I can confidently state the fact that sharpening knives for a jointer is not an entirely simple matter and many carpenters do not have sufficient skills for this or they do not have special tools. Basically, I faced the same problems until I found some professional advice and instructions on auxiliary equipment on an English-language channel.

High-quality sharpening of planing knives

To work accurately and accurately with cutting tools, it is necessary to monitor their condition and periodically sharpen them. The working tool can be made even sharper by entrusting it to our experienced craftsmen. All of our employees are specialists with many years of experience, and they operate special machines perfectly. Without a doubt, sharpening thicknesser knives and sharpening flat knives of any type is exactly the service that we provide better than all competitors on the market.

| Our craftsmen will not only carry out high-quality sharpening of reismx knives, but will also remove chips, if any, which is especially important for precision tool knives |

Sharpening of knives for planes and surface planers is carried out using professional equipment

We are open 7 days a week from 10:00 to 20:00

Depending on the specifics of the product being manufactured, the sharpening angle of the thicknesser knife may vary. An incorrectly selected sharpening angle can cause the blade to quickly become dull.

Sharpening of thicknesser knives, which our company offers, will allow your equipment to work at an impeccable level, just like right after purchase. Our service specialists use special tools in combination with innovative sharpening techniques. It is impossible to achieve the razor-sharp knife blades that you get after contacting our company on your own at home.

Rules for working with milling machines

Knowledge of the rules for working with a surface planer will improve the quality of lumber processing, relieving the homeowner of any difficulties in operating the tool he has made.

The operating rules are as follows:

- The machine pin is installed in the correct position.

- Depending on the size of the parts being processed, the thicknesser stroke is set, for which the guide bar is fixed.

- The machine is slightly tilted, which opens the cutting part of the pin, the processed lumber is placed inside, after which the tool is pulled towards itself, this allows the cutting head to remove a thin layer of wood.

- Over and over again, forward movements are performed with the head of the thicknesser, removing a layer of wood from the processed lumber, achieving their perfectly flat surface.

A properly assembled thickness planer based on an electric planer will not be inferior to expensive factory equipment in terms of functionality, efficiency and productivity. You just need to find a high-quality plan for manufacturing a surface planer on the Internet and then follow the drawings when assembling an electric machine. The easiest way to make such a tool is on the basis of an electric plane, which is mounted on a plywood base. The simplest thicknesser, made independently, will differ in functionality in use, guaranteeing high-quality wood processing.

Sharpening process and operating rules

The holder moves to the right and left, movements are made relative to the sharpening stone. The blade should not be allowed to go beyond the edge. It is best to immediately install the holder 12 mm from the edge of the working circle. If sharpening is carried out, water cooling must be supplied. You will have to add water to the tank, you need to make sure that it does not run out. It is necessary to ensure that water does not accumulate on the floor near your feet. This is done for security reasons.

When performing work, you must ensure that the stone remains clean at all times, as it gets dirty quite quickly. A special whetstone is used for cleaning; it is recommended to carry out this procedure frequently, since only clean stones can be used for sharpening. The choice of stone itself depends on what kind of knives are used. Today, manufacturers produce jointing knives from soft or hard tool steel, so working conditions will vary.

Sharpening takes approximately 20 minutes, then fine-tuning is done. A special paste is used for this. After polishing, there should be no burrs left on the surface, otherwise the jointing knife will not be ready for use. The test is simple to carry out; a finished knife with excellent sharpening should easily and evenly cut a sheet of paper while hanging, leaving a neat cut.

Benefits of contacting our company:

Our service is located at the station. Taganskaya metro station, on Verkhnyaya Radishchevskaya street, at building 9. If you would like to call us to clarify details, you can do this by phone.

We carry out the following sharpening work:

- Sharpening circular saws. Approximate price 400 rub.

- Sharpening and setting a hacksaw for wood. Approximate price 300 rub.

- Sharpening claw clippers. Approximate price 200 rub.

- Sharpening ice axes. Approximate price 150 rub.

- Sharpening manicure tools. Approximate price 350 rub.

- Knife sharpening. Approximate price 250 rub.

- Sharpening blender blades. Approximate price 250 rub.

- Sharpening lawn mower blades. Approximate price 250 rub.

- Sharpening machine knives. Approximate price 450 rub.

- Sharpening knives for meat grinders. Approximate price 225 rub.

- Sharpening planer knives. Approximate price 300 rub.

- Sharpening scissors for metal. Approximate price 220 rub.

- Sharpening hairdressing scissors. Approximate price 250 rub.

- Sharpening tailor's scissors. Approximate price 200 rub.

- Sharpening planes. Approximate price 220 rub.

- Sharpening garden pruners. Approximate price 200 rub.

- Sharpening axes. Approximate price 250 rub.

- Sharpening cutters. Approximate price 120-200 rubles.

