Radio technicians and amateurs often encounter various breakdowns of radio equipment. For repairs, a regular soldering iron with a copper tip can be used, but with the advancement of technology, very small parts are installed in some devices. It is inconvenient or completely impossible to work with such devices with a regular soldering iron; for example, SMD elements must be soldered by heating the common soldering area. To carry out such processes, there are various soldering stations and hair dryers.

Features of soldering hair dryers

A soldering hair dryer is used when working with low-melting alloys and metals. In addition, it is often used to remove paint coatings from the surface of old parts and when they are heated. The temperature of the air leaving the hair dryer nozzle reaches 800 °C. It is regulated using a special relay, but besides this, the temperature depends on the voltage used, the fan and the distance to the heated object.

Working with a soldering iron

The nozzle is made of heat-resistant materials and has a specific design that is convenient for use in one hand, if it is not a stationary soldering gun.

Why YOUYUE 8586

The YOUYUE 8586 soldering station is a combination of low price, ample capabilities (soldering iron plus hair dryer, covering all the needs of a home craftsman) and fairly high-quality materials and assembly (not without flaws, of course, but more on that below). As well as high-quality packaging and good equipment.

In the review there will be many critical remarks about the station in question, but you need to remember that all the shortcomings are a consequence of its low price and they are all compensated for by the same low price.

Hot air gun design

The main parts that make up a soldering hair dryer are similar to the elements of other heating devices:

- Lever. It is made from heat-resistant materials with the expectation that it will withstand high temperatures. For example, ebonite, ceramics, porcelain. In addition, the handle can be wrapped in heat-resistant fabric, which will also reduce the surface temperature.

- Frame. The same requirements apply to it as to the handle.

- Nozzles Most often this is a steel tube with a small hole diameter. The use of other metals is not recommended due to less durability or higher cost.

- A heating element. A small radius nichrome wire is used, which holds its shape well when heated.

- Fan. It is installed on the back side of the soldering gun and supplies air to the heating element. It must be small for convenient use of the tool.

Soldering hair dryer device

Hot air gun attachments

The station itself

Now some photos of the YOUYUE 8586 soldering station itself without any accessories. Front view. All controls are visible, as well as indicators and connectors for connecting a soldering iron and hair dryer.

Side view. There are noticeable recesses on the sides, which are convenient to use when carrying the station.

Left view. Below you can see two of the four screws securing the station's metal casing to the base.

Rear left view. There are two visible holes for attaching the soldering gun holder. There are similar holes on the opposite side of the case for attaching a hair dryer holder on the right side.

Back view. Factory nameplate with station data, power cord connector and ventilation holes on the rear wall.

Main characteristics of a soldering hair dryer

There are several parameters that you should pay attention to when choosing a hair dryer for soldering - voltage and power.

To successfully solder computer chips and radio components at home, the power should be at least 100 watts, but more is better.

Let the resulting temperature be higher than necessary, it can be adjusted using a relay, wire or distance to the heated surface. In industrial soldering guns, the power reaches 1.7 kW or more.

Recommended voltage range 24-36 Volts. Smaller values will not allow you to achieve the required power, and larger values can be dangerous. Additionally, the voltage will depend on the resistance in the heater wire. It is recommended to use nichrome wire with a resistance of 6 Ohms for a voltage of 24 Volts.

Assembling an air soldering iron from a regular one

It’s easy to assemble a hot air gun with your own hands from a simple soldering iron. The question arises, why are we upgrading the soldering iron? The answer is simple: there are often situations in which it is not possible to melt solder with a regular tip.

The design of such a device is simple and anyone can assemble it. To make it, you will need a regular pen with a wooden handle and a standard power of 40 watts. To supply air, you need a source of compressed air. An aquarium compressor is suitable for this.

It is necessary to remove the tip and leave the heating element unchanged. We make a hole in the wall and bring the power wire out through it. We glue a sleeve to the rear end of the soldering iron in which a tube connected to a source of compressed air will be attached. We seal the places where the wires pass.

In the metal part of the device, you need to cover the holes with foil, then wrap it with copper wire - this will increase the heat capacity. To replace the tip, you need to install a steel tube of the same diameter so that it holds well and does not fall out during operation. Such a tool usually allows you to heat the surface up to 300 °C.

The operating principle of a DIY soldering gun is as follows:

The air enters the heating element, the heat capacity of which was increased by wrapping the tube with foil and copper wire. Next, the heated air enters a steel tube installed instead of a tip, and through a hole in it is directed to the heated surface.

The disadvantages of such a device include the fact that there is no way to regulate the temperature and it is not high enough for some metals. It can be increased by changing the airflow. This tool, assembled with your own hands, will allow you to work with some radio circuits, but will not be able to replace professional equipment, such as a soldering station.

Mini soldering station with great capabilities

Such a station can be made, for example, from a plastic medicine jar. This device is very compact. It consists of a tube with a spiral installed inside (you can find one in old capacitors) and a fan.

No handle is required for the station, and the power supply on the controller allows you to adjust the temperature.

Such a tool, assembled independently, is comparable in quality to the original store-bought version.

Models on the market

A huge range of hot air guns confuses buyers. To select a device that will fully meet your requirements, you need to study its capabilities and characteristics. For professional electronics engineers and those who like to tinker with microcircuits, we invite you to familiarize yourself with a selection of the best models offered by manufacturers.

Hot air gun Weller WHA 900 Set station based

Weller WHA 900 Set

Professional grade analog equipment. Temperature adjustment and smooth change in the strength of hot air flows are provided. The hair dryer is equipped with a built-in turbine for pumping air. Heating temperature in the range of 50-550 degrees. The antistatic version eliminates the possibility of damaging the board being processed. The manufacturer offers a large selection of special attachments that increase the heating efficiency and localize the work area.

