The structural components of exhaust pipes on many cars fall into the category of problematic parts. They rust quickly, often burn out and break. Replacing the exhaust system is also not an option, since it can become unusable after serving for less than a year. Some car enthusiasts prefer to make a muffler with their own hands and try to use more durable consumables. What do the step-by-step instructions look like, and what will you need to complete the work?

The exhaust pipe system may seem quite simple, but this is just the first impression. In fact, it implements a number of functions, including not only noise reduction, but also reducing the toxicity of exhaust gases, their temperature and sound intensity during fuel combustion. In the muffler area, due to dispersion, the exhaust is finally deprived of temperature and speed indicators. How can you make a muffler with your own hands, and which methods should you give preference to?

What does white smoke from the exhaust pipe mean? You can find the answer to this question in the detailed material of our author.

We also recommend reading our specialist’s article, which talks about how to make a flame arrester for a car with your own hands.

There are several options that car enthusiasts use to make a muffler for their car with their own hands. The choice of a specific method depends on the exhaust system tuning option and the size of the budget you are counting on. This could be a muffler made from a powder fire extinguisher or the manufacture of a straight-through muffler.

Why is a homemade element better than a factory one?

Due to the large number of fakes, it is very difficult to find a truly high-quality spare part today. And if such a part is found, the price for it will be simply exorbitant. Moreover, most of the complaints concern the elements of the exhaust systems. The muffler rusts and burns out very quickly. Its service life does not exceed 1-2 years. It doesn’t matter how intensively you use your car. It burns out not from mileage, but from time. Even if the car is driven once a week, this will not add life to the muffler. It will still have to be changed in a year or two.

After this time, car enthusiasts have a question about the need to replace or repair this part. If you repair the muffler yourself or make it from scratch, you can be sure that it will last much longer. After all, we will not skimp on important materials. Also, by making a muffler with your own hands, you can add your own configuration to the exhaust system. For example, make a forward flow to increase engine power. However, driving long distances with such a “can” will be uncomfortable. Therefore, you can remake the system in a different way by adding an additional resonator to it. This way the machine will run much quieter.

Noise standards and liability for exceeding them

Responsibility for loud exhaust from a muffler is provided for under Article 8.23 of the Code of Administrative Offenses. The driver is charged for operating a vehicle with excess noise levels in accordance with the Technical Regulations of the Customs Union 018/2011 “On the safety of wheeled vehicles”, paragraph 9.9.

Table: dependence of the maximum permissible sound level on the vehicle category

| Vehicle category | Sound level (in decibels) |

| M1, N1, L | 96 |

| M2, N2 | 98 |

| M3, N3 | 100 |

Category M1, N1 and L are passenger cars with no more than 8 seats, trucks with a permissible maximum weight of no more than 3.5 tons, motorcycles/mopeds/ATVs. Category M2 and N2 are cars with more than 8 seats (except for the driver), but whose maximum weight does not exceed 5 tons, and trucks with a permissible maximum weight from 3.5 to 12 tons, respectively. Category M3 and N3 are full-fledged buses and trucks with a permissible maximum weight of more than 12 tons (trucks, most dump trucks).

According to 12.5.1 of the Code of Administrative Offenses, the driver (or owner) is charged for making changes to the design of the car without the permission of the supervisory authority - the traffic police.

So, the fine for a straight-through muffler can be either a warning plus a fine of 500 rubles, or two fines of 500 rubles each (in practice, two warnings cannot be issued).

The manufacture of a direct-flow muffler and its further improvement is within the power of most car enthusiasts. Despite the restrictions on the operation of such devices in our society, there are more and more people who want to make their own and install a direct-flow muffler on a car. Thanks to detailed instructions with photographs and videos, it will be much easier to make a forward flow.

Material and manufacturing method

Before you make a muffler with your own hands, you need to decide on the budget and the option for reworking the exhaust system. There are several tuning methods:

- Modification of a new factory muffler.

- Making your own. By the way, you can make a muffler with your own hands using both stainless steel and ordinary steel.

Experts do not recommend using old mufflers or other parts of the exhaust system that have already been used. In this case, even if they look good (after all, they can be repainted before selling), the inside will be covered with corrosion or even burnt out. Remember that with each engine start, the metal in the system heats up and changes its properties. It’s easy to guess what condition a muffler will be in if it’s been used for about 2-3 years on a car. Therefore, do not fall for the tricks of “lightly used” sellers and do not buy a used muffler. Best of all, make it yourself.

A less expensive solution from a financial point of view would be tuning the standard muffler. Making a part with your own hands from stainless steel is a very reliable, but expensive option. However, such an element will be more durable and will not burn out at the most inopportune moment.

Opening the jar

It happens that the exhaust system operates loudly, but no obvious signs of rot or cracks are detected.

In this case, we can assume that the muffler has burned out inside. This may be a perforated tube or its partitions. Therefore, to accurately determine the diagnosis, we mark the necessary fields and open part of the “can” using a grinder. We bend the excess sheet of metal and cut out or re-weld the bar. At the end of the work, we bend the sheet again and scald it on all sides.