- Sharpening chains for chainsaws. Approximate price 250 rub.

Why should you contact us for sharpening planing knives?

Running unconfirmed advertising and playing on the feelings of our customers is not in the rules of our serious company. Our goal is to serve our customers efficiently and quickly, to sharpen the planer knife so that you return to us as a regular customer. All clients who trust us must be served in such a way that they can use the tools sharpened by us for a long time and receive only positive emotions from it. These are the basic principles of our company. We are constantly working on our reputation.

Contact us for sharpening knives for surface planers and you will receive:

- Professional attitude

- There is a guarantee for every service

- Affordable prices

- Quality service and kind treatment

Don’t hesitate to contact us, everyone who has been served by us once becomes our regular customers. Our prices and service will not leave you indifferent and you will remember our productive cooperation for a long time.

| Our craftsmen know how to properly sharpen a surface planer knife so that you can make the most of its potential. |

The price of sharpening knives on a thickness planer is 250-450 rubles.

Address of the workshop for sharpening thicknesser knives: Moscow, Taganskaya metro station, st. Verkhnyaya Radishchevskaya, 5, building 5. (Call for directions).

Working hours: seven days a week from 10:00 to 21:00

Special machines are used for sharpening knives of planer and jointer types. The work can be done with your own hands; the machine can be assembled independently if necessary. Sharpening is carried out according to certain rules; several options are used. You need to be careful and not violate the technology.

Otherwise, knives for planers, jointers and planers will be poorly processed and will not be able to fully perform their functions. In addition to special equipment, sharpening stones can be used for sharpening, but a small sharpening machine that has cooling is best suited for the job.

Mechanized disc sharpening

- saw blade;

- disc sharpening machine;

- pendulum protractor;

- marker.

How to sharpen a circular saw mechanized? There are a large number of different machines. Some mechanisms have software systems to provide fully automated turning mode. In a home workshop, when turning discs is occasional, you can use a simpler device.

The sharpening angles of the circular saw teeth are: rake angle (γ), back angle (α) and bevel angles of the front and rear planes (ε1 and ε2).

How to sharpen a disc? In such a machine, after it is installed and secured in a position that provides the required sharpening angle, all other operations of turning the blade around its axis and controlling the thickness of the metal removed from the tooth are performed manually.

Sharpening a straight tooth along the front plane is performed in the following sequence. Place the blade on the machine frame. Clamped using a centering sleeve. Then, using a mechanism, it is installed in a strictly horizontal position. Thus, the bevel angle of the front plane is equal to zero. If the machine does not have a built-in angular scale, the horizontalness of the disk is checked using a pendulum inclinometer.

Then the screw of the mechanism is rotated, which ensures horizontal movement of the frame with the circle. Set the required rake sharpening angle. The blade moves in a position in which the front plane of each element fits tightly to the working surface of the circle.

A marker is used to mark the first tooth from which sharpening begins. Then turn on the engine and sharpen the front plane. The machine brings the tooth into contact with the wheel and performs several movements of the blade back and forth while simultaneously pressing the element against the wheel.

READ How to Cut Tiles with a Glass Cutter

After sharpening one element, the blade is removed from contact with the abrasive wheel and rotated by one element. Then the operation is repeated in a similar way. This way the machine works until the element marked with a marker completes a full circle, showing that all elements are sharpened.

Sharpening a beveled tooth differs from sharpening a straight one in that the saw is positioned with an inclination equal to the bevel angle of the front plane. To sharpen an element along the back plane, it is necessary that the machine allows you to install the blade so that the back plane of the element is in the same plane as the surface of the circle.

To sharpen a circular saw on a machine, you do not need to have special skills. Anyone can do this job if they follow all the instructions and rules for working with disc sharpening machines.

Sharpening saw blades

The circular saw is sharpened from the back surface if you work in a position facing the material being processed.

- The front surface, which runs into the material when sawing, remains in the same position.

- The disc can be sharpened directly in the machine. Otherwise, you can remove it from the machine or circular saw.

- In the first option, you must first pull out the plug from the socket to prevent the consequences of starting the machine, which can happen accidentally.

- The disk needs to be wedged, for which you need to place thin pieces of wood on both sides of it and press them against the teeth.

- With a marker, you need to mark the side of the tooth from which you will begin sharpening. This will allow you to avoid mistakes in such important work.

- Care and extreme caution must be exercised.

It is important to remember the number of movements you make when sharpening the first tooth, while using a file or diamond needle file.

You will need the same effort to sharpen all the other teeth.

If you removed the disk from the machine, you need to clamp it in a vice to do the same steps that you read about above.

Next, the disk is returned to the machine, and the unnecessary wood is sawn. It is necessary to check the tooth height if your work was accompanied by loud noise or uneven feed. This can be done by bringing a marker to the cutting edge and turning the disc with your hand in a slow rhythm one turn in the direction opposite to the direction of rotation. Each tooth will receive a mark, and when examining the disc, it will become clear which teeth are higher than others. If there is a significant difference, it is necessary to carefully reduce their height.

