing process. During operation, such a blade is easy to straighten, and it is suitable for household work with a variety of materials. For blades with one and a half sharpening, it is much easier to make a sharpener, since there are no edges in the profile geometry.

A simple way to restore sharpness to a blade Source ytimg.com

See also: Catalog of companies that specialize in the reconstruction and rebuilding of houses

The straightening and finishing of blades with one-and-a-half sharpening is carried out using a sharpening device and an abrasive. Abrasives vary in material and grain size. The abrasive number indicates the number of grains per square millimeter, that is, the degree of grinding of the metal surface. Processing is performed depending on the purpose of the tool:

- For straightening and finishing kitchen tools, abrasive No. 800-1100 is used.

- If the quality of the cut is important (for example, for a straight razor), pre-treatment with an abrasive is carried out. Then the surface of the blade is polished using a leather whetstone until it is mirror smooth. GOI paste for fine or fine polishing (dark green color) will help you get the desired effect.

- Finishing is usually not used for tourist (hiking) and hunting knives. Firstly, with such a tool it is often necessary not to cut, but to chop or file, and a knife copes with this more easily without finishing. Secondly, a cut on the skin from such a weapon is not smooth, but slightly ragged, which reduces bleeding, speeds up healing and reduces the likelihood of infection.

Compact mechanical sharpener Source ice-people.ru

Sandpaper grit

Each grinding stage has its own grit level, which is measured in micrometers (1000 microns - 1 mm). For roughing:

- P22 - (800 – 1000 µm);

- P24 – (630 – 800 µm);

- P36 – (500 – 630 µm).

Rough woodwork corresponds to:

- P40 – (400 – 500);

- P46 – (315 – 400);

- P60 – (250 – 315).

Primary grinding and smoothing involves:

- P80 – (200 – 250);

- P90 – (160 – 200).

To remove small defects:

- P100 – (125 – 160);

- P120 – (100 – 125).

Durum varieties are prepared using P150 - (80 - 100).

Sand the old paint for painting with P180 – (63 – 80).

Fine-grained options rely on finer work:

- P240 – (50 – 63) – for final sanding of hard wood;

- P280 – (40 – 50) – for sanding between coats;

- P400 – (28 – 40) – for final polishing;

- P600 – (20 – 28) – for wet grinding;

- P1000 – (14 – 20) – for grinding plastic, ceramics, metal;

- Р1200 – (10 – 14) – for fine grinding;

- P1500 – (7 – 10) – for polishing;

- P2000 – (5 – 7), P2500 – (3 – 5) – for removing small scratches and stains.

The sandpaper is suitable for sharpening and grinding.

What to sharpen: grit

The main characteristic of whetstones (brushes) used for sharpening knives is grain size. It is designated differently in different countries; It is more convenient to define grain size as the number of grains per unit area, but the designation in English terminology is also accepted. The classification of stone grain size is as follows:

- Rough (coarse) stone. Sharpening is carried out using sharpening stones No. 300-350. The coarse abrasive helps form the correct angle (geometry). Often used if the cutting edge has visible damage.

- Medium. For it, choose abrasive No. 400-500. The metal surface is ground to the required smoothness.

- Fine. The most common type of material suitable for household use. Restores the sharpness of knives that have become dull during normal use.

- Very fine (extra or ultra fine). Final finishing is carried out if necessary; The connections are polished to a mirror finish.

Sharpening stones with different grain sizes Source top-nozhi.ru

Apex similar sharpening systems

The APEX EDGE PRO sharpening system was developed in the 90s of the last century, and gave rise to a whole class of sharpening devices. It is one of the best samples for professional and amateur knife sharpening.

It is a plastic frame with a pressure table, on which you can use a pressure screw and a stop to adjust the position of the knife for sharpening. In the original system, the knife must be held by hand; numerous replicas began to use powerful neodymium magnets, which makes the sharpening process more comfortable.

