Chrome plating is the application of a thin layer of chromium to a metal or plastic surface in order to give it a more attractive appearance, enhance the strength of the metal and increase its resistance to corrosion. However, with use, physical wear of the chrome coating occurs, which is why it loses its aesthetics, so many people think about how to remove chrome from plastic at home. Today, there are several main ways to do this, each of which involves the use of certain equipment, special solutions or other available means. Regardless of which method of removing chrome plating you choose, you must follow certain rules and precautions.

Removing chrome plating using specialized equipment

If you are looking for an answer to the question of how to remove chrome from plastic, then the easiest and most common way is to use specialized equipment.

In this case, there is no need to use various chemical solutions and come into contact with them, however, you must understand that such equipment is quite expensive. Such equipment includes:

- abrasive unit;

- ultrasonic cleaner.

Using an abrasive unit

An abrasive unit is equipment that uses special powder. Under the influence of high air pressure, this powder gradually erases the chrome coating. Similar installations can be found in specialized stores or at many enterprises whose activities are related to construction.

Depending on the thickness of the layer, a powder with a certain grain size is selected. When working with the installation, it is recommended to use face and respiratory protection, since small particles of chromium that enter the air are dangerous to human health.

Possible defects

Chrome plating is a thin layer of chromium that appears on a metal surface during a galvanic procedure. Chrome plating can also be applied to plastic. But since the base is a dielectric, an adhesive layer of a conductive substance is first applied to the plastic element.

In the case of plastic, chrome plating can significantly increase the resistance of the element to physical influences. For metal, chrome plating serves as a kind of protection against corrosion. In this case, the chrome coating itself can be destroyed under the influence of various factors.

Chrome can receive the following types of damage:

- Scratches and abrasions.

- Microcracks.

- Cloudiness.

- Loss of original shine.

- Color change (yellowing)

- The appearance of a white coating.

- Occurrence of corrosion areas.

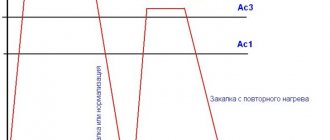

At home, using products for cleaning chrome car parts, it is impossible to eliminate the following damage: peeling of chrome from the substrate, loss of the chrome film in recessed areas. If such a defect appears while the car is under warranty, then you need to contact the dealer to have it fixed, since this damage is a manufacturing defect. To eliminate such a defect, you need to completely remove the old coating and re-chrome the element.

Use of chemicals

If you are interested in how to remove chrome from plastic very quickly, then in this case you should resort to the help of special chemical solutions.

They are very powerful and effective and are capable of removing even the thickest and highest quality layer of chrome plating. However, when working with such products, you must be extremely careful and follow all safety precautions, since they are very toxic. Chemicals include:

- hydrochloric acid;

- sulfuric acid

- sodium hydroxide.

How to remove chrome from plastic using hydrochloric acid? You will need to make a 40 percent acid solution. To do this, dilute hydrochloric acid in water in a ratio of 1 to 3. Ready-made solutions are also available for sale, the instructions for which tell you how to remove chrome from plastic. "Mole" is one of such means.

The chrome-plated part is placed in a solution of hydrochloric acid until the chrome coating is completely removed, after which it is thoroughly washed under running water and soap and sent for drying.

The principle of using sulfuric acid to remove chrome plating is completely identical to that with hydrochloric acid.

“How to remove (remove) chromium from plastic using sodium hydroxide?” - you ask. In the same way as described above. However, there is one important nuance here. When working with this substance, contact with water and aluminum should be avoided, since when it reacts with them, sodium hydroxide releases toxic and flammable gas.

To prepare the solution, you will need a plastic container in which you need to mix 8 to 12 ounces of sodium hydroxide and add 3.8 liters of water. Next, the chrome plated part is placed in the solution until the spraying is completely behind. It’s worth noting right away that this can take quite a long period of time. After completing the removal process, the part is also washed thoroughly in clean water and soap.

Removing chromium from metal

Chrome parts are in demand among car enthusiasts - they make the car shine and make it stand out in traffic. Chrome is an expensive material that corrodes, like other modern metals. It is characterized by consistent tarnishing and brittleness, and chrome parts must be carefully maintained.

Expensive cleaning products are not financially accessible to everyone, and cheap, low-quality analogues contain aggressive chemicals that accelerate the destruction of the material. This article will discuss the process of answering the question “how to remove rust from a chrome part” using available tools.