Sharpening circular saws

- saw blade;

- file;

- diamond file;

- marker;

- thin wooden blocks;

- vice;

- wiring;

- adjustable wrench.

How to sharpen a circular saw with a disc? The circular saw must be sharpened from the back surface if you work with the blade facing the wood. The front surface, which touches the material when cutting, remains in the same position.

You can turn a disk in a machine. You can pull the canvas out of it. If turning is performed in the device, the plug must be removed from the electrical outlet to prevent the device from being turned on accidentally. You need to wedge the product by placing thin blocks under it on both sides and pressing them against the teeth.

It is necessary to mark with a marker the element from which turning begins. When turning, you must be careful and apply maximum attention. Turning is performed using a file or diamond needle file.

It is necessary to remember the number of movements and efforts applied when turning the first tooth. The same efforts must be made when turning other parts. If the blade has been removed from the machine, you need to clamp it in a vice, then sharpen each tooth in the same way. Then the canvas is installed back into the device.

Check the cut on a sample. If there is noise during operation or the material feed is uneven, you need to check the height of the teeth. To do this, you need to bring a marker to the cutting edge. Then you need to slowly turn the blade by hand 1 turn in the direction opposite to the direction of rotation. A mark will appear on each tooth. Upon inspection, you can find out which elements are higher than others. If the difference turns out to be significant, you need to carefully reduce the height of the elements.

Device and principle of operation

A typical wood planer can successfully replace two pieces of equipment: a mechanical drive jointer and a planer (transverse for short products, or longitudinal for long ones).

Homemade thickness planer

The simplest layout of a thicknessing machine (with one-sided supply of source material) includes the following components:

- Drive motor.

- Transfer. It can be a standard V-belt, toothed, with a variator, as well as with replaceable pulleys (the latter option has minimal values of transmitted power, and therefore is used only in low-power equipment).

- Knife shaft. May have multiple instruments with different configurations. Spiral knives are considered particularly successful because they produce minimal noise during operation.

- the upper direction unit, which, in turn, consists of a pair of rollers - front and rear. The front roller has a corrugated surface: in order to improve traction with wood and prevent a possible change in the direction of movement of the board being processed. The rear roller is always smooth;

- a clamping unit that prevents jamming of chips and possible cracking of the material. Structurally, the clamp can be made in the form of claw grips that penetrate into the wood, or it can also be made in the form of a massive metal element equipped with spring-loaded teeth;

- a lower direction unit, facilitating the feeding of the workpiece into the workspace;

- a table with devices for adjusting the technological gaps between the rollers of the upper and lower clamps;

- the bed on which all other elements of the working circuit of the machine are located.

Sharpening the saw

Let's go over the material on how to sharpen a wood saw or sharpen a circular saw.

How to set disc teeth

Sharpening a circular saw tooth along one and two planes.

If it is necessary for the disc to move more freely, then the teeth are set.

It is necessary to bend all the teeth in turn in different directions to the same distance. The work is done using wiring. Routing is a tool for routing elements. To perform the wiring, you can use an adjustable wrench. When working with soft woods, they are diluted more. Less when working with hard rocks.

To choose the right wiring, you need to test the device when cutting durable wood. The best wiring option would be approximately 0.3-0.5 mm in one direction. The main requirement is to distribute elements no more than the thickness of the fabric on both sides. The layout is carried out before sharpening.

In cases where it is necessary to turn a blade of higher quality, a mechanized turning machine is used.

Safe to use equipment

When performing any homemade woodworking machine, you need to take care of the safety of working on the equipment. If possible, the cutter should be covered with protective devices, and working on a machine where the working cutting element does not have any protection is prohibited. Most home-made planer manufacturing schemes have high-quality protection for the electric planer, which eliminates injuries when working with such equipment.

- When working with homemade tools, you must use safety glasses and work gloves. In particular, the latter will be required when working with coarse, dense workpieces, when beating of a homemade surface planer from an electric planer is observed when processing the material.

- The studs used must not have cracks, defects or damage. If cracks or damage are found, the defective parts of the machine should be replaced.

If you follow the simplest safety measures, working with a thickness planer will not present any difficulty, and the machine itself will last for many years. Using homemade machines, it will be possible to perform high-quality wood processing, saving on the purchase of industrial milling cutters.

Sharpening and setting the saw

The main cutting element of any hand saw. a series of teeth cut on the blade and representing wedge-shaped cutters. Wood, in the manufacture of all kinds of products from it, is sawn along, across and at an angle Θ to its fibers; in this regard, transverse, longitudinal sawing and sawing at an angle to its fibers are distinguished, and in each case they use the appropriate type of saw, which differs from others in shape teeth

A. cross cutting; b. longitudinal sawing; 1. wood; 2. cut; 3. marking line for sawing; Θ. the angle of inclination of the marking to the wood fibers during mixed sawing.