There is a rotating unit on the rod, to which an abrasive holder is attached. The sharpening angle varies over a wide range with high accuracy, using a protractor or an application on a smartphone. The kit usually uses high-quality abrasive stones from Boride. A set that allows you to form a cutting line from scratch and polish the leads to a mirror finish.

The only drawback of the system is the rather high cost. Which, in fact, first gave rise to numerous Chinese counterfeits, and then to a whole range of sharpening systems of varying costs and quality levels.

What to sharpen: a variety of materials

Sharpening stones can be divided into materials of natural and artificial origin. Natural stones are slates, quartz, chalcedony and corundum of various types and colors (for example, black Brazilian slate). They wear down faster than their artificial counterparts; the grain size is often uneven and rarely fine. Artificial ones include ceramic and diamond varieties.

The most durable and hard sharpening device for knives is considered to be a diamond whetstone. It is based on metal or plastic, with a thin layer of diamond coating applied on top. The device cannot be called cheap, but it will serve for a very long time, since it practically does not wear down. The diamond stone needs time to grind in and produce excellent results, and can be cleaned under running water.

The market offers technological varieties of material, for example, CBN sharpening stones. They have a continuous working layer made of cubic boron nitride, are characterized by high hardness and resistance to the chemical components of alloys and steels.

Stones with two types of grain size Source ytimg.com

The most convenient type of whetstone is an elongated whetstone, as this makes the sharpening process easier. Ideally, the length of the bar should be greater than the length of the blade. At home, it is enough to have two medium-grained bars (different), and one or two fine-grained ones. The option with double grain has proven itself well; on one side it is coarse, on the other it is finer (for example, grain 125/100).

To improve the quality of sharpening, natural stone is moistened with water (or soaked in it for a short time) before use. Water is absorbed into the structure of the material, and during operation it is released and mixed with particles separated under the pressure of the blade. A mixture of water and abrasive forms a paste that improves sharpening quality.

Water can be replaced with mineral oil. Knives are always sharpened using oil on Arkansas stone, which has different textures. Hard varieties are used for additional grinding and the sharpest sharpening, medium - for sharpening the tool, soft - for quick grinding. After work, Arkansas stone is cleaned with a brush, hot water and soap.

Wetting with water increases work efficiency Source prom.st

Possibility of adjusting the position of the knife

An alternative to a machine with a moving sharpening stone is a device where it is possible to adjust the position of the knife relative to the whetstone. Basically, its design is similar to the machine with an adjustable bar, a little easier to manufacture.

A movable block is mounted on the base plane to secure the rod with the bar. Clamps are also installed on it, one is adjustable, the other is persistent. Using an adjustable clamp, you can adjust the sharpening angle.

The only drawback of this model is the appearance of wear on the bar in one specific place. This drawback can be eliminated by installing a long pin to adjust the edge relative to the surface being processed.

Each option described above has its own advantages and disadvantages. When making your choice in favor of one model or another, you need to focus on the level of skills and the magnitude of the needs for operating the machine.

Sharpening devices, practical at home

The list of sharpening devices used in everyday life includes hand-held devices. A popular option is musat. Professional chefs use it to quickly sharpen (sharpen) a knife that has become slightly dull. Musat looks like a long rod with a round cross-section and a handle. It is convenient for beginners to use, but only if a minor correction is needed. If the blade is completely dull, more radical action will be required.

A mechanical sharpener is designed to improve the blades of kitchen knives; it sets the optimal sharpening angle. The design consists of a plastic case in which the sharpening discs are hidden. The device can be equipped with several holes, and they are used for both sharpening and straightening.

There are models designed for sharpening scissors and bread knives with a saw-tooth edge (serrated). Mechanical devices are easy to use, affordable in price, and the result is achieved without much effort. A significant disadvantage is the low quality; the blade quickly becomes dull and the process has to be repeated.

Musat is a professional editing tool Source stockfood.com

Electric sharpeners (machines) are found in home kitchens much less frequently than their mechanical counterparts. The devices are designed for household and professional use and do not require special skills. They are a universal and effective tool for owners who prefer simplicity and speed of the process (it only takes a couple of minutes).