Causes and signs of corrosion

The problem of destruction of chrome, along with paintwork, is an eternal problem for car owners. The appearance of rust is irreversible, but the period of its formation depends on the care of the car. The main reasons for the rapid formation of corrosion:

- Harsh road conditions (dirt, temperature changes);

- Mechanical damage to the coating (scratches and cracks from gravel or poor parking);

- Inappropriate care (washing with strong substances, using rough materials), which creates microcracks.

Due to the presence of these factors, the material deteriorates faster, which contributes to the accelerated appearance of plaque and rust.

A chrome surface has a number of characteristics that clearly indicate a loss of the original qualities of the material:

- Fading of color;

- Multi-colored stains;

- Strong sticking of dirt, unusual for the material.

Even a well-polished and varnished part after six months loses its external shine and stands out as an element of dull color against the background of the bright color of the car.

If one of the described signs is found, there is a high probability that rust has formed behind the dirt and grease, especially in hard-to-reach places. To remove it, you will need to carry out a series of measures to clean the surface of foreign substances, and then restore the lost qualities.

Preparing to remove rust from a chrome part

The task is complicated by the fact that chrome is a thin material, and a local area of rust has a destructive effect on the rest of the surface of the part. Moreover, the scale of the spread of rust is difficult to assess without cleaning it from dirt and grease, behind the layers of which it may be hidden. To begin removing rust, you must follow several rules that relate to the properties of chromium:

- Sudden changes in temperature are prohibited, because it promotes accelerated destruction of the material;

- Do not use salt-containing products;

- The use of cleaning cloths with a rough surface is strictly prohibited.

How to clean chrome car parts - various ways to restore the appearance at home

Chrome parts appeared with the first cars and are used today. They give the car sophistication and beauty, but, unfortunately, they cannot resist time and the aggressive external environment. It is sometimes difficult to restore chrome parts to their former beauty, but it is possible.

1 Plaque - how to restore the original appearance

The first signs of rust are noticeable as a coating on a shiny surface. Before they turn into strong hot spots, you should clean the chrome parts of your car.

Practitioners do not recommend using household chemicals for this purpose, which give a matte and dull appearance. It is better to take ordinary substances that everyone can find at home.

The effect will be no worse than the most expensive cleaners. What to choose is up to you.

A very popular cleaning product is Coca-Cola and foil. They easily cope with rust on chrome. First, clean the part from dust with a soft cloth and wash it with warm water. We take ordinary food foil, crumple it into a ball, moisten it with Coca-Cola and three places with traces of plaque and rust. After processing, polish using felt or a soft cloth.

To use the method, you need foil, not a rag: the method is based on the exchange of electrons between metals and reversing the rusting process.

You can clean it with fine abrasive substances, each separately: soda, crushed chalk or tooth powder, fine salt and lemon juice. We make a paste of water and a fine abrasive (for salt - lemon juice), apply it to a flannel cloth and process the part. To remove residual product and rust, wipe with a damp cloth and wipe dry until shiny.

2 Rust on chrome parts - how to remove

We remove obvious traces of corrosion using methods, the use of which depends on the degree of damage. We remove rust that covers a large area with GOI paste. We apply it to a piece of felt and process the part, then wipe it, removing any remaining paste and rust. The paste has quite strong abrasive properties and should be used carefully.

A good effect from using chemicals prepared at home. We take a small bag of copper sulfate (sold in 200 g packets) and 50 ml of hydrochloric acid, dilute it in 1 liter of water. We put on rubber gloves - we work with acid - and dip a swab into the solution. Wipe off the rust and let it sit for a few minutes. Neutralize the acid with a weak soda solution and wipe dry.

Severe corrosion, when nothing else helps, we remove it with the well-known product WD-40. Spray it on the rust spots and leave it for a while. A minimum of 15 minutes is required, but the best effect is achieved after an hour of exposure. Wipe well with a soft dry cloth.

The listed methods are good if corrosion has not damaged the metal to a great depth. Otherwise, more radical measures will be needed. We use hand tools or power tools. We use metal brushes, sandpaper, hard drill bits and even a grinder to remove heavy rust. Clean until pure metal appears. Remains of rust in the recesses can be removed with anti-rust.