When cross-cutting, cross-cut saws are used, the cutting edges of the teeth of which, when moving in the wood, cut its fibers like a knife and form a cut. Longitudinal sawing differs from cross-cutting in that the direction of movement of the saw is parallel to the grain of the wood. The leading edges of the teeth of rip saws plan wood, like knives in planes, and, going deeper, form a cut. When sawing wood at an angle Θ, universal (mixed) saws with teeth that are an intermediate form of teeth for transverse and longitudinal saws are used to its fibers.

Sharpening process and operating rules

The holder moves to the right and left, movements are made relative to the sharpening stone. The blade should not be allowed to go beyond the edge. It is best to immediately install the holder 12 mm from the edge of the working circle. If sharpening is carried out, water cooling must be supplied. You will have to add water to the tank, you need to make sure that it does not run out. It is necessary to ensure that water does not accumulate on the floor near your feet. This is done for security reasons.

When performing work, you must ensure that the stone remains clean at all times, as it gets dirty quite quickly. A special whetstone is used for cleaning; it is recommended to carry out this procedure frequently, since only clean stones can be used for sharpening. The choice of stone itself depends on what kind of knives are used. Today, manufacturers produce jointing knives from soft or hard tool steel, so working conditions will vary.

Sharpening takes approximately 20 minutes, then fine-tuning is done. A special paste is used for this. After polishing, there should be no burrs left on the surface, otherwise the jointing knife will not be ready for use. The test is simple to carry out; a finished knife with excellent sharpening should easily and evenly cut a sheet of paper while hanging, leaving a neat cut.

How to sharpen jointing knives with your own hands?

Special machines are used for sharpening knives of planer and jointer types. The work can be done with your own hands; the machine can be assembled independently if necessary. Sharpening is carried out according to certain rules; several options are used. You need to be careful and not violate the technology.

Otherwise, knives for planers, jointers and planers will be poorly processed and will not be able to fully perform their functions. In addition to special equipment, sharpening stones can be used for sharpening, but a small sharpening machine that has cooling is best suited for the job.

READ Converting a Cordless Screwdriver to Lithium Batteries

Making a thicknesser with your own hands

On the Internet you can find various designs for homemade jointers, which are distinguished by their functionality and ease of manufacture. Subsequently, you should adhere to the scheme on hand, selecting the appropriate components and correctly assembling the machine, the functionality of which will fully meet the requirements of homeowners.

Necessary materials

There are many options for making homemade planing machines, which will differ in their basis. The easiest way to make such a tool is using an electric planer or jigsaw.

To perform a surface planer you will need the following:

- Electric planer.

- Screwdrivers and keys.

- Ruler and corner.

- Screwdriver.

- Drive sprockets.

- Bicycle chain.

- Wooden beams and slats.

- A sheet of plywood 15 millimeters thick.

- Long threaded screws.

Plywood and timber will be required to make the base of the machine and the manual table, on which the electric planer and other elements responsible for the functionality and safety of using the equipment will subsequently be attached.

It is necessary to use high-quality wood, which is additionally recommended to be treated with impregnations against rotting.

Step-by-step instruction

Making a surface planer is not difficult, so almost anyone can handle this type of equipment.

The following work will need to be done:

- A sheet of plywood 15 millimeters thick is cut into a rectangle with a width of 400 millimeters and a length of 500 millimeters.

- In the middle of the rectangle, a mount-stand is made, to which the electric planer will subsequently be attached. The stand for the surface planer is made from a piece of plywood and is attached to the base with screws from the back side, which will ensure the strength and reliability of the machine made by yourself.

- A platform for an electric planer is being built. An opening is made in the platform, which is identical in size to the shape of an electric planer. The electrical appliance used is attached to the platform with screws and clamps.

- A drive mechanism is mounted on the base of the platform, which is responsible for raising and lowering the platform with the surface planer. Large-threaded screws are attached to the corners of the base. Subsequently, four sprockets are attached to the installed screws.

- Small stands are made from plywood, on which the platform with the upper part of the surface planer is installed. The stands are attached to the platform with screws or similar fasteners. It is necessary to think about the proper placement of the cable from the electric planer, which should be located at a short distance from the working saw of the planer.

- Fix the handle, which is intended to adjust the location of the platform. The easiest way is to fix the handle with a long screw with a large thread or secure it with several screws at once.

- At the final stage of work, an indicator and a measuring bar are installed.

- Using a measuring strip, you can measure the thickness of the processed lumber. It can be made from a small piece of plastic or wooden ruler. The indicator can be made from a pointer or a tin strip.