V-shape sharpeners

To be fair, such devices are used not so much for sharpening as for straightening a knife. That is, to quickly restore working acuity. It is extremely difficult to change the sharpening angle or remove damage to the cutting edge using such devices.

The most famous example of sharpening systems from this group is Triangle from Spiderco. The sharpening system is a plastic base with holes for abrasive stones. Triangle involves sharpening at the two most popular angles of 30 and 40 degrees.

Triangular-shaped abrasive stones are supplied with the sharpening system. Two brown stones, 600 grit. They are labeled as Medium and are intended for primary processing. And two white stones with a grit value of 1000 units. Marked as Fine and intended for finishing the cutting edge.

The sharpening process on Triangle is as follows. Brown stones are installed in the holes at a selected angle, with an acute angle inward. We take the knife at an angle of 90 degrees to the table surface, press it against the inclined abrasive, and with a little effort draw it down, on the left side of the knife, and then on the right. After completing 20-30 passes like this, we turn the stones over with the flat side inward and repeat the procedure. Then we install the white stones with a sharp downward angle and continue the editing process. Again we place the stones with the wide side inward and continue sharpening the knife.

The main advantage of Triangle is its simplicity and efficiency. In just 5-10 minutes, without extra effort and skill development, a knife can be sharpened into a razor. Separately, you can purchase polishing stones that are labeled as ExtraFine, or special diamond stones. Which are characterized by high productivity, and with their help it is quite possible to resharpen the knife to a different angle (30 or 40) and remove chips from the cutting edge. The disadvantage is the high cost of diamond abrasives; it exceeds the cost of the sharpening system itself.

Video description

About the classic homemade sharpener in the following video:

Electric machines operate on mains power; special guides allow you to sharpen the blade in compliance with the sharpening angle, so that the knife remains sharp for a long time. Sharpening is carried out using flexible abrasive belts; some devices are supplemented with abrasive discs with preset sharpening angles. All this allows you to sharpen not only straight blades, but also more complex blades: fillet, curved, with a hook.

Many owners do without expensive tools. When the need arises to sharpen a blade, and specialized tools are not available, emery for sharpening knives or a wooden block is used. Owners of a tabletop (grinding) sharpening machine do not have problems with dull knives. The work can also be done by carpentry grinding machines in which the saw blade can be replaced with a grinding wheel.

The simplest device for a certain angle Source mtdata.ru

Tips for sharpening knives quickly

There are times in life when, finding yourself in nature, you need to sharpen a dull knife, but there is no opportunity to use a sharpening tool. Some tips that can help in this situation:

- For editing, cobblestone is suitable as an abrasive stone. By choosing the right angle and having experience in editing the blade, you can achieve a decent result with it;

- you can use the second knife as a grinder;

- glass and ceramic products (back side of the plate) can act as a sharpening stone;

- A tightened leather belt can be a substitute for musat; you won’t be able to achieve much sharpness, but the blade will polish “excellent.”

Choose good knives and take care of them. In return, they will “thank you” with high-quality and long-term work.

Homemade devices

Since professional sharpening devices cost a lot of money, many owners make such devices on their own. The designs of homemade knife sharpening machines presented on the Internet are divided into several main types.

Common knife sharpener design Source odstroy.ru

A practical solution is those options that provide the ability to set the desired sharpening angle, depending on the type of knife (kitchen, tourist, universal, hunter or survivalist knife).

Popular devices are those in which the knife is fixed motionless, and the abrasive surface (the same sandpaper) is fixed at the required angle. After adjusting the angle, all that remains is to sharpen the blade, periodically removing waste so that it does not spoil the cutting edge.

Some craftsmen copy the design of the factory model, making a sharpener in which the bars are hidden in a body with a hole, while one abrasive sharpens the edge, the other polishes it. Devices are made in which a block is fixedly fixed, and the performer remains to control the vertical movement of the knife, which is quite simple with a certain skill.