We remake the muffler with our own hands

When choosing this tuning method, it is best to completely redo the exhaust system. To do this, purchase a pipe of the required size (most often its diameter is from 30 to 52 millimeters). Of course, the thin-walled tube that comes to the car from the factory will be very difficult to find. Therefore, we use thin-walled tap water as an analogue.

The housing for the muffler is made from a car fire extinguisher. Moreover, the outlet and inlet holes should be shifted relative to each other. The ends of thin-walled pipes should be inserted 60 percent inside the container. Numerous holes should also be made in them. As for partitions that are installed in factory versions, it is not necessary to weld them. Using the same principle, you can make a muffler for a carbine yourself.

Do-it-yourself welding of a new resonator

This is not a difficult task.

It is necessary to make the resonator body from steel, produced in the form of sheets, then weld the partitions, and also insert pipes with holes. It is necessary to place mineral basalt wool into the resonator cavity, and then weld the end. For a car with an engine capacity of 1600 cc. cm, a pipe with a diameter of 52 mm is sufficient. After welding is completed, the seams are processed. You need to paint the resonator with heat-resistant paint. Before installing the exhaust system elements, you should take a closer look at the pipes between the muffler and the resonator. In bends, the aggressive influence of exhaust gases increases, which is why burnouts may occur. It is necessary to brew them if found.

Upon completion of the above work, the exhaust system is assembled and attached.

The most important thing is the installation of gaskets. After this, the problem will be eliminated for a certain period of time.

The vehicle and exhaust system parts should be inspected from time to time. Fasteners and suspension require the most attention. Vibration worsens the rigidity of connections.

Professionals recommend introducing an anti-corrosion mixture into the muffler before installation. As a result, it is possible to extend the operating time of the vehicle.

Pay attention to weight

Due to the fact that the water pipe weighs an order of magnitude more than the one that comes with the part from the factory, you will have to strengthen the fastenings. In addition, you should insert the flexible corrugation into place that goes after the exhaust manifold.

Thanks to such changes, the noise level will be significantly reduced, and the service life of the part will be more than 2 years. By the way, the heavier the pipe, the less vibration it will emit.

Adviсe

In order to reduce the noise of a homemade muffler, it is recommended to fill its body with some material such as glass wool. It is also recommended to make a condensate drain hole at the bottom of the muffler. Thus, it will not rust prematurely and make extraneous noise.

If this is a muffler made with your own hands from stainless steel, it is important to think through its design. Make it partially collapsible. This way you will periodically clean the pipe cavities from dirt and change the filler if necessary. Thanks to the collapsible design, the service life of the part will increase several times. Do-it-yourself installation and replacement of the muffler is done in standard places. The main thing is to strengthen them, since the weight of the structure increases slightly.

Painting issue

Is it worth painting the muffler? There is no clear answer to this question. Most car enthusiasts say that the paint for it should be fire-resistant. Otherwise, it will simply burn. The ideal solution would be to make a muffler made of stainless steel. You can see an example in the photo below.

Using stainless steel will close the issue of painting once and for all. Well, you can paint the muffler on the carbine with your own hands with matte black paint. The main thing is that it is resistant to high temperatures.

How to use?

Do-it-yourself cold welding of a muffler is done as follows. First, the surface goes through a preparation procedure. The area should be cleaned with sandpaper. After this, the surface is degreased using white spirit, gasoline or another solvent. Next, you should prepare the adhesive composition. Cut off the required amount of sealant and knead it. In the case of using liquid analogues, mix them thoroughly. Next, apply glue to the damaged area of the muffler and level the mixture.

Please note that the composition hardens within a few minutes, so all work with the sealant must be done very quickly.

Finally, you need to wait until the mixture dries completely. Depending on the brand of the manufacturer, this takes from 1 hour to a day.

How else can you reduce exhaust system noise?

To do this, you can install an additional muffler resonator. You can make it from scratch, like the muffler itself, or you can make it again from a fire extinguisher. However, the material of this part is not particularly designed for high temperatures. But, as practice shows, such resonators are quite effective in operation.

The most important thing when making an additional resonator is to place the tubes correctly. They must be offset relative to each other (everything is similar to making a muffler). To swirl the exhaust gases, holes are made in the pipe. Thus, the gas pressure level decreases and they do not create much noise at the outlet. As you can see, making a resonator for a muffler with your own hands is not so difficult.

The weight of the newly manufactured element should also be taken into account. If it is heavier than the standard one, you will have to strengthen the fastenings on the bottom, otherwise the part may come off right on the move. It is not necessary to fill the inside of the resonator, nor is it necessary to install partitions.

So, we found out how to make a muffler with our own hands.

Forward flow is an opportunity to increase the power of a car’s engine, add aggressiveness to the car and improve jerkiness. You can assemble and install it yourself by studying the step-by-step instructions.

What to make a gasket from

The joints between pipes and manifolds, resonators and mufflers are equipped with gaskets. Without them, a creak appears in the system, and rapid wear of the metal occurs. Elements are subjected to heavy loads and fail faster than other components of the assembly.

The muffler gasket for a car can be made from reinforced asbestos sheet.