Of course, after such stringent measures, the part must be restored. We use putty if the depth of the damaged area is small, or even welding in case of significant damage, including through ones. Only after giving the part a flat, smooth surface do we proceed to restoring the chrome coating.

3 Polishing - the use of industrial and folk remedies

When the chrome on parts simply fades and loses its shine, it is not difficult to return it to its original appearance. The chrome layer is very thin, so care must be taken when cleaning and polishing.

We choose one of the cleaning products, apply it to a napkin and wipe the chrome surfaces. Wash off the residue with water and wipe dry. When it is noticeable that the chrome has tarnished, cut the lemon, leaving only the skin, which we use to wipe the part. Rinse again with water, dry and rub with a soft cloth until shiny.

Let's start polishing. GOI paste gives a good effect - it not only restores the shiny surface, but also removes minor scratches. Depending on the size of the abrasive, it is produced under different numbers:

- 4 – the roughest, removes oxides, polishes deep scratches;

- 3 – medium, gives the surface a smooth matte finish;

- 1.2 – finishing, returns original quality.

To restore chrome on a car, numbers 3, 2, 1 in that order are enough. For convenient work, use a few drops of oil. The bumper, radiator grille and other external parts, except door handles, are not cleaned of oil after polishing. Its thin layer will create a good protective film, invisible to the eye, and protect against salt on the roads in winter.

You can use special polishes for chrome. We manually polish with a cotton cloth or microfiber with an applied compound, wiping until shiny.

High-quality polishing is carried out using a polishing machine or polishing wheels using an electric drill. We carry it out in two stages. First, we use a felt circle and turn on the tool at medium speed.

For final processing we use a felt or foam rubber circle, the speed is also medium.

It is important not to overheat the parts! We do not linger in one place; we moisten the part with water.

4 Vinyl film - gluing technology

In some cases, restoration of chrome plating is impossible - the damage to the surface is too great. You can restore the original appearance by using vinyl film, or rather, one of its varieties: chrome-plated. Decorating with regular film is easier than with chrome-look film. It has its own characteristics, the process is not so difficult as it requires accuracy.

We remove the part from the car, remove the entire layer of chrome and clean the metal. Next is cleaning: wash thoroughly and degrease with an aqueous solution of white spirit. We apply the film to the part without tearing off the backing. We choose a placement and outline the boundaries, trim off the excess, but with a margin. We definitely invite an assistant - we can’t cope further alone.

Spray the part with soapy water, sparing it. Remove the backing from the film and apply it to the part, fixing it with your fingers in the corners. We heat the film with a hair dryer, while simultaneously running the squeegee from the middle to the edges. We ensure that the film adheres tightly to the part, following its contours.

Use a squeegee to squeeze out air bubbles and soap solution. We trim the film with a margin of 5 mm. For gluing we use special glue Primer 94, follow the instructions for use.

Wipe with a napkin and leave to dry. It takes a week for it to dry completely. It is important at this time to maintain the temperature that was during pasting, without washing.

The film is very thin; further washing should be done carefully with a soft, damp cloth.

5 Imitation chrome – paint application

Truly chrome plating using electroplating at home is very difficult and impractical, and seeking services from specialized workshops is expensive.

The solution could be painting that imitates chrome plating. Even with high-quality paints, light reflection does not exceed 95%; the protective properties are also incomparable with galvanic coating.

But, nevertheless, such a budget option has the right to life.

Which method is not recommended?

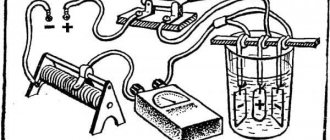

Some experts recommend one piece of advice on how to quickly and efficiently remove chrome. It involves reversing the galvanization process. This method is very effective, but it is not recommended to use it yourself at home, since it is based on the use of electric current, and in the process of removing the binding of chromium elements to the metal, some very dangerous and toxic substances are released. Therefore, if you are looking for a way to remove chrome from plastic, then you should not experiment with this, but rather choose another method described above, or seek help from a qualified specialist.

How to remove chrome from metal

In everyday life, we often encounter the problem of rust on various materials. In this article we will tell you how to remove rust from a chrome surface. There is an opinion that chrome parts are less likely to corrode. But this is not so - chrome becomes covered with red spots no worse than ordinary iron.

What is chrome plating?

Chrome plating is a technology for coating metal surfaces with a thin layer of chromium. The most common method of chrome plating is the galvanic method.