Diagram of a simple sharpener Source bassin.ru

How to make a homemade knife sharpener

All homemade knife sharpeners solve the main problem - they allow you to accurately maintain a given angle of inclination of the block to the blade, which is very important for obtaining a good cutting edge. There are very simple devices, and some are a little more complex, but they allow you to work with greater comfort. Choose according to your taste.

Some of the options are from improvised means

A simple device for sharpening knives

Essentially this is a holder for sharpening stones. Everything is elementary: two triangles made of wood, which are connected by pins with wings. A block is clamped between the corners at the required angle. You can set the angle using a protractor, a special program on your smartphone, or using the rules of trigonometry (right triangle).

Knife sharpening device - abrasive holder

When sharpening on such a device, the knife must be kept pointed strictly vertically at all times. It's much easier than holding it at a certain angle.

The same idea has another embodiment: on a reliable basis, make movable holders into which bars are inserted and secured in the desired position. The corporate prototype is pictured below.

Holder for whetstones when sharpening a knife

A homemade device for sharpening knives is made of wooden blocks. It turns out to be light, so that it does not move from its place, it needs to be fixed with something. To avoid holding with your hand, you can use clamps.

Rotating holders allow you to set a given angle, and then fix it with the help of “wings”

Such a device for sharpening knives, of course, makes the work easier, but it is still quite difficult to maintain the angle: you must constantly control the verticality of the blade. Such a habit can be developed over time, but starting is difficult.

Device on wheels

An interesting version of a manual knife sharpener with a fixed block and a wheeled cart on which the knife is mounted. It is made on the basis of sharpeners for knives, chisels and planes. This device also works well with a knife, but you need to get used to sharpening a rounded edge.

Homemade tool for sharpening knives on wheels

In this version, as in manual sharpening, the block is stationary, but the blade of the knife, mounted on a movable trolley, moves. The angle is set by the height of the bar relative to the platform on which the blade is mounted. The peculiarity of this device is that the table must be level. It can be a tabletop made of natural stone, or you can put glass on a regular table.

In the version presented above, the angle changes slightly, which is usually sufficient for sharpening similar types of knives - kitchen knives, for example. If necessary, the design can be improved by adding holders (pictured below).

Improved model

All this is implemented very simply, as it resembles a regular construction set: strips with holes in them, everything is assembled with bolts and screws.

There is also a device to ensure the immobility of the block.

To fix the bar

The advantage of this whole design is that it is easy to unfold the knife while maintaining perpendicularity on the rounded area, and it is also very easy to handle on the other side: you need to turn the cart over. For this purpose, four pairs of wheels were made.

Homemade manual machine for sharpening knives

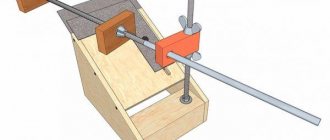

Slightly more complex and much more convenient homemade devices, which are made on the basis of well-known branded devices. They have an adjustable platform on which the knife is fixed. The site is set at a given angle. The block is mounted on a movable rod attached to the stand.

One of the branded knife sharpening devices

Self-made devices in some ways repeat the design presented above, but there are some differences. There are many options. Let's give some.

Option one: a fixed platform on which the blade is fixed

This device is made from leftover laminate (chipboard can be used), two steel rods with a diameter of 8 mm and a movable fastener.

General view of the device for sharpening knives

This design has a fixed base, to which a platform with a knife lock is attached on regular hinges. The near edge of the platform can be raised at some angle convenient for work. But otherwise she is motionless.

On a vertically mounted steel rod there is a movably mounted latch, in which a loop is attached to the side. A rod is inserted into it, on which the block is fixed. This loop is a simple, but not the best solution: there is no rigid fixation, which means the angle will “walk.”

Loop into which the second rod is inserted

Particular attention should be paid to the bar lock. An emphasis is placed on the rod at some distance from the edge (about 30-35 cm). This will be a permanent fixture. The second one is made movable; it is fixed after installing the bar using a screw and a thread cut into the body of the holder. The second option is to cut a thread on the rod and tighten the installed bar using a nut.