Preparatory work

Anyone who has a plane or jointer faces the problem of sharpening knives. It is expensive to constantly buy new ones, especially since knives can be easily sharpened with your own hands using special machines or sharpening stones. If the jointer is used frequently, like other woodworking equipment, then it will be inconvenient to constantly send knives to the workshop for sharpening. It is better to assemble the machine yourself. To ensure that the jointer is always in working order, it is recommended to sharpen it at home. The easiest way to do this is with a regular sharpener. You only need to take a sharpener with low speed, its quality should be high. Water cooling must be available.

You can also use a sharpening stone, but it must first be leveled with a special device. Usually it comes complete with a small sharpening machine, so there is no need to additionally look for such devices. After the editing is completed, it is necessary to smooth the stone; a block is used for this. Sharpening a jointer knife without this step will be problematic.

What to do next? You need to set the angle of inclination. A special screw will allow you to correctly secure the blade relative to the position of the sharpening stone. Using this screw, you can subsequently set any angle of inclination of the knife. Next, take the holder that comes with the machine. jointing is installed in it . Experts advise starting sharpening knives with a width of at least 13 mm. The length is not critical; if necessary, the knife holder can be rearranged to any position.

The knife must be securely fastened in the holder, otherwise sharpening will be carried out skewed, and this will worsen the quality of the jointer. How to properly secure a knife in a holder? While holding the blade in the desired position, tighten the clamping screws until they stop. To control the sharpening angle, you must use a marker; it marks the sharpened chamfer of the knife. It is with this simple method that you can easily monitor the quality and progress of work. The sharpening will be correct if the corner of the knife touches the stone. The stone must be rotated manually to determine if further adjustment is necessary.

How to make a sharpening machine for planing knives - step by step

The result was this machine. I like the operation of the unit, now I don’t have to worry about the problem of sharpening knives.

The issue of the power engine was resolved by taking an unnecessary pumping station. The engine used from it perfectly suited the requirements for this machine.

To make the frame of the machine, I used a 20 x 40 profile pipe. It was screwed with self-tapping screws onto a wooden base - this made the structure more rigid, which is a very important point. A guide profile with the same size was welded in the central part. It directs the movement of the carriage.

The sharpening unit is made on a powerful metal base; the metal was previously used with railway linings for rails, which were discovered in the workshop.

After the necessary processing, a guide plate was installed on the base, and an electric motor was attached to it at three points, including one adjustment point. I fixed the guide plate relative to the support plate as movable, using two piston pins from the Moskvich machine. The issue of guide shafts was resolved by taking it from a UAZ gearbox. The whetstone is fed to the knife using a screw with a fine thread. The entire machine moves along guides, where there are sealed ball bearings, 4 support and 4 guides. The design must be extremely accurate, without any minimum play.

The stone of the unit is made in the shape of a plate - thanks to this, sharpening is done according to all the rules provided for such a knife.

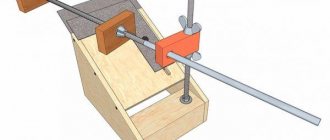

The knife is fixed using a special device with a changeable sharpening angle. An angle of 45–60° is required for planing. To fix the knife on the device, awnings that stood on the furniture set are used.

You can adjust the knife during sharpening using two adjusting screws, taking into account the gap between the knife plate and the sharpening stone. I was pleased with the reliable and inexpensive fasteners.

Having completed the adjustments, you need to turn on the emery and start moving the device along the guides, from one edge of the bed to the other. During the process, you need to gradually tighten the feed screw, but do not overdo it so that the knife does not burn.

The issue with the shaft for moving the carriage was resolved by ordering the appropriate kit from China - the kit was quite suitable. It included a 60 cm shaft, bearings, a self-aligning coupling, and a bushing guide.

As a result, I can work with such a device - a semi-automatic machine for sharpening knives and planing tools.

Here the work consists only of tightening the feed screw.

How to make a machine with your own hands?

To sharpen a jointer knife, you need to use special sharpening machines. This is especially important when jointers, planers and other woodworking equipment are used frequently. The sharpening machine is compact in size and can be installed even in a garage or small shed on a summer cottage. Before starting assembly, you must prepare the appropriate tools that will be used during assembly of the sharpening machine:

- the table on which the work will be carried out;

- faceplate;

- vacuum cleaner;

- engine;

- casing for the machine.

You need to start assembling the machine by finding a suitable faceplate. It is one of the most important parts for a sharpening machine. All jointer knives are quite narrow, so they can only be sharpened using a suitable type of faceplate. Then the sharpening work will be high-quality, safe, and fast. The faceplate takes up the bulk of the cost of all equipment. Making a sharpening machine yourself is more profitable; you don’t need expensive parts for it. Manufacturing will be quite justified if you have to frequently carry out woodworking.

You need to buy new faceplates; it is recommended to take American or German-made elements. They have the highest quality, and the cost fluctuates around 25,000 rubles. Next, you need to choose a motor for the future sharpening machine, it is best to take a 1-1.5 kW motor, you can even use a used element. Motors from old washing machines are excellent for the machine, but first you need to make sure the engine is working.