The essence of this process is the deposition of chromium from the electrolyte onto a metal part under the influence of an electric current.

Such actions significantly increase the strength of the material, make it more resistant to corrosion and allow the treated metal to be used for decorative purposes.

As a rule, chrome-plated metal is used in plumbing and mechanical engineering. Unfortunately, the beautiful, shiny chrome surface eventually develops small scratches that reveal the metal underneath the chrome. Under the influence of oxygen, an oxidation reaction occurs, as a result of which rust appears on the surface.

Important! The best way to get rid of rust is to prevent it from occurring.

Recommendations regarding the care of chrome elements of the car

To prevent any damage to the chrome surfaces of your car, you should first of all take care of them:

- When washing a car with chrome elements, it is advisable to use warm soapy water. It is necessary to wipe all chrome parts with a soft cloth or sponge immediately after washing.

- It is better to wipe the chrome-plated bumper with a cloth moistened with warm water to make it soft.

Important! When treated with rough materials, chrome parts become covered with a network of micro-scratches and quickly become dull.

- To reliably protect the bumper from corrosion, after cleaning it with any rust remover, it is necessary to generously lubricate the inside of the lining with “Lithol”.

- For the durability of chrome-plated parts, exposure to strong temperature changes and high humidity should be avoided.

Important! In summer, after washing, it is better to place the car in the shade. In winter, it is recommended to use special protective sprays.

- The water pressure during cleaning should be low. This will allow you to gently clean delicate surfaces.

Important! It is not recommended to leave the garage with traces of moisture on chrome parts. Wipe them dry before riding or wait until the drops dry naturally.

- From time to time, you can wipe the chrome parts with kerosene, then rinse it off with warm water. It is necessary to ensure that kerosene, gasoline or white spirit never remains on the surface of the parts. Kerosene is also used to degrease chrome before polishing.

Important! Keep baking soda and mineral oil away from chrome surfaces.

- To protect chrome parts, you can use a special varnish or technical Vaseline. These substances provide good corrosion protection, but may slightly degrade the appearance of chrome.

Important! This protection must be updated once every 2-3 months.

- To remove traces of stains and grease, use cleaners.

- For effective and high-quality protection, it is better to use products specifically designed for this purpose.

How to remove rust from a chrome surface at home?

If stains of corrosion do appear, the first step is to localize the source of its spread, clean and remove the rusted area. After this, coat the surface with oil varnish. To remove rust from a chrome surface, you can do without special expensive cleaners. You can find the substances necessary for this at home.

Baking soda

It is necessary to use this product with great care, as soda can cause small scratches. But if you apply it correctly, you will be able to remove rust from a chrome surface without damaging it. For this:

- Mix baking soda with water to form a paste.

- Apply the mixture to the damaged surface and leave for a few minutes.

- Remove baking soda and dirt with a damp soft cloth.

Important! Make sure the baking soda doesn't dry out. Do not leave the paste on the surface for a long time.

Ground chalk or tooth powder:

- A similar fine abrasive substance is applied to a flannel cloth and the surface is treated.

- After cleaning the rust stains, remove any remaining powder and rust with a damp soft cloth.

Coca-Cola + foil

For this method of removing corrosion, you can use not only Coca-Cola. Pepsi and other similar drinks can easily cope with rust on chrome surfaces:

- Wipe all chrome surfaces with a soft cloth to remove dust and dirt.

- Wash the parts with warm water.

- Take regular food foil, moisten it with Coca-Cola and sand the chrome parts, removing rust stains.

- It is advisable to polish the surface with felt or a soft cloth after treatment.

Important! The aluminum foil method works by transferring electrons between metals, reversing the corrosion process. This method must first be tested on a small, inconspicuous area to make sure that such an action will not damage the surface.

Table vinegar:

- Fill a plastic bag with vinegar.

- Secure the bag over the pieces with a rubber band and leave for several hours or overnight. Small parts can be thrown inside the bag.

Important! The amount of time the vinegar remains on the surface is determined by the degree of rust damage.

Salt and lemon juice:

- Mix lemon juice and salt in equal proportions.

- Use a soft cloth soaked in the mixture to treat the damaged surface.

GOI paste + motor oil:

- Dilute GOI paste with two drops of motor oil.

- Using a piece of felt soaked in the resulting product, treat the rusty surface.

- Carefully remove any remaining rye and product using a clean, damp cloth.