Knife holder - one or two steel plates mounted on a movable platform. They are fixed movably using screws and wings. Having loosened the fasteners, insert the knife blade and clamp it. It is very difficult to move it. Then, installing a pin with a fixed bar in the loop, adjust its height so that the required angle is set.

Setting the angle

You can, as in the photo, make templates with the required angles and ensure that the planes match. After the crossbar is secured, you can work - move the bar in the desired direction.

This device for sharpening knives works well, but you can only move the abrasive along the blade when sharpening a kitchen knife. Classic sharpening - movement perpendicular to the cutting edge. This can be achieved on the straight part of the blade. If the blade is short, this will be almost perpendicular, but on a rounded part on a fixed holder this cannot be done. And all such devices “suffer” from this drawback. Once again: they are an excellent option for sharpening kitchen knives (below is another good option from the same series).

Option two: with a movable platform and a magnetic holder

In this version of a homemade device for sharpening knives, the problem of previous sharpenings is solved. Here the frame remains motionless, which sets the angle of movement of the bar. The bar holder moves freely along a guide set at the desired angle. The knife is mounted on a movable table. You can, as in the presented version, make a magnetic holder, or you can make a regular one from a metal plate and “lambs”. Move the table so that the movement of the abrasive is perpendicular. Actually, everything is in the video. One clarification: in this case it is very important that the surface on which the table with the attached knife moves is horizontal and level. You can put glass or use a polymer tabletop (marble will also work).

We recommend:

Briefly about the main thing

Sharpening a knife is a necessary operation, no matter how expensive and high quality it is. When the blade loses its former sharpness, you have to resort to manual or machine sharpening. To restore the functionality of the knife, it is important to know what the sharpening angle should be. Its value depends on the method of using the blade, the shape of the cutting edge, and the material.

For manual sharpening, sharpening stones are used. In order not to spoil the blade, it is important to choose the right characteristics of the bar: grain size and material. An easier way to sharpen a knife is to use a mechanical or electric sharpener.

At home, alternative solutions are often found: they use sandpaper and construction power tools (for example, a grinder). If desired, you can make a simple sharpener with fixation of the knife or sharpening surface.

Making sharpening stones

It will not be difficult for a modern craftsman to make sharpening stones with his own hands. For this you will need:

- a wooden die to the size of the future sharpener;

- epoxy resin;

- cardboard boxes according to the size of the block;

- abrasive;

- protective rubber gloves.

You can use ready-made powder as an abrasive, or you can prepare your own abrasive, for example, from an old Soviet-made green block. Such a block can be ground into powder and used in the future as an abrasive.

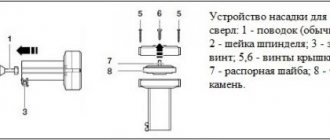

Knife sharpening device

The wooden die needs to be treated on one side with sandpaper and frequent cuts must be made with a saw. Mix epoxy resin with abrasive chips. Having previously placed the block in a cardboard box glued to the size of the block, cover the prepared surface of the wooden block with a mixture of epoxy resin and abrasive. Once the resin has completely cured, the block is ready for use.

Another option for making your own sharpening stones is to create a sharpening stone from small rectangular glass plates about 5 mm thick. Using double-sided adhesive tape, sandpaper is glued to the surface of the glass plate. The sharpening stone is ready for use.

Materials and tools required for the device

To make a simple and quite high-quality device, you need to take care of preparing the following workpieces and tools:

- plywood or small laminated chipboard sheet;

- steel stud with a diameter of 8 mm (the thread on it must be cut along the entire length);

- textolite or ebonite bars (alternatively can be replaced with hard wood - beech, oak, etc.);

- aluminum plate (with a thickness of at least 5 mm);

- fasteners – bolts, nuts (wing);

- neodymium magnet (you can find it on an old computer HDD).