The motor is mounted under the tabletop, the faceplate is mounted to the moving part.

It is imperative to provide a button to turn the machine on/off. It should be located within reach of your hand. The faceplate is covered on top with a casing, which is made in the form of a square. One corner of the casing must be cut off, since from this side the jointing knives will be sharpened with your own hands. A hole is made in the lower part of the tabletop; it will be intended for a vacuum cleaner pipe, with the help of which all contaminants that arise during sharpening will be removed. In addition to sharpening jointing knives, a similar machine can be used for other work, for example, for processing ax blades, saws and other tools used in the garden.

Sharpening jointing knives can be done using various methods. Special sharpening stones are suitable for this. However, you can assemble a compact sharpening machine yourself. It will be used to sharpen a variety of tools including saws and axes.

Features of working with an automatic machine

- the wet method is more suitable for sharpening planing knives, because the blade is constantly cooled;

- at the preparation stage, you already need to set all the parameters, including the angle of inclination and the distance of movement of the carriage;

- the most important factor is the installation of knives on the carriage;

- the process should be carried out quite smoothly, without sudden twitching

Homemade thickness planer in your own workshop: choosing parameters

There is a significant number of different models of the equipment in question on the market, both from domestic manufacturers (Corvette, Enkor, Krasny Metalist, etc.) and imported ones. The latter options are dominated by dubious Chinese brands, which are not reliable in operation, and, in addition, often have underestimated parameters compared to the passport ones. In such cases, and also if the proposed machines do not fit into the available space dimensions, it makes sense to make a surface planer with your own hands.

It’s worth noting right away that it’s better to purchase a number of components and parts rather than try to make them yourself. This, first of all, concerns the knife shaft itself along with the mounting bearings: home-made options will not differ in the required mating accuracy, as a result of which the part will overheat greatly under load.

When choosing a machine diagram, they are guided by the available drawings (can be found on the Internet), but before that it is worth clarifying a number of elements of the device. For example, if in one unit there is a need to combine a jointer and a surface planer, then it is advisable to make equipment with a double-sided drive. Then, on one side of the device, it is possible to carry out preliminary cutting of the workpiece, and on the other hand, to carry out the final processing of the wood “to size”.

You also need to decide on the longest length of the knife shaft: a homemade machine with a shaft longer than 500 mm may lose rigidity when working on hard types of wood: pear, hornbeam, oak. As a result, wavy ridges up to 1 mm high may appear on the surface of the board, which will require further processing of the semi-finished product. The landing dimensions and diameter must be made such that home-made equipment can be used to produce plinth, baguette profiles, as well as other decorative elements made of wood.

When choosing a design, safety measures for subsequent operation of the unit should be fully taken into account. Homemade thicknessing machine Do-it-yourself machines must have a reliable fence for the working area of the table, and also eliminate the possibility of the board going backwards if the gap is too large, as well as its destruction during processing.

When analyzing the available drawings of home-made devices, it is worth keeping in mind that the presence of two lower clamps in the table will reduce the force of moving the board into the workspace, since the workpiece will move along the smooth surface of the roll, and not along the table.

Sharpening jointer knives

The hand jointer has been actively used in carpentry since ancient times and is now widely used. And since then, special attention has been paid to such an event as sharpening jointer knives. After all, only a well-adjusted tool allows you to obtain a high-quality product.

So, sharpening jointer knives with your own hands begins with removing the knife along with the chipbreaker, which is subsequently unscrewed. After this, the resin and dirt that formed during work are washed off the knife. Gasoline copes well with this task. After cleaning the knife, you can proceed directly to sharpening. Sharpening jointer knives can be done in many ways. Anyone who does this often and has enough experience sharpens a knife by simply holding it with his hands at the desired angle. For those who have less experience, there are a lot of devices, electrified and manual. Since machines for sharpening and straightening blades are expensive, hand tools are most often used. Such products are both factory-made and home-made. An extremely simple device for maintaining the sharpening angle unchanged is shown in the photo below. It is a furniture bolt, about fifteen centimeters long with a semicircular head. This shape of the bolt head reduces friction during sharpening. There are two nuts attached to the bolt threads, one of which is fixed relative to the other. By moving these nuts up or down you can change the sharpening angle within a wide range. In addition to the nuts, the bolt has two wide washers, between which the jointer blade is clamped. The knife is secured using a wing nut. The assembled structure is shown below. The sharpening angle of the jointer knives can be calculated geometrically or measured using a protractor. For planing soft wood, the jointer knives are sharpened at an angle of 25 degrees; for planing hard wood and for soft steel, the jointer knife should be sharpened at an angle of 30 degrees. There are also factory-made devices for sharpening carpentry tools on sale. In addition to jointing knives, such devices can be used to sharpen chisels, turning cutters and other cutting tools. The photo below shows the most common and inexpensive device for sharpening jointer knives with your own hands. With its help, it is easy to adjust the sharpening angle by moving the knife up to increase the angle and down to decrease it. The set sharpening angle of the tool can be determined using the existing ruler, which is folded down in this photo below. The knife is secured with two screws. The scale is graduated for the most common sharpening angles - 25,30,35 degrees. Among the disadvantages of such a device, it can be noted that sharpening often occurs unevenly, due to an unevenly clamped blade. The shaft, thanks to which the device moves, is made of plastic and is not very durable. Sharpening of jointer knives, regardless of the chosen device, is done on sandpaper, which is attached to a piece of tempered glass. By changing the grain of the paper, acceptable sharpness is achieved. Finish sharpening by grinding and polishing the blade chamfer. For sanding, use the finest-grained paper available. Polish the blade on a leather belt, onto which GOI paste is applied. After finishing polishing on the paste, the blade reflects objects like a mirror and has a razor sharpness.