Important! This method must be used carefully, since the paste is usually coarse-grained.

But this particular product gives excellent results, even if you need to remove rust from a chrome surface with a large area of damage.

Potatoes and laundry soap:

- Cut the potatoes into two parts.

- Rub each part in the cut area thoroughly with laundry soap.

- Place the potatoes on the rusty spots for several hours.

- Remove any remaining corrosion after a while with a damp soft cloth.

Copper sulfate and hydrochloric acid:

- Mix 200 grams of copper sulfate and 50 grams of strong hydrochloric acid in 1 liter of water.

- Dip a swab into the resulting solution and blot all rust stains with it.

- Afterwards, you need to wipe everything with a weak solution of baking soda, rinse with warm water and dry.

Important! Be sure to carry out this entire procedure only with rubber gloves.

Be careful not to get the solution on your skin or clothing.

Dry cement

Using such a fine abrasive will help not only remove rust from the chrome surface, but also polish it:

- Apply dry cement using a soft cloth or felt to the damaged areas of chrome metal. Rub them lightly.

- Wipe with a dry cloth and degrease the metal.

- Place the soft cloth in a metal jar with melted medical wax (paraffin).

- When the fabric is soaked, remove it from the jar, wait until it cools and beat off the excess wax.

- Rub the surface with a wax cloth until it shines.

WD-40

In case of severe corrosion, as a last resort, you can use the common product WD-40. It is applied like this:

- Spray generously and leave for at least 15 minutes.

Important! The optimal processing time to obtain the best result is 1 hour.

- After time has passed, wipe the parts well.

The chrome will shine like new.

Removing rust from chrome surfaces of plumbing fixtures and kitchen items

We come across chrome surfaces all the time in our daily lives. Initially, they delight us with their brilliance and radiance in the bathroom and kitchen.

Soap scum, mold on plumbing fixtures, dust and dirt in any form play a big role in the loss of the beautiful appearance of such elements.

Regular cleaning and maintenance of chrome components is essential to maintaining a clean, shiny appearance. To do this, you can use the following tools:

- Multifunctional cleaning products, as well as glass washing liquids (“Mr. Muscle”, “Help”, “Clin” and others). Clean chrome with a soft cloth.

- Baking soda and carbonated water are natural alternatives to commercial detergents.

- Traces of soap scum from chrome parts of plumbing fixtures can be removed using antistatic wipes or cooking spray.

- To remove soap scum, you can mix baking soda with water, apply it to the surface and leave for a few minutes. After this, wipe the surface with a soft damp cloth.

Helpful tips for removing rust from chrome surfaces:

- If rust has eaten through the chrome coating, mechanical treatment is necessary. The grit level of the sanding materials is determined by how deeply the parts are damaged by corrosion. In some cases, fine sandpaper is sufficient, in others, coarser grains are needed.

Important! Carefully select the material with which you will apply the cleanser.

Sandpaper of any grit is absolutely not suitable for these purposes, as it can cause scratches.

Remember that each new scratch is an additional access of oxygen to the metal, it intensifies the rusting process.

- If mechanical friction removes a significant amount of metal, it is necessary to protect it by applying primer to weld seams and other areas.

- The use of acids is possible only if they are immediately removed from the surface of the parts after processing.

- Polish can be used if the damage is shallow. The presence of acid or anhydrous ammonia in the composition of polishes is not allowed.

- To remove rust from chrome surfaces without damaging them, you can use steel wool. For particularly stubborn rust, metal wool can be combined with other cleaning products.

- You can apply a protective layer of chrome polish, rust spray or deep penetrating lubricant like Prolong, NANOPROTECH, Nordtech, etc. Although these products are quite expensive, they are cost effective in the long run because they The wear of surfaces will be significantly reduced, which will save you from expensive rust removal procedures.

- It is best to restore chrome parts damaged by corrosion using specialized compounds that can be purchased at automotive stores.

Removing a thin layer of chrome using improvised means

Before we talk about how to remove chrome from plastic using improvised means, it is immediately worth noting that the methods discussed below will only help in the case of a very thin layer of chrome plating, and in many cases they will be extremely ineffective. Most of these methods are based on the personal experiments of some innovators, so they may not be useful in your particular case. In most cases, they will help in removing fake chrome from plastic parts.

How to remove saffron milk caps using professional means

There are a relatively small number of professional products used to remove rust stains on chrome parts.