Advantages:

- high-quality manufacturing;

- precise setting of temperature and air flow;

- assortment of replaceable nozzles;

- performance;

- power.

The disadvantages include the high price. This is compensated by the fact that the device is professional.

The Quick 857DW+ hair dryer has 4 attachments and a comfortable handle

Quick 857DW+

Professional heat gun with a diaphragm compressor and a power of about 580 W. Suitable for sensitive boards and radio components. Heating up to 450 degrees is controlled by a microprocessor. The temperature indicator is displayed on a digital display. The set contains 4 nozzles of different diameters.

Fastening is carried out with a bolt tie, which prevents collapse during expansion. The degree of heating and the amount of incoming air are regulated by special switches. The comfortable handle is equipped with an extended spring that prevents breakage. Thanks to the diaphragm compressor, the air flow rate per minute is 100 liters.

Advantages:

- four nozzles included;

- advanced functionality;

- performance;

- reliability;

- Ease of Management.

The disadvantage is the need for calibration.

Full set

Lukey 702

The device comes complete with a station of the same name, equipped with a control unit and a soldering iron. Adjustment of the required temperature and air flow is provided. Placing a turbine compressor in the handle allows you to reduce the dimensions of the device, as well as improve its internal dynamics. The device operates almost silently. When the soldering iron is placed on the stand, the “sleep” mode is automatically activated.

Advantages:

- presence of a soldering iron;

- wide functionality;

- temperature Range;

- performance;

- the possibilities outweigh the cost.

You might be interested in Electrical tester

Flaws:

- visually flimsy design;

- calibration required;

- Temperature inaccuracy.

Easy to use digital hair dryer

Yaxun YX-8032

The compact device allows you to dismantle plastic cases, work with circuit boards, and heat up soldering elements. There is a function that protects against static discharge. The package contains several nozzles with different diameters of the outlet nozzle. Capable of working with different parameters of a stationary power supply: 220, 110, 100 V. A smooth change in the mass flow of air flow is also provided. The temperature range ranges from 100-420 degrees. A special support is provided for convenient placement of the device.

Advantages:

- practicality and ease of use;

- light weight;

- a set of nozzles allows you to efficiently heat and localize the work area;

- decent quality.

The negative quality of the device is its high price, although it is justified by its rich functionality.

Compact size ensures ease of use

YIHUA 8858

Universal air heating hair dryer. Used for heating plastic cases of mobile phones, contactless soldering of radio elements, heating electronic boards. To fix various parts, it can be used as a glue gun, melting polyethylene rods.

The device allows you to connect electrical wires using heat-shrinkable tubes. Equipped with a turbine supercharger and ceramic heater. During a break and the device is placed on the stand, it is automatically blown, accelerating the cooling process.

Benefits6

- compactness;

- light weight;

- comfortable handle;

- several airflow modes;

- replaceable nozzles;

- "sleep mode";

- Euro plug;

- automatic airflow

Flaws:

- rough processing of welds along the hull;

- bayonet method of attaching attachments.

High-quality soldering gun based on the station

BISON 55350

Professional soldering gun at an affordable price. It is used for non-contact soldering and dismantling of electronic radio elements. Capable of heating up to a maximum of 500 degrees in a matter of seconds. Three replaceable nozzles, differing in the diameter of the output nozzle, allow you to localize the heating location. During temporary breaks, the economy mode is activated. It is possible to regulate the air flow up to a maximum of 120 l/min.

Advantages:

- lightness, ease of use;

- The comfortable handle is equipped with an anti-slip coating;

- smooth adjustment;

- decent amount of air flow;

- display;

- electronic control;

- affordable price.

No shortcomings have yet been identified with this unit.

Homemade products also have the right to life

How to properly assemble a hot air gun with your own hands

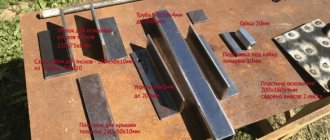

Before you start assembling a homemade soldering gun, you need to make a heating element spiral. A wire with a cross-section of 4 to 7 mm is used with tension, onto which a nichrome spiral (sometimes made of fechral) is wound. The required cross-section should be 0.5-0.6 mm. The spiral should be wound onto a tubular base in neat, uniform turns. It is important to ensure that the turns do not touch. A layer of asbestos or fiberglass is placed on top of it, which should be secured with heat-resistant glue. The ends and exit points of the spirals should also be covered with a layer of glue.

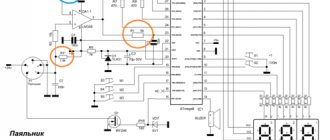

Hot air gun assembly diagram

Then, a tube is installed on the layer of glue to isolate the incoming heat from the coil. It is made from high-temperature resistant materials, such as ceramics. The ends and exit points of the spirals should also be covered with a layer of heat-resistant glue

The outputs of the spiral must be brought out and connected to the power drive using screws on the mount. It is important that it has heat-resistant insulation. The wire must be routed through the starting switch and rheostat. This will make it possible to regulate the voltage.

On the other side of the soldering gun, a fan or other air supply element to the heater is installed. If it is not possible to install it on the body of the hair dryer, then you can use a bushing to install a tube through which air will be supplied. The wires from the fan are also connected to the switch so that it is possible to control the air flow.

The nozzle is then attached to the body. It is recommended to provide a design that allows you to replace the nozzle with others of different diameters.