READ How to Sharpen a Hacksaw with a Chain Sharpening Machine

10, total, today

Sharpening knives in specialized workshops

If you are unable to organize the correct sharpening of planing knives or it becomes difficult to set the desired level of inclination, then contacting a workshop will be an excellent solution to the problem. This method has the following advantages.

It couldn't be simpler! A device for quickly sharpening planer and planer knives.

- Expensive and high quality equipment is used. The straightness of the cutting edge will be much better than when processing it yourself.

- Modern cooling systems are used that will prevent the cutting surface from overheating and collapsing.

- Additional materials and special technologies are used to refine the knife, which affects the functionality and service life of such knives.

- In a workshop environment, it is possible to obtain the most even edge due to the absence of overheating and weight differences. In practice, the result should be an ideal instrument.

Advantages of homemade machines

A do-it-yourself jointing machine is distinguished by its versatility of use. The functionality of such equipment will be sufficient for high-quality wood processing. Using homemade machines, you can not only plan lumber, but also finish the boards, giving them the required thickness and a perfectly flat surface.

The advantages of hand-made surface planers include the following:

- Simplicity of the device of a planer for wood.

- Functionality and versatility of use.

- Affordable cost of the components used.

- Possibility of subsequent upgrades.

- Reliability and maintainability of equipment.

To make a homemade surface planer with your own hands, you can use an electric planer, which is used to create a machine that allows for high-quality wood processing, including planing, edge processing and chamfering. It is only necessary to select a high-quality project for the manufacture of a homemade thickness planer, which will be the key to producing reliable and universally-usable equipment.

DIY sharpening machine

If desired, it is possible to assemble the sharpening machine yourself. You will need the following items: table, faceplate, vacuum cleaner, motor and machine cover. The faceplate will become the main and most expensive component. It is advisable to choose American or German manufacturers. Then an engine with a power of 1.5 kW is selected; even supported options are suitable. For example, you can purchase motors from washing machines.

The motor must be installed under the tabletop, and the faceplate must be secured to the moving element. Don't forget to consider the on and off buttons. You need to put a casing on the faceplate, cutting off one side, from which sharpening will be done. You will also need to make a cutout at the bottom of the tabletop for a vacuum cleaner. This machine is also suitable for working with other cutting surfaces.

Classification and capabilities

The design of the units in question can be quite varied. Machines are classified according to the following criteria:

- By drive type. Homemade mini-devices can also have a manual drive, but in most cases they still use an electric drive. At the same time, household models are equipped with a 220 V motor, and professional ones – with a 380 V motor.

- By type of delivery. The machine design may have one or two pairs of feed rollers; accordingly, in the first case, it will be necessary to make the pressure of the workpiece being processed to the table more powerful; vibrations at the time of cutting cannot be excluded. Double-sided roller feeds are more advanced and convenient to use. A number of foreign companies (Makita, DeWalt, etc.) equip their products with automatic feed units, but this option is justified only with significant production programs of the same type of products.

- According to the number of knife shafts. This determines how many different profiles the machine can process simultaneously. True, the number of operators will increase accordingly.

- By functionality. The design of thicknessing machines allows not only dimensional processing of a semi-finished product, but also its subsequent calibration. This eliminates the appearance of transverse chips, dents and other defects that may appear on the treated surface in case of non-compliance with the jointing technology or with an excessively large supply of starting material.

- According to its technological characteristics. In practice, the equipment under consideration is produced with a power range of 1...40 kW, at a shaft speed of up to 10000...12000 min -1, planing width up to 1350 mm, stroke up to 50 m/min and thickness of the initial workpiece 5...160 mm.

In addition, some models differ in the way they adjust the gaps and the design of the main drive bearing assembly.