These include the following substances:

- WD-40. This product can be purchased at a cost of up to 200 rubles per 100 ml.

- Doctor Wax. This substance is sold at prices ranging from 300 to 500 rubles per 300 ml.

- Metal Polish. The polish is sold at a cost of about 350 rubles per 75 ml.

Each of the above products has its own unique formula. Each component in their composition is responsible for a specific function - polishing, cleaning, restoration of appearance and protection.

It is worth noting that the products from the list can be used in different cases, regardless of what type of coating - aluminum, chrome, steel, etc.

It is necessary to use polishes according to the following algorithm of actions:

- Initially, you need to wipe the surface from dirt with a dry, clean cloth.

- A small amount of the product should be applied to the metal and rubbed with a soft cloth.

- Using circular movements, distribute the composition over the surface, thus cleaning and polishing it.

- Next, the excess product must be wiped off with a new, dry and clean cloth.

- In the end, all that remains is to polish the surface with a clean cloth without the listed products.

Doctor Wax metal polish

To use polishes effectively, you must follow the instructions for use indicated on the labels and bottles.

Removing chrome using improvised means

How can you remove chrome from plastic at home? An excellent option would be to use an abrasive. It can be made from ordinary baking soda or cleaning powder, which must be diluted a little with water to a paste-like state and then rubbed into the chrome coating until it begins to peel off. This method will only work if you are dealing with a very thin coating. When doing this, you should be very careful not to damage the base material.

Another chrome stripper that everyone probably has in their home is an aerosol stove cleaner. It has excellent degreasing properties, so it can help quickly remove light chrome plating from plastic. Such products are applied to the part for ten minutes, after which they are simply wiped off with a rag along with the coating itself. It is worth noting that some cleaners can have a negative effect on the base material, so it is recommended to remove chromium using them in several stages at short intervals. When working with household chemicals, be very careful and do not allow it to come into contact with your skin, eyes or respiratory tract.

How to remove chrome from plastic at home?

Hi all. Many of you have had to deal with such a nuisance... Chrome parts gradually lose their former luster over time and constant contact with the environment and, instead of emphasizing some features of the car, on the contrary, they make the appearance wretched or give away its age.

Given this feature, car owners quite often try to get rid of chrome by hiding it under film or paint in every possible way. However, in practice everything is not so simple. The film is short-lived and over time the chrome still breaks through from under the film, and the paint does not adhere well and, as a rule, peels off after several days, weeks or months.

Why isn’t it removed before covering it with a layer of paint or film, you ask? The fact is that chromium applied by galvanic chromium plating is very difficult to remove mechanically. And it’s bad, that’s not the right word, it can’t be removed at all... Sandpaper won’t take it, and working with a grinder is not always convenient, plus, you can remove the plastic layer along with the chrome, ruining the part.

In general, removing the chrome layer mechanically is another test...

How to be? In fact, there is a way out, and it’s quite simple and quick, it’s only important to know how, and to follow the safety rules. In this article I will tell you how and how to remove chrome from plastic quickly and efficiently, without making almost any effort.

First, a few words about what it is and how it is done... Chrome elements and parts are chrome plated by applying a galvanic layer, which is a mirror chrome coating. Chromium plating refers to an electrochemical process in which metal particles are applied to plastic.

It happens something like this: three metal layers are applied to the plastic: copper, nickel, and then chromium. The last layer interacts with nickel and lies evenly on the surface, completely covering it.

This type of chrome plating is used to apply chrome to various decorative parts, such as emblems, radiator grilles, moldings and other inserts that emphasize the gloss and status of the car.

How and with what to remove chrome from plastic?

Everything that cannot be removed mechanically can be removed chemically... It is chemistry that allows you to remove chrome without a trace without causing harm to the product. To work, you will need ferric chloride, which will do all the dirty and hard work for us.

What is ferric chloride?

Ferric chloride or ferric chloride (designated FeCl3 ) is an average salt of ferric iron and hydrochloric acid - as it is written on Wikipedia. This chemical composition appears as a soft, crystalline mass of reddish-brown, reaching almost black in color in places. In industry it is mainly used for etching printed circuit boards.

How to prepare a solution for removing chromium from plastic?

Now let’s talk about how to prepare a miracle composition that will help you get rid of chromium once and for all.