First, make a drawing of the part on paper and cut it out along the contour. Attach the paper version to the asbestos sheet and trace it with a pencil. Carefully, so that the material does not crumble, cut out the gasket.

All that remains is to clean the part, treat it with heat-resistant sealant, install it in the intended place, and secure it with bolts.

About direct flow or PG

A direct-flow muffler (PG) is an improved alternative to a stock exhaust, which is not capable of ensuring a quick and timely release of gases from the engine system (ICE). The standard exhaust system especially suffers (chokes) after installing a sports camshaft or after boring the cylinder head cylinders (in other words, on a forced engine).

A straight-through muffler is designed to improve the exhaust system

The GHG is designed to modernize the exhaust system, which increases gas emissions. In addition, a correctly installed PG will provide an increase in internal combustion engine power by 10–15 hp. However, you need to be prepared for drastic changes: everything will need to be replaced, from the catalyst to the tip.

Increasing the power of a power unit using a PG, unfortunately, also has a “other side of the coin”, associated primarily with a loud sound attack of about 120 dB. This is the norm for sports cars, but hardly for civilian ones. And this explains the mass of cases of fines issued by law enforcement inspectors to the owners of such cars.

To minimize this modernization flaw, craftsmen use various methods to reduce sound. Installing a flute muffler, oval or round resonator are all types of methods to improve the performance of a forward flow muffler. “Form and content” can make it quiet.

For example, craftsmen say that a square resonator installed in the middle of the path (the path for gases to escape into the aircraft) reduces noise much better than an oval or round one. And in general, it’s better not to use a round one, but to use an oval one as a last resort, since it has a larger volume of cans and, accordingly, a quieter sound.

Oval resonators from Volvo S60R and Saab have proven themselves to be quite good.

Before thoroughly understanding what GHG is, you should remember the functioning of the vehicle exhaust system. Many motorists do not even suspect how many tasks it performs, although it does not seem so at first glance.

The forward flow kit is a ready-made option for tuning

Of course, the main task of the exhaust is to remove gases. But an equally important function is to ensure timely and high-quality ventilation of the internal combustion engine cylinders.

Ventilation of the cylinders is carried out as follows. When the valves of one cylinder of the internal combustion engine are closed, a vacuum is created in the exhaust manifold. It moves through the system at high speed, and, having been reflected from obstacles, returns to the collector. At the moment the gases leave the cylinder, a reduced pressure is created here, which promotes better ventilation and purge.

Among other things, the exhaust system (ES) is designed to combat noise. This is what the muffler is designed for.

Compared to a conventional standard muffler, the PG does not have many separate sections inside. Accordingly, it has a more simplified design. It is this fact that allows craftsmen to make it at home or in the garage.

But is it even worth it for an ordinary motorist to change the standard muffler to a PG one? Certainly not. If he does not prefer active driving, does not intend to use the car for sporting purposes, does not have complexes about a “gray” car that does not stand out from the general traffic flow, then he should not carry out modernization.

On the contrary, if the bassy and thoroughbred roar of the engine resonates in the soul of the car enthusiast, then the installation of direct flow must be carried out. Moreover, this gives many advantages of the following nature:

- the power of the internal combustion engine increases due to increased throughput;

- The service life of the entire aircraft is extended due to the use of high-quality materials.

As for the disadvantages of modernization, these are:

- problems with the law due to loud noise (can be excluded if the installation of GHGs is carried out using a new system);

- possible difficulties with service maintenance;

- greater sensitivity of the power unit to low temperatures;

- decreased clearance.

Do not confuse forward flow with a muffler. The fact is that the entire exhaust system is called direct flow, and in most cases only part of it is subject to modernization - the muffler.

What is required to build an ASG (direct-flow exhaust system): tuning kit

Undoubtedly, installing a PG is a tuning, a modernization. And everything you need to build such a sporty exhaust option is available in stores.

The first is the resonator. Note that the sports PG does not have partitions that prevent the escape of gases. Its entire design is aimed only at ridding the internal combustion engine of excess gases generated during fuel combustion. As a result, power increases due to increased airflow.

Interesting point. On cars equipped with a naturally aspirated internal combustion engine, installing a sports PG allows you to increase power by 10 percent of the standard power, and on turbocharged cars - by 20 percent or even more.

The second necessary element, of course, is a new direct-flow flame arrester. The universal damper is intended as an alternative to the standard catalyst when constructing a direct flow. Such an element must be made of stainless steel (there is an option of aluminized steel). The internal part of such a flame arrester has a universal design, designed to increase the power of the machine’s power unit.

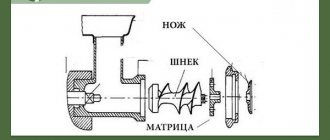

The structure of the muffler in the form of a diagram gives a complete picture of it

Fastening elements and other accessories, which must include various adapters, adapters, flanges, thermal tape for the exhaust manifold, etc., are also part of the system.

And finally, the muffler pipe, made of stainless steel or aluminized. The pipe itself must have an increased diameter (usually in the range of 38–76 mm). The length of the pipe is about 1000 mm, the wall thickness is 1.5 mm.