Kitchen knife made from a circular disk

Greetings to those who love to craft, I offer for consideration a high-quality kitchen knife that any cook will be happy with. The starting material for the knife was a circular saw blade. The blade was hardened, the blade was sharpened so much that the knife easily cuts paper. The manufacturing process is not difficult, but you will have a lot of sanding work to do, so it will be useful to have a belt sander. If the project interests you, I suggest you study it in more detail!

Materials and tools used by the author:

List of materials: - saw blade (better than the old model); - wood for the handle; - brass, textolite or G10 for the bolster; - brass rod for the pin; - epoxy glue; - acid for etching; - heat-resistant cement.

Step one. Cutting out the main profile First you need to select high-quality source material. The author used a saw blade for such purposes. Before making a knife, it is important to check the steel for hardening, since in modern disks the steel may be bad and the knife will turn out unsuccessful. Well, then we draw the desired profile of the knife on the disk with a marker and cut it out. For cutting, the author used an ordinary grinder.

The easiest way to sharpen the knives of a jointer or planer. How to sharpen jointer knives.

Step three. Bevels We begin to form bevels on the knife, but for this we first make markings. It is important for us to draw a line along the blade, which, after grinding, will become the blade itself. This can be done with a special device, or using a drill of the same diameter as the thickness of the workpiece. And so that the fishing line is clearly visible, we paint over the metal with a marker.

Next, you can start sanding, in this case we will need a belt sander. The author holds the workpiece with his hands, and to prevent the steel from overheating, we wet the blade in water from time to time. When working, make sure that the bevels are symmetrical. The blade after work must have a thickness of at least 2 mm, otherwise the steel will burn out during hardening.

Step four. Heat treatment Let's start hardening, the author decided to use a hamon line on the blade, with it the blade looks unique. To obtain such a mowing line, we need heat-resistant cement; we coat the upper part of the knife with it. Where this coating is, there the steel will then differ in color.

That's all, now heat the blade until it glows red and lower it into the oil. To avoid unpleasant surprises such as cracks and deformations, the oil must first be heated. After hardening, we check the blade with a file; there should be no scratches.

After hardening, we must temper the steel to give it spring properties. As a result, the blade will be able to withstand high bending loads; it will also break if thrown onto concrete. We release the blade in the oven, the temperature should be around 200°C. As for the time, this is usually about 2 hours; you need to ensure that the blade is covered with a straw-colored coating, this will indicate the tempering of the steel.

Step five. Pickling To obtain the hamon mowing line, we need to pickle the steel. To begin, sand the blade very carefully until it shines. The steel must also be well degreased, otherwise the reagent will not react with the steel. We lower the blade into the acid for a while and watch the process, waiting for the desired result.

After etching, treat the blade with soda or another reagent to neutralize the acid. Then the knife is washed under running water and now we have a wonderful blade ready.

Step six. Blank for a handle To make a handle, we will need a block of beautiful wood, as well as G10 material or sheet brass, if desired, to make a bolster. First, we make a bolster, cut off a piece of the required size and make a slotted hole for the shank of the knife. If you don’t have a router, you can use a drill and flat files.

Also, a slotted hole must be drilled in the block, from which the handle will then be made. You can drill a series of holes and then combine them. That's all, now we glue all these parts onto the shank of the knife. We use epoxy resin as glue. The steel must be well degreased for high-quality gluing. We clamp the whole thing with a clamp and leave it to dry.

Step seven. Forming a handle When the glue is completely dry, you can now set the desired profile for the handle. We cut off the excess on a band cutting machine or with a hand jigsaw. Next, we refine the handle with wood files and sandpaper. The wood must be brought to a perfectly smooth state, so the handle will be pleasant to the touch, and you will also get an expressive wood pattern.

When the handle is ready, saturate it with wood oil or wax. This impregnation will perfectly protect the wood from moisture, which is important for a kitchen knife. Oil also emphasizes the natural beauty of wood.

Step eight. Completion That's all, the knife is ready, all that remains is to sharpen . For such purposes, it is very convenient to use sharpening stones or a manual machine based on sharpening stones. The author sharpened the knife to the point of a blade; it easily cuts paper. Of course, such a knife will cut greens and other products perfectly.

In general, if the knife is not left to sour in the sink, it will last quite a long time. At this point the project can be considered successfully completed, I hope you liked it. Good luck and creative inspiration if you decide to do this again. Don't forget to share your ideas and crafts with us!

Sources:

https://kakpravilno-sdelat.ru/kak-pravilno-tochit/kak-pravilno-razvesti-i-natochit-disk-cirkuljarki.html https://moiinstrumenty.ru/rasxodnyj/zatochka-fugovalnyx-nozhei-svoimi-rukami .html https://elton-zoloto.ru/raznoe/kak-tochit-nozhi-na-fuganke.html https://usamodelkina.ru/14469-kuhonnyj-nozh-iz-diska-ot-cirkuljarki.html