To make the magic composition you need to take one part of ferric chloride and mix it in three parts of hot water. During cooking, a reaction releases heat and steam, so you should “boil” it in a heat-resistant container, but not in a metal one.

Also take care to protect your hands and respiratory tract so that God forbid you do not harm yourself!!! Ferric chloride is poured into water in small portions, while the composition is constantly stirred. Stir gently until the mixture becomes homogeneous and there is no sediment in it.

In general, many pros recommend using a purified composition, which has been well settled for 5-7 hours, after which it has been filtered.

How to remove chrome at home?

After you have made the correct solution (it is advisable that its temperature be above 60 C°, this significantly speeds up the process of chromium removal), the parts to be treated are immersed in the composition and left in it for some time. It’s difficult to say which one, it all depends on many factors, such as: chromium layer, temperature of the composition, quality of ferric chloride, etc.

The process can be monitored by periodic checking; it should be checked no earlier than after 2-3 hours. The effect will be as follows: the part will completely get rid of chrome and will look white or black depending on what color of plastic you have. If you are satisfied with the result, you can stop the process at any time.

After carrying out all the work related to removing chrome, I recommend washing the parts using water and detergent. Further processing, be it water-print painting or film, is carried out as usual, without any differences.

In conclusion, I would like to add that all work must be carried out in a well-ventilated area in compliance with all safety regulations using gloves and a respirator.

Careless handling of chemical composition may cause harm to you or your health. If the solution gets on your skin or, God forbid, in your eyes, wash it off with plenty of soap and water.

If irritation or itching occurs, consult a doctor immediately.

How to remove chrome from plastic video

Chrome bleaching

Another effective method is to soak the part to be desprayed in bleach. The part is completely immersed in the solution for approximately 24 hours. The removal process may take longer. It all depends on the thickness of the layer and the quality of the spraying. The advantage of using bleach is that it only affects the chrome plating without causing any harm to the base material. An important nuance: the bleach in which the chrome part was soaked must not be reused, since it will contain chromium, which is toxic to humans.

How to clean plaque on chrome car parts

Currently, there are quite a lot of products that can be used to clean and remove plaque from chrome parts of a car. Moreover, it is important to mention that for this there is no need to run to a car store and spend money. And by the way, not every product for cleaning chrome elements will always cope with this. To some extent it will cope, but the cleaning process may take a long time. Therefore, below we will list the means that are probably in every home. And this:

- Baking soda;

- Medical alcohol;

- Citric acid (especially effective);

- Acetic acid;

- Foil and water;

- Liquid for washing dishes or windows.

There is definitely at least one from the above list in every home. Therefore, there is no need to spend money on cleaning products at the auto store.

Interesting video on cleaning chrome parts

This video shows how, oddly enough, cleaning a chrome surface occurs with water and ordinary foil.

Removing chrome plating using brake fluid

The last method of removing a layer of chrome is perfect for car enthusiasts. Because it is based on the use of brake fluid. The thing is that it has a similar effect on light chrome plating as a solvent on paint, so brake fluid can help remove the chrome coating from a plastic part. However, it is immediately worth noting that this method cannot be called fast, since the process lasts several days.

The chrome part is wiped with brake fluid and left for 10 minutes, after which it is washed under running water. It is not recommended to leave the liquid on the part for a long time, since it can dissolve not only the chrome, but also the base material. Repeat this procedure until the chrome plating is completely removed.

What is chrome plating and how is it done?

To give surfaces a mirror-like metallic shine, the chrome plating method is used.

This is the application of a special galvanic layer to the car. The process is called galvanization or simply chrome plating.

This is a rather complex electrochemical process. When galvanizing, chromium (metal) particles are deposited on plastic or metal. Usually 3 sequentially applied layers are used:

- first comes the copper coating;

- then the part is coated with nickel;

- and at the final stage chromium is used.

Chromium interacts with nickel, which allows you to create a perfectly smooth surface after processing.

This method is relevant when decorating various plastic and metal elements of the machine:

- icons;

- emblems;

- inscriptions;

- radiator grilles;

- moldings;

- pens;

- inserts, etc.

Thus, the automaker or the car owner himself wants to improve the appearance of the car, make it brighter, more noticeable and beautiful.

Indeed, chrome parts visually enhance the status of the car. But you shouldn’t overuse chromium either. Then the car looks like a Christmas tree. Everywhere you need to know when to stop.